Service manual cp-06-01 cp-06-01 cp-06-01 cp-06-01 cp-06-01 january - 2007 microp microp microp microp micropak ak ak ak ak tm tm tm tm tm controller controller controller controller controller model: a1 model: a1 model: a1 model: a1 model: a11789 1789 1789 1789 1789 impor impor impor impor import t...

Cp-06-01.

Cp-06-01 micropak controller - contents contents contents contents contents contents safety: safety: safety: safety: safety: safety precautions............................................................................................................ Hazards/safeguards.................................

Cp-06-01 safety precautions safety precautions safety precautions safety precautions safety precautions before operating, maintaining or servicing any itw ransburg electrostatic coating system, read and understand all of the technical and safety literature for your itw ransburg products. This manual...

Cp-06-01 micropak controller - safety 2 2 2 2 2 a r e a a r e a a r e a a r e a a r e a tells where hazards may occur. H a z a r d h a z a r d h a z a r d h a z a r d h a z a r d tells what the hazard is. S a f e g u a r d s s a f e g u a r d s s a f e g u a r d s s a f e g u a r d s s a f e g u a r...

Cp-06-01 3 3 3 3 3 micropak controller - safety halogenated hydrocarbon solvents for example: methylene chloride and 1,1,1,-trichloroethane are not chemically compatible with the aluminum that might be used in many system components. The chemical reaction caused by these solvents reacting with alumi...

Cp-06-01 4 4 4 4 4 micropak controller - safety spray area / spray area / spray area / spray area / spray area / high voltage high voltage high voltage high voltage high voltage equipment equipment equipment equipment equipment this is a high voltage device that can produce electrical arcs capable o...

Cp-06-01 5 5 5 5 5 micropak controller - introduction introduction introduction introduction introduction introduction general description general description general description general description general description the micropak micropak micropak micropak micropak tm tm tm tm tm controller contro...

Cp-06-01 6 6 6 6 6 micropak controller - introduction specifica specifica specifica specifica specifications tions tions tions tions (a (a (a (a (at sea-level conditions) t sea-level conditions) t sea-level conditions) t sea-level conditions) t sea-level conditions) electrical electrical electrical ...

Cp-06-01 7 7 7 7 7 micropak controller - installation inst inst inst inst installa alla alla alla allation tion tion tion tion > in general, conduit must be used for approved ac installation, however, if na- tional and local codes permit, the ac power may be supplied via the factory supplied line co...

Cp-06-01 8 8 8 8 8 micropak controller - installation safety ground safety ground safety ground safety ground safety ground install the ground wire assembly supplied with the micropak controller from the ground stud on the rear of the controller to a true earth ground. For maximum noise immunity, cu...

Cp-06-01 9 9 9 9 9 micropak controller - installation 4. Strip the jacket off the cable(s) 3” from the end and remove the braid 1.5” from the end (see figure 5). 5. Strip the individual cable wires, install appropriate wire ferrules, and connect to the terminal blocks according to table 1. > if mult...

Cp-06-01 1 0 1 0 1 0 1 0 1 0 micropak controller - installation figure 3: rear view of controller figure 3: rear view of controller figure 3: rear view of controller figure 3: rear view of controller figure 3: rear view of controller figure 4: connector p3 wiring figure 4: connector p3 wiring figure...

Cp-06-01 1 1 1 1 11 1 1 1 1 micropak controller - installation figure 5: stripping of i/o cable(s) figure 5: stripping of i/o cable(s) figure 5: stripping of i/o cable(s) figure 5: stripping of i/o cable(s) figure 5: stripping of i/o cable(s) description of table description of table description of ...

Cp-06-01 1 2 1 2 1 2 1 2 1 2 micropak controller - installation w a r n i n g w a r n i n g w a r n i n g w a r n i n g w a r n i n g > never set dipswitch sw3-3 to the off position with the remote ready input active (connected to ground) or high voltage will be on all the time (whenever ac power is...

Cp-06-01 1 3 1 3 1 3 1 3 1 3 micropak controller - installation discreet i/o board dipswitch discreet i/o board dipswitch discreet i/o board dipswitch discreet i/o board dipswitch discreet i/o board dipswitch sw2-1 sw2-1 sw2-1 sw2-1 sw2-1 this dipswitch is set according to the cascade in use with th...

Cp-06-01 1 4 1 4 1 4 1 4 1 4 micropak controller - installation figure 6a: micropak process board figure 6a: micropak process board figure 6a: micropak process board figure 6a: micropak process board figure 6a: micropak process board figure 6b: discreet i/o board figure 6b: discreet i/o board figure...

Cp-06-01 1 5 1 5 1 5 1 5 1 5 micropak controller - installation a special cable grommet fitting has been provided for i/o connector p3 of the controller (see figure 4). When the nut is tightened, the spring in the grommet compresses and makes 360 ° contact with the braid of the cable. This electrica...

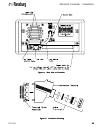

Cp-06-01 1 6 1 6 1 6 1 6 1 6 micropak controller - operation opera opera opera opera operation tion tion tion tion opera opera opera opera operating controls ting controls ting controls ting controls ting controls (see figures 2 & 8) (see figures 2 & 8) (see figures 2 & 8) (see figures 2 & 8) (see f...

Cp-06-01 1 7 1 7 1 7 1 7 1 7 micropak controller - operation opera opera opera opera operating ting ting ting ting procedures procedures procedures procedures procedures (see figures 2 & 8 for operating (see figures 2 & 8 for operating (see figures 2 & 8 for operating (see figures 2 & 8 for operatin...

Cp-06-01 1 8 1 8 1 8 1 8 1 8 micropak controller - operation t t t t typical remote mode ypical remote mode ypical remote mode ypical remote mode ypical remote mode 1. Ensure the ac power, safety ground, low voltage cable, i/o, and interlock connections are made as described in the “installation” se...

Cp-06-01 1 9 1 9 1 9 1 9 1 9 micropak controller - maintenance maintenance maintenance maintenance maintenance maintenance troubleshooting troubleshooting troubleshooting troubleshooting troubleshooting following are some areas to investigate when high voltage faults occur: • dirty atomizer interior...

Cp-06-01 2 0 2 0 2 0 2 0 2 0 micropak controller - maintenance troubleshooting guide (continued on next page) (continued on next page) (continued on next page) (continued on next page) (continued on next page) w a r n i n g w a r n i n g w a r n i n g w a r n i n g w a r n i n g > the “troubleshooti...

Cp-06-01 2 1 2 1 2 1 2 1 2 1 micropak controller - maintenance t t t t troubleshooting guide (cont.) roubleshooting guide (cont.) roubleshooting guide (cont.) roubleshooting guide (cont.) roubleshooting guide (cont.) general problem general problem general problem general problem general problem pos...

Cp-06-01 2 2 2 2 2 2 2 2 2 2 micropak controller - maintenance signal ifb vct vct drb dra siggnd kvfb plfb vctret from wire 2 (white) 3 (red) 4 (black) 5 (green) 6 (blue) 9 (grn/yel) 10 (gray) 11 (orange) 16 (bare) to wire 2 (white) xx open ckt. Open ckt. Open ckt. Open ckt. 19k - 21k 400k-600k 0 - ...

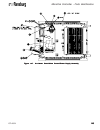

Cp-06-01 p p p p par ar ar ar arts identifica ts identifica ts identifica ts identifica ts identification tion tion tion tion 2 3 2 3 2 3 2 3 2 3 micropak controller - parts identification figure 10: micropak controller parts diagram figure 10: micropak controller parts diagram figure 10: micropak c...

Cp-06-01 2 4 2 4 2 4 2 4 2 4 micropak controller - parts identification 1 ---- micropak control unit 2 76037-03 discrete i/o module (0-10vdc) 3 78835-00 24vdc power supply 4 72771-19 fuse, 5a, 250v, 5 x 20mm, type t (time delay) 5 76449-00 ac line cord, detachable 6 70539-00 ground wire assembly 7 a...

Cp-06-01 2 5 2 5 2 5 2 5 2 5 micropak controller - parts identification figure 11a: a11789-01 stand-alone control/power supply assembly figure 11a: a11789-01 stand-alone control/power supply assembly figure 11a: a11789-01 stand-alone control/power supply assembly figure 11a: a11789-01 stand-alone co...

Cp-06-01 2 6 2 6 2 6 2 6 2 6 micropak controller - parts identification figure 11c: a11789-01 stand-alone control/power supply assembly figure 11c: a11789-01 stand-alone control/power supply assembly figure 11c: a11789-01 stand-alone control/power supply assembly figure 11c: a11789-01 stand-alone co...

Cp-06-01 2 7 2 7 2 7 2 7 2 7 micropak controller - parts identification 1 a10464-00 vario case, 1/2, 19”, 400 (15.75), d 3u 1 2 76044-18 10.6 micropak, dual, dio lo profile 1 3 table a - “a” table a - “a” table a - “a” table a - “a” table a - “a” micropak controller 505i “e” “e” “e” “e” “e” 4 table ...

Cp-06-01 2 8 2 8 2 8 2 8 2 8 micropak controller - parts identification note: included but not shown: a10593-00 wiring diagram (1) 76449-00 ac power cord (1) tr-ssem-200 cable ties (10) 76453-00 conduit adapter kit (1) screws are supplied with case. Attach (1) 70539-00 gnd clamp assembly. Remove alu...

Cp-06-01 2 9 2 9 2 9 2 9 2 9 micropak controller - parts identification figure 11e: a1178-01 stand-alone control/power supply schematic figure 11e: a1178-01 stand-alone control/power supply schematic figure 11e: a1178-01 stand-alone control/power supply schematic figure 11e: a1178-01 stand-alone con...

Cp-06-01 3 0 3 0 3 0 3 0 3 0 micropak controller - parts identification n o t e s n o t e s n o t e s n o t e s n o t e s.

Cp-06-01 3 1 3 1 3 1 3 1 3 1 evolver micropak controller - warranty policies w w w w warranty arranty arranty arranty arranty policies policies policies policies policies limited w limited w limited w limited w limited warranty arranty arranty arranty arranty itw ransburg will replace or repair with...

Cp-06-01.

Service manual price: $30.00 (u.S.) service manual price: $30.00 (u.S.) service manual price: $30.00 (u.S.) service manual price: $30.00 (u.S.) service manual price: $30.00 (u.S.) form no. Cp-06-01 litho in u.S.A. 01/07 © 2007 illinois tool works inc. All rights reserved. Models and specifications s...