Summary of REB15538

Page 1

5000 reb15538 operator's manual 532 43 32-65.

Page 2: Safety Rules

2 safety rules safe operation practices for ride-on mowers danger: this cutting machine is capable of amputating hands and feet and throw ing objects. Failure to observe the following safety instructions could result in serious injury or death. I. General operation • read, understand, and follow all...

Page 3: Safety Rules

3 safety rules safe operation practices for ride-on mowers • be sure the area is clear of bystanders before operat- ing. Stop machine if anyone enters the area. • never carry passengers. • do not mow in reverse unless absolutely necessary. Al ways look down and behind before and while backing. • nev...

Page 4: Table of Contents

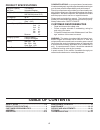

4 table of contents safety rules ......................................................... 2-3 product specifications ....................................... 4 customer responsibilities ................................. 4 assembly ................................................................. 6-7...

Page 5: Unassembled Parts

5 unassembled parts steering wheel (1) washer seat (1) seat steering boot steering extension shaft steering wheel adapter keys (2) keys slope sheet (1) hex bolt (1) hex bolt (1) 5/16 lock washer (1) large flat washer steering wheel insert.

Page 6: Assembly

6 fig. 2 assembly tools required for assembly a socket wrench set will make assembly easier. Stan dard wrench sizes are listed. (2) 7/16" wrench utility knife (1) 1/2" wrench tire pres sure gauge pliers when right or left hand is mentioned in this man ual, it means when you are in the operating po s...

Page 7: Assembly

7 assembly note: you may now roll your tractor off the skid. Follow the appropriate instruction below to remove the tractor from the skid. Warning: before starting, read, un der stand and follow all in struc tions in the operation section of this manual. Be sure tractor is in a well-ventilated area....

Page 8: Operation

8 operation these symbols may appear on your tractor or in literature supplied with the product. Learn and understand their meaning. Danger, keep hands and feet away free wheel (automatic models only) keep area clear slope hazards 15 15 (see safety rules section) battery reverse forward fast slow en...

Page 9: Operation

9 03014 operation know your tractor read this owner's manual and safety rules before operating your tractor compare the illustrations with your tractor to familiarize yourself with the locations of various controls and ad just ments. Save this manual for future reference. Attachment clutch lever - u...

Page 10: Operation

10 02442 note: under certain conditions when tractor is standing idle with the engine running, hot engine exhaust gases may cause “brown ing” of grass. To eliminate this possibility, al- ways stop engine when stopping tractor on grass areas. Caution: always stop tractor com- plete ly, as described a...

Page 11: Operation

11 to operate on hills warning: do not drive up or down hills with slopes great er than 15° and do not drive across any slope. • choose the slowest speed before starting up or down hills. • avoid stopping or changing speed on hills. • if stopping is absolutely necessary, push clutch/brake pedal quic...

Page 12: Operation

12 operation to start engine (see fig. 5) when starting the engine for the first time or if the engine has run out of fuel, it will take extra cranking time to move fuel from the tank to the engine. • sit on seat in operating position, depress clutch/brake pedal and set parking brake. • place gear s...

Page 13: Maintenance

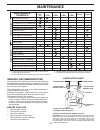

13 maintenance lubrication chart d spindle zerk d front wheel bearing zerk c sae 30 or 10w30 motor oil d general purpose grease e refer to maintenance “engine” section important: do not oil or grease the pivot points which have special nylon bearings. Viscous lu bri cants will attract dust and dirt ...

Page 14: Maintenance

14 maintenance tractor always observe safety rules when per form ing any main- te nance. Brake operation if tractor requires more than five (5) feet to stop at highest speed in high est gear on a level, dry concrete or paved surface, then brake must be checked and ad just ed. (see “to check brake” i...

Page 15: Maintenance

15 maintenance v-belts check v-belts for deterioration and wear after 100 hours and replace if necessary. The belts are not adjustable. Re place belts if they begin to slip from wear. Transaxle cooling keep transaxle free from build-up of dirt and chaff which can restrict cooling. Fig. 10 fig. 9 to ...

Page 16: Service and Adjustments

16 service and adjustments to remove mower (see fig. 12) mower will be easier to remove from the right side of tractor. • place attachment clutch in “dis en gaged” position. • move attachment lift lever forward to low er mower to its lowest po si tion. • roll belt off engine pulley. • remove small r...

Page 17: Service and Adjustments

17 service and adjustments front-to-back adjustment (see figs. 15 and 16) important: deck must be level side-to-side. If the following front-to-back adjustment is necessary, be sure to ad just both front links equal ly so mower will stay level side-to-side. To obtain the best cutting results, the mo...

Page 18: Service and Adjustments

18 service and adjustments fig. 17 fig. 18 to replace motion drive belt (see fig. 18) park the tractor on level surface. En gage parking brake. For as sis tance, there is a belt installation guide decal on bottom side of left footrest. Belt removal - • remove mower (see “to re move mower” in this se...

Page 19: Service and Adjustments

19 service and adjustments to remove wheel for repairs (see fig. 20) • block up axle securely. • remove axle cover, retaining ring and washers to allow wheel removal (rear wheel contains a square key - do not lose). • repair tire and reassemble. • on rear wheels only: align grooves in rear wheel hub...

Page 20: Service and Adjustments

20 engine to ad just throttle con trol cable the throttle control has been preset at the factory and ad just ment should not be necessary. If adjustment is nec- es sary, see engine manual. To adjust carburetor your carburetor is not adjustable. If your engine does not operate properly due to suspect...

Page 21: Storage

21 storage immediately prepare your tractor for storage at the end of the season or if the tractor will not be used for 30 days or more. Warning: never store the trac tor with gas o line in the tank inside a building where fumes may reach an open flame or spark. Allow the engine to cool before stori...

Page 22: Troubleshooting Points

22 troubleshooting points problem cause correction will not start 1. Out of fuel. 1. Fill fuel tank. 2. Engine not “choked” properly. 2. See “to start engine” in operation section. 3. Engine flooded. 3. Wait several minutes before attempting to start. 4. Bad spark plug. 4. Replace spark plug. 5. Dir...

Page 23: Troubleshooting Points

23 troubleshooting points problem cause correction excessive vibration 1. Worn, bent or loose blade. 1. Replace blade. Tighten blade bolt. 2. Bent blade mandrel. 2. Replace blade mandrel. 3. Loose/damaged part(s). 3. Tighten loose part(s). Replace damaged parts. Engine continues to run when oper- at...

Page 24: Service Notes

24 service notes.

Page 25: Service Notes

25 service notes.

Page 26: Service Notes

26 service notes.

Page 27

27 15 degrees max. Fold along dotted line this is a 15 degree slope only ride up and down hill, not across hill suggested guide for sighting slopes for safe operation warning: to avoid serious injury, operate your tractor up and down the face of slopes, never across the face. Do not mow slopes great...

Page 28

12.21.09 ja printed in the u.S.A..