1/29/2008 pp mnl0706 operator’s manual this manual provides information on installation, operating, maintenance, trouble shooting & replacement parts for 8000n series preparation tables notify carier of damage at once. It is the responsibility of the consignee to inspect the container upon receipt o...

2 2 2 2 800-621-8560 table of contents page 2………………………………….…………congratulations page 3……………………………………parts & service hotline page 3………………………………...…serial number location page 4-7……………………………….Randell limited warranty page 8…………………………………………unit specifications page 9-10…..……………………………………...Unit operation ...

Unifiedbrands.Net 3 in addition, all randell food service equipment is backed by some of the best warranties in the food service industry and by our professional staff of service technicians. Retain this manual for future reference. Notice: due to a continuous program of product improvement, randell...

4 4 4 4 800-621-8560 warranty policies congratulations on your purchase of a randell manufactured piece of equipment. Randell believes strongly in the products it builds and backs them with the best warranty in the industry. Standard with every unit comes the peace of mind that this unit has been th...

Unifiedbrands.Net 5 temperature adjustments are not covered under warranty, due to the wide range of ambient conditions. For warranty inquiries call our field service department at: 1-800-621-8560. When optional 5 year compressor warranty applies 1. Provide reimbursement to an asa for the cost of lo...

6 6 6 6 800-621-8560 notice: food loss is not covered under warranty 3. Repairs caused by abuse such as broken glass, freight damage, excessive force, or scratches and dents. 4. Electrical component failure due to water damage from cleaning procedures. 5. Drawer repairs that are the result of improp...

Unifiedbrands.Net 7 damages all crating conforms to general motor carrier specifications. To avoid concealed damage, we recommend inspection of every carton upon receipt. In the event the item shows rough handling or visible damage to minimize liability, a full inspection is necessary upon arrival. ...

8 8 8 8 800-621-8560 unit specifications 8260n pictured model l d h work hgt. Doors h.P. Volts amp s nem a r-404a / oz. Cub ft btu rating of cond unit 8148n 48" 33" 42.9" 35" 1 (27”) 1/3 115 9 5-15p 16 9 1380 8260n 60” 33” 42.9” 35” 2 (24”) 1/3 115 9 5-15p 16 14.8 1380 8268n 68” 33” 42.9” 35” 2 (27”...

Unifiedbrands.Net 9 unit operation randell has attempted to preset the cold controls to ensure that your unit runs at an optimum temperature, but due to varying ambient conditions, including elevation, food product as well as type of operation, you may need to alter this temperature. Additional adju...

10 10 10 10 800-621-8560 unit operation (cont.) figure 2 illustrates the evaporator blower coil assembly inside the lower refrigerated base. The thermostat adjustment knob is located at the top, front of the coil assembly. Morning startup (prep rail) 1. Rail cleaning may be performed at this time. 2...

Unifiedbrands.Net 11 unit operation (cont.) drawer removal and installation to remove and re-install individual drawers and drawer tracks, please refer to figure 2 below for proper installation instructions. Figure 2.

12 12 12 12 800-621-8560 preventive maintenance randell strongly suggests a preventive maintenance program which would include the following monthly procedures: if a failure of the equipment is a direct result of any of the preventative maintenance guidelines being neglected the repairs will not be ...

Unifiedbrands.Net 13 preventive maintenance (cont.) recommended cleaners for your stainless steel include the following: job cleaning agent comments routine cleaning soap, ammonia, detergent medallion apply with a sponge or cloth fingerprints and smears arcal 20, lac-o-nu, ecoshine provides a barrie...

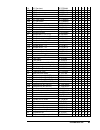

14 14 14 14 800-621-8560 electrical diagram.

Unifiedbrands.Net 15 trouble shooting guide symptom possible cause procedure unit doesn't run 1. No power to unit 1. Plug in unit (check power switch) 2. Temperature control turned off 2. Check temperature control 3. Temperature control faulty 3. Test temperature control 4. Compressor overheated 4. ...

16 16 16 16 800-621-8560 replacement parts 8000n series – exploded view.

Unifiedbrands.Net 17 replacement parts 8000n series – exploded view drawer assembly.

18 18 18 18 800-621-8560 replacement parts 8000n series – exploded view mechanical area.

Unifiedbrands.Net 19 replacement parts 8000n series – exploded view evaporator coil assembly.

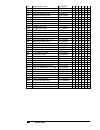

20 20 20 20 800-621-8560 replacement part list 8000n series item description part # 8 1 4 8 n 8 2 6 0 n 8 2 6 8 n 8 3 8 3 n 8 3 9 5 n 8 4 1 1 1 n 1 6" caster w/ break hd cst060 x x x x x x 2 6" caster w/o break hd cst061 x x x x x x 3 4" caster w/ break hd cst040hd x x x x x x 4 4" caster w/o break ...

Unifiedbrands.Net 21 19 21" dwr front rp frt9903 x x 19a 24" dwr front rp frt9904 x x x 19b 27" dwr front rp frt9905 x x x 19c 27" dwr front - 3 tier rp frt0117 x x x 20 21" dwr frame rp frm0301 x x 20a 24" drwr frame rp frm0302 x x x 20b 27" dwr frame rp frm0303 x x x 20c 27" dwr frame - 3 tier rp ...

22 22 22 22 800-621-8560 45 evap coil drain tube pl tbg075 x x x x x x 46 evap coil housing - rear panel rp pnl108 x x x x x x 47 evap coil housing - front panel rp pnl109 x x x x x x 48 evap coil housing -side rp pnl107 x x x x x x 49 evap fan motor w/ blade el mtr2338 x x x x x x 51 evap fan mount...