- DL manuals

- Ransomes

- Lawn Mower

- Mastiff 91

- Safety, Operation & Maintenance Manual

Ransomes Mastiff 91 Safety, Operation & Maintenance Manual

®

RJL 100 January 2015

GB

United

Kingdom

Safety, Operation & Maintenance Manual

Ransomes Mastiff 91 - Honda GX390 UT2 LXE4

Series: FN4 & FP4

Product code: LDEA330 & LDEA340

WARNING

WARNING: If incorrectly used this machine can

cause severe injury. Those who use and maintain

this machine must be trained in its proper use,

warned of its dangers and must read the entire

manual before attempting to set up, operate, adjust

or service the machine.

25081G-GB (Rev.0)

Summary of Mastiff 91

Page 1

® rjl 100 january 2015 gb united kingdom safety, operation & maintenance manual ransomes mastiff 91 - honda gx390 ut2 lxe4 series: fn4 & fp4 product code: ldea330 & ldea340 warning warning: if incorrectly used this machine can cause severe injury. Those who use and maintain this machine must be trai...

Page 2

1 contents © 2015, ransomes jacobsen limited. All rights reserved introduction important ....................................................................... 3 product identification ..................................................... 4 guidelines for the disposal of scrap products .......... 5...

Page 3

En-3 introduction 2 2.1 important __________________________________________________________ the ransomes mastiff is a petrol-engine chain driven cylinder mower. The cutting cylinder is chain driven. An opc safety system is fitted. Important: follow the maintenance schedule indicated in this manual....

Page 4

En-4 2 introduction 2.2 product identification ___________________________________________ a maximum front axle load in kg (for the machines driven on the highway) b gross weight in kg c maximum rear axle load in kg (for the machines driven on the highway) d power in kw e date code f machine type g ...

Page 5

En-5 introduction 2 2.3guidelines for the disposal of scrap products _____________________ 2.3.1 during service life _______________________________________________ used oil, oil filters and engine coolant are hazardous materials. Follow the recommended procedures for their safe disposal. If a fluid...

Page 6

En-6 2 introduction 2.4 parts manual ______________________________________________________ in compliance with the iso14001 standard, ransomes jacobsen limited does not send a paper parts manual with every product. The parts manuals are available on-line or from ransomes jacobsen. 1. Website – www.R...

Page 7

En-7 introduction 2 d c a b 2.6 assembly___________________________________________________________ a. Remove the sides and top of the container from the mower. Leave the mower on the base. B. Remove the plastic cover and cable ties that hold the handles in position. Assembly the handle assembly (a)...

Page 8: Warning

En-8 3 safety 3.1 how to operate safely __________________________________________________ 3.2 safe operation a. Read the operator’s manual and other training material. If the operator or technician can not read this manual, the owner is responsible to describe this material to the operators and tec...

Page 9

En-9 safety 3 3.4 operation a. Never operate the engine without enough ventilation or in an enclosed area. The carbon monoxide in the exhaust fumes can increase to dangerous levels. B. Never carry passengers. Keep other persons or animals away from the mower. C. Disengage all drives and engage the p...

Page 10

En-10 3 safety 3.5 safe handling of fuels a. The fuel and the fuel vapors are flammable. Use caution when you add the fuel to the mower. The fuel vapors can cause an explosion. B. Never use the containers that are not approved to keep or transfer fuel. C. Never keep the mower or fuel containers near...

Page 11

En-11 safety 3 3.7 when you put the mower on a trailer a. Be careful when you load or unload the mower on a trailer. Trailer must be wider than the mower and can carry the weight of the mower. B. Use a full-width ramp to load or unload the mower on a trailer. C. Use straps, chains, cables or ropes t...

Page 12

En-12 3 safety 3.7.1 important safety notes this safety alert symbol is used to alert you to possible hazards. Danger indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning indicates a potentially hazardous situation which, if not avoided, ...

Page 13

En-13 safety 3 warning california proposition 65 engine exhaust, some of its constituents, and some vehicle components contain or release chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. Warning explosive gases are released by batteries. The ba...

Page 14

En-14 3 safety warning never mow if there is a risk of lightning or you hear thunder. If you are in the middle of mowing, stop in a safe place, turn off the engine and go inside a building. Caution personal protective equipment (ppe), for example safety glasses, leather work shoes or boots, a hard h...

Page 15

En-15 safety 3 notes.

Page 16

En-16 4 decals 4.1 safety decals ec___________________________________________________ a. 009034910read operator's manual. B. 009034890keep a safe distance from the machine. C. 009034920stay clear of hot surfaces. D. 009034940caution rotating blades. E. 009034900do not remove safety shields while en...

Page 17

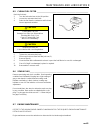

En-17 decals 4 4.2 instruction decals _________________________________________________ a 009034760 - decal - noise 100db b 4329286 - decal - ignition c 009034990 - decal - forward / reverse d 4157021 - decal - throttle e 009039700 - decal - parking brake a 4329286 009034990 b c d e.

Page 18

En-18 5 controls f 4329286 g 5.1 throttle control (a)_______________________________________________ move the throttle lever forward to increase the engine speed which in turn engages the centrifugal clutch thus driving the machine. The direction of travel and blade engagement is determined by the g...

Page 19: Note

En-19 controls 5 cold hot b 5.7 choke control ____________________________________________________ move the choke lever to the closed position to start the engine. 5.8 fuel tap ___________________________________________________________ the fuel tap (b) is turned on by moving the lever to the right....

Page 20: Caution

En-20 6 operation 6.1 daily inspection _____________________________________________________ 1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardware and missing or damaged components. Check for fuel and oil leaks to ensure connections are tight and hoses and tubes a...

Page 21: Warning

En-21 operation 6 6.2 operator presence and safety interlock system _________________ 1. The engine can be started but drive cannot be engaged until the operator presence system has been engaged. When the primary drive is engaged the machine will move forward, the cylinder will only rotate if the cy...

Page 22: Caution

En-22 6 operation 6.3 operating procedure ______________________________________________ 1. Under no circumstances should the engine be started with the operator presence system engaged. 2. Do not operate the machine or attachments with loose, damaged or missing components. Whenever possible mow whe...

Page 23: Caution

En-23 operation 6 b a 8. Stop and inspect the equipment for damage immediately after striking an obstruction or if the machine begins to vibrate abnormally. Have the equipment repaired before resuming operation. 6.4 before starting the engine for the first time ___________________ 1. Remove the sump...

Page 24: Note

En-24 6 operation d 6.5 starting the engine ________________________________________________ 1. Electric start apply the brake.Turn starter switch (f) clockwise to the first position, then turn further clockwise to the start position and engine will start. If engine fails to start within 10 seconds,...

Page 25: Note

En-25 operation 6 b before starting the engine, check or set the following points: 1. Check that the cylinder and landroll drive clutches are disengaged and the brake is applied. 2. Turn the fuel tap b ‘on’ by positioning the lever vertically downwards. 3. Move the choke control lever to the left fo...

Page 26: Note

En-26 6 operation 6.8 how to remove a blockage from cutting units ____________________ 1) disengage the power to the cutting unit. 2) set the parking brake. 3) move the throttle control lever to the slow position. 4) turn the ignition key to the off position and remove the key. 8) use the ransomes j...

Page 27

En-27 operation 6 notes.

Page 28: Note

En-28 7 adjustments 7.1 height of cut adjustment __________________________________________ the cutting height is determined by the position of the front rolls in relation to the bottom blade; variation of this setting is made by adjusting the front roll: 1. Loosen the bolts securing the front roll ...

Page 29: Note

En-29 adjustments 7 7.3 cylinder to bottom blade adjustment_____________________________ to check that the cutting cylinder is set correctly to the bottom blade: tilt the machine back, hold a thin piece of paper between the edge of the blade and spiral cutters, and turn the cylinder manually. Wear g...

Page 30

En-30 7 adjustments 7.5 chain tensioners __________________________________________________ automatic adjustment self adjusting chain tensioners need no adjustment. 7.6 brake _____________________________________________________________ if adjustment is necessary: 1. Slacken the locknut (a). 2. Turn...

Page 31

En-31 adjustments 7 7.8 removing the cutting cylinder and bottom blade assembly _______ 1. Remove the chaincase and the cylinder drive chain. 2. Tilt the machine back until it rests on the handles. Ensure ithe machine is fully supported before continuing 3. Remove the front roll by extracting the pi...

Page 32

En-32 7 adjustments 7.10 balance bar (walk behind machines only) _________________________ when the machine is used without the grassbox fitted, the balance bar (fig. 39), fitted at the base of the handle, must be removed and fitted to the grassbox arms. 7.11 seat (steering seat) ___________________...

Page 33: Note

En-33 adjustments 7 a b a b a b c f e g h j d 7.13 testing gear selection ____________________________________________ perform the following tests to determine the correct function of the gear selection mechanism; do not use the machine until any failures have been rectified 1. Select forward drive ...

Page 34

En-34 7 adjustments k l 8. Change the length of the gear lever by rotating the clevis joint until the holes in the clevis joint (k) and the hole in the bell crank (l) align. 9. Refit the locating pin and repeat the checks detailed in section 9.13. 10. If all checks are passed extend the gear lever b...

Page 35

En-35 adjustments 7 notes.

Page 36

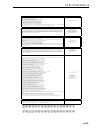

En-36 8 maintenance and lubrication 8.0 maintenance & lubrication chart __________________________________ 9 maintenance and lubrication chart machine service interval chart interval item section first 20 hours change engine oil 8.2.1 daily 10 hours check engine oil level. Clean around engine exhaus...

Page 37

En-37 maintenance and lubrication 8 8.2.1 8.2.1 8.2.6 8.2.5 8.3.4 8.2.2.

Page 38: Note

En-38 8 maintenance and lubrication b a 8.1 lubrication ________________________________________________________ before using the machine for the first time lubricate all points. For recommended lubricants see section 8.1. Should the number of working hours that the machine is in use during the indi...

Page 39: Caution

En-39 maintenance and lubrication 8 8.1.2 machine __________________________________________________________ lubricate the following with engine oil: cutting cylinder bearings (a). Front rolls, or side rolls, where fitted (b). Landroll bearing housings (c). Outer landrolls on 91cm (36in) machine. 8....

Page 40: Caution

En-40 8 maintenance and lubrication 8.1.5 gearbox ___________________________________________________________ check oil level (a) release screws on both sides of cover and remove cover over gearbox and clutch shaft. (b) remove filler plug (c) and using the straight dipstick check level of oil. (c) t...

Page 41

En-41 maintenance and lubrication 8 h b c d e a e g f a a b 8.2 maintenance 8.2.1 cooling fins and air intake ____________________________________________ check to ensure that the air blower and cooling fins (a) linkages and exhaust (b) are kept free of all grass clippings and debris. This is essent...

Page 42: Caution

En-42 8 maintenance and lubrication 8.3 battery ____________________________________________________________ before you service the battery, make sure the ignition switch is in the off position and the key is removed. Keep the battery terminals tight, to prevent corrosion, apply a layer of silicone ...

Page 43

En-43 maintenance and lubrication 8 c b a 8.5 clean fuel filter __________________________________________________ drain the fuel tank 2 turn the fuel valve lever to the on position. 3 loosen the carburetor drain bolt. 4 drain the fuel from the carburetor and fuel tank into an approved container. 5 ...

Page 44

En-44 9 problem solving 9.1 problem solving general fault remedy variations in the height of cut grass across the width of cut front rolls are not square with bottom blade. Make necessary adjustment as per instruction in section 7.1 grass is cut unevenly in wavy or hummocky fashion alignment of cutt...

Page 45

En-45 problem solving 9 notes.

Page 46

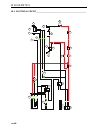

En-46 10 schematics m w/g w/r 00 00 1 3 2 5 4 (ig n it io n sw it c h ) 1 2 3 r/ w g/k g/p b 1 b 2 g/p 3 n/ b 2 g/b 1 w 2 r 1 r 4 w 3 b/ w 2 b 1 r w b/ w b r 1 1 b 2 r 1 y b/ w b/ w w w/g w/ r n/ b g/b y b g/k w w/g w w w w b r y w/g w/ r r/w w b b b b b 12 12 12 12 12 w s1 y 1 y u s b 1 3 2 5 4 bat...

Page 47

En-47 schematics 10 12.1 electrical circuit 1 starter solenoid (battery positive) 2 starter solenoid (actuator) 3 starter motor 4 battery 5 engine ground 6 ignition coil 7 spark plug 8 emergency kill switch 9 ignition switch 10 start control 11 stop relay 12 gear switch 13 operator presence control ...

Page 48

En-48 11 torques 11.1 torques ____________________________________________________________________ fine pitch metric threads dia (mm) grade 4.6 grade 4.8 grade 8.8 grade 10.9 grade 12.9 (nm) (nm) (nm) (nm) (nm) 6 0 0 0 0 0 8 12 16 32 45 54 10 24 31 63 88 106 12 42 57 113 159 191 14 67 90 179 252 302...

Page 49

En-49 specifications 12 12.1 engine specification _______________________________________________ 12.2 dimensions & weights ______________________________________________ manufacture honda model id honda gx390 ut2 lxe4 type air cooled 4 stroke overhead valve single cylinder 389 cm³ petrol with 2:1 r...

Page 50

En-50 12 specifications 12.3 machine specification ______________________________________________ chassis: pressed steel welded fabrication. Transmission: gearbox with half speed reverse to heavy duty roller chains to land roll and cutting cylinder. Clutches: main centrifugal clutch. Separate land r...

Page 51

En-51 specifications 12 12.4 vibration level ____________________________________________________ the machine was tested for hand/arm vibration levels. The operator was in the normal position to drive the vehicle, with two hands on the steering mechanism. The engine was in operation and the cutting ...

Page 52

En-52 12 specifications 12.5 noise level ________________________________________________________ when the machine was tested for sound pressure (operator ear). The machinery safety directive 2006/42/ec and exposure of workers to the risks arising from physical agents (noise) directive 2003/10/ec by...

Page 53

En-53 specifications 12 (10% allowance is included for normal overlaps and turning at the end of each cut. 12.9 recommended lubricants__________________________________________ engine oil:should be to mil-l-2104b/ or to a.P.I. Classification sc grades and as givenin the table below: gearbox oil:sae ...

Page 54

En-54 12 specifications %xvlqhvvqdphdqgixoodgguhvvriwkhpdqxidfwxuhuƒɌɴɪɝɨɜɫɤɨɢɦɟɢɩɴɥɟɧɚɞɪɟɫɧɚɩɪɨɢɡɜɨɞɢɬɟɥɹƒ 2efkrgqtmppqrdsoqidguhvdyêurefhƒ3urgxfhqwhqvilupdqdyqrjixoghdguhvvhƒ%hgulmivqddphqyroohgljdguhvydqghideulndqwƒ7rrwmdlulqlplmdwllholnddguhvvƒ 9doplvwdmdqwrlplqlplmdwl\ghoolqhqrvrlwhƒ1rpfrpphufl...

Page 55

En-55 specifications 12 2shudwru(du1rlvh/hyhoƒɈɩɟɪɚɬɨɪɧɚɧɢɜɨɬɨɧɚɞɨɥɨɜɢɦɨɬɭɯɨɬɨɲɭɦƒ +odglqdkoxnxyreodvwlxãtrshuiwrudƒ6w¡mqlyhdxli¡uhuv¡uhk¡mghƒ *hoxlgvqlyhdxrruehvwxxughuƒ0udwdvhrshuddwruln}uydvƒ 0hoxwdvrnl\wwlmlqnruydqnrkgdoodƒ1lyhdxgheuxlwjkdxwhxughvruhloohvgho¶rspudwhxuƒ 6fkdooshjhodp%hglhqhurkuƒ...

Page 56

En-56 12 specifications ransomes jacobsen limited west road, ransomes europark, ipswich, england, ip3 9tt product code serial number lmab029 yd wir verpflichten uns, auf eine begründete aufforderung durch die nationalen behörden hin, relevante informationen über die teilgefertigte maschine zu überse...

Page 57

En-57 specifications 12 ransomes jacobsen limited west road, ransomes europark, ipswich, england, ip3 9tt 1st december 2014 mbg5208 (rev.5) 'dƺƝmlsdehljwxlhnƗuwxqhguƯnvwqrgrwhnvsoxdwƗflmƗoƯg]jdoƯjƗlhnƗuwdnxuƗwƗlumƗlhenjyƝlughnoduƝwddwelovwrãlgluhnwƯydv1u(.Qrwhlnxplhp ,opdnnlqdumxolmnxqsdu]mdophqwohvw...

Page 58

En-58 12 specifications ransomes jacobsen limited west road, ransomes europark, ipswich, england, ip3 9tt product code serial number lmac253 ft we zijn van plan, in reactie op een redelijk verzoek van de nationale autoriteiten, relevante informatie over de gedeeltelijk voltooide machinerie te verzen...

Page 59

En-59 specifications 12 ransomes jacobsen limited west road, ransomes europark, ipswich, england, ip3 9tt 1st october 2014 4157569 (rev.1) c d clifford engineering director 1st october 2014 ransomes jacobsen limited west road, ransomes europark, ipswich, england, ip3 9tt &huwlilfdwh1xpehuƒɇɨɦɟɪɧɚɫɟɪ...

Page 60

En-60 13 guarantee warranty warranty is subject to specific terms and conditions, e.G. Wearing parts, unapproved modifications, etc. Are not included. For a full set of warranty conditions, contact your local dealer or distributor. Service a network of authorised sales and service dealers has been e...

Page 62

Europe & rest of the world except north & south america ransomes jacobsen limited west road, ransomes europark, ipswich, ip3 9tt english company registration no. 1070731 www.Ransomesjacobsen.Com north & south america jacobsen, a textron company 11108 quality drive, charlotte, nc 28273, usa www.Jacob...