- DL manuals

- Ransburg

- Paint Sprayer

- Vector Solo AA90 79698

- Keypad Body

Ransburg Vector Solo AA90 79698 Keypad Body

SERVICE MANUAL

AH-08-04.2

(REPALACE: AH-08-04.1)

February - 2013

Ransburg

VECTOR SOLO

AA90 APPLICATORS

TM

IMPORTANT: Before using this equipment,

carefully read SAFETY PRECAUTIONS, starting

on page 1, and all instructions in this manual.

Keep this Service Manual for future reference.

Service Manual Price: $50.00 (U.S.)

MODELS: 79698

Summary of Vector Solo AA90 79698

Page 1

Service manual ah-08-04.2 (repalace: ah-08-04.1) february - 2013 ransburg vector solo aa90 applicators tm important: before using this equipment, carefully read safety precautions, starting on page 1, and all instructions in this manual. Keep this service manual for future reference. Service manual ...

Page 2: Ransburg

Ah-08-04.2 ransburg vector solo aa90 applicators note: this manual has been changed from revision ah-08-04.1 to revision ah-08-04.2. Reasons for this change are noted under “manual change summary” inside the back cover of this manual..

Page 3: Ransburg

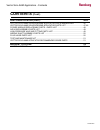

Vector solo aa90 applicators - contents ah-08-04.2 ransburg suitable solvents for cleaning vector solo applicators .........................21 routine schedule ..........................................................................................................22-23 applicator repair .............

Page 4: Ransburg

Vector solo aa90 applicators - contents ransburg ah-08-04.2 vector solo aa90 solventborne applicator parts breakdown .................. 46 vector solo aa90 solventborne applicator parts list .................................. 47-48 power module replaceable parts - parts list ...........................

Page 5: Ransburg

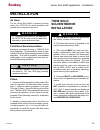

Vector solo aa90 applicators - safety ransburg 1 ah-08-04.2 safety precautions before operating, maintaining or servicing any ransburg electrostatic coating system, read and understand all of the technical and safety litera- ture for your ransburg products. This manual contains information that is i...

Page 6: Ransburg

Vector solo aa90 applicators - safety ransburg 2 ah-08-04.2 spray area area tells where hazards may occur. Hazard tells what the hazard is. Safeguards tells how to avoid the hazard. Fire hazard improper or inadequate oper- ation and maintenance proce- dures will cause a fire hazard. Protection again...

Page 7: Ransburg

Vector solo aa90 applicators - safety ransburg 3 ah-08-04.2 area tells where hazards may occur. Hazard tells what the hazard is. Safeguards tells how to avoid the hazard. Electrical equipment high voltage equipment is uti- lized. Arcing in areas of flam- mable or combustible mat-erials may occur. Pe...

Page 8: Ransburg

Vector solo aa90 applicators - safety ransburg 4 ah-08-04.2 area tells where hazards may occur. Hazard tells what the hazard is. Safeguards tells how to avoid the hazard. Spray area general use and maintenance electrostatic arcing never operate the applicator without properly grounding the following...

Page 9: Ransburg

Vector solo aa90 applicators - atex/fm ransburg 5 ah-08-04.2 european atex directive 94/9/ec, annex ii, 1.0.6 the following instructions apply to equipment covered by certificate number sira 08atex5060: 1. The equipment may be used with flammable gases and vapors with apparatus groups ii and with te...

Page 10: Ransburg

Vector solo aa90 applicators - atex/fm ransburg 6 ah-08-04.2 vector solo aa90 79698 atex product marking definitions ex certificate number: sira 08atex5060 sira = notified body performing ec-type examination 08 = year of certification atex = reference to atex directive 5 = protection concept code (c...

Page 11: Ransburg

Vector solo aa90 applicators - atex/fm ransburg 7 ah-08-04.2 configuration dwg. 79926 rev a vector solo rs90-aa solvent based 79698 - abcde base model no. Option designations (ordering information only) "c" designations "e" designations "b" designations "d" designations "a" designations.

Page 12: Ransburg

Vector solo aa90 applicators - atex/fm ransburg 8 ah-08-04.2 vector solo rs90-aa solvent based 79698 - abcde base model no. Option designations (ordering information only) configuration dwg. 79926 rev a approved spare tip list 0509 tip : 79691-0509, 0511 tip : 79691-0511, 0513 tip : 79691-0513 1009 ...

Page 13: Ransburg

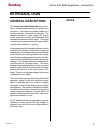

Vector solo aa90 applicators - introduction ransburg 9 ah-08-04.2 general description the vector solo tm aa90 applicators are a com- bined air/airless powered only by a pressurized air source. Pressurized air creates rotation of a turbine generator that powers a cascade. The cascade generates a high...

Page 14: Ransburg

Vector solo aa90 applicators - introduction ransburg 10 ah-08-04.2 fluid flow capacity: variable to 1,500 cc/minute (spray tip dependent) wetted parts: stainless, polyethylene, nylon, acetal polymer, tungsten carbide operating pressure fluid: 207 bar (0-3000 psi) max. Air: 6.9 bar (0-100 psi) max. A...

Page 15: Ransburg

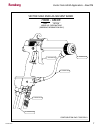

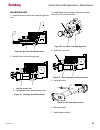

Vector solo aa90 applicators - introduction ransburg 11 ah-08-04.2 5 1 2 3 6 7 8 10 11 13 4 9 12 figure 1: vector solo aa90 solventborne electrostatic spray applicator air cap / spray tip barrel replaceable hook fan air adjustment trigger lock fluid hose connection air inlet connection kv setpoint s...

Page 16: Ransburg

Vector solo aa90 applicators - introduction ransburg 12 ah-08-04.2 vector solo applicator ball valve air regulator w/pressure gauge air/water separator main air supply line fluid supply (grounded) fluid regulator air hose (79727-xx) air hose ground wire fluid line figure 2: vector solo aa90 typical ...

Page 17: Ransburg

Vector solo aa90 applicators - installation ransburg 13 ah-08-04.2 air hose for the vector solo aa90 to properly function safely, the 79727-xx air hose assembly with ground wire is required to be used. Fluid hose recommendation ransburg recommends using a 7994-xx fluid hose assembly. This assembly i...

Page 18: Ransburg

Vector solo aa90 applicators - installation ransburg 14 ah-08-04.2 installation 1. Ensure there is a true earth ground connection available. Both the fluid source and the air hose ground must be connected to true earth ground. W a r n i n g ! 2. Connect the fluid source to true earth ground. 3. Ensu...

Page 19: Ransburg

Vector solo aa90 applicators - operation ransburg 15 ah-08-04.2 1. Ensure the on/off switch is in the desired po- sition for voltage. Figure 6: voltage on/off position 2. Ensure the voltage high/low switch is in the desired position. Figure 7: high/low voltage selection 3. Open the fluid supply - 20...

Page 20: Ransburg

Vector solo aa90 applicators - operation ransburg 16 ah-08-04.2 figure 9: air pressure at regulator 4. Increase air pressure to the applicator depend- ing upon amount of air required to eliminate the tails. Minimum pressure is 2.75 bar (40 psig) at the handle. Use either gauge from maintenance and t...

Page 21: Ransburg

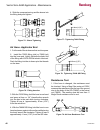

Vector solo aa90 applicators - operation ransburg 17 ah-08-04.2 figure 11: air cap alignment locating pin position figure 12: pre-orifice seal sizes dash number location 6. The aa90 applicator incorporates a new feature, that being a locating air cap. (refer to figure 11 for a view showing the locat...

Page 22: Ransburg

Vector solo aa90 applicators - operation ransburg 18 ah-08-04.2 79692-01 79692-02 79692-03 79692-04 79692-06 79692-07 .1010" (.256mm) .1021" (.307mm) .0141" (.358mm) .0161" (.409mm) .0201" (.511mm) .0221" (.561mm) part # restrictor orifice size matching spray tip part # 79691-0509,-1009 79691-0511, ...

Page 23: Ransburg

Vector solo aa90 applicators - operation ransburg 19 ah-08-04.2 the right technique following are some basic electrostatic spray tech- niques. Depending on the spray target, it may be necessary to adjust the technique. Spray width determination the size of the object being coated is the deter- minin...

Page 24: Ransburg

Vector solo aa90 applicators - operation ransburg 20 ah-08-04.2 ransburg recommends the use of a fluid filter in addition to the filter in the applicator fluid line to reduce nozzle clogging. Preparation paint a selection of the proper paint mixture is essential to electrostatic operation. Paint tes...

Page 25: Ransburg

Vector solo aa90 applicators - maintenance ransburg 21 ah-08-04.2 the user must read and be familiar with the safety instructions in this manual. If compressed air is used in cleaning, remember that high pressure air can be dangerous and should never be used against the body . It can blind, deafen, ...

Page 26: Ransburg

Vector solo aa90 applicators - maintenance ransburg 22 ah-08-04.2 routine schedule follow these maintenance steps to extend the life of the applicator and ensure efficient opera- tion: several times daily • inspect the air cap for paint accumulation. Clean as frequently as necessary with a soft bris...

Page 27: Ransburg

Vector solo aa90 applicators - maintenance ransburg 23 ah-08-04.2 do not allow the fluid lines to stand empty without flushing first! This will cause dried paint flaking and clogging of the fluid lines, applicator passages, and/or nozzles. All repairs should be made on a clean, flat sur- face. If a ...

Page 28: Ransburg

Vector solo aa90 applicators - maintenance ransburg 24 ah-08-04.2 flushing procedures the fluid system should be thoroughly cleaned by flushing with a clean compatible solvent whenever a color change is made, or when the applicator will not be used for an extended period. 1. Turn off the control uni...

Page 29: Ransburg

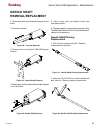

Vector solo aa90 applicators - maintenance ransburg 25 ah-08-04.2 1. Turn the paint and air supplies off. Relieve both fluid and air pressures. Set the trigger stop lever. 2. Unscrew the air cap retaining ring completely from the barrel. 3. With the front of the barrel tilted downward, remove the ai...

Page 30: Ransburg

Vector solo aa90 applicators - maintenance ransburg 26 ah-08-04.2 2. Remove fluid hose at base of applicator. Figure 18: counter-clockwise to remove fluid hose 3. Remove air hose at base of applicator. Figure 19: clockwise to remove qd stem/air hose figure 21: spray tip and seal removal spray tip re...

Page 31: Ransburg

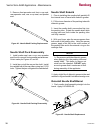

Vector solo aa90 applicators - maintenance ransburg 27 ah-08-04.2 barrel removal 1. Remove air cap and fluid nozzle. Figure 23: rear cover removal figure 24: fluid adjust bushing removal 4. Remove the trigger and fluid line. Figure 25: fluid line/trigger removal 2. Remove two (2) screws with a 3mm a...

Page 32: Ransburg

Vector solo aa90 applicators - maintenance ransburg 28 ah-08-04.2 5. Remove the two (2) jam nuts using the 79793- 00 removal tool while holding the needle shaft with the 79793-00 special wrench. Figure 26: jam nut removal 6. Remove three (3) 5mm screws using a 4mm allen wrench. Remove the hook. Figu...

Page 33: Ransburg

Vector solo aa90 applicators - maintenance ransburg 29 ah-08-04.2 reinstalling barrel 1. Replace the hook. Install the barrel against the handle and hand tighten two (2) long 5mm screws, in an alternating sequence with the 4mm allen wrench. Tighten the hook screw with the same 4mm wrench. Figure 33:...

Page 34: Ransburg

Vector solo aa90 applicators - maintenance ransburg 30 ah-08-04.2 c w c w figure 34: second jam nut replacement 3. Tighten second jam nut with raised center facing out, while holding the needle shaft. Figure 37: rear cover replacement 4. Install the fluid adjustment assembly along with the air and f...

Page 35: Ransburg

Vector solo aa90 applicators - maintenance ransburg 31 ah-08-04.2 figure 41: needle shaft packing replacement 5. Clean cavity with non-metallic brush and non-polar solvent. 6. Replace needle components as required. (see "needle shaft parts list" in the "parts identification" section for breakdown.) ...

Page 36: Ransburg

Vector solo aa90 applicators - maintenance ransburg 32 ah-08-04.2 3. Remove front spreader seal, front u-cup seal, rear spreader seal, rear u-cup seal, and pusher seal. Figure 43: needle shaft packing replacement figure 44: needle shaft packing reassembly needle shaft pack reassembly 1. Install push...

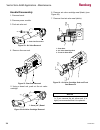

Page 37: Ransburg

Vector solo aa90 applicators - maintenance ransburg 33 ah-08-04.2 the power modules are not serviceable. Note 2. Remove three (3) bolts using a 3mm allen wrench. Figure 48: power module removal 3. Pull the module straight off the handle. Figure 49: power module removal 2. Tighten rear nut using spec...

Page 38: Ransburg

Vector solo aa90 applicators - maintenance ransburg 34 ah-08-04.2 4. Remove the rear seal. Figure 51: rear seal removal 5. Using a dowel rod, push out the air valve cartridge. Figure 52: air valve cartridge removal 6. Remove air valve cartridge seal (black) (see figure 48). 7. Remove front air valve...

Page 39: Ransburg

Vector solo aa90 applicators - maintenance ransburg 35 ah-08-04.2 4. Install the rear seal. 5. Install air valve. Figure 57: rear cartridge seal replacement figure 58: air valve replacement figure 56: air valve cartridge alignment 3. Install the air valve cartridge. Align the cartridge with tab at 1...

Page 40: Ransburg

Vector solo aa90 applicators - maintenance ransburg 36 ah-08-04.2 figure 60: fluid fitting removal power module - fluid fitting removal 1. Remove swivel from the power module and the power module from thehandle. Figure 59: power module removal 2. Remove two (2) screws using a 2.5mm allen wrench. 3. ...

Page 41: Ransburg

Vector solo aa90 applicators - maintenance ransburg 37 ah-08-04.2 test and maintenance kit usage (79870-00) figure 66: 79870 test and maintenance kit 1 2 3 4 5 6 79870 test and maintenance kit item# brass tee fitting 100 psi pressure gauge 6" air hose assembly left hand male fitting barb fitting tub...

Page 42: Ransburg

Vector solo aa90 applicators - maintenance ransburg 38 ah-08-04.2 3. Connect the other end of the air hose to the regulated air supply. 4. Turn on main air. Trigger the applicator with kv switch on high (down position). Read the pressure at the 100 psi pressure gauge. This pressure should be at leas...

Page 43: Ransburg

Vector solo aa90 applicators - maintenance ransburg 39 ah-08-04.2 7. Connect the 79727 air hose to main air. 8. Turn on main air and set the pressure so the pressure gauge [2] in the 79870 test and main- tenance kit reads 25 psi (1.7 bar). The voltage kv setpoint lever should be in the high voltage ...

Page 44: Ransburg

Vector solo aa90 applicators - maintenance ransburg 40 ah-08-04.2 4. Slide the compression ring and the sleeve into the fitting body and tighten. Air hose -applicator end 1. Cut the end of the air hose so that end is square. 2. Install the 79930 fitting (std) or 79868 (qd) into the hose end. Lightly...

Page 45: Ransburg

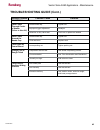

Vector solo aa90 applicators - maintenance ransburg 41 ah-08-04.2 (continued on next page) troubleshooting guide general problem possible cause solution electrical no kv low kv poor atomization and distribution on-off lever in wrong position low pressure no ground connection cascade not functioning ...

Page 46: Ransburg

Vector solo aa90 applicators - maintenance ransburg 42 ah-08-04.2 (continued on next page) troubleshooting guide (cont.) general problem possible cause solution electrical poor wraparound paint wraps back on operator no paint delivery excessive surging persistent nozzle clogging poor atomization exc...

Page 47: Ransburg

Vector solo aa90 applicators - maintenance ransburg 43 ah-08-04.2 troubleshooting guide (cont.) general problem possible cause solution electrical paint leaks through center of nozzle (failure to shut off) loose nozzle cap improper trigger adjustment defective or dirty valve seat tighten nut. Readju...

Page 48: Ransburg

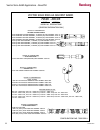

Vector solo aa90 applicators - parts identification ransburg 44 ah-08-04.2 spray tip size when ordering, use 79698-a, b, c, d, and e as indicated by tables a, b, c, d, and e. Five digits must follow the basic part number, for example: 79698 - a b c d e air hose length basic part number fluid inlet t...

Page 49: Ransburg

Vector solo aa90 applicators - parts identification ransburg 45 ah-08-04.2 2-finger trigger table c - trigger type 2 79694-00 dash # "c" description carbide tip assembly carbide tip assembly carbide tip assembly carbide tip assembly table d - spray tip size 0 1 2 3 79691-0811 79691-0813 79691-1011 7...

Page 50: Ransburg

Vector solo aa90 applicators - parts identification ransburg 46 ah-08-04.2 figure 80: vector solo aa90 applicators parts breakdown 57 22 22 56 18 52 54 51 48 50 49 53 47 46 46 45 44 43 36 35 42 41 40 39 38 37 33 4 29 32 2 1 5 11 31 12 21 6 3 8 9 23 18 17 10 26 19 28 27 34 15 15 15 13 16 16 14 20 7 3...

Page 51: Ransburg

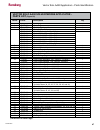

Vector solo aa90 applicators - parts identification ransburg 47 ah-08-04.2 (continued on next page) 1 79668-00 assembly, fluid nozzle 1 2 72375-03 seal, teflon 1 3 table "d" carbide tip assemblies 1 4 79692-00 seal, no pre-orifice 1 79692-00-k3 kit of 3 (optional, no pre-orifice) 79692-01 seal, .010...

Page 52: Ransburg

Vector solo aa90 applicators - parts identification ransburg 48 ah-08-04.2 1 79919-00 fluid inlet, aa 1 2 79746-00 grounding clip 1 3 79814-00 socket head cap screw, 4mm x 20mm lg. 2 4 79637-00 1/4 power module -- 5 79636-00 3/4 power module -- item # power module replaceable parts - parts list (fig...