- DL manuals

- RAMSET

- Tools

- ROCKET TOOL

- Operator's safety & operating instruction manual

RAMSET ROCKET TOOL Operator's safety & operating instruction manual

Summary of ROCKET TOOL

Page 1

Ramset rocket tool operator’s safety & operating instruction manual danger this tool for use by licensed operators only. Read and obey all safety and operating instructions before operating tool. Semi-automatic, low velocity piston type fastening tool.

Page 2: Safety Introduction

Just as no one can merely read a book about driving an automobile and then hope to drive one safely, no one should attempt to use any ramset tool without adequate, competent personal instruction. And just as one must be licensed to drive an automobile, one must also be licensed to use a powder actua...

Page 3: Preparation

Preparation acceptable base materials powder actuated fastening is suitable for use in the following base materials only: • poured concrete • structural steel • masonry joints (see page 8) never attempt to fasten into any other type of material. Fastening into other materials can cause blindness or ...

Page 4: Safety Instructions

Loads & load selection safety 1. Always make a test fastening after being sure that the base material is suitable for powder actuated fastening. Failure to determine the correct power level to be used may result in the use of excessive power, allowing the fastener to pass completely through the work...

Page 5: Danger

Tool handling safety 1. Always be sure tool is operating properly before attempting to use it. Follow the “daily function check” shown to the right and described on page 9. 2. Always load tool using a strip load selected directly from a box indicating the power load type and number. Never attempt to...

Page 6: Failure To Follow

Failure to follow instructions can cause injury to the tool operator or to bystanders. Fastener driving safety 1. Only use the tool for fastening into a suitable base material. 2. Never fire the tool without a fastener. Firing a tool without a fastener will cause the piston to strike the work surfac...

Page 7: Fasteners

Your ramset rocket tool uses only the ramset fasteners and loads shown below or listed for the tool in the product catalog. Fasteners fasteners / loads fasteners / loads 7 never use any other types of fasteners or strip loads in the ramset rocket tool. Use of other types of fasteners or loads may ca...

Page 8: Fastening Applications

Fastening applications your ramset tool can be used for a wide range of fastening needs in a variety of base materials.Reading and follow these important fastening guidelines will help you get the best results from your tool, fasteners, and powder loads, as well as help you perform these fastening o...

Page 9

Tool operation daily function test always check the tool first to make sure that it does not contain a strip load or fastener. Test the tool several times by depressing the muzzle bushing fully on a hard surface and pulling the trigger. You should hear an audible click as the firing pin releases. Le...

Page 10

4. Hold the tool perpendicular (90°) to the work surface with both hands and press firmly to fully depress the tool. Maintain firm downward pressure on the tool with both hands and pull the trigger to drive the fastener. Do not depress the tool against anything other than the intended work surface. ...

Page 11: Troubleshooting

Refer to parts schematic for proper assembly of parts – overdriving of fasteners – excessive power – change to the next lower power level load strip color and number. Reduce power by turning the power adjustment wheel. – soft base material – check base material (see page 3) – tool fails to fire – fa...

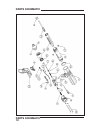

Page 12: Parts Schematic

Parts schematic parts schematic 12.

Page 13: Parts List

Ramset rocket tool parts list key part no. Description qty 1 a1049a muzzle bushing assembly 1 2 a1000-11 trigger assembly 1 3 a1001-1 firing pin assembly 1 4 a1001-2 advance lever assembly 1 5 a1001-3 power adjustment assembly 1 6 a1029 end cap 1 7 a1001-5 housing assembly 1 8 a1000-6 receiver assem...

Page 14: Maintenance

Maintenance maintenance 14 always make sure the tool is not loaded before performing any service or repair and always wear safety goggles when cleaning or servicing the tool. Normal cleaning all front end parts shown in the disassembly section are to be cleaned daily with a good detergent oil and wi...

Page 15: Disassembly

Tool disassembly 1. Unscrew the barrel retention sleeve and slide it away from the tool housing. Handle the tool carefully after the sleeve is unscrewed to prevent the two barrel pawls from falling out. 2. Remove the two pawls from the slots in the sides of the tool housing while holding the retenti...

Page 16: Disassembly

6. Unscrew the muzzle bushing assembly which includes the plastic outer sleeve. Note: if this is difficult to do by hand, grasp the barrel under the plastic sleeve and use a wrench on the flats on the muzzle collar to loosen the entire muzzle bushing assembly. 7. Remove the piston and the buffer ass...

Page 17: Magazine Assembly

Magazine assembly magazine assembly 17 the ramset rocket magazine has a unique feature that allows the user to “position and hold” the magazine every 90 degrees. Adjust the magazine angle: rotate the magazine to the desired position. Rocket magazine removal/ installation: 1. Be sure the tool is unlo...

Page 18

Rocket warranty and limitations powder actuated tool manufactures' institute inc. Tm concrete fastening systems glendale heights, il 60139 800-ramset6 (1-800-726-7386) www.Ramset.Com buy with confidence... Buy from your authorized distributor an illinois tool works company © illinois tool works 2008...