- DL manuals

- Ransburg

- Power Tool

- vector solo 79965 solventborne RS70-AS

- Service Manual

Ransburg vector solo 79965 solventborne RS70-AS Service Manual

SERVICE MANUAL

AH-08-02.6

January - 2013

VECTOR SOLO

65 KV APPLICATOR

TM

Ransburg

MODEL: 79965 Solventborne RS70-AS

IMPORTANT: Before using this equipment,

carefully read SAFETY PRECAUTIONS, starting

on page 1, and all instructions in this manual.

Keep this Service Manual for future reference.

Service Manual Price: $50.00 (U.S.)

Summary of vector solo 79965 solventborne RS70-AS

Page 1

Service manual ah-08-02.6 january - 2013 vector solo 65 kv applicator tm ransburg model: 79965 solventborne rs70-as important: before using this equipment, carefully read safety precautions, starting on page 1, and all instructions in this manual. Keep this service manual for future reference. Servi...

Page 2: Ransburg

Note: this manual has been changed from revision ah-08-02.5 to revision ah-08-02.6. Reasons for this change are noted under “manual change summary” inside the back cover of this manual. Ah-08-02.6 ransburg.

Page 3: Contents

Suitable solvents for cleaning vector solo applicators ............................ 20 routine schedule ............................................................................................................. 21-22 applicator repair .................................................................

Page 4: Contents (Cont.)

Page parts identification: 41-52 vector solo 65kv applicator parts breakdown ................................................. 41 vector solo 65kv solventborne applicator parts list ................................... 42-43 vector solo rs70-as model identification 4 ....................................

Page 5: Safety Precautions

Vector solo 65kv applicator - safety safety precautions before operating, maintaining or servicing any ransburg electrostatic coating system, read and understand all of the technical and safety litera- ture for your ransburg products. This manual contains information that is important for you to kno...

Page 6: Ransburg

Vector solo 65kv applicator - safety spray area area tells where hazards may occur. Hazard tells what the hazard is. Safeguards tells how to avoid the hazard. Fire hazard improper or inadequate oper- ation and maintenance proce- dures will cause a fire hazard. Protection against inadvertent arcing t...

Page 7: Ransburg

Vector solo 65kv applicator - safety 3 electrical equipment high voltage equipment is uti- lized. Arcing in areas of flamma- ble or combustible materials may occur. Personnel are exposed to high voltage during operation and maintenance. Protection against inadvertent arcing that may cause a fire or ...

Page 8: Ransburg

Vector solo 65kv applicator - safety 4 area tells where hazards may occur. Hazard tells what the hazard is. Safeguards tells how to avoid the hazard. Spray area general use and maintenance electrostatic arcing improper operation or mainte- nance may create a hazard. Personnel must be properly traine...

Page 9: Ransburg

Vector solo 65kv applicator - atex/fm 5 european atex directive 94/9/ec, annex ii, 1.0.6 the following instructions apply to equipment covered by certificate number sira 08atex5060x: 1. The equipment may be used with flammable gases and vapors with apparatus groups ii and with temperature class t6. ...

Page 10: Ransburg

Vector solo 65kv applicator - atex/fm 6 vector solo 79965 atex product marking definitions ex certificate number: sira 08atex5060x sira = notified body performing ec-type examination 08 = year of certification atex = reference to atex directive 5 = protection concept code (code 5 is titled encapsula...

Page 11: Ransburg

Vector solo 65kv applicator - atex/fm 7 ah-08-02.6 ransburg.

Page 12: Ransburg

Vector solo 65kv applicator - atex/fm 8 vector solo rs70-as solvent based 79965 - abcde base model no. Option designations (ordering information only) configuration dwg. 79944 rev c approved spare fluid nozzles list 80101-46 (1.06mm id, std. Wear), 79377-47 (.71mm id, std. Wear), 80101-48 (1.19mm id...

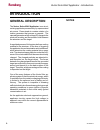

Page 13: General Description

Vector solo 65kv applicator - introduction general description the vector solo tm 65kv applicator is an air at- omizing applicator powered only by a pressurized air source. Pressurized air creates rotation of a turbine generator that powers a cascade. The cascade generates a high voltage dc charge t...

Page 14: Specifications

Vector solo 65kv applicator - introduction 10 fluid flow capacity: 1000 ml/minute** wetted parts: stainless, polyethylene, nylon, acetal polymer operating pressure (air spray) fluid: (0-6.9 bar) 0-100 psi air: (0-6.9 bar) 0-100 psi ambient temp.: 40°c to 0°c (104°f to 32°f) consumption: 470 slpm (16...

Page 15: Ransburg

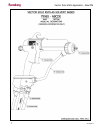

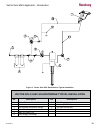

Vector solo 65kv applicator - introduction 11 figure 1: vector solo 65kv solventborne electrostatic spray applicator 1 2 3 4 5 6 7 no. Description needle/electrode barrel replaceable hook fan air adjustment fluid needle travel adjustment fluid hose connection air inlet connection vector solo 65kv so...

Page 16: Ransburg

Vector solo 65kv applicator - introduction 12 figure 2: vector solo 65kv solventborne typical installation 1 2 3 4 5 6 no. Description vector solo ball valve air regulator w/pressure gauge air / water separator main air supply line fluid supply (grounded) vector solo 65kv solventborne typical instal...

Page 17: Installation

Vector solo 65kv applicator - installation installation air hose 13 fluid hose recommendation ransburg recommends using a 79548 fluid hose assembly. This assembly is made to specifically fit the fluid fitting size engineered into the applica- tor. This hose is available from your authorized ransburg...

Page 18: Installation

Vector solo 65kv applicator - installation 14 1. Ensure there is a true earth ground connection available. Both the fluid source and the air hose ground must be connected to true earth ground. W a r n i n g ! Figure 3: voltage off lever position (bottom view) figure 4: air hose connections figure 5:...

Page 19: Ransburg

Vector solo 65kv applicator - installation 15 ah-08-02.6 notes ransburg.

Page 20: Operation

Vector solo 65kv applicator - operation 16 ah-08-02.6 operation 1. Ensure the on/off switch is in the desired position for voltage. Figure 6: voltage on/off position 2. Ensure the voltage high/low switch is in the desired position. Figure 7: high/low voltage selection figure 9: air pressure at regul...

Page 21: Flushing / Color

Vector solo 65kv applicator - operation 17 ah-08-02.6 figure 12: electrostatics lever off position flushing / color change procedure 1. Turn electrostatic lever to off position. Figure 10: fan pattern size adjustment 5. Adjust fan pattern size. Counter-clockwise makes the pattern longer; clockwise m...

Page 22: Ransburg

Vector solo 65kv applicator - operation 18 ah-08-02.6 2. Turn off supply air. 3. Discharge fluid into appropriate grounded me- tallic container. Figure 13: applicator supply air - off figure 14: applicator flush out 4. Load next color or remove applicator from in- stallation as required. Notes 1 - m...

Page 23: Fluid Nozzle / Air Cap

Vector solo 65kv applicator - operation 19 ah-08-02.6 fluid nozzle / air cap the fluid nozzle and air cap must be selected according to the application. The following charts show the nozzles and air caps available for the vector solo. * material: lacquer, 18 sec. No. 4 ford cup @ 72 o f. Results are...

Page 24: Maintenance

20 vector solo 65kv applicator - maintenance ah-08-02.6 maintenance the user must read and be familiar with the safety instructions in this manual. If compressed air is used in cleaning, remember that high pressure air can be dangerous and should never be used against the body . It can blind, deafen...

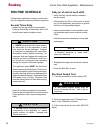

Page 25: Routine Schedule

Vector solo 65kv applicator - maintenance 21 ah-08-02.6 routine schedule follow these maintenance steps to extend the life of the applicator and ensure efficient operation: several times daily • inspect the air cap for paint accumulation. Clean as frequently as necessary with a soft bristled brush a...

Page 26: Applicator Repair

Vector solo 65kv applicator - maintenance 22 ah-08-02.6 do not allow the fluid lines to stand empty without flushing first! This will cause dried paint flaking and clogging of the fluid lines, applicator passages, and/or nozzles. C a u t i o n ! All repairs should be made on a clean, flat sur- face....

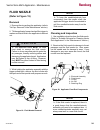

Page 27: Air Cap

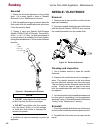

Vector solo 65kv applicator - maintenance 23 ah-08-02.6 1. Remove applicator from the worksite after fol- lowing the "flush procedure". 2. Remove fluid hose at base of applicator. Figure 16: counter-clockwise to remove fluid hose figure 17: clockwise to remove air hose air cap removal 1. While holdi...

Page 28: Fluid Nozzle

24 vector solo 65kv applicator - maintenance ah-08-02.6 fluid nozzle (refer to figure 19) removal 1. Remove the air cap from the applicator (refer to "air cap - removal" in the "maintenance" section). 2. Tilt the applicator forward and pull the trigger to make sure that all fluid in the applicator i...

Page 29: Needle / Electrode

Vector solo 65kv applicator - maintenance 25 ah-08-02.6 reinstall 1. Check the electrode tightness on the needle shaft. If it is loose, tighten it (refer to "needle/ electrode" in the "maintenance" section). 2. With the applicator trigger actuated, place the fluid nozzle over the needle/electrode an...

Page 30: Needle / Electrode

Vector solo 65kv applicator - maintenance 26 ah-08-02.6 needle / electrode resistance testing the electrical resistance of the needle/electrode should be tested periodically (typically on a weekly basis) or any time it is removed from the applicator. To test 1. Install the needle/electrode onto the ...

Page 31: Ransburg

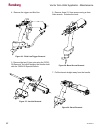

Vector solo 65kv applicator - maintenance 27 ah-08-02.6 4. Remove the trigger and fluid line. Figure 26: fluid line/trigger removal 5. Remove the two (2) jam nuts using the 79793- 00 removal tool while holding the needle shaft with the 79854-00 special wrench. Figure 27: jam nut removal 6. Remove th...

Page 32: Ransburg

Vector solo 65kv applicator - maintenance 28 ah-08-02.6 figure 30: cascade/one way valve removal remove cascade 1. Pull the cascade out of the barrel. 2. Wipe off excess dielectric lubricant. 3. Remove excess lubricant from inside barrel with a clean cloth or rag. 4. Remove one-way valves. Replace c...

Page 33: Ransburg

Vector solo 65kv applicator - maintenance 29 ah-08-02.6 figure 34: second jam nut replacement 3. Tighten second jam nut with raised center facing out, while holding the needle shaft. Figure 37: rear cover replacement 4. Install the fluid adjustment assembly along with the air and fluid return spring...

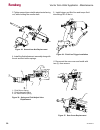

Page 34: Needle Shaft

Vector solo 65kv applicator - maintenance 30 ah-08-02.6 figure 39: needle shaft removal 3. Remove rear nut using the 79854-00 special wrench. Figure 40: needle shaft removal 4. Attach a jam nut to the assembly and pull straight out of the barrel. Figure 41: 79911-00 needle shaft with 2k adjust- able...

Page 35: Ransburg

Vector solo 65kv applicator - maintenance 31 ah-08-02.6 2. Tighten rear nut using special wrench 79854- 00. Tighten until drag is felt on the shaft when it is pushed back and forth. Figure 43: adjustable needle shaft reinstall needle shaft / barrel 1. Push needle shaft assembly straight into the bar...

Page 36: Ransburg

Vector solo 65kv applicator - maintenance 32 ah-08-02.6 4. Remove the rear seal. Figure 48: rear seal removal 5. Using a dowel rod, push out the air valve cartridge. Figure 49: air valve cartridge removal figure 47: air valve removal handle disassembly 1. Remove barrel. 2. Remove power module. 3. Pu...

Page 37: Ransburg

Vector solo 65kv applicator - maintenance 33 ah-08-02.6 6. Remove air valve cartridge seal (black) (see figure 48). 7. Remove front air valve seal (white). Figure 50: air valve cartridge seal and front seal removal figure 52: cartridge seal replacement 2. Install the air valve cartridge seal. Figure...

Page 38

Vector solo 65kv applicator - maintenance 34 ah-08-02.6 figure 57: fluid fitting removal power module - fluid fitting removal 1. Remove power module from handle. 2. Remove two (2) screws using a 2.5mm allen wrench. 4. Install the rear seal. 5. Install air valve. Figure 54: rear cartridge seal replac...

Page 39: Ransburg

Vector solo 65kv applicator - maintenance 35 ah-08-02.6 3. Install the 1/4 module into the 3/4 module and tighten the two (2) screws. Figure 61: module assembly 4. Install power module to handle and tighten three (3) screws. Reinstall the fluid line and torque fluid tube fittings to 40-45 lbs-in. 3....

Page 40: Test And

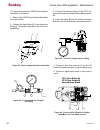

Vector solo 65kv applicator - maintenance 36 ah-08-02.6 test and maintenance kit usage (79870-00) figure 63: 79870 test and maintenance kit 3 6 5 2 4 1 the 79870 test and maintenance kit allows the user to determine the inlet pressure at the base (handle) of the vector solo hand-held applicators. Th...

Page 41: Ransburg

Vector solo 65kv applicator - maintenance 37 ah-08-02.6 figure 65: remove power module from handle 6 1 l h 5 figure 66: connect barb and tubing to tee fitting 3. Connect the left-hand fitting of the 79727 air hose to the male inlet of the test and maintenance kit. 4. Insert the tubing [6] into the s...

Page 42: Air Hose

Vector solo 65kv applicator - maintenance 38 ah-08-02.6 7. Connect the 79727 air hose to main air. 8. Turn on main air and set the pressure so the pressure gauge [2] in the 79870 test and main- tenance kit reads 25 psi (1.7 bar). The voltage kv setpoint lever should be in the high voltage position (...

Page 43: Ransburg

Vector solo 65kv applicator - maintenance 39 ah-08-02.6 3. With the 79330 fitting, hold the hose in one hand and press a 6mm or 1/4" t-handle allen wrench into the hex in the part while turning clockwise. Tighten till cap is approximately .8 mm (1/32") from the swivel nut. Resistance test 1. If the ...

Page 44: Troubleshooting Guide

Vector solo 65kv applicator - maintenance 40 ah-08-02.6 troubleshooting guide general problem possible cause solution inadequate delivery electrical ensure the on/off lever is in the on position. Ensure 40 psig (2.75 bar) at the applicator handle with applicator triggered. Ensure the air hose is pro...

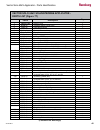

Page 45: Parts Identification

Vector solo 65kv applicator - parts identification 41 ah-08-02.6 parts identification figure 77: vector solo 65kv applicator parts breakdown ransburg.

Page 46: Ransburg

Vector solo 65kv applicator - parts identification 42 ah-08-02.6 (continued on next page) 1 table d-"d2" nozzle, fluid 1 2 80099-00 assembly, barrel, vector solo 1 3 79907-00 cascade assembly 1 4 79832-00 gasket, barrel 1 5 79881-00 gasket, exhaust, wrap-around 1 6 table d-"d1" cap, air 1 7 79724-00...

Page 47: Ransburg

Vector solo 65kv applicator - parts identification 43 ah-08-02.6 vector solo rs70-as model identification 79965 - a b c d e 1 = 10m (33 ft.) standard air hose 2 = 15m (49 ft.) standard air hose 3 = 20m (60 ft.) standard air hose 4 = 30m (99 ft.) standard air hose 5 = 10m (33 ft.) qd air hose 6 = 15m...

Page 48: Ransburg

Vector solo 65kv applicator - parts identification 44 ah-08-02.6 2 2-finger trigger 79787-00 c dash # table c - trigger selection "c" description 1 standard fluid tube, .093" id x 3/8" od 79878-11 2 coil fluid hose, .125" id, low flow 79871-01 3 standard fluid tube, 1/8" id x 3/8" od 79878-12 4 stan...

Page 49: Ransburg

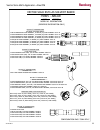

Vector solo 65kv applicator - parts identification 45 ah-08-02.6 a a section a-a 2 3 4 5 6 8 7 9 10 12 1 11 1 70430-01 electrode, high wear 1 2 74653-00 adapter, male chevron 1 3 14323-00 seal, 3/8" diameter chevron 4 4 18821-00 adapter, female chevron 1 5 79912-00 tube, packing 1 6 79910-00 assembl...

Page 50: Ransburg

Vector solo 65kv applicator - parts identification 46 ah-08-02.6 figure 79: 79911-01 needle shaft with non-adjustable packings, 1k 1 70430-01 electrode, high wear 1 2 78626-00 assembly, seal cartridge, non- adjustable 1 3 79912-00 tube, packing 1 4 79910-00 assembly, needle shaft, solo 65kv 1 5 7862...

Page 51: Accessories

Vector solo 65kv applicator - parts identification 47 ah-08-02.6 79548-10 fluid hose assembly, 10m (33 ft.) 79548-15 fluid hose assembly, 15m (49 ft.) 79548-20 fluid hose assembly, 20m (66 ft.) 79548-31 fluid hose assembly, 30m (99 ft.) 1 14599-00 nut 1 2 7623-00 union stem 1 3 7617-00 ferrule 1 4 7...

Page 52: Ransburg

Vector solo 65kv applicator - parts identification 48 ah-08-02.6 figure 83: air cap test kit - optional 74035-27 air cap test kit, 65v 74035-28 air cap test kit, 98v air cap test kit - (optional) (figure 83) part # description 79727-10 79727-11 79727-11-ss 79727-15 79727-16 79727-16-ss 79727-20 7972...

Page 53: Ransburg

49 vector solo 65kv applicator - parts identification ah-08-02.6 79870-00 test and maintenance kit test and maintenance kit - (optional) (figure 84) part # description figure 84: test and maintenance kit - optional figure 85: coiled fluid tube 79871-00 coiled fluid tube, 3.2mm (.125"), 16 coils 7987...

Page 54: Ransburg

Vector solo 65kv applicator - parts identification 50 ah-08-02.6 79837-00 gasket, handle to power module 79832-00 gasket, barrel 79836-00 gasket, exhaust 79881-00 gasket, exhaust, wraparound 79876-00 label, voltage on/off, solo 79658-00 gasket kit - parts list description part # the 79658-00 gasket ...

Page 55: Ransburg

Vector solo 65kv applicator - parts identification 51 ah-08-02.6 1 79379-00 nut, retaining, air nozzle 1 2 79374-65 standard air spray cap, air 1 79374-122 trans-tech. Air spray cap, air 3 80101-xx standard air spray nozzle, fluid 1 80122-xxx trans-tech. Air spray nozzle, fluid4 4 79809-00 standard ...

Page 56: Ransburg

Vector solo 65kv applicator - parts identification 52 ah-08-02.6 80101-44 nozzle, fluid, 1.4mm 2 80099-00 assembly, barrel, vector solo 1 79907-00 cascade assembly 1 79832-00 gasket, barrel 1 79374-65 cap, air, 65r 2 79724-00 nut, retaining, air nozzle 1 lsor0005 o-ring, ptfe encapsulated 1 emf-202-...

Page 57: Ransburg

53 ah-08-02.6 vector solo 65kv applicator - parts identification notes ransburg.

Page 58: Warranty Policies

Vector solo 65kv applicator - warranty policies 54 ah-08-02.6 warranty policies limited warranty ransburg will replace or repair without charge any part and/or equipment that fails within the specified time (see below) because of faulty work- manship or material, provided that the equipment has been...

Page 59: Manual Change Summary

Manual change summary this manual was published to supersede service manual ah-08-02.5 vector solo 65kv applicator to make the following changes: 1. Updated manual due to nozzle thread change, addition of air stream one-way valves and clarification of special conditions for safe use. Vector solo 65k...

Page 60: Ransburg

Form no. Ah-08-02.6 litho in u.S.A. 1/13 technical support representative will direct you to the appropriate telephone number for ordering spare parts. Manufacturing 1910 north wayne street angola, indiana 46703-9100 telephone: 260-665-8800 fax: 260-665-8516 technical service — assistance 320 philip...