- DL manuals

- Ransburg

- Paint Sprayer

- RansFlex 80520 RFXw

- Service Manual

Ransburg RansFlex 80520 RFXw Service Manual

SERVICE MANUAL

AH-16-02.1

AUGUST - 2017

APPLICATORS

By Ransburg

®

MODEL: 80520 RFXw

Service Manual Price: $50.00 (U.S.)

IMPORTANT: Before using this equipment, carefully read SAFETY

PRECAUTIONS, starting on page 1, and all instructions in this manual.

Keep this Service Manual for future reference.

FOR DIRECT CHARGE

WATER BASED APPLICATORS

Summary of RansFlex 80520 RFXw

Page 1

Service manual ah-16-02.1 august - 2017 applicators by ransburg ® model: 80520 rfxw service manual price: $50.00 (u.S.) important: before using this equipment, carefully read safety precautions, starting on page 1, and all instructions in this manual. Keep this service manual for future reference. F...

Page 2

Note: this manual has been changed from revision ah-16-02 to revision ah-16-02.1. Reasons for this change are noted under “manual change summary” on page 59 of this manual. Ah-16-02.1 ransflex applicators - manual changes.

Page 3: Contents

Page safety: 1-5 safety precautions .......................................................................................................................................1 hazards / safeguards .............................................................................................................

Page 4: Safety Precautions

W a r n i n g safety precautions before operating, maintaining or servicing any ransburg electrostatic coating system, read and understand all of the technical and safety literature for your ransburg products. This manual contains information that is important for you to know and understand. This in...

Page 5

Fire hazard improper or inadequate operation and maintenance procedures will cause a fire hazard. Protection against inadvertent arcing that is capable of causing fire or explosion is lost if any safety interlocks are disabled during operation. Frequent power supply or controller shutdown indicates ...

Page 6

Area tells where hazards may occur. Hazard tells what the hazard is. Safeguards tells how to avoid the hazard. Spray area improper operation or maintenance may create a hazard. Personnel must be properly trained in the use of this equipment. Explosion hazard improper or inadequate operation and main...

Page 7

Area tells where hazards may occur. Hazard tells what the hazard is. Safeguards tells how to avoid the hazard. Spray area / high voltage equipment electrical discharge there is a high voltage device that can induce an electrical charge on ungrounded objects which is capable of igniting coating mater...

Page 8

Area tells where hazards may occur. Hazard tells what the hazard is. Safeguards tells how to avoid the hazard. Toxic substances certain material may be harmful if inhaled, or if there is contact with the skin. Follow the requirements of the material safety data sheet supplied by coating material man...

Page 9

The following instructions apply to equipment covered by certificate number sira 14atex 5343: 1. The equipment may be used with flammable gases and vapors with apparatus groups ii and with temperature class t6. 2. The equipment is only certified for use in am- bient temperatures in the range +0°c to...

Page 10: Atex Requirements

Label 80528-00 requirements these applicators are fm approved when the product setup is configured to drawings shown on page 8. This product is approved for use only with non-flammable water based materials when the materials meet the fm definition for a water based spray material*. It is the end us...

Page 11: 80520 -

Ah-16-02.1 8 ransflex applicators - atex/fm ransflex rfxw - water base only 80520 - base model no. Optional designations abc0ef (ordering information only) configuration dwg. 80521-00 rev. A f e a c b return to contents.

Page 12

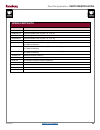

Ah-16-02.1 9 ransflex applicators - atex/fm 0 v series 1.2mm 80265-00 80264-12 79809-00 1 v series 1.4mm 80265-00 80264-14 79809-00 2 v series 1.8mm 80265-00 80264-18 79809-00 3 c series 1.2mm 80231-00 80230-12 79809-03 4 c series 1.4mm 80231-00 80230-14 79809-03 5 c series 1.8mm 80231-00 80230-18 7...

Page 13: “Z”

Ah-16-02.1 10 ransflex applicators - atex/fm 0 no air hose, standard --- 80236-00 1 standard air hose, 10m 79727-10 80236-00 2 standard air hose, 15m 79727-15 80236-00 3 standard air hose, 20m 79727-20 80236-00 4 standard air hose, 30m 79727-30 80236-00 5 no air hose, qd --- 80302-00 6 qd air hose, ...

Page 14

80264-07 v series 0.7mm 80265-00 black 80264-10 v series 1.0mm 80265-00 black 80239-07 t series 0.7mm 80240-00 black 80239-10 t series 1.0mm 80240-00 black part no. Description available accessories nozzle color 80558-05 lh thread 5m 80558-06 q.D. 5m 80558-10 rh thread 10m 80558-11 q.D. 10m part no....

Page 15: Ransflex New Features

Ransflex new features • light weight and easy to maneuver. • ergonomic handle design to reduce operator fatigue. • three phases of turbine protection: - divorced turbine air supply cartridge - sealed nozzle/atomization passages - strategic turbine location • devilbiss spray technology integration in...

Page 16: 80520 Ransflex Direct

Ah-16-02.1 13 ransflex applicators - introduction fluid flow capacity: 1000 ml/minute** wetted parts: stainless, polyethylene, nylon, acetal polymer operating pressure (air spray) fluid: (0-6.9 bar) 0-100 psi air: (0-6.9 bar) 0-100 psi ambient temp.: 40°c to 5°c (104°f to 32°f) consumption (with vol...

Page 17

Ah-16-02.1 14 ransflex applicators - introduction figure 1: ransflex water base direct charge electrostatic spray applicator 80520 1 needle/electrode 2 barrel 3 handle 4 fan adjustment 5 fluid adjustment 6 air hose no. Description ransflex water base direct charge electrostatic spray applicator 8052...

Page 18

Ah-16-02.1 15 ransflex applicators - introduction figure 2: ransflex typical waterborne installation no. Description ransflex waterborne typical installation no. Description 7 fluid regulator 8 air hose (79727-xx) 9 air hose ground wire 10 isolated waterborne hose 11 voltage isolation / protection 1...

Page 19: Installation

Return to contents ah-16-02.1 16 installation ransflex applicators - installation w a r n i n g ! The user must read and be familiar with the "safety" section of this manual. This hand held device is intended to be used by trained personnel only. This manual must be read and thoroughly understood by...

Page 20: Waterborne Isolation

Return to contents using waterborne coating with electrostatic equipment requires that the fluid source be isolated from ground. Precautions should be taken to ensure operation safety and system efficiency. The following guidelines should be followed: • the fluid lines and source must be isolated fr...

Page 21: Or...

Or... Return to contents 3. Connect air. 4. Trigger applicator with fluid off. Look for leaks in any connections. 5. Activate fluid, check for leaks with solvent flush if required. Ah-16-02.1 18 ransflex applicators - installation.

Page 22: Operation

Ah-16-02.1 19 operation ransflex applicators - operation applicator operation 1. Set fluid pressure using flow regulator, insure voltage is discharged from system. 2. Disconnect the air to the applicator. 3. Activate trigger to start material stream into grounded metal bucket or suitable area. 4. Re...

Page 23

Ah-16-02.1 20 ransflex applicators - operation 10. Turn on voltage and trigger applicator. Green light should be on. (horns horizontal) 11. Adjust fluid pressure and air pressure as required to achieve finish. 12. Adjust air cap position as required. 6. Adjust air pressure. 7. Position air cap to ac...

Page 24: Flushing / Color

Ah-16-02.1 21 ransflex applicators - operation return to contents note the compensation valve adjustment is used to adjust fan and atomization pressure at the same time when the pressure to run the turbine is higher than the atomization fan pressure desired. 15. Adjust compensation valve with small ...

Page 25: Fluid Nozzle / Air Cap

Ah-16-02.1 22 ransflex applicators - operation 79727-xx length t-40 air cap 80240-00 static pressure at wall bar dynamic pressure at wall psig bar psig 30 m 4.5 65 4.3 62 20 m 4.3 62 3.9 57 15 m 4.1 60 3.8 55 10 m 4.0 58 3.7 53 79727-xx length c-31 air cap 80231-00 static pressure at wall bar dynami...

Page 26

Ah-16-02.1 23 ransflex applicators - operation 79727-xx length v-65 air cap 80265-00 static pressure at wall bar dynamic pressure at wall psig bar psig 30 m 4.5 65 4.1 60 20 m 4.1 60 3.9 56 15 m 4.0 59 3.7 54 10 m 3.8 55 3.6 52 80264-07 80265-00 black 0.7 mm 80264-10 80265-00 black 1.0 mm 80264-12 8...

Page 27

80230-12 80231-00 red 1.2 mm 80230-14 80231-00 grey 1.4 mm 80230-18 80231-00 green 1.8 mm 80231-00 / 80230-xx c series nozzle part number for use with air cap p/n color nozzle opening 80239-07 80240-00 black 0.7 mm 80239-10 80240-00 black 1.0 mm 80239-12 80240-00 red 1.2 mm 80239-14 80240-00 grey 1....

Page 28

80264-12 1.2/.047 250 air spray 355/14.0 76/3.0 79809-00 (yellow) 80264-14 1.4/.055 250 air spray 343/13.5 76/3.0 79809-00 (yellow) 80264-18 1.8/.070 250 air spray 267/10.5 76/3.0 79809-00 (yellow) v-65 - 80265-00 nozzle orfice id (mm/in) *fluid delivery (ml/min) spray type pattern length (mm/in) pa...

Page 29: Maintenance

Ah-16-02.1 26 maintenance ransflex applicators - maintenance return to contents w a r n i n g ! The user must read and be familiar with the safety instructions in this manual. If compressed air is used in cleaning, remember that high pressure air can be dangerous and should never be used against the...

Page 30: Routine Schedule

Ah-16-02.1 27 ransflex applicators - maintenance return to contents never remove the fluid nozzle assembly while paint is in the applicator or paint may enter into the air passages. Clogged or restricted air passages will cause poor atomization and/or electrical shorting. Air passages that are clogg...

Page 31

Ah-16-02.1 28 ransflex applicators - maintenance return to contents • straighten the applicator electrode if necessary. • clean the fluid filter, if used. Daily (or at start of each shift) • verify that all solvent safety containers are grounded! • check within 6m (20-ft.) of the point of operation ...

Page 32

Ah-16-02.1 29 ransflex applicators - maintenance return to contents fluid nozzle removal 1. Insert 80353-00 wrench onto nozzle flats. 2. Insert o-ring, replace as required. 3. Install fluid nozzle using 80353-00 wrench. Tighten till nozzle seats on o-ring and then 1/8 additional turn. W a r n i n g ...

Page 33

Ah-16-02.1 30 ransflex applicators - maintenance return to contents 2. Remove fluid tube. 3. Remove barrel screws. 4. Pull barrel away. Remove/replace cascade 1. Pull cascade straight out. 2. Carefully disconnect harness by pulling connec- tor on both sides by hand and rocking it side to side to rem...

Page 34

Ah-16-02.1 31 ransflex applicators - maintenance return to contents packing removal/replace 1. Remove barrel from handle. 2. Use 80353-00 wrench to remove nut. 3. Pull straight out of barrel. 4. Remove jam nuts using 10mm wrench. 5. Remove all parts, clean with non-polar solvent. Inspect for any dis...

Page 35

Ah-16-02.1 32 ransflex applicators - maintenance return to contents 10. Install bellville washers in sequence shown. 11. Install rear nut. Install jam nuts finger tight. 12. Set air before fluid adjustment. 13. Tighten jam nuts. Re-install needle shaft into barrel 1. Install needle shaft into barrel...

Page 36

Ah-16-02.1 33 ransflex applicators - maintenance return to contents re-install barrel 1. Install barrel over cascade. 2. Tighten barrel screws. 3. Re-install fluid tube. 4. Re-install trigger. Rear cover/motor module repair 1. Loosen cover screw with 3mm driver. 2. Remove fan air cartridge with 10mm...

Page 37

Ah-16-02.1 34 ransflex applicators - maintenance return to contents motor removal 1. Remove light pipe. 2. Remove screw and retainer. 3. Remove motor assembly by pulling out on 3 arms, pull motor out. 4. Remove porting block. 5. Remove fluid valve cartridge o-ring. Note block must be pulled out with...

Page 38

Ah-16-02.1 35 ransflex applicators - maintenance return to contents re-assembly 1. Install porting block on motor. Align screw heads into porting recess. 2. Align motor slots with 3 tab arms. Note there is only one way to install the motor. 3. Install cartridge then o-ring (if removed). 4. Install s...

Page 39

Ah-16-02.1 36 ransflex applicators - maintenance return to contents 7. Push rear cover assembly into handle and tighten cartridge. 8. Install fan air valve cartridge. Air valve remove/replace 1. Remove trigger. 2. Remove rear cover assembly. 3. Remove air valve and spring. 4. Remove air valve packin...

Page 40

Ah-16-02.1 37 ransflex applicators - maintenance return to contents 5. Insert air valve and spring. 6. Tighten packing nut till light drag is felt on the shaft while moving it back and forth. Fluid bracket removal 1. Remove nut and ferrules. 2. Remove air fitting. 7. Install rear cover assembly. 8. ...

Page 41

Ah-16-02.1 38 ransflex applicators - maintenance 3 1 2 1 3 610mm min. (24” min.) 12.7mm (1/2”) 57.1mm (2.25”) 101.6mm (4.00”) return to contents 5. Re-install hose components. 6. Install gasket, o-ring and bracket. Hose cut dimensions if the water base hose is serviced for any reason, the cut dimens...

Page 42

Ah-16-02.1 39 ransflex applicators - maintenance gun wrench functions 80353-00 1. Adjust packings. 2. Remove nozzles for c & t series for v series 3. Air fitting. 4. Remove rear cartridge. Return to contents.

Page 43: Troubleshooting Guide

Ah-16-02.1 40 ransflex applicators - maintenance return to contents no pressure fluid tube may be plugged fluid nozzle may be plugged electrode not properly assembled material too viscous no adjustment of fan pattern poor atomization fluid in air passages spits general problem possible cause solutio...

Page 44: Parts Identification

Ah-16-02.1 41 parts identification ransflex applicators - parts identification return to contents ransflex rfxw - direct charge water base 80520 - base model no. Optional designations abc0ef * note: all nozzles available in kits of 3. 0 v series 1.2mm 80265-00 80264-12 79809-00 / yellow 1 v series 1...

Page 45

Ah-16-02.1 42 ransflex applicators - parts identification return to contents “f” dash no. “f” description air hose - table of “f” dashes “7” “8” “e” dash no. “e” description fluid hose - table of “e” dashes “6” 0 no air hose, standard 80236-00 --- 1 standard air hose, 10m 80236-00 79727-10 2 standar...

Page 46

Ah-16-02.1 43 ransflex applicators - parts identification return to contents item no. Description retaining ring 80377-00 qty. Part no. 1 80377-00 nut, retaining & o-ring assembly (contains all parts) 1 2 lsor0005-17 o-ring, encapsulated 1 retaining ring 80377-00 2 1.

Page 47: Items For Rfxw (65Kv) Unit

Ah-16-02.1 44 ransflex applicators - parts identification return to contents item no. Description rfxw 65kv barrel qty. Part no. 1 80489-00 assembly, barrel & o-ring 1 2 80263-65 assembly, needle shaft 1 3 80242-00 nut, rear jam 1 4 80243-00 nut, front jam 1 5 80258-00 spring, fluid return 1 6 80250...

Page 48

Ah-16-02.1 45 ransflex applicators - parts identification item no. Description rfxw 65kv needle shaft qty. Part no. 1 70430-01 assembly, electrode, high wear 1 2 74653-00 adapter, male 1 3 14323-00 seal, chevron, 3/8 dia. 4 14323-00-k4 seal, chevron (kit of 4) 1 4 18821-00 adapter-female-chevron 1 5...

Page 49

Ah-16-02.1 46 ransflex applicators - parts identification handle components for all models return to contents 6 5 3 8 4 10 12 13 2 7 1 9 11 14.

Page 50

Ah-16-02.1 47 ransflex applicators - parts identification item no. Description handle components qty. Part no. 1 80375-00 includes handle (80305-00) and rear cover with motor (80378-00) assembly (adjustable fluid control) 1 80375-01 includes handle (80305-01) and rear cover with motor (80378-00) ass...

Page 51

Ah-16-02.1 48 ransflex applicators - parts identification return to contents handle with rear cover with motor 80375-00/01 1 80305-00 assembly, handle 1 2 80244-00 assembly, valve, air 1 3 80533-00 spring, air valve 1 4 80262-00 assembly, valve, adjustable fluid control 1 80262-01 assembly, valve, n...

Page 52

Ah-16-02.1 49 ransflex applicators - parts identification handle assembly 80305-00 item no. Description handle assembly 80305-00 qty. Part no. 1 80305-00 assembly, handle includes all parts below, motor control board and harnesses 1 2 80274-00 screw, barrel-handle 2 3 80229-00 nut, retaining, air va...

Page 53

Ah-16-02.1 50 ransflex applicators - parts identification 80273-00 fan air cartridge item no. Description 80273-00 fan air cartridge qty. Part no. 1 80273-00 ass’y., fan valve (includes all parts below) 1 2 79001-16 o-ring, solvent proof 1 1 80262-01 assembly, fluid cartridge (non-adjustable) 1 2 79...

Page 54

Ah-16-02.1 51 ransflex applicators - parts identification return to contents 80378-00 rear cover with motor assembly item no. Description 80378-00 rear cover with motor assembly qty. Part no. 1 1 80378-00 cover, rear assembly (includes all parts below) 1 2 80213-00 pipe, light 1 3 80255-00 assembly,...

Page 55

Ah-16-02.1 52 ransflex applicators - parts identification return to contents 80255-00 motor assembly item no. Description 80255-00 motor assembly qty. Part no. 1 80255-00 assembly, motor (includes all parts below) 1 2 80217-00 cover support, motor 1 3 79796-00 screw, motor 3.

Page 56

Ah-16-02.1 53 ransflex applicators - parts identification return to contents 80254-00 rear cover assembly item no. Description 80254-00 rear cover assembly qty. Part no. 1 80254-00 cover, rear (contains parts below) 1 2 80274-00 m4 x .7 shcs 1.

Page 57

Ah-16-02.1 54 ransflex applicators - parts identification 7 4 3 2 1 6 5 return to contents item no. Description water base hose assemblies 80500-xx, 80501-xx qty. Part no. 1 80498-10 3/16” id hose 1 80498-15 3/16” id hose 1 80499-10 1/4” id hose 1 80499-15 1/4” id hose 1 2 10553-05 nut, special 1 3 ...

Page 58

Ah-16-02.1 55 ransflex applicators - parts identification return to contents accessories included with rx or rfx lsch0009 grease 79862-02 3mm hex driver 80353-00 gun wrench 80395-00 27141-081 wrap, spiral 59972-00 pack of 4 lsch0009 grease 76102-00 applicator mounting bracket 76652-01 hv probe 76652...

Page 59

Ah-16-02.1 56 ransflex applicators - parts identification return to contents spare parts kits description part # 79001-07-k3 fluid inlet o-ring of barrels 80264-xx-k3 v series nozzles in kits of 3 (xx = 12, 14 or 18) 80464-xx-k3 v series high wear nozzles in kits of 3 (xx = 14, 18) 80230-xx-k3 c ser...

Page 60

Ah-16-02.1 57 ransflex applicators - parts identification part # description ransflex recommended spare parts (quantities per applicator) qty 80264-xx nozzle, fluid v series (see page 42) 1 80264-xx-k3 nozzle, fluid v series (see page 42) (kit of 3) 1 80230-xx nozzle, fluid c series (see page 42) 1 ...

Page 61: Warranty Policies

Return to contents ah-16-02.1 58 warranty policies ransflex applicators - warranty policy limited warranty ransburg will replace or repair without charge any part and/or equipment that falls within the specified time (see below) because of faulty workmanship or material, provided that the equipment ...

Page 62: Manual Change Summary

Return to contents ah-16-02.1 replaces service manual ah-16-02 with the following changes: 1. Update revision number ............................................................................................................ All pages 2. Add text to “atex requirements” ................................

Page 63: Ransburg

Form no. Ah-16-02.1 litho in u.S.A. 08/17 technical support representative will direct you to the appropriate telephone number for ordering spare parts. Manufacturing 1910 north wayne street angola, indiana 46703-9100 telephone: 260-665-8800 fax: 260-665-8516 technical service — assistance 320 phill...