- DL manuals

- RAM

- Automobile

- Truck 2014

- Owner's Manual

RAM Truck 2014 Owner's Manual

Summary of Truck 2014

Page 1

R a m t r u c k chrysler group llc o w n e r ’ s m a n u a l 2 0 1 4 2014 ram truck diesel 14d241-226-aa first edition printed in u.S.A. D i e s e l s u p p l e m e n t.

Page 2

Vehicles sold in canada with respect to any vehicles sold in canada, the name chrysler group llc shall be deemed to be deleted and the name chrysler canada inc. Used in substitution therefore. Driving and alcohol drunken driving is one of the most frequent causes of accidents. Your driving ability c...

Page 3: Ram Diesel Supplement

Ram diesel supplement ram 1500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 ram 2500 / 3500 / 4500 / 5500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119 index . . . . . . . . ....

Page 5: Ram 1500

Ram 1500

Page 7: Table Of Contents

Table of contents section page 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 2 things to know before starting your vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 3 understanding your ins...

Page 9: Introduction

Introduction contents 䡵 a message from chrysler group llc . . . .8 1.

Page 10

A message from chrysler group llc chrysler group llc welcome you as a turbocharged diesel-powered truck owner. Your diesel truck will sound, feel, drive, and operate differently from a gasoline-powered truck. It is important that you read and understand this manual. Almost 100% of the heavy trucks i...

Page 11: Contents

Things to know before starting your vehicle contents 䡵 remote starting system . . . . . . . . . . . . . .10 ▫ how to use remote start . . . . . . . . . . . . . . . .10 䡵 engine break-in recommendations . . . .11 2.

Page 12

Remote starting system this system uses the remote keyless entry (rke) transmitter to start the engine conve- niently from outside the vehicle while still maintaining security. The system has a range of approximately 300 ft (91 m). Note: • the vehicle must be equipped with an automatic transmission ...

Page 13

Warning! • do not start or run an engine in a closed garage or confined area. Exhaust gas contains carbon mon- oxide (co) which is odorless and colorless. Carbon monoxide is poisonous and can cause serious in- jury or death when inhaled. • keep remote keyless entry (rke) transmitters away from child...

Page 14

• observe vehicle oil pressure and temperature indica- tors. • check the coolant and oil levels frequently. • vary throttle position at highway speeds when carry- ing or towing significant weight. Note: light duty operation such as light trailer towing or no load operation will extend the time befor...

Page 15: Contents

Understanding your instrument panel contents 䡵 instrument cluster . . . . . . . . . . . . . . . . .14 䡵 instrument cluster — laramie . . . . . . .15 䡵 instrument cluster descriptions . . . . .16 䡵 electronic vehicle information center (evic) . . . . . . . . . . . . . . . . . . . . . . . .26 ▫ evic d...

Page 16

Instrument cluster 14 understanding your instrument panel.

Page 17

Instrument cluster — laramie 3 understanding your instrument panel 15.

Page 18

Instrument cluster descriptions 1. Tachometer the tachometer indicates engine speed in revolutions per minute (rpm x 1000). Caution! Do not operate the engine with the tachometer pointer at high rpm for extended periods. Engine operation over 3200 rpm (redline) can result in significant damage that ...

Page 19

3. Malfunction indicator light (mil) the malfunction indicator light (mil) is part of an onboard diagnostic (obdii) system which monitors the emissions and engine control sys- tem. If the vehicle is ready for emissions testing, the light will come on when the ignition is first turned on and remain o...

Page 20

Warning! A malfunctioning catalytic converter, as referenced above, can reach higher temperatures than in normal operating conditions. This can cause a fire if you drive slowly or park over flammable substances such as dry plants, wood, cardboard, etc. This could result in death or serious injury to...

Page 21

Caution! Driving with a hot engine cooling system could damage your vehicle. If the temperature gauge reads “h” pull over and stop the vehicle. Idle the vehicle with the air conditioner turned off until the pointer drops back into the normal range. If the pointer remains on the “h” and you hear cont...

Page 22

Has been corrected. If the problem is related to the brake booster, the abs pump will run when applying the brake and a brake pedal pulsation may be felt during each stop. The dual brake system provides a reserve braking capac- ity in the event of a failure to a portion of the hydraulic system. A le...

Page 23

The light also will turn on when the parking brake is applied with the ignition switch in the on/run posi- tion. Note: this light shows only that the parking brake is applied. It does not show the degree of brake application. 7. High beam indicator this indicator shows that headlights are on high be...

Page 24

If the gauge pointer moves to either extreme of the gauge, the check gauges indicator will illuminate and a single chime will sound. 11. Speedometer the speedometer shows the vehicle speed in miles per hour and/or kilometers per hour (mph/km/h). 12. Park/headlight on indicator — if equipped this ind...

Page 25

As an added safety feature, your vehicle has been equipped with a tire pressure monitoring system (tpms) that illuminates a low tire pressure telltale when one or more of your tires is significantly under-inflated. Accordingly, when the low tire pressure telltale illumi- nates, you should stop and c...

Page 26

Caution! The tpms has been optimized for the original equipment tires and wheels. Tpms pressures and warning have been established for the tire size equipped on your vehicle. Undesirable system opera- tion or sensor damage may result when using re- placement equipment that is not of the same size, t...

Page 27

Note: the highest available transmission gear is dis- played in the lower right corner of the electronic vehicle information center (evic) whenever the electronic range select (ers) feature is active. Use the +/- selector on the steering wheel to activate ers. Refer to “auto- matic transmission” in ...

Page 28

Note: the “esc off indicator light” and the “esc activation/ malfunction indicator light” come on momentarily each time the ignition switch is turned to on/run. Each time the ignition is turned to on/run, the esc system will be on, even if it was turned off previously. The esc system will make buzzi...

Page 29

This system conveniently allows the driver to select a variety of useful information by pressing the switches mounted on the steering wheel. Refer to “electronic vehicle information center – if equipped” in the owner’s manual for further informa- tion. Evic displays when the appropriate conditions e...

Page 30

• exhaust system – regeneration completed • engine will not restart in xxxx mi def low refill soon • engine will not restart in xxxx mi refill def • engine will not restart refill def • service def system see dealer • incorrect def detected see dealer • engine will not restart in xxx mi service def ...

Page 31

Wait to start light the “wait to start” telltale will illuminate for approximately two seconds when the ignition is turned to the run position. It’s duration may be longer based on colder operating conditions. Vehicle will not initiate start until telltale is out. Refer to “starting proce- dures” in...

Page 32

• engine will not restart in xxxx mi def low refill soon – this message will display when def driving range is less than 500 miles, def fluid top off is required with in the displayed mileage. The message will be displayed in the evic during vehicle start up with the current allowed mileage and acco...

Page 33

When the def system needs to be serviced the following warnings will display: • service def system see dealer — this message will display when the fault is initially detected and each time the vehicle is started. The message will be accom- panied by a single chime and the malfunction indica- tor lig...

Page 34

• engine will not restart service def system see dealer — this message will display if def system issue detected is not serviced during the allowed period. Your engine will not restart unless your vehicle is serviced by your authorized dealer. This message will be displayed when under 1 mile until e...

Page 35

Vehicle information (customer information features) press and release the up or down button until “vehicle info” displays in the evic and press the select button. Press the right and left button to scroll through the available information displays, then press select to display anyone of the followin...

Page 37: Starting And Operating

Starting and operating contents 䡵 starting procedures . . . . . . . . . . . . . . . . .37 ▫ normal starting . . . . . . . . . . . . . . . . . . . . . . .38 ▫ automatic transmission . . . . . . . . . . . . . . . . .38 ▫ keyless enter-n-go™ . . . . . . . . . . . . . . . . . . .38 ▫ extreme cold weathe...

Page 38

▫ trailer towing weights (maximum trailer weight ratings) . . . . . . . . . . . . . . . . . . . . . . .56 ▫ trailer and tongue weight . . . . . . . . . . . . . . .56 ▫ towing requirements . . . . . . . . . . . . . . . . . . .58 ▫ towing tips . . . . . . . . . . . . . . . . . . . . . . . . . .68 䡵 di...

Page 39

Starting procedures before starting your vehicle, adjust your seat, both inside and outside mirrors, and fasten your seat belts. The starter is allowed to crank for up to 30-second intervals. Waiting a few minutes between such intervals will protect the starter from overheating. Warning! Never leave...

Page 40

Caution! (continued) • if the “water in fuel indicator light” remains on, do not start engine before you drain the water from the fuel filters to avoid engine damage. Refer to “maintenance procedures/draining fuel/water separator filter” in “maintaining your vehicle” for further information. Normal ...

Page 41

Normal starting procedure – keyless enter-n-go™ observe the instrument panel cluster lights when starting the engine. Note: normal starting of either a cold or a warm engine is obtained without pumping or pressing the accelerator pedal 1. Always apply the parking brake. 2. For vehicles equipped with...

Page 42

Extreme cold weather the engine block heater is a resistance heater installed in the water jacket of the engine. It requires a 110–115 volt ac electrical outlet with a grounded, three-wire exten- sion cord. Its use is recommended for environments that routinely fall below -10°f. It should be used wh...

Page 43

Warning! (continued) • never leave children alone in a vehicle, or with access to an unlocked vehicle. Allowing children to be in a vehicle unattended is dangerous for a number of reasons. A child or others could be seriously or fatally injured. Children should be warned not to touch the parking bra...

Page 44

Cold weather precautions operation in ambient temperature below 32°f (0°c) may require special considerations. The following charts sug- gest these options: fuel operating range note: use “ultra low sulfur diesel fuels” only. *no. 1 ultra low sulfur diesel fuel should only be used where extended arc...

Page 45

Engine oil usage refer to “maintenance procedures” in “maintaining your vehicle” for the correct engine oil viscosity. Engine warm-up avoid full throttle operation when the engine is cold. When starting a cold engine, bring the engine up to operating speed slowly to allow the oil pressure to stabili...

Page 46

Driving condition load turbo- charger tempera- ture idle time (min.) be- fore en- gine shut- down stop and go empty cool less than one stop and go medium one highway speeds medium warm two city traffic maximum gcwr three highway speeds maximum gcwr four uphill grade maximum gcwr hot five note: under...

Page 47

Do not operate the engine with low oil pressure if the low oil pressure warning light turns on while driving, stop the vehicle and shut down the engine as soon as possible. A chime will sound when the light turns on. Note: do not operate the vehicle until the cause it corrected. This light does not ...

Page 48

Engine block heater — if equipped the engine block heater warms engine coolant and permits quicker starts in cold weather. Connect the heater cord to a ground-fault interrupter protected 110–115 volt ac electrical outlet with a grounded, three-wire exten- sion cord. Its use is recommended for enviro...

Page 49

Good performance. If the vehicle is exposed to extreme cold (below 20°f or -7°c), or is required to operate at colder-than-normal conditions for prolonged periods, use climatized no. 2 diesel fuel or dilute the no. 2 diesel fuel with 50% no. 1 diesel fuel. This will provide better protection from fu...

Page 50

Climatized diesel fuels. Experience has shown that it also operates on no. 1 ultra low sulfur diesel fuels or other fuels within specification. Note: if you accidentally fill the fuel tank with gasoline on your diesel vehicle, do not start the vehicle. If you restart your vehicle you risk damage the...

Page 51

(b6–b20) will result in premature engine wear. Such wear is not covered by the new vehicle limited warranty. Biodiesel is a fuel produced from renewable resources typically derived from animal fat, rapeseed oil (rapeseed methyl ester (rme) base), or soybean oil (soy methyl ester (sme or some) base)....

Page 52

Fuel oxidation stability – must use fuel within six months of manufacture biodiesel fuel has poor oxidation stability which can result in long term storage problems. Fuel produced to approved astm standards, if stored properly, provides for protection against fuel oxidation for up to six months. Fue...

Page 53

Note: under no circumstances should oil change inter- vals exceed 8,000 miles (12 875 km) or 6 months, if regular operation occurs with greater than 5% and less than 20% biodiesel blends. Under no circumstances should fuel filter intervals exceed 20,000 miles (40 233 km), if regular operation occurs...

Page 54

Exceed the gvwr. Refer to “vehicle loading/vehicle certification label” in “starting and operating” for further information. Gross trailer weight (gtw) the gtw is the weight of the trailer plus the weight of all cargo, consumables and equipment (permanent or tem- porary) loaded in or on the trailer ...

Page 55

Tongue weight (tw) the tongue weight is the downward force exerted on the hitch ball by the trailer. In most cases it should not be less than 10% of the trailer load. You must consider this as part of the load on your vehicle. Frontal area the frontal area is the maximum height multiplied by the max...

Page 56

Steering and brake control thereby enhancing towing safety. The addition of a friction / hydraulic sway control also dampens sway caused by traffic and crosswinds and contributes positively to tow vehicle and trailer stability. Trailer sway control and a weight distributing (load equalizing) hitch a...

Page 57

Trailer hitch classification definitions class max. Trailer hitch in- dustry standards class i - light duty 2,000 lbs (907 kg) class ii - medium duty 3,500 lbs (1 587 kg) class iii - heavy duty 5,000 lbs (2 268 kg) trailer hitch classification definitions class iv - extra heavy duty 10,000 lbs (4 54...

Page 58

Trailer towing weights (maximum trailer weight ratings) the rear bumper is intended to tow trailers up to a 5,000 lbs (2 268 kg) without added equipment or alterations to the standard equipment. Ram 1500 diesel 1500 st slt bighorn/lonestar laramie outdoorsman 3.0l turbo diesel eight-speed automatic ...

Page 59

Hitch. Consider the following items when computing the weight on the rear axle of the vehicle: • the tongue weight of the trailer • the weight of any other type of cargo or equipment put in or on your vehicle • the weight of the driver and all passengers. Note: remember that everything put into or o...

Page 60

Towing requirements to promote proper break-in of your new vehicle drive- train components the following guidelines are recom- mended: caution! • do not tow a trailer at all during the first 500 miles (805 km) the new vehicle is driven. The engine, axle or other parts could be damaged. • then, durin...

Page 61

Warning! (continued) • safety chains must always be used between your vehicle and trailer. Always connect the chains to the hook retainers of the vehicle hitch. Cross the chains under the trailer tongue and allow enough slack for turning corners. • vehicles with trailers should not be parked on a gr...

Page 62

• check for signs of tire wear or visible tire damage before towing a trailer. Refer to “tires – general information” in “starting and operating” for the proper inspection procedure. • when replacing tires, refer to “tires – general infor- mation” in “starting and operating” for proper tire replacem...

Page 63

Warning! • do not connect trailer brakes to your vehicle’s hydraulic brake lines. It can overload your brake system and cause it to fail. You might not have brakes when you need them and could have an accident. • towing any trailer will increase your stopping distance. When towing you should allow f...

Page 64

The user interface consists of the following: manual brake control lever slide the manual brake control lever to the right to activate power to the trailer’s electric brakes independent of the tow vehicle’s brakes. If the manual brake control lever is activated while the brake is also applied, the g...

Page 65

Sliding the manual brake control lever will display the gain setting for 10 seconds and the “trailer brake status indicator light” will not be displayed. If a fault is detected in the trailer wiring or the integrated trailer brake module (itbm), the “trailer brake status indicator light” will flash....

Page 66

4. Press the up or down button on the steering wheel until “trailer tow” appears on the screen. 5. Press the right arrow on the steering wheel to enter “trailer tow”. 6. Press the up or down buttons until trailer brake type appears on the screen. Note: 1500 models only – light electric and heavy ele...

Page 67

* the suggested selection depends and may change depending on the customer preferences for braking per- formance. Condition of the trailer brakes, driving and road state may also affect the selection. Evic display messages the trailer brake control interacts with the electronic vehicle information c...

Page 68

Note: • an aftermarket controller may be available for use with trailers with air or electric-over-hydraulic trailer brake systems. To determine the type of brakes on your trailer and the availability of controllers, check with your trailer manufacturer or dealer. • removal of the itbm will cause er...

Page 69

Four-pin connector 1 — female pins 4 — park 2 — male pin 5 — left stop/turn 3 — ground 6 — right stop/turn seven-pin connector 1 — battery 5 — ground 2 — backup lamps 6 — left stop/turn 3 — right stop/turn 7 — running lamps 4 — electric brakes 4 starting and operating 67.

Page 70

Towing tips before setting out on a trip, practice turning, stopping and backing the trailer up in an area away from heavy traffic. Automatic transmission the “drive” range can be selected when towing. The transmission controls include a drive strategy to avoid frequent shifting when towing. However...

Page 71

Electronic speed control – if equipped • do not use in hilly terrain or with heavy loads. • when using the speed control, if you experience speed drops greater than 10 mph (16 km/h), disengage until you can get back to cruising speed. • use speed control in flat terrain and with light loads to maxim...

Page 72

First and only technology in decades to be as good for the environment as it is good for business and vehicle performance. The purpose of the scr system is to reduce levels of nox (oxides of nitrogen emitted from engines) that are harm- ful to our health and the environment to an almost near-zero le...

Page 73

Refer to “electronic vehicle information center (evic)” in “understanding your instrument panel” for system messages and warnings. Note: • your vehicle is equipped with a def injection system. You may occasionally hear an audible clicking noise from under the vehicle at a stop. This is normal operat...

Page 74

2. There is no fuel filler cap. A flapper door inside the filler pipe seals the system. 3. Insert the fuel nozzle fully into the filler pipe – the nozzle opens and holds the flapper door while refuel- ing. 4. Fill the vehicle with fuel – when the fuel nozzle “clicks” or shuts off the fuel tank is fu...

Page 75

2. Insert funnel into same filler pipe opening as the fuel nozzle. 3. Ensure funnel is inserted fully to hold flapper door open. 4. Pour fuel into funnel opening. 5. Remove funnel from filler pipe, clean off prior to putting back in the jack kit. Fuel fill funnel location 1500 models emergency fuel ...

Page 76

Caution! To avoid fuel spillage and overfilling, do not “top off” the fuel tank after filling. Warning! • never have any smoking materials lit in or near the vehicle when the fuel door is open or the tank is being filled. • never add fuel when the engine is running. This is in violation of most stat...

Page 77

If the vehicle will not start, refer to “maintenance procedures/priming if the engine has run out of fuel” in “maintaining your vehicle” for further information. Warning! Do not open the high pressure fuel system with the engine running. Engine operation causes high fuel pressure. High pressure fuel...

Page 78

Adding diesel exhaust fluid the def gauge (located on the instrument cluster) will display the level of def remaining in the tank. Refer to “instrument cluster” and “instrument cluster descrip- tions” in “understanding your instrument panel” for further information. Note: driving conditions (altitud...

Page 79

Caution! • to avoid def spillage, and possible damage to the def tank from overfilling, do not “top off” the def tank after filling. • do not overfill. Def will freeze below 12 degrees f (-11 degrees c). The def system is designed to work in temperatures below the def freezing point, however, if the...

Page 80

Filling the def tank in cold climates since def will begin to freeze at 12°f (-11°c), your vehicle is equipped with an automatic def heating system. This allows the def injection system to operate properly at temperatures below 12°f (-11°c). If your vehicle is not in operation for an extended period...

Page 81: Maintaining Your Vehicle

Maintaining your vehicle contents 䡵 engine compartment — 3.0l diesel . . . . .80 䡵 maintenance procedures . . . . . . . . . . . .81 ▫ engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . .82 ▫ engine air cleaner filter . . . . . . . . . . . . . . . .84 ▫ draining fuel/water separator filte...

Page 82

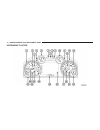

Engine compartment — 3.0l diesel 1 — air cleaner filter 5 — battery 2 — engine oil dipstick 6 — power distribution center (pdc) 3 — engine oil fill 7 — washer fluid reservoir 4 — brake fluid reservoir 8 — engine coolant 80 maintaining your vehicle.

Page 83

Maintenance procedures the pages that follow contain the required maintenance services determined by the engineers who designed your vehicle. Besides those maintenance items specified in the fixed maintenance schedule, there are other components which may require servicing or replacement in the futu...

Page 84

Engine oil engine oil selection for best performance and maximum protection under all types of operating conditions, the manufacturer recom- mends engine oils that meet the requirements of chrysler material standard ms-11106, and that are approved to fiat 9.55535-s1 or fiat 9.55535-s3 and acea c3. C...

Page 85

Mark. The total capacity from the min mark to the max mark is 1.3 qts (1.2 l). Caution! Overfilling or underfilling the crankcase will cause oil aeration or loss of oil pressure. This could damage your engine. Note: it is possible for your oil level to be slightly higher than a previous check. This ...

Page 86

The engine oil filler cap also shows the recommended engine oil viscosity for your engine. For information on engine oil filler cap location, refer to the “engine com- partment” illustration in this section. Materials added to engine oil the manufacturer strongly recommends against the ad- dition of...

Page 87

Warning! The air induction system (air cleaner, hoses, etc.) can provide a measure of protection in the case of engine backfire. Do not remove the air induction system (air cleaner, hoses, etc.) unless such removal is necessary for repair or maintenance. Make sure that no one is near the engine comp...

Page 88

Draining fuel/water separator filter the fuel filter/water separator filter housing is located above the rear axle next to the fuel tank. The best access to this water drain valve is from under the vehicle. Caution! • do not drain the fuel/water separator filters when the engine is running. • diesel...

Page 89

Caution! If the “water in fuel indicator light” remains on, do not start the engine before you drain water from the fuel filters to avoid engine damage. If the “water in fuel indicator light” comes on and a single chime is heard while you are driving, or with the ignition in the on position, there m...

Page 90

If more than two ounces or 60 milliliters of fuel have been drained, follow the directions for “priming if the engine has run out of fuel.” underbody mounted fuel filter replacement note: using a fuel filter that does not meet the manu- facturer’s filtration and water separating requirements can sev...

Page 91

3. Open the water drain valve, and let any accumulated water drain. 4. Close the water drain valve. 5. Remove bottom cover using a strap wrench. Rotate counterclockwise for removal. Remove the used o-ring and discard it. 6. Remove the used filter cartridge from the housing and dispose of it accordin...

Page 92

Caution! The starter motor will engage for approximately 30 seconds at a time. Allow two minutes between the cranking intervals. Note: the engine may run rough until the air is forced from all the fuel lines. Warning! Do not use alcohol or gasoline as a fuel blending agent. They can be unstable unde...

Page 93

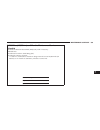

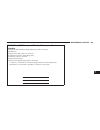

Intervention regeneration strategy – evic message process flow this engine meets all required epa diesel engine emis- sions standards. To achieve these emissions standards, your vehicle is equipped with a state-of-the-art engine and exhaust system. These systems are seamlessly inte- grated into your...

Page 94

Exhaust system – regeneration required now ⬙exhaust filter xx% full safely drive at highway speeds to remedy ⬙ will be displayed on the electronic vehicle information center (evic) if the exhaust particulate filter reaches 80% of its maximum storage capacity. Under conditions of exclusive short dura...

Page 95

Exhaust service required – see dealer now regeneration has been disabled due to a system malfunc- tion. At this point the engine powertrain control module (pcm) will register a fault code, the instrument panel will display a mil light. Caution! See your authorized dealer, as damage to the exhaust sy...

Page 96

Caution! (continued) case. Also, if a “fast charger” is used while the battery is in vehicle, disconnect both vehicle battery cables before connecting the charger to the battery. Do not use a “fast charger” to provide starting voltage. Warning! Battery posts, terminals, and related accessories con- ...

Page 97

Check the engine cooling system hoses for brittle rubber, cracking, tears, cuts and tightness of the connection at the coolant recovery bottle and radiator. Inspect the entire system for leaks. With the engine at normal operating temperature (but not running), check the cooling system pressure cap f...

Page 98

Caution! • mixing of engine coolant (antifreeze) other than specified organic additive technology (oat) en- gine coolant (antifreeze), may result in engine damage and may decrease corrosion protection. Organic additive technology (oat) engine cool- ant is different and should not be mixed with hybri...

Page 99

Adding coolant your vehicle has been built with an improved engine coolant (oat coolant conforming to ms-12106) that allows extended maintenance intervals. This engine cool- ant (antifreeze) can be used up to ten years or 150,000 miles (240,000 km) before replacement. To prevent reduc- ing this exte...

Page 100

Note: mixing engine coolant (antifreeze) types is not recommended and can result in cooling system damage. If hoat and oat coolant are mixed in an emergency, have a authorized dealer drain, flush, and refill with oat coolant (conforming to ms-12106) as soon as possible. Cooling system pressure cap t...

Page 101

Disposal of used engine coolant used ethylene glycol-based engine coolant (antifreeze) is a regulated substance requiring proper disposal. Check with your local authorities to determine the disposal rules for your community. To prevent ingestion by ani- mals or children, do not store ethylene glycol...

Page 102

• make sure that the coolant expansion bottle overflow hoses are not kinked or obstructed. • keep the front of the radiator clean. If your vehicle is equipped with air conditioning, keep the front of the condenser clean. • do not change the thermostat for summer or winter operation. If replacement i...

Page 103

Brake system brake master cylinder – brake fluid level check the fluid level of the master cylinder should be checked when performing under the hood service, or immedi- ately if the “brake system warning light” indicates system failure. The brake master cylinder has a translucent plastic reservoir. ...

Page 104

Warning! (continued) • to avoid contamination from foreign matter or moisture, use only new brake fluid or fluid that has been in a tightly closed container. Keep the master cylinder reservoir cap secured at all times. Brake fluid in a open container absorbs moisture from the air resulting in a lowe...

Page 105

Fluid capacities u.S. Metric fuel (approximate) 3.0l diesel engine 26 gallons 98.5 liters engine oil with filter 3.0 liter diesel engine (sae 5w-30 synthetic, api certified low ash) 8 quarts 7.7 liters cooling system 3.0l turbo diesel engine (mopar® engine coolant/ antifreeze 10 year/150,000 mile fo...

Page 106

Fluids, lubricants and genuine parts engine component fluid, lubricant, or genuine part engine coolant we recommend you use mopar® antifreeze/coolant 10 year/150,000 mile formula oat (organic additive technology). Engine oil we recommend you use acea c3 5w-30 engine oil meeting chrysler material sta...

Page 107

Component fluid, lubricant, or genuine part fuel selection use good quality diesel fuel from a reputable supplier in your vehicle. Federal law requires that you must fuel this vehicle with ultra low sulfur highway diesel fuel (15 ppm sulfur maximum) and prohibits the use of low sulfur highway diesel...

Page 108

Component fluid, lubricant, or genuine part diesel exhaust fluid mopar® diesel exhaust fluid (api certified) (def) or equivalent that has been api certified to the iso 22241 standard. Use of fluids not api certified to iso 22241 may result in system damage. Note: if the vehicle is exposed to extreme...

Page 109

Chassis component fluid, lubricant, or genuine part automatic transmission we recommend you only use mopar® zf 8&9 speed atf™ automatic transmission fluid. Failure to use the correct fluid may affect the function or performance of your transmission. Transfer case we recommend you use mopar® bw44–44 ...

Page 111: Maintenance Schedule

Maintenance schedule contents 䡵 maintenance schedule . . . . . . . . . . . . .110 ▫ maintenance chart – diesel fuel up to b5 biodiesel . . . . . . . . . . . . . . . . . . . . . . . . . . .112 ▫ maintenance schedule – b6 to b20 biodiesel . . . . . . . . . . . . . . . . . . . . . . . . .114 6.

Page 112

Maintenance schedule your vehicle is equipped with an automatic oil change indicator system. The oil change indicator system will remind you that it is time to take your vehicle in for scheduled maintenance. Based on engine operation conditions, the oil change indicator message will illuminate. This...

Page 113

Required maintenance refer to the maintenance schedules on the following pages for required maintenance. At every oil change interval as indicated by oil change indicator system: • change oil and filter. • completely fill the diesel exhaust fluid tank. • rotate the tires. Rotate at the first sign of...

Page 114

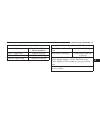

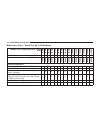

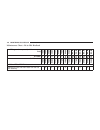

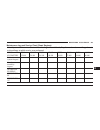

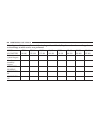

Maintenance chart – diesel fuel up to b5 biodiesel mileage or time passed (whichever comes first) 10,000 20,000 30,000 40,000 50,000 60,000 70,000 80,000 90,000 100,000 1 10,000 120,000 130,000 140,000 150,000 or years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 or kilometers: 16,000 32,000 48,000 64,000 8...

Page 115

Mileage or time passed (whichever comes first) 10,000 20,000 30,000 40,000 50,000 60,000 70,000 80,000 90,000 100,000 1 10,000 120,000 130,000 140,000 150,000 or years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 or kilometers: 16,000 32,000 48,000 64,000 80,000 96,000 1 12,000 128,000 144,000 160,000 176,0...

Page 116

Warning! • you can be badly injured working on or around a motor vehicle. Do only service work for which you have the knowledge and the right equipment. If you have any doubt about your ability to perform a service job, take your vehicle to a competent me- chanic. • failure to properly inspect and m...

Page 117

• check the fluid levels of the coolant reservoir, brake master cylinder, power steering and transmission as needed • check function of all interior and exterior lights required maintenance refer to the maintenance schedules on the following pages for required maintenance. At every oil change interv...

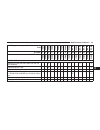

Page 118

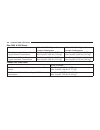

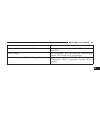

Maintenance chart – b6 to b20 biodiesel mileage or time passed (whichever comes first) 10,000 20,000 30,000 40,000 50,000 60,000 70,000 80,000 90,000 100,000 1 10,000 120,000 130,000 140,000 150,000 or years: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 or kilometers: 16,000 32,000 48,000 64,000 80,000 96,00...

Page 119

Warning! • you can be badly injured working on or around a motor vehicle. Do only service work for which you have the knowledge and the right equipment. If you have any doubt about your ability to perform a service job, take your vehicle to a competent me- chanic. • failure to properly inspect and m...

Page 121

Ram 2500 / 3500 / 4500 / 5500

Page 123: Table Of Contents

Table of contents section page 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123 2 things to know before starting your vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 3 understanding your instr...

Page 125: Introduction

Introduction contents 䡵 a message from chrysler group llc. . . .124 1.

Page 126

A message from chrysler group llc chrysler group llc and cummins® welcome you as a cummins® turbocharged diesel-powered truck owner. Your diesel truck will sound, feel, drive, and operate differently from a gasoline-powered truck. It is important that you read and understand this manual. Almost 100%...

Page 127: Contents

Things to know before starting your vehicle contents 䡵 remote starting system — if equipped . . . . . . . . . . . . . . . . . . . . . . . . .126 ▫ how to use remote start . . . . . . . . . . . . . . .126 䡵 engine break-in recommendations . . .130 2.

Page 128

Remote starting system — if equipped this system uses the remote keyless entry (rke) transmitter to start the engine conve- niently from outside the vehicle while still maintaining security. The system has a range of approximately 300 ft (91 m). Note: • the vehicle must be equipped with an automatic...

Page 129

Warning! • do not start or run an engine in a closed garage or confined area. Exhaust gas contains carbon mon- oxide (co) which is odorless and colorless. Carbon monoxide is poisonous and can cause serious in- jury or death when inhaled. • keep remote keyless entry (rke) transmitters away from child...

Page 130

Temperature conditions, the diesel vehicle may delay crank up to 30 seconds for the fuel and grid heater. Once the vehicle has started, the engine will run for 15 minutes. Note: • the park lamps will turn on and remain on during remote start mode. • for security, power window and power sunroof op- e...

Page 131

To exit remote start mode and drive the vehicle to exit remote start mode and drive the vehicle before the end of the 15-minute cycle, press and release the unlock button on the rke transmitter to unlock the door and disarm the vehicle security alarm system (if equipped). Then prior to the end of th...

Page 132

Engine break-in recommendations the cummins® turbocharged diesel engine does not require a break-in period due to its construction. Normal operation is allowed, providing the following recommen- dations are followed: • warm up the engine before placing it under load. • do not operate the engine at i...

Page 133: Contents

Understanding your instrument panel contents 䡵 instrument cluster . . . . . . . . . . . . . . . . .132 䡵 instrument cluster descriptions . . . . .133 䡵 electronic vehicle information center (evic) . . . . . . . . . . . . . . . . . . . . . . .143 ▫ electronic vehicle information center (evic) display...

Page 134

Instrument cluster 132 understanding your instrument panel.

Page 135

Instrument cluster descriptions 1. Tachometer the tachometer indicates engine speed in revolutions per minute (rpm x 1000). Caution! Do not operate the engine with the tachometer pointer at high rpm for extended periods. Engine operation over 3200 rpm (redline) can result in significant damage that ...

Page 136

Come on when the ignition is first turned on and remain on for 15 seconds, then blink for 5 seconds, and remain on until the vehicle is started. If the bulb does not come on during starting, have the condition investigated promptly. If this light comes on and remains on while driving, it suggests a ...

Page 137

Note: a continuous chime will sound if the vehicle is driven more than 1 mile (1.6 km) with either turn signal on. Check for an inoperative outside light bulb if either indicator remains on and does not flash, or flashes at a rapid rate. 5. Engine coolant temperature this gauge shows the engine cool...

Page 138

Warning! (continued) vehicle.” follow the warnings under the “cooling system pressure cap” paragraph. 6. Brake warning light this light monitors various brake functions, including brake fluid level and parking brake application. If the brake light turns on it may indicate that the parking brake is a...

Page 139

Warning! Driving a vehicle with the red brake light on is dangerous. Part of the brake system may have failed. It will take longer to stop the vehicle. You could have a collision. Have the vehicle checked immediately. Vehicles equipped with the abs, are also equipped with electronic brake force dist...

Page 140

Flash or remain on continuously. Refer to “occupant restraints” in “things to know before starting your vehicle” for further information. 9. Air bag warning light this light will turn on for four to eight seconds as a bulb check when the ignition switch is first turned to on/run. If the light is eit...

Page 141

14. Fuel gauge shows level of fuel in tank when ignition switch is in the on/run position. 15. Vehicle security light — if equipped this light will flash at a fast rate for approxi- mately 15 seconds, when the vehicle security alarm is arming, and then will flash slowly until the vehicle is disarmed...

Page 142

Your vehicle has also been equipped with a tpms malfunction indicator to indicate when the system is not operating properly. The tpms malfunction indicator is combined with the low tire pressure telltale. When the system detects a malfunction, the telltale will flash for approximately one minute and...

Page 143

17. Front fog light indicator — if equipped this indicator will illuminate when the front fog lights are on. 18. Electronic vehicle information center (evic) the electronic vehicle information center (evic) fea- tures a driver-interactive display that is located in the instrument cluster. For furthe...

Page 144

22. Tow/haul the tow haul button is located on the center stack upper switch bank. This light will illumi- nate when tow haul mode is selected. 23. Electronic stability control (esc) activation/ malfunction indicator light — if equipped the “esc activation/malfunction indicator light” in the instrum...

Page 145

In the electronic vehicle information (evic) section under the heading of diesel exhaust fluid (def) warn- ing messages. Electronic vehicle information center (evic) the electronic vehicle information center (evic) fea- tures a driver-interactive display that is located in the instrument cluster. Th...

Page 146

Electronic vehicle information center (evic) displays when the appropriate conditions exist, the electronic vehicle information center (evic) displays the follow- ing messages: • system setup unavailable – vehicle not in park • system setup unavailable – vehicle in motion • service air filter • perf...

Page 147

• coolant low • engine power reduced during warmup • engine power reduced up to 30-sec during warmup • engine power reduced up to 2-min during warmup • active airbox service required see dealer evic warning lights water in fuel indicator light the “water in fuel indicator light” will illumi- nate wh...

Page 148

Cold ambient derate mode messages the vehicle will display messages when a derate (engine power reduction) is activated to protect the turbocharger during engine start up in cold ambient temperatures. • engine power reduced during warmup - this message will display during start up when the ambient t...

Page 149

• speed limited to 5 mph in xxx mi refill def – this message will continuously display if the “def low refill soon” message is ignored, and the frequency of occurance of the chime will increase unless up to 2 gallons (7.5 liters) of def is added to the tank. • 5 mph max speed on restart, long idle o...

Page 150

Diesel exhaust fluid (def) fault warning messages there are four different messages which are displayed if the vehicle detects that the def system has been filled with a fluid other than def, has experienced component failures, or when tampering has been detected. The vehicle may be limited to a max...

Page 151

• 5 mph max speed on restart, long idle or refuel service def see dealer — this message will continu- ously display when the mileage counter reaches zero, and will be accompanied by a periodic chime. • the vehicle will only be capable of a maximum speed of 5 mph upon the first of the following condi...

Page 152

Ram active air system your vehicle is equipped with an advanced ram active air system that provides enhanced performance, espe- cially when towing under demanding hot or high alti- tude conditions. If the evic displays the message “ac- tive airbox service required see dealer”, vehicle performance ma...

Page 153

• engine hours displays the total hours of engine operation, and the hours in drive and at idle. • oil filter life displays the percentage of oil filter life remaining, and the miles since the last reset. • fuel filter life displays the percentage of fuel filter life remaining, and the miles since t...

Page 155: Starting And Operating

Starting and operating contents 䡵 starting procedures . . . . . . . . . . . . . . . .156 ▫ manual transmission – if equipped . . . . . . . .157 ▫ automatic transmission – if equipped . . . . . .157 ▫ keyless enter-n-go™ . . . . . . . . . . . . . . . . . .157 ▫ extreme cold weather . . . . . . . . . ...

Page 156

▫ operating precautions . . . . . . . . . . . . . . . . . .174 ▫ cooling system tips – automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . .175 䡵 engine block heater — if equipped . . .176 ▫ block heater usage . . . . . . . . . . . . . . . . . . . .177 䡵 diesel exhaust brake (engi...

Page 157

䡵 adding fuel – 2500/3500 diesel models . . . . . . . . . . . . . . . . . . . . . . . . . . . .206 䡵 adding fuel – chassis cab models . . . .209 ▫ fuel filler cap . . . . . . . . . . . . . . . . . . . . . . .210 ▫ avoid using contaminated fuel . . . . . . . . . . .210 ▫ bulk fuel storage – diesel fu...

Page 158

Starting procedures before starting your vehicle, adjust your seat, adjust both inside and outside mirrors, and fasten your seat belts. The starter should not be operated for more than 15- second intervals. Waiting a few minutes between such intervals will protect the starter from overheating. Warni...

Page 159

Manual transmission – if equipped apply the parking brake, place the shift lever in neu- tral and press the clutch pedal to the floor before starting the vehicle. This vehicle is equipped with a clutch interlocking ignition system. It will not start unless the clutch is fully pressed. Automatic tran...

Page 160

4. If you wish to stop the cranking of the engine prior to the engine starting, remove your foot from the brake pedal and press the button again. Note: normal starting of either a cold or a warm engine is obtained without pumping or pressing the accelerator pedal. Note: under cold weather conditions...

Page 161

Note: if the ignition switch is left in the acc or run (engine not running) position and the transmission is in park, the system will automatically time out after 30 minutes of inactivity and the ignition will switch to the off position. Engine start/stop button functions – with driver’s foot off th...

Page 162

Follow the steps in the “normal starting” procedure except: 1. Pushing the engine start button with the driver’s foot on the brake will move the ignition from off or acc to run, and will illuminate the ⬙wait to start⬙ telltale. The engine will not immediately crank, this is normal operation. 2. The ...

Page 163

5. After engine start-up, check to see that there is oil pressure. 6. Allow the engine to idle about three minutes until the manifold heaters have completed the post-heat cycle. 7. Release the parking brake and drive. Note: • engine idle speed will automatically increase to 1,000 rpm and engage the ...

Page 164

Note: the engine block heater cord is a factory in- stalled option. If your vehicle is not equipped, heater cords are available from your authorized mopar® dealer. • a 12 volt heater built into the fuel filter housings aid in preventing fuel gelling. It is controlled by a built-in thermostat. • a he...

Page 165

Caution! Do not crank engine for more than 15 seconds at a time or starter motor damage may result. Turn the ignition switch to the off position and wait at least two minutes for the starter to cool before repeating start procedure. 5. When the engine starts, release the key fob. 6. Check that the o...

Page 166

2. While the ⬙wait to start” telltale is on, the evic will additionally display a gauge or bar whose initial length represents the full ⬙wait to start⬙ time period. Its length will decrease until it disappears when the ⬙wait to start⬙ time has elapsed. Caution! If the “water in fuel indicator light”...

Page 167

• automatic equipped vehicles with optional keyless enter-n-go™ – if the start button is pushed once while in park with the ignition off and driver’s foot on the brake pedal, the vehicle will automatically crank and start after the wait to start time has elapsed. If it is desired to abort the start ...

Page 168

Note: excessive white smoke and poor engine perfor- mance will result if manifold heaters are not recycled. 2. Heat generated by the manifold heaters dissipates rapidly in a cold engine. If more than two minutes pass between the time the “wait to start” telltale turns off and the engine is started, ...

Page 169

Starting fluids warning! Starting fluids or flammable liquids must never be used in the cummins® diesel engine (see warning label). Never pour diesel fuel, flammable liquid, starting fluids (ether) into the air cleaner canister, air intake piping, or turbocharger inlet in an attempt to start the veh...

Page 170

Normal operation – diesel engine observe the following when the engine is operating. • all message center lights are off. • malfunction indicator light (mil) is off. • engine oil pressure is above 10 psi (69 kpa) at idle. • voltmeter operation: the voltmeter may show a gauge fluctuation at various e...

Page 171

Note: • use of climatized ultra low sulfur diesel fuel or number 1 ultra low sulfur diesel fuel results in a noticeable decrease in fuel economy. • climatized ultra low sulfur diesel fuel is a blend of number 2 ultra low sulfur and number 1 ultra low sulfur diesel fuels which reduces the temperature...

Page 172

Battery blanket usage a battery loses 60% of its cranking power as the battery temperature decreases to 0°f (-18°c). For the same de- crease in temperature, the engine requires twice as much power to crank at the same rpm. The use of 120 vac powered battery blankets will greatly increase starting ca...

Page 173

Note: • if ambient temperatures are low and the coolant temperature is below 180°f (82°c), the engine idle speed will slowly increase to 1,000 rpm after two minutes of idle, if the following conditions are met: • foot is off brake pedal and throttle pedal • automatic transmission is in park • vehicl...

Page 174

Idle-up feature – automatic transmission only the driver-controlled high idle speed feature will help increase cylinder temperatures and provide additional cab heat, however, excessive idling may still cause the exhaust aftertreatment system to not properly regenerate. Extended periods of idle time ...

Page 175

Note: • during engine shut down on vehicles equipped with manual transmissions, it is normal for the diesel en- gine to resonate heavily for a moment during engine shut off. When the engine is connected to a manual transmission, this resonance causes load gear rattle from the transmission. This is c...

Page 176

Idle shutdown this feature can be enabled so that the truck will auto- matically shutdown when the truck has been idling for a set period of time when the engine is at operating temperature. Idle time can be set in 5 minute increments between 5 and 60 minutes. See your local authorized dealer to ena...

Page 177

Avoid low coolant temperature operation continual operation at low engine coolant (antifreeze) temperature below the normal range on the gauge 140°f (60°c) can be harmful to the engine. Low engine coolant (antifreeze) temperature can cause incomplete combus- tion which allows carbon and varnish to f...

Page 178

Do not operate the engine with failed parts all engine failures give some warning before the parts fail. Be on the alert for changes in performance, sounds, and visual evidence that the engine requires service. Some important clues are: • engine misfiring or vibrating severely • sudden loss of power...

Page 179

Warning! Remember to disconnect the cord before driving. Damage to the 110–115 volt electrical cord could cause electrocution. Note: the block heater will require 110 volts ac and 6.5 amps to activate the heater element. Block heater usage for ambient temperatures below 0°f (-18°c), engine block hea...

Page 180

Until the ⬙exhaust brake indicator⬙ is illuminated. Nor- mal (full strength) exhaust brake mode is indicated by a yellow ⬙exhaust brake indicator⬙. Once the ⬙exhaust brake indicator” is illuminated and the vehicle is moving faster than 5 mph (8 km/h); the exhaust brake will automatically operate whe...

Page 181

Note: for optimum braking power it is recommended to use the exhaust brake while in tow/haul mode. The exhaust brake feature can also be used to reduce the engine warm up time. To use the exhaust brake as a warm-up device, the vehicle must be stopped or moving less than 5 mph (8 km/h), the ⬙exhaust ...

Page 182

Caution! (continued) • do not shift between park, reverse, neu- tral, or drive when the engine is above idle speed. • before shifting into any gear, make sure your foot is firmly pressing on the brake pedal. Warning! • unintended movement of a vehicle could injure those in and near the vehicle. As w...

Page 183

Warning! (continued) • never leave children alone in a vehicle, or with access to an unlocked vehicle. Allowing children to be in a vehicle unattended is dangerous for a number of reasons. A child or others could be seriously or fatally injured. Children should be warned not to touch the parking bra...

Page 184

Position, and the transmission is locked in park when- ever the ignition switch is in the full off position. Brake/transmission shift interlock system this vehicle is equipped with a brake transmission shift interlock system (btsi) that holds the shift lever in park unless the brakes are applied. To...

Page 185

Only shift from drive to park or reverse when the accelerator pedal is released and the vehicle is stopped. Be sure to keep your foot on the brake pedal when shifting between these gears. The transmission shift lever has only park, reverse, neutral, and drive shift positions. Manual down- shifts can...

Page 186

Precaution, turn the front wheels toward the curb on a downhill grade and away from the curb on an uphill grade. On four-wheel drive vehicles be sure that the transfer case is in a drive position. Warning! • never use the park position as a substitute for the parking brake. Always apply the parking ...

Page 187

Warning! (continued) • unintended movement of a vehicle could injure those in and near the vehicle. As with all vehicles, you should never exit a vehicle while the engine is running. Before exiting a vehicle, always apply the parking brake, shift the transmission into park, turn the engine off, and ...

Page 188

Caution! • before moving the shift lever out of park, you must turn the ignition switch from the off posi- tion to the on/run position, and also press the brake pedal. Otherwise, damage to the shift lever could result. • do not race the engine when shifting from park or neutral into another gear ran...

Page 189

Warning! Do not coast in neutral and never turn off the ignition to coast down a hill. These are unsafe practices that limit your response to changing traffic or road conditions. You might lose control of the vehicle and have a collision. Caution! Towing the vehicle, coasting, or driving for any oth...

Page 190

If the transmission temperature exceeds normal operat- ing limits, the powertrain controller will modify the transmission shift schedule and expand the range of torque converter clutch engagement. This is done to prevent transmission damage due to overheating. If the transmission becomes extremely h...

Page 191

Accelerate under heavily loaded conditions may be re- duced. In all cases, normal operation will resume once the transmission temperature has risen to a suitable level. Transmission limp home mode transmission function is monitored electronically for abnormal conditions. If a condition is detected t...

Page 192

If the transmission cannot be reset, authorized dealer service is required. Electronic range select (ers) operation the electronic range select (ers) shift control allows the driver to limit the highest available gear when the shift lever is in the drive position. For example, if you shift the trans...

Page 193

Warning! Do not downshift for additional engine braking on a slippery surface. The drive wheels could lose their grip and the vehicle could skid, causing a collision or personal injury. Screen display 1 2 3 4 5 6 d actual gear(s) allowed 1 1-2 1-3 1-4 1-5 1-6 1-6 note: to select the proper gear posi...

Page 194

When to use tow/haul mode when driving in hilly areas, towing a trailer, carrying a heavy load, etc., and frequent transmission shifting oc- curs, press the tow/haul switch to activate tow/ haul mode. This will improve performance and reduce the potential for transmission overheating or failure due ...

Page 195

Warning! Do not use the “tow/haul” feature when driving in icy or slippery conditions. The increased engine braking could cause the rear wheels to slide, and the vehicle to swing around with the possible loss of vehicle control, which could cause an accident possi- bly resulting in personal injury o...

Page 196

Cause damage to the transmission. The torque con- verter will refill within five seconds after starting the engine. Manual transmission — if equipped warning! You or others could be injured if you leave the vehicle unattended without having the parking brake fully applied. The parking brake should a...

Page 197

Shifting truck models with manual transmission are equipped with a clutch interlocking ignition system. The clutch pedal must be fully pressed to start the vehicle. Fully press the clutch pedal before shifting gears. As you release the clutch pedal, lightly press the accelerator pedal. This transmis...

Page 198

Maximum recommended up-shift speeds gear selection 1 to 2 2 to 3 3 to 4 4 to 5 5 to 6 maximum speed 7 mph (11 km/h) 15 mph (24 km/h) 25 mph (40 km/h) 40 mph (64 km/h) 45 mph (72 km/h) downshifting moving from a high gear down to a lower gear is recommended to preserve brakes when driving down steep ...

Page 199

Maximum recommended downshifting speeds gear selection 6 to 5 5 to 4 4 to 3 3 to 2 2 to 1 maximum speed 68 mph (109 km/h) 50 mph (80 km/h) 32 mph (51 km/h) 19 mph (31 km/h) 10 mph ) (16 km/h caution! If you skip a gear while downshifting or downshift at too high of a vehicle speed, these conditions ...

Page 200

That they are about to shift the transmission into re- verse (r). Due to this feature, a slow shift to reverse (r) can be perceived as a high shift effort. To shift out of reverse bring the vehicle to a complete stop and press the clutch. Shifting out of reverse prior to a complete stop may cause hi...

Page 201

• brake pedal must not be applied • vehicle engine must be running • no vehicle, brake or clutch switch faults present • pto must be correctly installed using the vehicle provided circuits the electronic vehicle information center (evic) will display a ⬙pto on⬙ message for five seconds if the above ...

Page 202

Pto manufacturer to ensure that their electrical (switches and remote) system is compatible with the vehicle’s electrical architecture and software functionality. Note: single set speed can be programmed via the pto menu on the evic screen. Further details are available at the ram truck bodybuilders...

Page 203

Note: for application specific information with respect to pto and pump requirements and additional vehicle information (wiring schematics, preset idle values, en- gine speed limits, and vehicle hardware and software requirements) please refer to the body builders guide by accessing www.Rambodybuild...

Page 204

Fuel requirements use good quality diesel fuel from a reputable supplier in your vehicle. Federal law requires that you must fuel this vehicle with ultra low sulfur highway diesel fuel (15 ppm sulfur maximum) and prohibits the use of low sulfur highway diesel fuel (500 ppm sulfur maximum) to avoid d...

Page 205

Caution! If the “water in fuel indicator light” remains on, do not start engine before you drain the water from the fuel filter(s) to avoid engine damage. Refer to “maintenance procedures/draining fuel/water sepa- rator filter” in “maintaining your vehicle” for fur- ther information. Fuel specificat...

Page 206

Must first be reconfigured by an authorized ram dealer and the provisions in the following section must be adhered to. Pickup models and chassis cab models ordered with b20 option your vehicle has been validated and approved for the use of biodiesel in blends up to 20% (b20) provided that you comply...

Page 207

Fuel oxidation stability - must use fuel within six months of manufacture biodiesel fuel has poor oxidation stability which can result in long term storage problems. Fuel produced to approved astm standards, if stored properly, provides for protection against fuel oxidation for up to six months. Fue...

Page 208

Caution! • under no circumstances should oil change inter- vals exceed 15,000 miles (24 000 km) pickup or 12,500 miles (20 000 km) chassis cab if operation occurs with greater than 5% biodiesel blends. Oil change intervals should not exceed 6 months in either case. Failure to comply with these oil c...

Page 209

2. There is no fuel filler cap. A flapper door inside the filler pipe seals the system. 3. Insert the fuel nozzle fully into the filler pipe – the nozzle opens and holds the flapper door while refuel- ing. 4. Fill the vehicle with fuel – when the fuel nozzle “clicks” or shuts off the fuel tank is fu...

Page 210

2. Insert funnel into same filler pipe opening as the fuel nozzle. 3. Ensure funnel is inserted fully to hold flapper door open. 4. Pour fuel into funnel opening. 5. Remove funnel from filler pipe, clean off prior to putting back in the jack kit. Fuel fill funnel location 2500/3500 models emergency ...

Page 211

Caution! To avoid fuel spillage and overfilling, do not “top off” the fuel tank after filling. Warning! • never have any smoking materials lit in or near the vehicle when the fuel door is open or the tank is being filled. • never add fuel when the engine is running. This is in violation of most stat...

Page 212

Warning! A fire may result if fuel is pumped into a portable container that is on a truck bed. You could be burned. Always place fuel containers on the ground while filling. Fuel filler cap if the fuel filler cap is lost or damaged, be sure the replacement cap is for use with this vehicle. Caution! ...

Page 213

Microbes form “slime” that will clog fuel filters and lines. Drain condensation from the supply tank and change the line filter on a regular basis. Note: when a diesel engine is allowed to run out of fuel, air is pulled into the fuel system. If the vehicle will not start, refer to “maintenance proce...

Page 214

Adding diesel exhaust fluid the def gauge (located on the instrument cluster) will display the level of def remaining in the tank. Refer to “instrument cluster” and “instrument cluster descrip- tions” in “understanding your instrument panel” for further information. Note: driving conditions (altitud...

Page 215

1 — diesel exhaust fluid fill location 2 — diesel fuel fill location 2. Insert def fill adapter/nozzle into def tank filler neck. Caution! • to avoid def spillage, and possible damage to the def tank from overfilling, do not “top off” the def tank after filling. (continued) def filler cap and fuel f...

Page 216

Caution! (continued) • do not overfill. Def will freeze below 12 degrees f (-11 degrees c). The def system is designed to work in temperatures below the def freezing point, however, if the tank is overfilled and freezes, the system could be damaged. • when def is spilled, clean the area immediately ...

Page 217

Extra care should be taken when filling with portable containers to avoid overfilling. Note the level of the def gauge in your instrument cluster. On pickup applica- tions, you may safely add a maximum of 2 gallons of def from portable containers when your def gauge is read- ing ½ full. On chassis c...

Page 218

Gross trailer weight (gtw) the gtw is the weight of the trailer plus the weight of all cargo, consumables and equipment (permanent or tem- porary) loaded in or on the trailer in its ⬙loaded and ready for operation ⬙ condition. The recommended way to measure gtw is to put your fully loaded trailer on...

Page 219

Frontal area the frontal area is the maximum height multiplied by the maximum width of the front of a trailer. Trailer sway control the trailer sway control can be a mechanical telescoping link that can be installed between the hitch receiver and the trailer tongue that typically provides adjustable...

Page 220

Trailer sway control and a weight distributing (load equalizing) hitch are recommended for heavier tongue weights (tw) and may be required depending on vehicle and trailer configuration / loading to comply with gross axle weight rating (gawr) requirements. Warning! • an improperly adjusted weight di...

Page 221

Trailer hitch classification the following chart provides the industry standard for the maximum trailer weight a given trailer hitch class can tow and should be used to assist you in selecting the correct trailer hitch for your intended towing condition. Trailer hitch classification definitions clas...

Page 222

Ram 2500 & 3500 diesel 2500 st slt bighorn/lonestar laramie outdoorsman 3500 st slt bighorn/lonestar laramie outdoorsman 6.7l cummins® turbo diesel 6-speed manual transmission max towing: 16,710 lbs (7 579 kg) max payload: 2,880 lbs (1 306 kg) max towing: 18,200 lbs (8 255 kg) max payload: 6,640 lbs...

Page 223

Chassis cab 4500 diesel st/slt/laramie 6.7l cummins® turbo diesel 6-speed manual trans- mission max towing: 20,200 lbs (9 162 kg) max payload: 8,741 lbs (3 964 kg) 6.7l cummins® turbo diesel 6-speed aisin automatic transmission max towing: 24,650 lbs (11 181 kg) max payload: 8,661 lbs (3 928 kg) cha...

Page 224

Note: for additional trailer towing information (maxi- mum trailer weight ratings) refer to the following website addresses: • http://www.Ramtrucks.Com • http://www.Ramtruck.Ca (canada) trailer and tongue weight always load a trailer with 60% to 65% of the weight in the front of the trailer. This pl...

Page 225

Note: remember that everything put into or on the trailer adds to the load on your vehicle. Also, additional factory-installed options or dealer-installed options must be considered as part of the total load on your vehicle. Refer to “tire safety information/tire and loading in- formation placard” i...

Page 226

Warning! Improper towing can lead to a collision. Follow these guidelines to make your trailer towing as safe as possible: • make certain that the load is secured in the trailer and will not shift during travel. When trailering cargo that is not fully secured, dynamic load shifts can occur that may ...

Page 227

Warning! (continued) 2. Gtw 3. Gawr 4. Tongue weight rating for the trailer hitch utilized. Towing requirements – tires • do not attempt to tow a trailer while using a compact spare tire. • proper tire inflation pressures are essential to the safe and satisfactory operation of your vehicle. Refer to...

Page 228

• an electronically actuated trailer brake controller is required when towing a trailer with electronically actuated brakes. When towing a trailer equipped with a hydraulic surge actuated brake system, an electronic brake controller is not required. • trailer brakes are recommended for trailers over...

Page 229

Integrated trailer brake module – if equipped your vehicle may have an integrated trailer brake mod- ule (itbm) for electric and electric over hydraulic (eoh) trailer brakes. Note: this module has been designed and verified with electric trailer brakes and new electric over hydrau- lic systems. Some...

Page 230

The user interface consists of the following: manual brake control lever slide the manual brake control lever to the right to activate power to the trailer’s electric brakes independent of the tow vehicle’s brakes. If the manual brake control lever is activated while the brake is also applied, the g...

Page 231

Adjusting gain note: this should only be performed in a traffic free environment at speeds of approximately 20–25 mph (30–40 km/h). 1. Make sure the trailer brakes are in good working condition, functioning normally, and properly ad- justed. See your trailer dealer if necessary. 2. Hook up the trail...

Page 232

9. If the trailer wheels lockup (indicated by squealing tires), reduce the gain setting; if the trailer wheels turn freely, increase the gain setting. Repeat steps 8 and 9 until the gain setting is at a point just below trailer wheel lockup. If towing a heavier trailer, trailer wheel lockup may not ...

Page 233

Caution! Connecting a trailer that is not compatible with the itbm system may result in reduced or complete loss of trailer braking. There may be a increase in stop- ping distance or trailer instability which could result in damage to your vehicle, trailer, or other property. Warning! Connecting a t...

Page 234

Towing requirements – trailer lights and wiring whenever you pull a trailer, regardless of the trailer size, stoplights and turn signals on the trailer are required for motoring safety. The trailer tow package may include a four- and seven- pin wiring harness. Use a factory approved trailer har- nes...

Page 235

Towing tips before setting out on a trip, practice turning, stopping and backing the trailer up in an area away from heavy traffic. Automatic transmission the “drive” range can be selected when towing. The transmission controls include a drive strategy to avoid frequent shifting when towing. However...

Page 236

When towing a loaded trailer up steep grades at low speeds (20 mph [32 km/h] or below), holding your vehicle in first gear (using the ers switches) can help to avoid transmission overheating. If you regularly tow a trailer for more than 45 minutes of continuous operation, then change the automatic t...

Page 237

Air conditioning turn off temporarily. Air suspension system to aid in attaching/detaching the trailer from the vehicle, the air suspension system can be used. Refer to “air suspension system” in “starting and operating” for further information. Note: the vehicle must remain in the engine running po...

Page 238

The def injection system consists of the following com- ponents: • def tank • def pump • def injector • electronically-heated def lines • def control module • nox sensors • nh3 sensor • temperature sensors • scr catalyst the def injection system and scr catalyst enable the achievement of diesel emis...

Page 239: Contents

What to do in emergencies contents 䡵 jump starting . . . . . . . . . . . . . . . . . . . . . .238 ▫ with portable starting unit. . . . . . . . . . . . . . .241 5.

Page 240

Jump starting warning! • to prevent personal injury or damage to clothing, do not allow battery fluid to contact eyes, skin or fabrics. Do not lean over a battery when connecting jumper cables or allow cable clamps to touch each other. Keep open flames or sparks away from battery vent holes. Always ...

Page 241

1. Attach one jumper cable to the positive terminal of booster battery and the other end of the same cable to the positive terminal of the discharged battery. Warning! Do not permit vehicles to touch each other as this could establish a ground connection and personal injury could result. 1 — dischar...

Page 242

2. Connect one end of the other jumper cable to negative (-) post of booster battery. Connect the other end of the jumper cable to a good ground on the engine block of the vehicle with the discharged battery. Make sure a good connection is made, free of dirt and grease. Warning! • do not connect the...

Page 243

Warning! Any procedure other than above could result in: • personal injury caused by electrolyte squirting out the battery vent; • personal injury or property damage due to battery explosion; • damage to charging system of booster vehicle or of immobilized vehicle. With portable starting unit there ...

Page 245: Maintaining Your Vehicle

Maintaining your vehicle contents 䡵 engine compartment — 6.7l diesel — six-speed 68rfe (2500/3500 models only) . . .245 䡵 engine compartment — 6.7l diesel — six-speed as69rc (3500 models only) . . . . . .246 䡵 engine compartment — 6.7l diesel (chassis cab models only) . . . . . . . . . . .247 䡵 main...

Page 246

▫ transfer case – if equipped . . . . . . . . . . . . . .273 ▫ manual transmission – if equipped . . . . . . . .274 ▫ automatic transmission – if equipped . . . . . .274 ▫ noise control system required maintenance & warranty . . . . . . . . . . . . . . . .277 䡵 fluid capacities . . . . . . . . . . ....

Page 247

Engine compartment — 6.7l diesel — six-speed 68rfe (2500/3500 models only) 1 — battery 7 — washer fluid reservoir 2 — engine coolant reservoir 8 — power steering fluid reservoir 3 — automatic transmission dipstick (if equipped) 9 — power distribution center 4 — brake fluid reservoir 10 — engine oil ...

Page 248

Engine compartment — 6.7l diesel — six-speed as69rc (3500 models only) 1 — battery 7 — washer fluid reservoir 2 — engine coolant reservoir 8 — power steering fluid reservoir 3 — automatic transmission dipstick (if equipped) 9 — power distribution center 4 — brake fluid reservoir 10 — engine oil dips...

Page 249

Engine compartment — 6.7l diesel (chassis cab models only) 1 — battery 7 — washer fluid reservoir 2 — engine coolant reservoir 8 — power steering fluid reservoir 3 — automatic transmission dipstick (if equipped) 9 — power distribution center 4 — brake fluid reservoir 10 — engine oil dipstick 5 — bat...

Page 250

Maintenance procedures the pages that follow contain the required maintenance services determined by the engineers who designed your vehicle. Besides those maintenance items specified in the fixed maintenance schedule, there are other components which may require servicing or replacement in the futu...

Page 251

Engine oil checking oil level to assure proper lubrication of your vehicle’s engine, the engine oil must be maintained at the correct level. Check the oil level at regular intervals. The best time to check the oil level is before starting the engine after it has been parked overnight. When checking ...

Page 252

Mark. The total capacity from the low mark to the high mark is 2 qts (1.9l). Caution! Overfilling or underfilling the crankcase will cause oil aeration or loss of oil pressure. This could damage your engine. Never operate the engine with oil level below the “add” mark or above the upper “safe” mark....

Page 253

Oils with a high ash content may produce damaging deposits on cylinder head valves and/or aftertreatment system damage. A maximum sulfated ash content of 1.00 mass % is recommended for all oil used in the engine. The same oil change interval is to be followed for synthetic oil as for petroleum based...

Page 254

Engine oil not designated by the chrysler or cummins® material standards and api cj-4 should not be used, as engine and exhaust system durability may be compromised. The engine oil filler cap also shows the recommended engine oil viscosity for your engine. For information on engine oil filler cap lo...

Page 255

Disposing of used engine oil and oil filters care should be taken in disposing of used engine oil and oil filters from your vehicle. Used oil and oil filters, indiscriminately discarded, can present a problem to the environment. Contact your authorized dealer, service station or governmental agency ...

Page 256

Caution! Driving with a restricted air filter can cause engine damage. Driving in dusty environments for extended periods will lead to rapid air filter plugging. Action should be taken as soon as the “service air filter” message is displayed. If the vehicle experiences a sudden loss of engine power ...

Page 257

Draining fuel/water separator filter there are two fuel filter assemblies. One is located on the driver’s side of the engine. The best access to this water drain valve is from under the hood. The second one is on the under body, located in front of the rear axle above the drive shaft on pick-up mode...

Page 258

Drained while the engine was running, the “water in fuel indicator light” may remain on for approximately three minutes. Note: care should be taken in disposing of used fluids from your vehicle. Used fluids, indiscriminately discarded, can present a problem to the environment. Contact an authorized ...

Page 259

Caution! • diesel fuel will damage blacktop paving surfaces. Drain the filter into an appropriate container. • do not prefill the fuel filter when installing a new fuel filter. There is a possibility debris could be introduced into the fuel filter during this action. It is best to install the filter...

Page 260

5. Remove lid using a socket or strap wrench. Rotate counterclockwise for removal. Remove used o-ring and discard it. 6. Remove the used filter cartridge from the housing and dispose of according to your local regulations. 7. Wipe clean the sealing surfaces of the lid and housing. 8. Install new o-r...

Page 261

Caution! • diesel fuel will damage blacktop paving surfaces. Drain the filter into an appropriate container. • do not prefill the fuel filter when installing a new fuel filter. There is a possibility debris could be introduced into the fuel filter during this action. It is best to install the filter...

Page 262

4. Close the water drain valve. 5. Remove lid using a socket or strap wrench. Rotate counterclockwise for removal. Remove used o-ring and discard it. 6. Remove the used filter cartridge from the housing and dispose of according to your local regulations. 7. Wipe clean the sealing surfaces of the lid...

Page 263