RAMSET HammerShot Operator Instructions Manual

THIS TOOL IS FOR USE ONLY BY LICENSED OPERATORS.

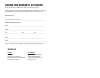

YOU MUST OBTAIN A LICENSE BEFORE USING IT. A

TOOL OPERATOR'S CARD WILL BE ISSUED TO YOU

AFTER SUCCESSFULLY COMPLETING THE ENCLOSED

EXAM AND RETURNING IT TO RECEIVE YOUR CARD

AND ACTIVATE YOUR WARRANTY. OPERATOR'S

LICENSE CAN ALSO BE OBTAINED AT: www.ramset.com

MODEL HD22

LOW VELOCITY POWDER ACTUATED TOOL

Operator's Instruction & Training Manual

• The Ramset HD22 is a light duty tool designed for applications such as small

room additions and basement remodels. Tool life will vary depending on work site

conditions and application.

• The model HD22 is a low velocity piston type fastening tool. It is designed for

use with Ramset .22 caliber CW powder loads and Ramset fasteners.

• Do not operate the Model HD22 before studying this manual carefully and

thoroughly understanding the material contained herein.

IMPORTANT

: The tool warranty is only activated upon receipt by ITW Brands of the

completed Operator's Exam.

Part #00022

Rev. 8/07

RD v001MA