- DL manuals

- Ransomes

- Lawn Mower

- Highway3

- Safety, Operation & Maintenance Manual

Ransomes Highway3 Safety, Operation & Maintenance Manual

RJL 100 July 2015

GB

United

Kingdom

Safety, Operation & Maintenance Manual

Ransomes Highway 3 Ride on Reel Mower

Engine- Kubota V1105

Highway 3 - 4 Wheel Drive

Series: GF

Product code: LGEA340

Highway 3 - 2 Wheel Drive

Series: GU

Product code: LGEA320

WARNING

WARNING: If incorrectly used this machine can

cause severe injury. Those who use and maintain

this machine must be trained in its proper use,

warned of its dangers and must read the entire

manual before attempting to set up, operate, adjust

or service the machine.

24881G-GB (Rev.3)

Summary of Highway3

Page 1

Rjl 100 july 2015 gb united kingdom safety, operation & maintenance manual ransomes highway 3 ride on reel mower engine- kubota v1105 highway 3 - 4 wheel drive series: gf product code: lgea340 highway 3 - 2 wheel drive series: gu product code: lgea320 warning warning: if incorrectly used this machin...

Page 2

1 contents © 2015 ransomes jacobsen limited. All rights reserved introduction important .................................................................................................. 1 product identification ................................................................................ 2 guide...

Page 3

En-1 introduction 2 2.1 important__________________________________________________________ the ransomes highway3 is a diesel engined self propelled rotary mower. The hydraulic systems are for the traction drive, the cutting unit lift and the lower and cutting unit drives and steering. Important: do...

Page 4

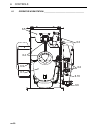

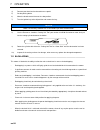

En-2 2 introduction m a d e i n j a pa n d1105 serial no.: code no.: xxxxxxx xxxxx-xxxxx kg kw kg kg west road ransomes europark ipswich ip3 9tt england a b c d e f g h j a b 2.2 product identification ___________________________________________ a maximum front axle load in kg (for machines being dr...

Page 5

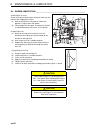

En-3 introduction 2 c d e kg a f west road ransomes europark ipswich ip3 9tt england b rops serial plate a weight of rops b date code c standard used d part number e used on product f serial number rops serial plate location the rops serial plate (c) is located at the base of the front of the rops m...

Page 6

En-4 2 introduction 2.3guidelines for the disposal of scrap products _____________________ 2.3.1 during service life _______________________________________________ used oil, oil filters and engine coolant are hazardous materials. Recommended procedures must be followed for their safe removal. If a ...

Page 7

En-5 introduction 2 2.4 parts manual ______________________________________________________ in compliance with the iso14001 standard, ransomes jacobsen limited does not send a paper parts manual with every product. To refer to a parts list for this mower you have four options: 1. Website – www.Ranso...

Page 8

En-6 2 introduction 2.5 key numbers _______________________________________________________ record the key numbers shown below: starter switch:- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - diesel tank:- - - - - - - - - - - - - - - - - - - - - - - - -...

Page 9: Warning

En-7 safety 3 3.1 how to operate safely __________________________________________________ 3.1.1 safe operation a read the operator’s manual and other training material. If the operator or technician can not read this manual, the owner is responsible to describe this material to the operators and te...

Page 10

En-8 3 safety 3.1.3 operation a never operate the engine without enough ventilation or in an enclosed area. The carbon monoxide in the exhaust fumes can increase to dangerous levels. B never carry passengers. Keep other persons or animals away from the mower. C disengage all drives and engage the pa...

Page 11

En-9 safety 3 3.1.4 rops a the rops is a safety device. Keep the rops in the vertical and locked position. Always use the seat belt when you operate the mower. Make sure the seat belt can be released quickly in an emergency. B only operate the mower with the rops in the folded position on flat and l...

Page 12

En-10 3 safety g charge the battery in an area with good airflow. The battery can release hydrogen gas that is explosive. To prevent an explosion, keep any device that can cause sparks or flames away from the battery. H disconnect the battery charger from the power supply before you connect or disco...

Page 13

En-11 safety 3 3.1.8 important safety notes this safety alert symbol is used to alert you to possible hazards. Danger: indicates a dangerous condition that will cause death or injury unless it is prevented. Warning: indicates a dangerous condition that can cause death or injury unless it is prevente...

Page 14

En-12 3 safety warning california proposition 65 engine exhaust, some of its constituents, and some vehicle components contain or release chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. Warning to prevent injury from the hot oil at high pressu...

Page 15

En-13 safety 3 warning vibration exposure limits exposure limits are calculated as a combination of the vibration level (magnitude) of the tool and the daily exposure time (trigger time). E.G. A product with 5m/s² vibration can be used up to 2 hours/day to reach the eav and up to 8 hours/day to reac...

Page 16

En-14 3 safety notes.

Page 17

En-15 specifications 4 4.1 engine specification ______________________________________________ model: d1105-t-e3b-rnuk-3 type: vertical, water-cooled, 4-cycle diesel engine number of cylinders 3 bore & stroke 78mm x 78.4mm total displacement 1123cm³ combustion chamber spherical type (e-tvcs) intake ...

Page 18

En-16 4 specifications 4.2 dimensions & weights _____________________________________________ a width of cut: 215 cm 84.6 in b overall width cutting: 240.5 cm 94.6 c overall width transport (minimum): 137 cm 54 in d overall height with rops frame up: 211 cm 83 in e overall height with rops frame dow...

Page 19

En-17 specifications 4 c j d h a b k e g f tyre pressure product front wheel rear wheel tyre size tyre type tyre pressure tyre size tyre type tyre pressure highway 3 23 x 10.50 - 12 bkt lg-306 6pr 1.00 - 1.37 bar 18.50 x 8.50 - 8 bkt lg-306 4pr 1.00 - 1.37 bar 23 x 10.50 - 12 bkt armaturf 6 ply 1.00...

Page 20

En-18 4 specifications 4.3 machine specification _____________________________________________ frame construction: heavy duty formed steel chassis with box section frame rails. Cutting unit drive: fixed displacement hydraulic motors. Transmission: four wheel drive on demand. Direct coupled variable ...

Page 21

En-19 specifications 4 the machine was tested for whole body vibration levels. The operator was in the normal position to drive the vehicle, with two hands on the steering mechanism. The cutting device was in rotation with the machine driven in a straight line at 6 km/hr on a level and cut lawn. The...

Page 22

En-20 4 specifications 4.7 cutting unit specification_________________________________________ note these cutting units are made to cut grass of maximum height 100 mm down to the available height of cut range. 4.8 cutting performance _____________________________________________ 2.5 hectares/hr. At ...

Page 23

En-21 specifications 4 %xvlqhvvqdphdqgixoodgguhvvriwkhpdqxidfwxuhuƒɌɴɪɝɨɜɫɤɨɢɦɟɢɩɴɥɟɧɚɞɪɟɫɧɚɩɪɨɢɡɜɨɞɢɬɟɥɹƒ 2efkrgqtmppqrdsoqidguhvdyêurefhƒ3urgxfhqwhqvilupdqdyqrjixoghdguhvvhƒ%hgulmivqddphqyroohgljdguhvydqghideulndqwƒ7rrwmdlulqlplmdwllholnddguhvvƒ 9doplvwdmdqwrlplqlplmdwl\ghoolqhqrvrlwhƒ1rpfrpphufld...

Page 24

En-22 4 specifications 2shudwru(du1rlvh/hyhoƒɈɩɟɪɚɬɨɪɧɚɧɢɜɨɬɨɧɚɞɨɥɨɜɢɦɨɬɭɯɨɬɨɲɭɦƒ +odglqdkoxnxyreodvwlxãtrshuiwrudƒ6w¡mqlyhdxli¡uhuv¡uhk¡mghƒ *hoxlgvqlyhdxrruehvwxxughuƒ0udwdvhrshuddwruln}uydvƒ 0hoxwdvrnl\wwlmlqnruydqnrkgdoodƒ1lyhdxgheuxlwjkdxwhxughvruhloohvgho¶rspudwhxuƒ 6fkdooshjhodp%hglhqhurkuƒǼ...

Page 25

En-23 specifications 4 ransomes jacobsen limited west road, ransomes europark, ipswich, england, ip3 9tt product code serial number lmac347-c gg100301 - gg199999 lmac347-l gg200301 - gg299999 lmac347-r gg300301 - gg399999 lmac348-c gh100301 - gh199999 lmac348-l gh200301 - gh299999 lmac348-r gh300301...

Page 26

En-24 4 specifications ransomes jacobsen limited west road, ransomes europark, ipswich, england, ip3 9tt 1st september 2014 4209780 (rev.1) 8u]ąg]hqldf]ĊĞflrzrxnrĔf]rqhjrqlhzroqrxĪ\wnrzdüdĪgrru]hf]hqld]jrgqrĞflxu]ąg]hqldzsrvwdflnrpsohwqhm] wymaganiami dyrektywy 2006/42/we. O equipamento parcial não ...

Page 27

En-25 specifications 4 notes.

Page 28

En-26 5 decals 4 4153197 a b c d e f g h j k l m r p 4146857 n 5.1 safety decals ec __________________________________________________.

Page 29

En-27 5 decals a. 009034910 read operator's manual. B. 009034890 keep a safe distance from the machine. C. 009034920 stay clear of hot surfaces. D. 009034880 do not open or remove safety shields while the engine is running. E. 009034940 caution rotating blades. F. 009034930 avoid fluid escaping unde...

Page 30

En-28 5 decals b f d g e 10a 10a 12v 12v c j m l a k 5.2 instruction decals ec ____________________________________________ h n p.

Page 31

En-29 5 decals description a. Maximum sound power level b. Parking brake c power socket 12v d transport - mow e throttle f reel rotation g backlap h ignition switch j foot pedal forward - reverse k horn l steering wheel tilt l lubrication point read manual m indicator stalk functions n jacking point...

Page 32

En-30 6 controls 6.2 6.3 6.4 6.5 6.10 9.7 6.6 6.9 6.1 operator workstation _______________________________________.

Page 33

En-31 6 controls a e f b h d g c 1234.5 j k m n p r l s a: starter key switch b: throttle control lever c: parking brake switch d. Hazard warning switch e: cutter switch f: backlap g: 4 wd in reverse h: visual display 6.2 instrument panel_____________________________________________ j. Right hand un...

Page 34

En-32 6 controls 6.2a starter key switch __________________________________________ the starter key (a) should be turned clockwise to the 'start' position to start the engine. After starting, the key should be released and allowed to return automatically to the 'on' position for normal running. Note...

Page 35

En-33 6 controls 6.2e cutting unit switch (pto) _____________________________________ to commence cutting ensure speed limiter is in mow position and the units have been lowered. Push bottom of the rocker switch and move joystick towards the lower position. To stop cutter unit rotation push top of r...

Page 36

En-34 6 controls warning if incorrectly used this machine can cause severe injury. Those who use and maintain this machine should be trained in its proper use, warned of its dangers and should read the entire operators manual before attempting to set up, operate, adjust or service the machine. Servi...

Page 37

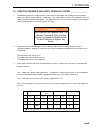

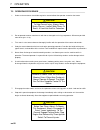

En-35 6 controls 6.2h.3 start up slope warning screen ______________________________ when the ignition switch is turned to crank one of the following screens will be shown. If the machine is fitted with the slope monitoring system the screen will display the logo “tst™” (tilt sensor technology ) and...

Page 38

En-36 6 controls 6.2h.4 main run screen ______________________________________________ the main run screen will give the operator all the information he needs to operate the machine, it should not require any operator in- put to view standard data whilst using the mower. If any error presents itself...

Page 39

En-37 6 controls 1234.5 blocked charge filter fault a a 6.2h.5 water temperature screen __________________________________ if the temperature increases to 108°c, the red leds (a) flash at a rate of two flashes every four seconds. The warning buzzer will sound at the same rate and the “clear bugscree...

Page 40

En-38 6 controls 15 22° 6.2h.7 slope warning screens_______________________________________ note slope warning screens will only appear when tst is installed. During work if the machine is driven onto a slope of 16º the screen will display this warning which over rides all other information, and wil...

Page 41

En-39 6 controls clock settings date - 21/06/2008 time - 16:08 6.2h.8 main menu ____________________________________________________ the tick can be moved up and down using buttons 2 and 3; button 4 then enters the selected page. Button 1 returns to the main menu. There will be three options within ...

Page 42

En-40 6 controls service required in 10 hours parts required for routine service 1234 fuel filter 1235 air filter 1236 engine oil filter 1237 hydraulic filter 6.2h.10 service menu _________________________________________________ the tick can be moved up and down using buttons 2 and 3; button 4 then...

Page 43

En-41 6 controls 13/05/2008 @ 13:05 max temp - 110°c time above 100°c - 17 mins language menu english deutsch francais danish swedish dutch 6.2h.11 datalogging menu____________________________________________ the last 50 “faults” that the controller detects will be recorded, once 50 faults are logge...

Page 44

En-42 6 controls note: the operator must be seated to enable lift / lower functions. 6.2j right hand unit lift/lower switch ____________________________ to lower the cutting unit move the switch lever forward. To raise the cutting unit move the switch lever rearwards note: if the pto is engaged when...

Page 45

En-43 6 controls m n p r 6.2l left hand unit lift/lower switch _____________________________ to lower the cutting unit move the switch lever forward. To raise the cutting unit move the switch lever rearwards note: the yellow pto led will illuminate when the pto is selected. The green led indicates t...

Page 46

En-44 6 controls a 6.3 traction pedal _______________________________________________ 1. Forward travel (traction pedal a) press the front of pedal down for forward travel. To slow and stop - gently return the fwd/rev foot pedal to the neutral position. Do not press traction pedal when parking brake...

Page 47

En-45 6 controls 6.5 horn _________________________________________________________ for machines without the lighting kit. The horn button (a) is situated on the foot plate. If the lighting kit is fitted the horn is located on the end of the indicator stalk. 6.6 power outlet ________________________...

Page 48

En-46 6 controls 6.8 parking brake release valve ________________________________ the parking brake release valve is situated under the seat plate, on the right hand chassis plate. It is used to release the parking brake when the engine is not running the parking brake can be released by rotating th...

Page 49

En-47 6 controls 7 8 x y z a 9 6.10 lighting kit (optional)___________________________________________ lighting control stalk a push away from operator to turn main beam on. B pull towards operator to flash headlights. C move stalk up to indicate right turn. D move stalk down to indicate left turn. ...

Page 50

En-48 7 operation 7.1 daily inspection ____________________________________________________ 1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardware and missing or damaged components. Check for fuel and oil leaks to ensure connections are tight and hoses and tubes ar...

Page 51

En-49 7 operation 7.2 operator presence and safety interlock system _________________ 1. The operator presence & safety interlock system prevents the engine from starting unless the parking brake is on, and the mowing device is switched off. The system stops the engine if the operator leaves the sea...

Page 52

En-50 7 operation 7.3 operating procedure _____________________________________________ 1. Under no circumstances should the engine be started without the operator seated on the tractor. 2. Do not operate tractor or attachments with loose, damaged or missing components. Whenever possible mow when gr...

Page 53

En-51 7 operation a b e d f c 9. Under no circumstances should the engine be started without the operator seated on the tractor. 10. Do not operate tractor or attachments with loose, damaged or missing components. 7.4 fitting the cutting unit to the machine_____________________________ front cutting...

Page 54

En-52 7 operation b a 7.5 operation of the machine _________________________________________ read the safety instructions. Before operating for the first time • check and adjust tyre pressure, if necessary, see section 4.2 specification. • add diesel fuel to tank if necessary. • check engine oil and...

Page 55

En-53 7 operation • do not move pedal suddenly–always operate slowly and smoothly. Never move pedal violently from forward to reverse or vice versa. • always keep foot firmly on the foot pedal–a too relaxed foot control may result in a jerky motion. 7.8 mowing _______________________________________...

Page 56: Note

En-54 7 operation 4) remove your foot from the forward/reverse pedal. 5) set the parking brake. 6) move the throttle control lever to the slow position. 7) turn the ignition key to the off position and remove the key. 8) use the ransomes jacobsen “cutting unit tool” part number 4184540 see below or ...

Page 57

En-55 7 operation a b c d ransomes jacobsen grinding paste: proccedure 1. Apply an even coat of backlapping compound to the entire length of each blade of the reel. 2. Turn the reel speed control valve counterclockwise (c) see section 6.8 reel speed control to allow reels to rotate at there slowest ...

Page 58

En-56 7 operation 7.12 transporting transport speed is for highway use only. Never select transport speed or 2 wheel drive off road. Transport in 2 wheel drive only. Make sure that the cutting units are held in the lifted position with the safety catches engaged. 1. Start the engine and set the thro...

Page 59

En-57 7 operation 7.13 mowing on slopes __________________________________________________ the mower has been designed for good traction and stability under normal mowing conditions. Use caution when operating on slopes, especially when the grass is wet. Wet grass reduces traction and steering contr...

Page 60

Safety, operators & maintenance manual en-58 7 operation warning when the machine is being used, whether cutting grass or not, on slopes, the rops frame should be deployed and the seat belt used.This rationale is based on the fact that a seat belt must be worn with a rops to comply with the machiney...

Page 61

En-59 7 operation slope calculation chart use either of these columns but not both the result of what you are measuring height ‘c’ in inches measured with a 1 yard horizontal edge ‘a’ height ‘c’ in millimeters measured with a 1 metre horizontal edge ‘a’ slope angle ‘d’ measured in degrees slope angl...

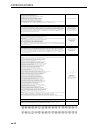

Page 62

En-60 8 maintenance & lubrication 8.1maintenance & lubrication chart ___________________________________ maintenance and lubrication chart interval item section first 50 hours change engine oil check fan belt tension change hydraulic filter 8.2 8.3 8.5 daily 10 hours check engine oil level. Check sa...

Page 63

En-61 8 maintenance & lubrication c c 8.2 8.2 8.2 8.3 8.4 8.5 8.5 8.7 8.7 8.8 8.9 c c a b b a c c e e d d.

Page 64

En-62 8 maintenance & lubrication a b c d 8.2 engine lubrication ________________________________________________ check engine oil level check the engine oil level before starting or more than five minutes after stopping the engine. (a) with the machine on level ground, remove the dipstick d, wipe i...

Page 65

En-63 8 maintenance & lubrication 8.3 engine: fan belt ____________________________________________________ check & adjust fan belt. The fan belt is adjusted so that it has sufficient tension to avoid undue stress on alternator bearings but does not slip on the alternator pulley. Use the following p...

Page 66

En-64 8 maintenance & lubrication b a 8.4 engine coolant ____________________________________________________ check engine coolant level (a) the level of coolant in the expansion tank should be between the max and min level indicators when cold. (b) if topping up is required, remove the plastic cap ...

Page 67

En-65 8 maintenance & lubrication a c b 8.5 hydraulic system __________________________________________________ check hydraulic oil level check hydraulic oil level using sight gauge (c). Change hydraulic oil (a) clean around hose (a) in bottom of hydraulic tank and remove. (b) allow tank to drain in...

Page 68

En-66 8 maintenance & lubrication c b a 8.6 hydraulic test ports _____________________________________________ if any problems are experienced with the hydraulic system service ports are provided to enable pressures to be checked. All tests, unless stated otherwise, should be carried out with the hy...

Page 69

En-67 8 maintenance & lubrication a b c d e 8.7 fuel system ________________________________________________________ use diesel fuel no.2-d (astm d975) bleeding air from fuel system (a) turn the ignition switch to the on position (don't start engine). (b) open air vent (b) on fuel filter housing to ...

Page 70

En-68 8 maintenance & lubrication 8.8 air cleaner________________________________________________________ cleaning the air filter note:after 6 cleanings replace the filter element. (a) raise engine cover. (b) remove end cap of air filter cartridge. (c) remove loose dirt from element with compressed ...

Page 71

En-69 8 maintenance & lubrication 8.10 machine maintenance_______________________________________________ other regular service. • verify proper operation of safety interlock switches (seat switch, etc.) • ensure nuts and bolts remain tight. • visually inspect for hydraulic leaks. • keep engine bay ...

Page 72

Safety, operators & maintenance manual en-70 8 maintenance & lubrication lubrication of cutting unit ____________________________________________ cutting reel bearings (a) hydraulic drive motor side. Cutting reel bearings (b) non drive side. Unit pivot (c) reel on cut adjusters if for any reason the...

Page 73

Safety, operators & maintenance manual en-71 8 maintenance & lubrication hydraulic motor drive shaft lower all cutting units onto level ground. Before leaving the driving position, stop the engine and make sure all moving parts are stationary. Apply brakes and disengage all drives. Remove the starte...

Page 74

En-72 9 adjustments a b c d 9.1 traction control pedal ________________________________________ the lpv transmission pump has an internal neutralising mechanism which cannot be adjusted. If the machine does however creep carry out the following. 1. Lift and support both front and rear wheels. 2. Rem...

Page 75

En-73 9 adjustments 9.3 cutting unit height of cut adjustment __________________________ to adjust spanner type: 1. Release the locknut under adjuster (a) on both sides of cutting unit. 2. Turn adjuster (a) at the rear of the unit clockwise to reduce the height of cut, or anticlockwise to increase t...

Page 76

En-74 9 adjustments 9.5 cutting cylinder to bottom blade adjustment _________________ to check that the cutting cylinder is set to the bottom blade correctly, hold a piece of thin paper between the edge of the blade and the spiral cutters and turn the cylinder manually. The paper should be cut clean...

Page 77

En-75 9 adjustments 9.6 cutting cylinder bearings _______________________________________ the cutting cylinder bearings are self adjusting taper roller bearings and require no adjustements. 9.7 front and rear roll bearings ___________________________________ the roll bearings are self adjusting tape...

Page 78

En-76 9 adjustments 9.9 general instructions for grammer seats ______________________ adjustments must not be made while driving. • after removal of the backrest upholstery, the backrest frame must be supported, for example held in place, • before the backrest adjuster is operated. If you fail to do...

Page 79

En-77 9 adjustments 9.10 seat (grammer msg85) ___________________________________________ the seat can be adjusted for operator's weight and leg reach to provide a comfortable position for operating the machine. 1. Adjustment for operator weight to adjust: rotate knob (a) to the right to increase th...

Page 80

En-78 9 adjustments 9.11 air suspension seat (grammer msg75 -521) _______________________ 9.11.1 weight adjustment______________________________________________ the seat is adjusted for the driver’s weight by pulling or pressing the lever for seat weight adjustment and with the driver sitting on the...

Page 81

En-79 9 adjustments 9.11.3 backrest extension * ** __________________________________________ the backrest extension can be individually adjusted by pulling it upwards or pushing it downwards over the various locking increments up the end stop. To remove the backrest extension, pull it upwards over ...

Page 82

En-80 9 adjustments 9.11.6 armrests * ** ____________________________________________________ the armrests can be folded up if required and the height individually adjusted. To adjust the armrests for height, separate the round cap (see arrow) from the cover, loosen the hexagon nut (size 13 mm) behi...

Page 83

En-81 9 adjustments 9.11.9 maintenance dirt can impair the function of the seat, so make sure you keep your seat clean! Upholstery does not need to be removed from the seat frame for cleaning. Caution: take care with the backrest - it may jerk forward and cause injury! When cleaning the backrest cus...

Page 84

En-82 10 accessories 10.4 rotary beacon kit _______________________________________________ kit number lmac290. 10.5 light kit__________________________________________________________ kit number lmac260. Storage racks, kit number lmac272 are included in the light kit. Maximum capacity per rack is 5...

Page 85

En-83 10 accessories 10.6 mirror kit________________________________________________________ kit number lmac270. 10.7 storage racks __________________________________________________ kit number lmac272. Maximum capacity per rack is 5kg..

Page 86

En-84 10 accessories notes.

Page 87

En-85 11 problem solving .1 problem solving general ______________________________________________________ symptoms possible causes action engine will not start glow plug has not timed out reset ignition switch and allow glow plug to time out before cranking engine. Battery low on charge or defectiv...

Page 88

En-86 12 quality of cut it is recommended that a “test cut” be performed to evaluate the mower’s performance before beginning repairs. An area should be available where “test cuts” can be made. This area should provide known and consistent turf conditions to allow accurate evaluation of the mower’s ...

Page 89

En-87 12 quality of cut 12.2 marcelling______________________________________________________ note: arrow indicates direction of travel. Marcelling, like washboarding, is a cyclical pattern of varying cutting heights, resulting in a wave-like cut appearance. In most cases, the wave tip-to-tip dis- t...

Page 90

En-88 12 quality of cut 12.3 step cutting _____________________________________________________ note: arrow indicates direction of travel. Step cutting occurs when grass is cut taller on one side of a reel than the other or one cutting unit to an- other. This is usually caused by mechanical wear or ...

Page 91

En-89 12 quality of cut 12.4 scalping ________________________________________________________ note: arrow indicates direction of travel. Scalping is a condition in which areas of grass are cut noticeably shorter than the surrounding areas, resulting in a light green or even brown patch. This is usu...

Page 92

En-90 12 quality of cut 12.5 stragglers ______________________________________________________ note: arrow indicates direction of travel. Stragglers are scattered blades of uncut or poorly cut grass. Probable cause remedy bedknife improperly adjusted. Adjust reel-to-bedknife setting. Dull reel or be...

Page 93

En-91 12 quality of cut 12.6 streaks _________________________________________________________ note: arrow indicates direction of travel. A streak is a line of uncut grass. This is usually caused by a nicked or bent bedknife. Probable cause remedy damaged bedknife. Replace bedknife. Damaged or uneve...

Page 94

En-92 12 quality of cut 12.7 windrowing ______________________________________________________ note: arrow indicates direction of travel. Windrowing is the deposit of clippings concentrated at one end of cutting unit(s) or between two cutting units, forming a line in the direction of travel. Probabl...

Page 95

En-93 12 quality of cut 12.8 rifling or tramlining ___________________________________________ 12.9 mismatched cutting units _______________________________________ note: arrow indicates direction of travel. Rifling or tramlining is a pattern of varying cutting heights, resulting in a wave-like cut ...

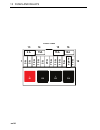

Page 96: 10 A

En-94 13 fuses and relays 10 a 2 1 spar e 5 a 10 a 10 a 7.5 a 20 a 5 a 10 a 10 a 5 a 1 5 a a 0 1 6 1 a 5 1 5 1 a 5 1 4 1 a 2 3 1 r1 r2 r3 r4 front view.

Page 97

En-95 13 fuses and relays 13.1 fuse and relay identification____________________________________ fuse number function 1 left hand side lamps 2 right hand side lamps 3 left hand head lamps 4 right hand head lamps 5 beacon 6 plus one supply 7 ignition on circuits 8 direction indicators 9 hazard lamps ...

Page 98

En-96 14 guarantee warranty warranty is subject to specific terms and conditions, e.G. Wearing parts, unapproved modifications, etc. Are not included. For a full set of warranty conditions, contact your local dealer or distributor. Service a network of authorised sales and service dealers has been e...

Page 100

Europe & rest of the world except north & south america ransomes jacobsen limited west road, ransomes europark, ipswich, ip3 9tt english company registration no. 1070731 www.Ransomesjacobsen.Com north & south america jacobsen, a textron company 11108 quality drive, charlotte, nc 28273, usa www.Jacob...