- DL manuals

- Ransomes

- Lawn Mower

- greens king IV 62289

- Service Manual

Ransomes greens king IV 62289 Service Manual

Service Course Manual

Greens King IV

Model: 62289

WARNING: If incorrectly used this machine can cause severe

injury. Those who use and maintain this machine should be

trained in its proper use, warned of its dangers and should

read the entire manual before attempting to set up, operate,

adjust or service the machine.

®

G B

Summary of greens king IV 62289

Page 1

Service course manual greens king iv model: 62289 warning: if incorrectly used this machine can cause severe injury. Those who use and maintain this machine should be trained in its proper use, warned of its dangers and should read the entire manual before attempting to set up, operate, adjust or se...

Page 3: Specification

1 2 3 4 5 6 7 8 9 10 specification controls engine steering wheels & tyres hydraulics electrical system preventative maintenance options notes index.

Page 5: Section 1

1 section 1 specifications product infomation............................................................................................................... Engine...................................................................................................................................... Cu...

Page 6

2 if ic a t io ns p r oduc t ide nt if ic a t ion 62287 .............................. G reens k ing iv, 16 hp gas oline engine, manual s teering. Without battery, s eat, or mowers. 62288 .............................. G reens k ing iv p lus, 18 hp gasoline engine, power s teering. Without battery, ...

Page 7

Tr ac t or t ires ................................ 18 x 9.5 - 8 tubeles s p ress ure: ......................... 8-12 ps i (55-83 kpa) b attery: type........................... 12 volt lead/acid g roup ........................ 22 g mf parking b rake.................. Mechanical front drum brakes hand...

Page 9: Section 2

2 section 2 controls contols control description.

Page 10

2 1 n r 1. Read operators manual. Do not allow untrained operators to use this machine. 2. Keep all shields in place and hardware securely tightened. 3. Before you clean, adjust or repair this equipment, disengage all drives, engage parking brake and stop engine. 4. Keep hands, feet and clothing awa...

Page 11

C ont r ol de s c r ip t ions a . R eel c ontrol l ever - used to operate the cutting units. P us h lever(s) forward for forward rotation. P ull lever(s) back for r evers e rotation. All three levers mus t be in of f position to start engine b . Parking b rake l ever - p ull back to engage and pus h...

Page 13: Section 3

3 section 3 engine engine specifications engine oil air filter.

Page 14

Model: d662 eb type: vertical water cooled, 4 cycle diesel engine number of cylinders: 3 bore & stroke : 64 x 68mm (2.52 x 2.68inches) total displacement: 0.656 litre (40.03 cu.In) combustion chamber: spherical type (new tvcs) order of firing: 1 - 2 - 3 direction of rotation: counter-clockwise (view...

Page 15

E ng ine oil c heck the engine oil at the s tart of each day, before starting the engine. If the oil level is low, remove oil filler cap and add oil as required. Dies el e ngine: perform initial oil change after firs t 50 hours of operation and every 75 hours thereafter. S ee e ngine manual. Use onl...

Page 17: Section 4

4 section 4 steering steering assembly steering valve assembly.

Page 18

In out lt r t to s teering unit lt port to s teering unit r t port to s teering unit in port to s teering unit out port 8 dies el units only.

Page 19

Out in r t lt s et torque steering nut to 34-41nm (25-30 ft/lbs) tighten in sequence gradually until final torque 27-33nm (20-24 ft lbs) is reached..

Page 21: Section 5

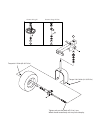

5 section 5 wheels and tyres tyre pressures wheel and axle assembly.

Page 22

T y r e s 1. Keep tyres properly inflated to prolong tyre life. C heck inflation pressure while the tyres are cool. Inspect tread wear. 9. C heck the press ure with an accurate, low pres sure tyre gauge. 10. Keep tyres inflated to: front - 10-12 psi - (69-83 kpa) r ear - 8-10 psi (55-69 kpa) c aut i...

Page 23

A a a g reens k ing iv g reens k ing iv p lus torque 110-134nm (81-99 ft lbs) torque 88-115nm (65-85 ft lbs) tighten axle nut then back off 1/2 to 1 turn. Wheel should rotate freely with very little side play..

Page 25: Section 6

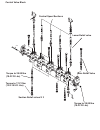

6 section 6 hydraulics tools required:standard automotive hand tools, including torque wrench, seal drivers, circlip pliers and bearing driver. Tachometer (photo/mechanical) obtain from local supplier or, graham and white instruments 135 hatfield road st. Albans herts. Al1 4lz united kingdom tel: 01...

Page 26: Hydraulics Components

Hydraulics components gear pump stack traction section - 0.59 ci (9.7cc) lift/lower section & right hand unit - 0.38 ci (6.23cc) centre unit drive - 0.38ci (6.23cc) left hand unit drive - 0.38ci (6.23cc) steering - 0.38ci (6.23cc) torque nuts in sequence to 22-24nm (16-18 ft lbs) lift/lower sequence...

Page 27

Control valve block traction control spool left hand cutting unit control spool centre cutting unit control spool right hand cutting unit/lift- lower control spool main relief cartridge.

Page 28

24 control valve block main relief valve lower relief valve section relief valves x 3 control spool sections torque to 25-30 nm (18-22 ft lbs) torque to 17-21 nm (12.5-15.5 ft lbs) torque to 25-30 nm (18-22 ft lbs).

Page 29

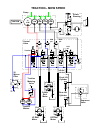

) ) ) ) pump power steering control valve traction lt reel ct reel rt reel lift / lower traction metering valve 20 micron filter center reel motor traction motors sequence valve front lift cylinder rear lift cylinder lf reel motor rf reel motor p c v ) .059 std. .052 soft 1500 psi 1500 psi 1500 psi ...

Page 30: Traction -- Transport Speed

) ) ) ) pump power steering control valve traction metering valve center reel motor traction motors lf reel motor rf reel motor traction -- transport speed traction lf reel ct reel rf reel lift / lower sequence valve front lift cylinder rear lift cylinder p c v ) .059 std. .052 soft 20 micron filter...

Page 31: Traction-- Mow Speed

) ) ) ) pump power steering control valve traction metering valve center reel motor traction motors lf reel motor rf reel motor traction-- mow speed traction lf reel ct reel rf reel lift / lower front lift cylinder rear lift cylinder p c v ) .059 std. .052 soft sequence valve 20 micron filter 1500 p...

Page 32: Lowering - Reels On

) ) ) ) pump power steering control valve traction metering valve center reel motor traction motors lf reel motor rf reel motor lowering - reels on traction lt reel ct reel rt reel lift / lower sequence valve front lift cylinder rear lift cylinder .059 std. .052 soft 20 micron filter 1500 psi 1500 p...

Page 33: Reels Down and On

) ) ) ) pump power steering control valve traction metering valve center reel motor traction motors lf reel motor rf reel motor reels down and on traction lt reel ct reel rt reel lift / lower sequence valve front lift cylinder rear lift cylinder p c v .059 std. .052 soft 20 micron filter 1500 psi 15...

Page 34: Lifting Cutting Units

) ) ) ) pump power steering control valve traction metering valve center reel motor traction motors lf reel motor rf reel motor lifting cutting units traction lt reel ct reel rt reel lift / lower sequence valve front lift cylinder rear lift cylinder p c v .059 std. .052 soft 20 micron filter 1500 ps...

Page 35: Backlap

) ) ) ) pump power steering control valve traction metering valve center reel motor traction motors lf reel motor rf reel motor backlap traction lt reel ct reel rt reel lift / lower sequence valve front lift cylinder rear lift cylinder p c v .059 std. .052 soft 20 micron filter 1500 psi 1500 psi 110...

Page 36: Traction-- Mow Speed

) ) ) ) pump power steering control valve traction metering valve center reel motor traction motors lf reel motor rf reel motor traction-- mow speed traction lt reel ct reel rt reel lift / lower sequence valve front lift cylinder rear lift cylinder p c v .059 std. .052 soft 20 micron filter 1500 psi...

Page 37: Section 7

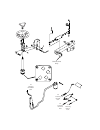

7 section 7 electrical system electric components electrical schematics 1 - hot 2 - start 3 - run 4 - backlap.

Page 38

Electrical components neutral switch parking brake switch brake switch seat time delay relay rectifier mow cut out switch backlap switch.

Page 39

D s g b l battery starter interlock solenoid traction switch brake switch mow switch backlap switch backlap lockout switch seat switch time delay relay ignition switch rectifier glow plug switch glow plugs fuel solenoid p h oil press. Switch temp gauge hour meter 30 amp fuse rd rd rd rd wht wht pk p...

Page 40: Hot

Hot d s g b l battery starter interlock solenoid traction switch brake switch mow switch backlap switch backlap lockout switch seat switch time delay relay ignition switch rectifier glow plug switch glow plugs fuel solenoid p h oil press. Switch temp gauge hour meter 30 amp fuse rd rd rd rd wht wht ...

Page 41: Start

Start d s g b l battery starter interlock solenoid traction switch brake switch mow switch backlap switch backlap lockout switch seat switch time delay relay ignition switch rectifier glow plug switch glow plugs fuel solenoid p h oil press. Switch temp gauge hour meter 30 amp fuse rd rd rd rd wht wh...

Page 42: Run

Run d s g b l battery starter interlock solenoid traction switch brake switch mow switch backlap switch backlap lockout switch seat switch time delay relay ignition switch rectifier glow plug switch glow plugs fuel solenoid p h oil press. Switch temp gauge hour meter 30 amp fuse rd rd rd rd wht wht ...

Page 43: Backlap

Backlap d s g b l battery starter interlock solenoid traction switch brake switch mow switch backlap switch backlap lockout switch seat switch time delay relay ignition switch rectifier glow plug switch glow plugs fuel solenoid p h oil press. Switch temp gauge hour meter 30 amp fuse rd rd rd rd wht ...

Page 45: Section 8

8 section 8 preventative maintenance lubrication chart maintenance chart.

Page 46

Maint e nanc e & l ub r ic at io n c har t s g e ne r al 1. Always clean the greas e fitting before and after lubricating. 2. Lubricate with grease that meets or exceeds nlg i g rade 2 lb s pecifications. Apply greas e with a manual greas e gun and fill s lowly until grease begins to s eep out. Do n...

Page 47

Maint e nanc e c hart s a - a dd or a djus t c - c lean i - ins pect l - l ubricate r - r eplace a r - a s r equired * indicates initial service for new machines. ** e very 250 hours or yearly, whichever comes firs t. *** ins pect vis ible hoses and tubes for leaks or oil marks. **** r eplace every ...

Page 49: Section 9

9 section 9 options options list: cutting unit options 7 blade fairway/tees reel (2 rh & 1 lh required per machine) 9 blade greens reel 11 blade greens reel verticut mower with 0.75” (19mm) spacing front roller options grooved disc assembly front roller solid tube front roller with scraper grooved m...

Page 51: Section 10

10 section 10 notes.

Page 52

Notes.

Page 53

10 notes.

Page 54

Notes.

Page 55

10 notes.

Page 56

Notes.

Page 57

10 notes.

Page 58

Notes.

Page 59

10 notes.

Page 60

Notes.