1/29/2008 pp mnl0504 rev b operator’s manual this manual provides information on installation, operating, maintenance, trouble shooting & replacement parts for pizza hut maketable ph120e2/ph120e2.1 notify carier of damage at once. It is the responsibility of the consignee to inspect the container up...

2 2 2 2 800-621-8560 table of contents page 2………………………………….…………congratulations page 3……………………………………parts & service hotline page 3………………………………...…serial number location page 4-7……………………………….Randell limited warranty page 8…………………………………………unit specifications page 9-10…………………………………………unit installation p...

Unifiedbrands.Net 3 in addition, all randell food service equipment is backed by some of the best warranties in the food service industry and by our professional staff of service technicians. Retain this manual for future reference. Notice: due to a continuous program of product improvement, randell...

4 4 4 4 800-621-8560 warranty policies congratulations on your purchase of a randell manufactured piece of equipment. Randell believes strongly in the products it builds and backs them with the best warranty in the industry. Standard with every unit is the peace of mind that this unit has been thoro...

Unifiedbrands.Net 5 the labor warranty for a period of ninety days following installation with proof of starting date, up to a maximum of six months from date of purchase. Temperature adjustments are not covered under warranty, due to the wide range of ambient conditions. To inquire if the equipment...

6 6 6 6 800-621-8560 weekly basis with a mild dish soap and warm water. With proper care randell gaskets can last up to two years, at which time we recommend replacement of all gaskets on the equipment for the best possible performance. Notice: food loss is not covered under warranty 3. Repairs caus...

Unifiedbrands.Net 7 randell will endeavor whenever practical to meet dealer’s request. Freight charges to be collect unless otherwise noted. Damages all crating conforms to general motor carrier specifications. To avoid concealed damage, we recommend inspection of every carton upon receipt. In the e...

8 8 8 8 800-621-8560 unit specifications * 33” with work surface removed. ** overall dimension to top of hood. Optional ticket rail adds approximately 17” to height. Model l d h work hgt. Doors h.P. Voltage amps ref/ qty nema ship wt. Ph120e2 120" 40"* 57"** 35" (4)24” ¾ 115/60/1 16 r404a/40oz 5-20p...

Unifiedbrands.Net 9 unit installation selecting a location for your new unit the following conditions should be considered when selecting a location for your unit: 1. Floor load: the area on which the unit will rest must be level, free of vibration, and suitably strong enough to support the combined...

10 10 10 10 800-621-8560 unit installation (cont.) electrical supply: the wiring should be done by a qualified electrician in accordance with local electrical codes. A properly wired and grounded outlet will assure proper operation. Please consult the data tag attached to the compressor to ascertain...

Unifiedbrands.Net 11 unit operation morning startup 1. Rail cleaning may be performed at this time. 2. Turn on the rail with the switch located on the front mechanical panel of the unit. 3. Allow 45 minutes to one hour for your unit to cool down before loading product. 4. Load the product and procee...

12 12 12 12 800-621-8560 unit operation (cont.) to raise temperature in the refrigerated rail: a. Push and hold the “set” button until 34 appears then release the “set” button. 34 is the current set point temperature. B. Push and release the up arrow 2 times until 36 is displayed. Push and release t...

Unifiedbrands.Net 13 preventive maintenance randell strongly suggests a preventive maintenance program which would include the following monthly procedures: 1. Cleaning of all condenser coils. Condenser coils are a critical component in the life of the compressor and must remain clean to assure prop...

14 14 14 14 800-621-8560 preventive maintenance (cont.) recommended cleaners for your stainless steel include the following: job cleaning agent comments routine cleaning soap, ammonia, detergent medallion apply with a sponge or cloth fingerprints and smears arcal 20, lac-o-nu, ecoshine provides a ba...

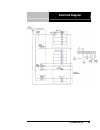

Unifiedbrands.Net 15 electrical diagram.

16 16 16 16 800-621-8560 trouble shooting guide symptom possible cause procedure unit doesn't run 1. No power to unit 1. Plug in unit 2. Temperature control turned off 2. Check temperature control 3. Temperature control faulty 3. Test temperature control 4. Compressor overheated 4. Clean condenser c...

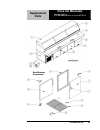

Unifiedbrands.Net 17 replacement parts pizza hut maketable ph120e2 prior to serial w27155-6.

18 18 18 18 800-621-8560 replacement parts pizza hut maketable ph120e2 prior to serial w27155-6.

Unifiedbrands.Net 19 replacement parts pizza hut maketable ph120e2 prior to serial w27155-6.

20 20 20 20 800-621-8560 replacement parts pizza hut maketable ph120e2.1 after serial w27155-6 unit exterior.

Unifiedbrands.Net 21 replacement parts pizza hut maketable ph120e2.1 after serial w27155-6 refrigerated rail top section.

22 22 22 22 800-621-8560 replacement parts pizza hut maketable ph120e2.1 after serial w27155-6 refrigerated rail condensing unit.

Unifiedbrands.Net 23 replacement parts pizza hut maketable ph120e2.1 after serial w27155-6 coil assembly.

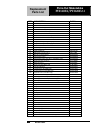

24 24 24 24 800-621-8560 replacement parts list pizza hut maketables ph120e2/ph120e2.1 item description part # 1 hood only ph hod0101 2 lid for rail hood, 38” x 13 ½” ph hod038 3 removable nosing and work surface ph nos001 4 door with handle, right hinged 23 ¾” x 24 ½” rp dor24phr 5 door with handle...

Unifiedbrands.Net 25 39 refrigeration valve for base coil assembly rf vlv404 40 evaporator coil assembly rp csy108sl 40a evaporator coil rf coi107 41 solenoid valve for base / rail rf sol9801 42 shield panel for base coil assembly rp pnl107 42a evap coil housing - rear panel rp pnl108 42b evap coil ...