Operators manual notify carrier of damage at once. It is the responsibility of the consignee to inspect the container upon receipt of same and to determine the possibility of any damage, including concealed damage. Randell suggests that if you are suspicious of damage to make a notation on the deliv...

2 800-621-8560 table of contents page 2………………………………….…………congratulations page 3……………………………………parts & service hotline page 3………………………………...…serial number location page 4-7……………………………….Randell limited warranty page 8…………………………………………unit specifications page 9-10…..……………………………..……...Unit installation pa...

Difoodservice.Com 3 in addition, all randell food service equipment is backed by some of the best warranties in the food service industry and by our professional staff of service technicians. Retain this manual for future reference. Notice: due to a continuous program of product improvement, randell...

4 800-621-8560 warranty policies congratulations on your purchase of a randell manufactured piece of equipment. Randell believes strongly in the products it builds and backs them with the best warranty in the industry. Standard with every unit comes the peace of mind that this unit has been thorough...

Difoodservice.Com 5 warranty for a period of ninety days following installation with proof of starting date, up to a maximum of nine months from date of purchase. Travel time is limited to one hour each direction or two hours per invoice. Any travel time exceeding two hours will be the responsibilit...

6 800-621-8560 the unlimited number of customer related circumstances that can cause gasket failure all gasket replacement issues are considered non- warranty. Randell recommends thorough cleaning of gaskets on a weekly basis with a mild dish soap and warm water. With proper care randell gaskets can...

Difoodservice.Com 7 not be held responsible for any carrier rate differences; rate differences are entirely between the carrier and purchaser. Point of shipping shall be determined by randell (weidman, mi/tucson, az). At dealer’s request, randell will endeavor whenever practical to meet dealer’s req...

8 800-621-8560 unit specifications 20072sc shown model l d h drawers 12x20x4 pan capacity h.P. Volts amps nema ship wt. Self contained 20048sc 48" 32.5" 26" (2)27"ext. 4 1/4 115 6 5-15p 400 20048sc-c4 48" 32.5" 24" (2)27"ext. 4 1/4 115 6 5-15p 400 20072sc 72" 32.5" 26" (4)27"ext. 8 1/3 115 7.4 5-15p...

Difoodservice.Com 9 unit installation selecting a location for your new unit the following conditions should be considered when selecting a location for your unit: 1. Floor load: the area on which the unit will rest must be level, free of vibration, and suitably strong enough to support the combined...

10 800-621-8560 note: all motors are oiled and sealed. Note: failure to follow installation guidelines and recommendations may void the warranty on your unit. Electrical supply: the wiring should be done by a qualified electrician in accordance with local electrical codes. A properly wired and groun...

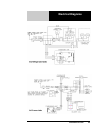

Difoodservice.Com 11 electrical diagrams.

12 800-621-8560 unit operation randell has attempted to preset the cold controls to ensure that your unit runs at an optimum temperature, but due to varying ambient conditions, including elevation, food product as well as type of operation, you may need to alter this temperature. It is strongly reco...

Difoodservice.Com 13 a. Push and hold the “set” button until 12 appears and then release the “set” button. 12 is the current set point temperature. Note: standard freezer units are preset to operate at 12° f. B. To lower the temperature, push and release the up arrow 2 times until 10 is displayed. P...

14 800-621-8560 preventive maintenance randell strongly suggests a preventive maintenance program which would include the following monthly procedures: 1. Cleaning of all condenser coils. Condenser coils are a critical component in the life of the compressor and must remain clean to assure proper ai...

Difoodservice.Com 15 note: do not pressure wash equipment as damage to electrical components may result. Preventive maintenance (cont.) to remove and re-install drawer tracks, please refer to figure 2 below for proper installation instructions. Figure 2 proper maintenance of equipment is the ultimat...

16 800-621-8560 maintenance and use, you will realize a profitable return on your investment and years of satisfied service..

Difoodservice.Com 17 trouble shooting guide symptom possible cause procedure unit doesn't run 1. No power to unit 1. Plug in unit 2. Temperature control turned off 2. Check temperature control 3. Temperature control faulty 3. Test temperature control 4. Compressor overheated 4. Clean condenser coil ...

18 800-621-8560 moisture around drawer or frame 1. Breaker strips faulty 1. Inspect strips 2. Frame heater defective 2. Call for service at 800-621-8561 3. Temperature set too low 3. Raise temperature setting ice in drain pan or water in bottom of unit or floor 1. Drain tube clogged 1. Clean drain 2...

Difoodservice.Com 19 replacement parts 20000 series low profile equipment stands.

20 800-621-8560 item description part # 1 drawer front, 27", top rp frt05t 1a drawer front, 19", top rp frt118.

Difoodservice.Com 21 1b drawer front, 32", top rp frt35t 2 drawer front, 27”, bottom rp frt05b 2a drawer front, 19”, bottom rp frt119 2b drawer front, 32”, bottom rp frt35b 3 sculptured handle, 12-13/16” hd hdl130 4 dial thermometer hd thr9901 5 mechanical housing louver, 20048sc & 20072sc only rp l...

22 800-621-8560 28 condensing unit, 20048sc rf con0004 28a condensing unit, 20072sc, 20078sc rf con9803 28b condensing unit, 20105sc rf con0006 28c condensing unit, 20048scf, 20072scf rf con0003 28d condensing unit, 20105scf rf con9901 29 condenser fan motor, 20048sc, 20072sc, 20078sc, 20048scf, 200...