- DL manuals

- Rapid

- Air Handlers

- 4024

- Installation, Operation & Service Manual

Rapid 4024 Installation, Operation & Service Manual

NOT FOR RESIDENTIAL USE

WARNING

Installation must be done by a contractor qualified

in the installation and service of gas-fired heating

equipment or your gas supplier.

Improper installation, adjustment, alteration, service

or maintenance can result in death, injury or

property damage. Read the Installation, Operation

and Service Manual thoroughly before installing or

servicing this equipment.

Installer

Please take the time to read and understand

these instructions prior to any installation.

Installer must give a copy of this manual to the owner.

Owner

Keep this manual in a safe place in order to provide

your service technician with necessary information.

Rapid Engineering LLC

1100 Seven Mile Road NW

Comstock Park, MI 49321

Telephone: +1.616.784.0500

Fax: +1 616.784.0435

www.rapidengineering.com

© 2018 Rapid Engineering LLC

WARNING

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. DO NOT try to light any appliance.

3. DO NOT use electrical switches.

4. DO NOT use any telephone in

your building.

5. Extinguish any open flame.

6. Leave the building.

7. Immediately call your local gas

supplier after leaving the building.

Follow the gas supplier’s

instructions.

8. If you cannot reach your gas

supplier, call the Fire Department.

Fire Hazard

Keep all flammable objects, liquids and

vapors the minimum required clear-

ances to combustibles away from

equipment.

Some objects will catch fire or explode

when placed close to equipment.

Failure to follow these instructions can

result in death, injury or property

damage.

CANADA: 100% OUTSIDE AIR ONLY

Rapid

®

4000-Series

Direct-Fired Air Handler

Installation, Operation &

Service Manual

4024

4036

4040

4044

4049

4054

4060

4066

4073

4080

4089

P/N RP140000NA Rev A 03/18

Summary of 4024

Page 1

Not for residential use warning installation must be done by a contractor qualified in the installation and service of gas-fired heating equipment or your gas supplier. Improper installation, adjustment, alteration, service or maintenance can result in death, injury or property damage. Read the inst...

Page 3

Table of contents section 1: air handler safety.............................................. 1 1.1 description of operation............................................... 1 1.2 inspection and setup ................................................... 1 1.3 temporary storage.............................

Page 5

List of tables table 1: recommended torque settings................................. 8 table 2: 4000 am dimensions ............................................... 11 table 3: 4000 am approximate shipping weights ................. 12 table 4: 4000 mua dimensions..........................................

Page 7

Table of figures figure 1: 4024 - 4049................................................................ 3 figure 2: 4054 and 4089 ........................................................... 4 figure 3: 4000-series interior ................................................... 5 figure 4: 4000 am vertic...

Page 9

Section 1: a ir h andler s afety 1 of 154 section 1: air handler safety your safety is important to us! This symbol is used throughout the manual to notify you of possible fire, electrical or burn hazards. Please pay special attention when reading and following the warnings in these sections. Instal...

Page 10

4000-s eries i nstallation , o peration and s ervice m anual 2 of 154 1.3 temporary storage if the air handler must be temporarily stored (ie. Job site is not ready for installation of the air handler), the following procedure should be performed. After unloading unit from truck, place on a flat cle...

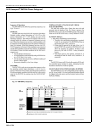

Page 11

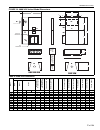

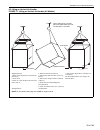

Section 1: a ir h andler s afety 3 of 154 1.6 label placement figure 1: 4024 - 4049 bd bd oa oa 7 11 7 vertical control side vertical opp. Control side horizontal opp. Control side horizontal control side 3 on shrink wrap 1 1 2 4 4 4 4 5 6 6 2 5 if used. 2 5 2 5 item part number description 1 19305 ...

Page 12

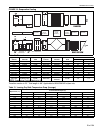

4000-s eries i nstallation , o peration and s ervice m anual 4 of 154 figure 2: 4054 and 4089 bd bd oa lifting rings oa lifting rings vertical control side vertical opp. Control side horizontal opp. Control side horizontal control side access door gas connection 6 x 2 x 12ga channel base frame disco...

Page 13

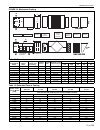

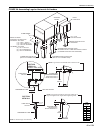

Section 1: a ir h andler s afety 5 of 154 figure 3: 4000-series interior 1 cone plate 12 13 2 12 motor & motor cooling duct inside control enclosure 8 9 7 7 9 2 control enclosure door prop 65 label rating tag electrical print rh inside wall control enclosure lh inside wall control enclosure 11 10 3 ...

Page 14: Warning

4000-s eries i nstallation , o peration and s ervice m anual 6 of 154 section 2: installer responsibility the installer is responsible for the following: • to install and commission the air handler, as well as the gas and electrical supplies, in accordance with applicable specifications and codes. R...

Page 15

Section 2: i nstaller r esponsibility 7 of 154 the air handler and accessories may be placed in a safe manner. The qualified installer or service technician is responsible for having the appropriate equipment for the safe installation and start-up of an industrial air handler. Tools required to comm...

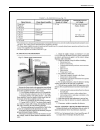

Page 16: Warning

4000-s eries i nstallation , o peration and s ervice m anual 8 of 154 section 3: critical considerations 3.1 required clearances to combustibles clearances are the required distances that combustible objects must be away from the air handler to prevent fire hazards. Combustibles are materials that m...

Page 17

Section 4: n ational s tandards and a pplicable c odes 9 of 154 section 4: national standards and applicable codes 4.1 gas codes the type of gas appearing on the nameplate must be the type of gas used. Installation must comply with national and local codes and requirements of the local gas company. ...

Page 18

4000-s eries i nstallation , o peration and s ervice m anual 10 of 154 section 5: specifications dimension and estimated weight tables apply to both vertical and horizontal units of the same style. All dimensions are in inches and all weights are in pounds, but are subject to change without notice. ...

Page 19

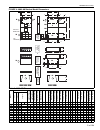

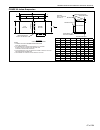

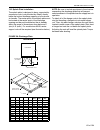

Section 5: s pecifications 11 of 154 figure 4: 4000 am vertical model dimensions table 2: 4000 am dimensions mod e l air handler base f rame f o rm ed channel base f rame str u ct ur al an g le f il ter s ecti on w idth f il ter mi xbo x len g th f il ter mi xbo x len g th wi th s id e r e tu rn dis...

Page 20

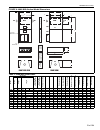

4000-s eries i nstallation , o peration and s ervice m anual 12 of 154 figure 5: 4000 am horizontal model dimensions table 3: 4000 am approximate shipping weights oa b f bd ud ld/rd q s electrical connection gas connection br ce v lr n rr t h & (h1) g v y x z a oa rd bd/ud br br a m k k j l d e c n ...

Page 21

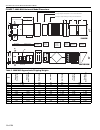

Section 5: s pecifications 13 of 154 figure 6: 4000 mua vertical model dimensions table 4: 4000 mua dimensions model air handler ba se f ram e f o rm ed channel ba se f ram e s tr u ct ur al an g le f ilt er sect ion w idth disc har g e len g th disc har g e w idth disc har g e hei g ht mini m u m l...

Page 22

4000-s eries i nstallation , o peration and s ervice m anual 14 of 154 figure 7: 4000 mua horizontal model dimensions table 5: 4000 mua approximate shipping weights model ho ri z o n tal fa n s e c ti o n ho ri z o n tal bur n er sectio n f ilt er s e ctio n inlet hoo d inle t plen u m v e rt ical f...

Page 23

Section 5: s pecifications 15 of 154 figure 8: 4000 fr vertical model dimensions table 6: 4000 fr dimensions model air handler bas e f ram e f o rm e d channel bas e f ram e str u ct ur al an g le ou ts id e a ir l e n g th f il ter s tand hei g ht disc h a rg e l e n g th disc har g e w id th disc ...

Page 24

4000-s eries i nstallation , o peration and s ervice m anual 16 of 154 figure 9: 4000 fr horizontal model dimensions table 7: 4000 fr approximate shipping weights b q z ud f bd ld/rd 80% (optional) gas connection 80% (optional) w oa a oa x t s r br p r ce fj e c d l j k m a k rd bd/ud ce fj electric...

Page 25

Section 5: s pecifications 17 of 154 figure 10: 4000 vav vertical model dimensions table 8: 4000 vav dimensions mod e l air handler base f ra m e fo rm e d c h a n n e l base f ra m e str u c tur al an g le f ilt e r s e c tion w idt h mi nim u m le g hei g ht disc har g e l e n g th disc har g e w ...

Page 26

4000-s eries i nstallation , o peration and s ervice m anual 18 of 154 figure 11: 4000 vav horizontal model dimensions table 9: 4000 vav approximate shipping weights c k a m k j l fj g n x y z gas connection f b 20% to 100% ai r electrical connection bd ce ce bd oa oa fj ad1 ad2 ad1 ad2 d e a fan se...

Page 27

Section 5: s pecifications 19 of 154 figure 12: evaporative cooling table 10: dimensions note: evaporative cooling section is 42". Transition section is 24". Total length is 66". Applicable for mua/am/vav styles only. Table 11: leaving dry bulb temperature drop (average) note: rapid engineering llc'...

Page 28

4000-s eries i nstallation , o peration and s ervice m anual 20 of 154 table 12: air density ratio note: table to be used when calculating total tonnage of cooling adjusted for elevation. Temperature (°f) density ratio for stated elevation (ft/in hg) 0/ 29.92 1,000/ 28.86 2,000/ 26.82 3,000/ 26.82 4...

Page 29

Section 5: s pecifications 21 of 154 figure 13: mechanical cooling table 13: dimensions table 14: estimated tons of cooling oa bd ud ld/rd electrical connection gas connection br ce oa rd bd/ud ce fj ld fj ad1 ad2 ad1 ad2 plan view right side view fan section burner section coil section (optional) e...

Page 30

4000-s eries i nstallation , o peration and s ervice m anual 22 of 154 figure 14: energy recovery table 15: dimensions fj gas connection electrical connection bd/ud ud bd rd ld/rd ld ce ce oa oa fj ad1 ad2 ad1 ad2 fan section burner section coil section (optional) evaporative cooler (optional) filte...

Page 31

Section 5: s pecifications 23 of 154 table 16: energy recovery note: model sizes apply to mua style cabinets. Consult factory when selecting energy recovery for am style cabinets. All weights are in pounds. Compatible cabinet size supply/exhaust air cubic feet per minute (cfm) pressure drop (in wc) ...

Page 32

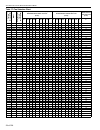

4000-s eries i nstallation , o peration and s ervice m anual 24 of 154 table 17: fan selection chart ai rf lo w c u b ic fe e t p e r min u te (cfm) model disc har g e v e lo city fe e t p e r min u te (fpm) required motor horse power (hp) @ noted external static pressure (in wc) brake horse power (...

Page 33

Section 5: s pecifications 25 of 154 table 18: fan selection chart (continued) * mua configuration only. ** am requires high velocity return air damper. ¤ class ii wheels cf= consult factory important notes: sound levels are in dba at 5' from the supply air opening. This figure does not account for ...

Page 34

4000-s eries i nstallation , o peration and s ervice m anual 26 of 154 table 19: static pressure drops for options note: calculate the static pressure for selected cabinet options plus any ductwork. Use external static pressure column found in page 24, table 17 through page 25, table 18 fan selectio...

Page 35: Warning

Section 6: l ifting an a ir h andler (r igging ) 27 of 154 section 6: lifting an air handler (rigging) the air handler must be installed in compliance with all applicable codes. The qualified installer or service technician must use best building practices when installing the air handler and any opt...

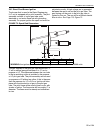

Page 36

4000-s eries i nstallation , o peration and s ervice m anual 28 of 154 6.2 lifting a horizontal air handler figure 15: lifting a horizontal air handler filter section and options (model 4024 - 4049) figure 16: lifting a horizontal air handler with options (model 4054 - 4089) lifting slings end view ...

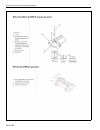

Page 37

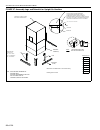

Section 6: l ifting an a ir h andler (r igging ) 29 of 154 6.3 lifting an vertical air handler figure 17: lifting an vertical air handler (all models) b a c b a c b a c wooden blocks base frame base frame note: sheet metal channel or angle iron frame must be aligned on all sections inlet shipping po...

Page 38

4000-s eries i nstallation , o peration and s ervice m anual 30 of 154 figure 18: lifting an vertical air handler with filter section and mixing box lifting lugs bu rner remove lifting eye bolts after setting section fil ter se ct. Se ct ion mix box sec tion fa n & fil te r s ect. Sectio n mix b ox ...

Page 39

Section 6: l ifting an a ir h andler (r igging ) 31 of 154 6.4 upright assembly alignment figure 19: inlet alignment rope wall external caulking field joint section view-a burner inlet/fan disch. Section filter mixbox disch./burner inlet alignment detail. (for uprights models 49-89 only) 5/8 x 2 3/4...

Page 40: Warning

4000-s eries i nstallation , o peration and s ervice m anual 32 of 154 section 7: air handler assembly for models 4024 - 4049, the burner and fan sections of the air handler are shipped as one piece. Filter section and/or filter mix box can be mounted to air handler when requested. For models 4054 -...

Page 41

Section 7: a ir h andler a ssembly 33 of 154 7.1 caulking the air handler figure 20: caulking air handler joints 3" (78.7 cm) roof tape provided by manufacturer (not required on vertical air handler or indoor units) housing skin housing skin caulk after assembly housing skin 3/8" x 3/4" strip clean ...

Page 42

4000-s eries i nstallation , o peration and s ervice m anual 34 of 154 7.2 caulking a horizontal air handler figure 21: caulking a standard horizontal air handler note: sections may vary as shown. A ple nu m inl et a inlet b bur ner fa n sec tio n sec tio n b horizontal air handler with inlet plenum...

Page 43

Section 7: a ir h andler a ssembly 35 of 154 7.3 caulking an vertical air handler figure 22: caulking a standard vertical air handler note: sections may vary as shown. Sheetmetal channel or angle iron frame must be aligned on all sections. Rain skirt on outdoor air handler "aÓ "aÓ "aÓ "aÓ legs "a" l...

Page 44

4000-s eries i nstallation , o peration and s ervice m anual 36 of 154 figure 23: assembling optional discharge / supply and return sleeves. - - typical assembly 3'-4" 3'-4" typical assembly note:discharge and return air sleeve's are a option and can be purchased thru rapid, see chart for actual od ...

Page 45

Section 7: a ir h andler a ssembly 37 of 154 7.4 accessory connections figure 24: electrically connecting joined sections figure 25: installing cooling coil section filter mixbox bd left side view lc br burner section fan section oa 1/2" conduit typ. Control cabinet wall detail a note: typically 6 t...

Page 46

4000-s eries i nstallation , o peration and s ervice m anual 38 of 154 figure 26: installing pressure transmitter tubing for am and vav figure 27: typical freeze protection (evaporative cooling package #1) modus lo hi protect tubing opening from the wind. (installed by others.) outside air duct buil...

Page 47

Section 7: a ir h andler a ssembly 39 of 154 figure 28: conductivity control and freeze protection (evaporative cooling package #2) figure 29: protection and auto-flush (evaporative cooling package #3) header evaporative cooling module float valve & make-up conn. Manual shut-off valve overflow conn....

Page 48

4000-s eries i nstallation , o peration and s ervice m anual 40 of 154 figure 30: evaporative cooling trap detail.

Page 49: Warning

Section 8: r oof c urb 41 of 154 section 8: roof curb the roof curbs that support the air handler and accessory sections are available for all horizontal air handlers. See page 41, table 20 for roof curb. Roof curbs are shipped unassembled and require field assembly. Double check dimensions after as...

Page 50

4000-s eries i nstallation , o peration and s ervice m anual 42 of 154 figure 31: roof curb note: adapter shown for models 4024 through 4089 horizontal am, fmb and mua..

Page 51

Section 8: r oof c urb 43 of 154 figure 32: roof curb installation counter flashing (by others) roofing (by others) cant strip (by others) unit curb angle ¥ models 4024-4049: 4 x 2 sheetmetal formed channel ¥ models 4054-4066: 6 x 2 sheetmetal formed channel cant strip (by others) roofing (by others...

Page 52

4000-s eries i nstallation , o peration and s ervice m anual 44 of 154 figure 33: roof curb assembly with brackets detail 2 detail 1 detail 3 detail 3 detail 3 overhead planview supply air or inlet end side splice & crossbrace 12 bolts, flat washers, lock washers, flange nuts intermediate crossbrace...

Page 53

Section 8: r oof c urb 45 of 154 figure 34: duct support adapter asm size a note: gasket sponge required on top side of flange perimeter. Material to be aluminized 20ga. Steel bottom return duct adapter asm 24 38.00 36 56.00 40 61.00 44 67.00 49 74.00 54 83.00 60 92.00 66 102.00 73 109.00 80 128.00 ...

Page 54: Warning

4000-s eries i nstallation , o peration and s ervice m anual 46 of 154 section 9: indoor suspension mounting - horizontal air handler 9.1 suspension mounting assembly and instructions indoor suspension mounting is available for all models in horizontal orientation. Suspension mounts are shipped asse...

Page 55

Section 9: i ndoor s uspension m ounting - h orizontal a ir h andler 47 of 154 figure 35: indoor suspension vibration isolators when specified support rods air handler controls right inlet end view approximate gas pipe location center supports rod size- 4036 – 4089 3/4 " Ø 4024 5/8 " Ø inlet g g con...

Page 56: Warning

4000-s eries i nstallation , o peration and s ervice m anual 48 of 154 section 10: leg mounting vertical mua, fr, am and 4024-4049 vav units require a quantity of four legs. Vertical 4054-4089 vav units without an oa filter section require a quantity of six legs (all of the same height). Vertical 40...

Page 57

Section 10: l eg m ounting 49 of 154 figure 36: assembling legs for horizontal air handlers curb angle a air handler intermediate bottom plate (bolts to 2 corner legs) access door 1/2"x 1-5/8" slotted holes corner support legs 4 - required controls right intermediate support legs required on all cur...

Page 58

4000-s eries i nstallation , o peration and s ervice m anual 50 of 154 figure 37: assembly legs and rainskirt for upright air handlers drawing #50010144 leg optional section (s) rain skirt (3 pcs.) note: rain skirt with outdoor air handlers only top and bottom plates bolt on outside of leg note - (1...

Page 59: Warning

Section 11: f ilter s ection 51 of 154 section 11: filter section all filter sections are shipped assembled. Models 4024-4049 ship attached to the base unit. Models 4054- 4089 shipped loose and required field assembly to base unit. Note: check to be sure that all required components are present. If ...

Page 60: Warning

4000-s eries i nstallation , o peration and s ervice m anual 52 of 154 section 12: inlet hoods inlet hoods are shipped unassembled and must be assembled prior to installation. Note: check to be sure that all required components are present. If any are missing, contact rapid engineering llc or your r...

Page 61

Section 12: i nlet h oods 53 of 154 figure 40: inlet hood without filters (4054-4089) figure 41: inlet hood with permanent filters roof tape field joint properly caulk notes: (1) failure to properly caulk the field joints will allow water to enter the air handler (2) all parts mounted to inlet end t...

Page 62

4000-s eries i nstallation , o peration and s ervice m anual 54 of 154 figure 42: inlet hood with moisture limiter c b detail b: scale: 4x a (2) braces front & back on models 4060 thru 4089 (1) brace front & back on models 4024 thru 4054 1 3 6 8 5 4 2 2 1 3 4 5 6 8 item 4 flush with inlet hood drip ...

Page 63: Warning

Section 13: s ervice p latform 55 of 154 section 13: service platform 13.1 service platform ladders are available as an additional accessory for service platforms. Ladders are available with or without cages at various heights. Service platforms are available for use with horizontal or vertical unit...

Page 64

4000-s eries i nstallation , o peration and s ervice m anual 56 of 154 figure 44: service platform for a horizontal air handler controls right 3/8" bolt field joint when required service platform support channel 3/8" bolts safety chain front railing sway tab support rods double nutted lifting eye ai...

Page 65: Warning

Section 14: d ischarge accessories 57 of 154 section 14: discharge accessories 14.1 one-way, three-way and four-way discharge head installation all discharge heads are shipped assembled. The discharge head is designed for mounting to the face of the air handler (covering the supply air opening) or t...

Page 66

4000-s eries i nstallation , o peration and s ervice m anual 58 of 154 figure 45: vertical air handler with duct sleeves and discharge head (supply air and return air duct sleeves available from manufacturer) detail a detail c air handler detail b typical assembly 2" self tapping screws alternate su...

Page 67

Section 14: d ischarge accessories 59 of 154 figure 46: one-way discharge head controls right curb angle access door air handler discharge head 1-way discharge head 1-way inlet air handler discharge head 1-way inlet a g d g c f 30” e detail a typical assembly 2” self tapping screws air handler housi...

Page 68

4000-s eries i nstallation , o peration and s ervice m anual 60 of 154 figure 47: three-way discharge head f d (typical) b a c e g g plan view front view side view model a b c d e f g 4024 44 25 24.4 14 20.3 29.3 2.1 4036 62 30 29.4 22 25.3 47.3 2.1 4040 65 31 37.4 23 33.3 50.3 2.1 4044 71 32 40.4 2...

Page 69

Section 14: d ischarge accessories 61 of 154 figure 48: four-way discharge head e inlet air handler c roof curb a access door controls right air handler duct not supplied by rapid engineering llc. Roof b d f f f f air handler 12" typical 12" typical right side view end view model a b c d e f 4024 40...

Page 70

4000-s eries i nstallation , o peration and s ervice m anual 62 of 154 figure 49: 120° discharge head horizontal bottom supply air model a c d e f g h j k disch id weight (lbs) 4024 40 20 1/4 24 1/4 3 7/8 40 5 3/8 19 47 30 24 x 29 75 4036 58 25 1/4 32 1/4 4 7/8 58 5 3/8 26 83 48 32 x 47 105 4040 63 ...

Page 71

Section 14: d ischarge accessories 63 of 154 14.2 splash plate installation the splash plate is designed to hang, supported by suspension rods (rods provided by others) directly below the bottom discharge opening of a horizontal air handler. The center point of the splash plate must be located at th...

Page 72: Warning

4000-s eries i nstallation , o peration and s ervice m anual 64 of 154 section 15: vibration isolation figure 51: suspended crush hazard use proper lifting equipment and practices. Falling hazard use proper safety equipment and prac- tices to avoid falling. Severe injury hazard use proper lifting pr...

Page 73

Section 15: v ibration i solation 65 of 154 figure 52: curb mounted roof curb roof curb.

Page 74

4000-s eries i nstallation , o peration and s ervice m anual 66 of 154 figure 53: platform mounting on vibration isolators note: all dimensions and weights are subject to change without notice and should not be used for construction unless certified. Type a b c d e h r – 3 r – 4 3 3/8 4 1/4 5 1/2 6 ...

Page 75

Section 15: v ibration i solation 67 of 154 figure 54: vibration isolation platform locations a2 note: all dimensions and weights are subject to change without notice and should not be used for construction unless certified. Note: for mua, exclude mix box model a2 b c e f g h d a1 h h 4024 4036 4040...

Page 76

4000-s eries i nstallation , o peration and s ervice m anual 68 of 154 section 16: cooling specifications 16.1 evaporative cooling table 21: formulas * bleed-off and recirculation rates will vary with locale, water quality and chemical treatment program. These values are only for approximation. Note...

Page 77: Warning

Section 17: d uct c onsiderations 69 of 154 section 17: duct considerations the air handler has been designed to operate at the specific air volume and external static pressure that was originally specified. Static pressure is increased by any additional components that are added to the air handler ...

Page 78: Warning

4000-s eries i nstallation , o peration and s ervice m anual 70 of 154 section 18: gas piping 18.1 gas manifolds all gas piping to the air handler must comply with: united states: refer to nfpa 54/ansi z223.1 - latest revision, national fuel gas code. Canada: refer to csa b149.1 - latest revision, n...

Page 79

Section 18: g as p iping 71 of 154 table 27: manifold component identification note: items vary by manifold type. All items may not apply. Figure 55: standard gas manifold item component identification a leg trap (by others) b lockable manual shut-off valve (by others) c high gas pressure regulator ...

Page 80

4000-s eries i nstallation , o peration and s ervice m anual 72 of 154 figure 56: fm gas manifold vent outside a alternate inlet inlet by others d m b c k e g h j n p r s l by others * integral vent limiter * integral vent limiter vent limiter vent limiter all vent piping to outside by others.

Page 81

Section 18: g as p iping 73 of 154 figure 57: xl insurance gas manifold all vent piping to outside by others vent outside f vent outside a alternate inlet inlet by others d b c k e g h j n p r s m l by others * integral vent limiter * integral vent limiter vent limiter vent limiter.

Page 82

4000-s eries i nstallation , o peration and s ervice m anual 74 of 154 18.3 gas piping the gas manifold connection extends through the side of the control enclosure for vertical equipment and through the bottom for horizontal equipment. The factory piping terminates with a male pipe connection in th...

Page 83: Danger

Section 19: e lectrical 75 of 154 section 19: electrical each air handler is equipped with a wiring diagram which will vary depending on the type of remote panel and/or options supplied. Air handlers can also be supplied as building management system (bms)-ready. In this case, a remote panel is not ...

Page 84

4000-s eries i nstallation , o peration and s ervice m anual 76 of 154 19.1 disconnect fuse sizing the fuse classification must be determined by the service disconnect rating plate and all applicable codes. Fuse sizing is determined by the motor size, control current and supply voltage. Fuses that a...

Page 85

Section 19: e lectrical 77 of 154 located on the blower motor. Current draw may be adjusted downward by reducing blower rotations per minute (rpm) or by increasing external static pressure. 19.5 control current draw the maximum current draw for an air handler’s controls and accessories is 3a. 19.6 s...

Page 86

4000-s eries i nstallation , o peration and s ervice m anual 78 of 154 19.6.4 flame control this device will check for both pilot flame and main flame within the burner. When a flame signal from the pilot flame is available, it will allow the main gas valve to open. Your air handler may equipped wit...

Page 87

Section 19: e lectrical 79 of 154 19.7 interlocks 19.7.1 carbon dioxide interlocks all air handlers that recirculate air from the heated space require either a control to limit the temperature rise in proportion to the amount of outdoor air or the use of a room carbon dioxide sensor. The carbon diox...

Page 88

4000-s eries i nstallation , o peration and s ervice m anual 80 of 154 19.8.9 service receptacle powered by others (wired) this option provides a service receptacle. It includes ground-fault interrupter (gfi) receptacle mounted on the interior or exterior of the control enclosure. Power to the recep...

Page 89

Section 19: e lectrical 81 of 154 19.9 safety systems safety systems are required for proper performance of the air handler. The air handler shall not be permitted to operate with any safety system disabled. If a fault is found in any of the safety systems, then the system shall be repaired only by ...

Page 90

4000-s eries i nstallation , o peration and s ervice m anual 82 of 154 19.10 remote panels 19.10.1 basic remote figure 58: basic remote 1 5 min. Lls r w c nc tr 1 low temp by-pass timer hls lo t-1 control trans. H1 h2 afs1 ps-1 high gas prs. Switch feeder protection ref: n.E.C. Table 430-152 sizing ...

Page 91

Section 19: e lectrical 83 of 154 figure 59: basic remote (continued) mrv 1 w 2 b uv t3 low voltage transformer amplifier sp t2 transformer ignition g f 9 8 l2 7 6 fr-1 10 5 sol.-1 valve burner on flame relay pilot valve solenoid primary shut-off 20 aa lt valves open 52 52 2 41 43 45 44 49 46 35 36 ...

Page 92

4000-s eries i nstallation , o peration and s ervice m anual 84 of 154 19.10.2 standard discharge control remote figure 60: standard discharge remote 1 hls t-1 control trans. H1 h2 afs1-lo ps-1 high gas prs. Switch reset manual feeder protection ref: n.E.C. Table 430-250 sizing by others. G lpj-25sp...

Page 93

Section 19: e lectrical 85 of 154 figure 61: standard discharge remote (continued) mrv 1 w 2 b uv t3 low voltage transformer amplifier sp t2 transformer ignition g f 9 8 l2 7 6 fr-1 10 5 sol.-1 valve burner on flame relay pilot valve solenoid primary shut-off 20 aa lt-2 valves open 52 52 2 41 43 45 ...

Page 94

4000-s eries i nstallation , o peration and s ervice m anual 86 of 154 19.10.3 deluxe room control remote figure 62: deluxe room control remote 1 hls t-1 control trans. H1 h2 afs1-lo ps-1 high gas prs. Switch reset manual feeder protection ref: n.E.C. Table 430-250 sizing by others. G lpj-30sp power...

Page 95

Section 19: e lectrical 87 of 154 figure 63: deluxe room control remote (continued) mrv 1 w 2 b uv t3 low voltage transformer amplifier sp t2 transformer ignition g f 9 8 l2 7 6 fr-1 10 5 sol.-1 valve burner on flame relay pilot valve solenoid primary shut-off 20 aa lt-2 valves open 52 52 41 43 45 4...

Page 96

4000-s eries i nstallation , o peration and s ervice m anual 88 of 154 19.10.4 standard room control remote figure 64: standard room control remote 1 hls t-1 control trans. H1 h2 afs1-lo ps-1 high gas prs. Switch reset manual feeder protection ref: n.E.C. Table 430-250 sizing by others. G lpj-125sp ...

Page 97

Section 19: e lectrical 89 of 154 figure 65: standard room control remote (continued) mrv 1 w 2 b uv t3 low voltage transformer amplifier sp t2 transformer ignition g f 9 8 l2 7 6 fr-1 10 5 sol.-1 valve burner on flame relay pilot valve solenoid primary shut-off 20 aa lt-2 valves open 52 52 2 41 43 ...

Page 98

4000-s eries i nstallation , o peration and s ervice m anual 90 of 154 19.11 ddc-ready controls figure 66: ddc-ready controls t-1 control trans. X4 120vac x1 h1 500va h4 feeder protection ref: n.E.C. Table 430-152 sizing by others. G lpj-40sp power supply ____v___ph___hz ____fla 460 l2 l1 l3 60 29.7...

Page 99

Section 19: e lectrical 91 of 154 figure 67: ddc-ready controls (continued) w b v3/mrv 2 1 uv 50 51 low voltage transformer amplifier sp t-2 transformer ignition g f 9 8 l2 6 7 fr-1 10 5 sol.-1 valve block valve flame relay pilot valve solenoid primary shut-off 20 hls lo afs1 ps-1 high gas prs. Swit...

Page 100

4000-s eries i nstallation , o peration and s ervice m anual 92 of 154 your rapid ® air handler may be equipped with one of the following ddc control offerings. If so, a separate manual providing wiring, operation and trouble shooting information, specific to that control offering, will also accompa...

Page 101

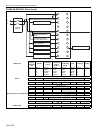

Section 19: e lectrical 93 of 154 figure 68: air handler styles bottom discharge optional motorized inlet damper 100% outside air optional motorized inlet damper bottom return 20% outside air 80% return air bottom discharge bottom discharge bottom return 20% outside air 80% combined outside air and ...

Page 102

4000-s eries i nstallation , o peration and s ervice m anual 94 of 154 19.13 hvac remote panels and panel options the remote panel should be mounted in the conditioned space in a convenient location for controlling the air handler. Do not locate a remote panel that contains temperature sensing equip...

Page 103

Section 19: e lectrical 95 of 154 to maintain the space temperature set on the selectrastat dial. The 7-day programmable touchscreen thermostat provides nighttime setback for unoccupied space heating. Auto/winter mode: occupied time: blower and burner cycle operate continuously to maintain a constan...

Page 104

4000-s eries i nstallation , o peration and s ervice m anual 96 of 154 table 32: factory preset schedule on th8110 thermostat 19.13.3 bms-ready control option the bms-ready option provides inputs to receive control signals from a customer determined control system. Each bms input is capable of recei...

Page 105

Section 19: e lectrical 97 of 154 1. Operating control - this indicator is on when power is present at terminals #1 and #7 of the flame safeguard. 2. Air flow - this indicator comes on at the same time as the one above. This is because the actual circuit is not used and is jumped out. It can be used...

Page 106

4000-s eries i nstallation , o peration and s ervice m anual 98 of 154 1. Timed pre-purge this must be a separate purge from the rest of the system. The trial for ignition must be delayed by 7 seconds while the blower in the unit is running. This is to guarantee that there are no combustible gases o...

Page 107

Section 19: e lectrical 99 of 154 pilot trial for ignition • jumpers jp6 and jp7 are used by the factory only to select the ptfi for the m4rt1. The factory set, default ptfi time is 10 seconds (jp6 installed, jp7 not installed). The ptfi time may only be set by the factory. Recycle/non-recycle opera...

Page 108

4000-s eries i nstallation , o peration and s ervice m anual 100 of 154 19.15 honeywell ® rm7890 flame safeguard.

Page 109

Section 19: e lectrical 101 of 154.

Page 110

4000-s eries i nstallation , o peration and s ervice m anual 102 of 154.

Page 111

Section 19: e lectrical 103 of 154.

Page 112

4000-s eries i nstallation , o peration and s ervice m anual 104 of 154.

Page 113

Section 19: e lectrical 105 of 154.

Page 114

4000-s eries i nstallation , o peration and s ervice m anual 106 of 154.

Page 115

Section 19: e lectrical 107 of 154.

Page 116

4000-s eries i nstallation , o peration and s ervice m anual 108 of 154.

Page 117

Section 19: e lectrical 109 of 154.

Page 118

4000-s eries i nstallation , o peration and s ervice m anual 110 of 154.

Page 119

Section 19: e lectrical 111 of 154.

Page 120: Warning

4000-s eries i nstallation , o peration and s ervice m anual 112 of 154 section 20: direct fired burner your unit will be equipped with a direct fired burner manufactured by either midco international or maxon corporation. Please consult the specification sheet provided with your air handler to conf...

Page 121

Section 20: d irect f ired b urner 113 of 154 figure 71: midco hma-2a burner.

Page 122

4000-s eries i nstallation , o peration and s ervice m anual 114 of 154.

Page 123

Section 20: d irect f ired b urner 115 of 154 20.1 direct fired burner ignition the burner that is used in the rapid engineering llc unit is equipped with a pilot assembly. The pilot assembly consists of a pilot gas tube, spark electrode or rod and a flame rod with grounding assembly. For proper ign...

Page 124

4000-s eries i nstallation , o peration and s ervice m anual 116 of 154 20.2 direct fired burner flame proving (flame rod) the flame rod in the burner is constructed of a material that produces a signal when heated. This signal is measured as a direct current micro amp. The path of the signal is fro...

Page 125

Section 20: d irect f ired b urner 117 of 154.

Page 126

4000-s eries i nstallation , o peration and s ervice m anual 118 of 154.

Page 127

Section 20: d irect f ired b urner 119 of 154 20.3 honeywell uv flame detector.

Page 128

4000-s eries i nstallation , o peration and s ervice m anual 120 of 154 20.4 honeywell uv flame detector (continued).

Page 129: Danger

Section 21: s tart - up p rocedures 121 of 154 section 21: start-up procedures electrical shock hazard disconnect electric before service. More than one disconnect switch may be required to disconnect electric from equipment. Equipment must be properly grounded. Severe injury hazard do not enter equ...

Page 130

4000-s eries i nstallation , o peration and s ervice m anual 122 of 154 installation code and annual inspections: all installation and service of rapid ® equipment must be performed by a contractor qualified in the installation and service of equipment sold and supplied by rapid engineering llc and ...

Page 131

Section 21: s tart - up p rocedures 123 of 154 21.2.2 belt tension • belt tension should be checked with a belt-tension gauge when one is available. Follow the belt tension gauge instructions. • when a tension gauge is not available, measure the belt span of the belts ( see page 123, figure 75). • a...

Page 132

4000-s eries i nstallation , o peration and s ervice m anual 124 of 154 adjustment. Table 35: motor sheave drive torque specifications table 36: motor and blower bushing torque specifications 21.4.2 burner pressure 1. A pressure tap is used to measure differential at the burner and to set high fire ...

Page 133

Section 21: s tart - up p rocedures 125 of 154 5. Adjust air handler high fire gas pressure. • determine the high fire gas pressure by adding the manifold pressure for maximum input (from the rating plate) and the burner negative pressure (from the measurement made in the burner pressure section of ...

Page 134

4000-s eries i nstallation , o peration and s ervice m anual 126 of 154 21.6 safety shut off valve check after the initial start up and gas pressure adjustment, verify gas soundness of each ssov (safety shut off valve). This check must be repeated after the first 100 hours of operation. 21.7 tempera...

Page 135

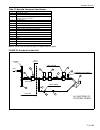

Section 21: s tart - up p rocedures 127 of 154 figure 77: mr 212 valve t n e v r 2a0 4 1 12a06 r low fire adjustment (loosen locking screw before adjustment) high fire adjustment cap modulator top view (cover removed) inlet pressure outlet pressure tap tap (burner pressure) side view note: for high ...

Page 136

4000-s eries i nstallation , o peration and s ervice m anual 128 of 154 figure 78: m611 valve figure 79: regulator (2005) low fire adjustment (under cap) gas inlet gas outlet note: modulating only. In psi 2 off on outlet pressure tap-1/8 npt inlet pressure tap-1/8 npt regulator adjustment below (hig...

Page 137: Warning

Section 22: m aintenance 129 of 154 section 22: maintenance falling hazard use proper safety equipment and practices to avoid falling. Do not use any part of equipment as support. Warning failure to follow these instructions can result in death, injury or property damage. Burn hazard allow equipment...

Page 138

4000-s eries i nstallation , o peration and s ervice m anual 130 of 154 prior to any maintenance or service of the air handler, shut off, lockout and tagout the electrical disconnect and gas valve that supplies the unit in accordance with osha regulations and allow ample time for the air handler to ...

Page 139

Section 22: m aintenance 131 of 154 drive belts and sheaves check for belt ride in the groove. In multiple groove drives, belt ride should be uniform. Check groove wear area for wear. Side wall of groove should be straight, not dished out. Bottom of groove should show no signs of belt contact. Sheav...

Page 140

4000-s eries i nstallation , o peration and s ervice m anual 132 of 154 22.4 manifold and controls 22.5 burner manifold periodically check gas control assembly and internal and external piping for leaks. Relief vent lines to outdoors on gas controls should be checked to ensure against blockage cause...

Page 141

Section 22: m aintenance 133 of 154 motors inspection: 1. Inspect motor every 3 months or 500 hours of operation, which ever occurs first. Keep the motor clean and vent openings clear. Lubrication: 1. Motors with grease fittings must be lubricated based on the table below. 2. A high grade ball or ro...

Page 142

4000-s eries i nstallation , o peration and s ervice m anual 134 of 154 22.6 optional equipment dampers check linkage when applicable and tighten set screws as required. All moving parts of dampers should be cleaned and then thoroughly lubricated with a light molybdenum oil in aerosol can. Dampers f...

Page 143: Warning

Section 23: r eplacement p arts 135 of 154 section 23: replacement parts a list of replacement parts specific to your air handler is / was included in the customer support documentation which accompanied your air handler. For your convenience, when ordering any replacement parts, please refer to tha...

Page 144: Danger

4000-s eries i nstallation , o peration and s ervice m anual 136 of 154 section 24: troubleshooting electrical shock hazard disconnect electric before service. More than one disconnect switch may be required to disconnect electric from equipment. Equipment must be properly grounded. Severe injury ha...

Page 145

Section 24: t roubleshooting 137 of 154 24.1 initial checks when encountering any abnormal operation or fault conditions of the equipment, all troubleshooting should start with the following initial checks. If a problem is discovered in these initial checks it must be corrected before moving on in t...

Page 146

4000-s eries i nstallation , o peration and s ervice m anual 138 of 154 24.3 burner problem possible cause solution flame control does not try for ignition auxiliary contact not closed. Properly mount contact or replace burner/winter switch closed? Replace switch high temp limit switch tripped? Manu...

Page 147

Section 24: t roubleshooting 139 of 154 burner (continued) 24.4 temperature controls if temperature control problems occur and are not remidied in the troubleshooting procedure, refer to the trouble shooting table for the unit specific temperature control amplifier. For units with the maxitrol ® ser...

Page 148

4000-s eries i nstallation , o peration and s ervice m anual 140 of 154 24.5 a1014 amplifier - field checklist symptom possible cause a. No gas flow 1. Modulating valve improperly installed. B. Continuous low fire (electronics problem). 2. Short circuit or no voltage to the amplifi er. 3. Open circu...

Page 149

Section 24: t roubleshooting 141 of 154 field test remedy 1. Arrow on side of valve should point in direction of gas fl ow. 1. Install properly. 2. Check for 24vac at amplifi er terminals 7 & 8. 3. Inspect for loose or broken wires between amplifi er terminals 1 & 2, and td114 terminals 1 & 2, and t...

Page 150

4000-s eries i nstallation , o peration and s ervice m anual 142 of 154 figure 80: rm7897c flame control g l2 3 4 5 6 7 8 9 10 f 22 21 20 19 18 17 16 15 14 13 12 line voltage alarm burner controller / limits 10sec. Interupted pilot / ignition main valve ignition flame detector pre-ignition interlock...

Page 151: Danger

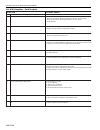

Section 25: rapid ® 4000-s eries s tart -u p p rocedures 143 of 154 section 25: rapid ® 4000-series start-up procedures customer: ________________________________ technician: _______________________________ start-up co: ______________________________ date: ____________________________________ model ...

Page 152

4000-s eries i nstallation , o peration and s ervice m anual 144 of 154 c. General inspection- burner inspection __ no obstructions to the burner. __ spark igniter is secured and tight. __ uv scanner is secured and finger tight. Comments ______________________________________________________________...

Page 153

Section 25: rapid ® 4000-s eries s tart -u p p rocedures 145 of 154 g. Operational checks- fan operation __ fan rotation is correct. (see rotation sticker in the unit.) __ check and record the following: volts (fan off) phase 1-2 ___ phase 2-3 ___ phase 1-3 ___ volts (fan on) phase 1-2 ___ phase 2-3...

Page 154

4000-s eries i nstallation , o peration and s ervice m anual 146 of 154 i. Operational checks: temperature control operation, conventional controls minimum discharge air temp setpoint (°f) __________________________________________________ maximum discharge air temp setpoint (°f) ___________________...

Page 155

Section 25: rapid ® 4000-s eries s tart -u p p rocedures 147 of 154 l. Operational checks: special controls (list any other special controls specific to this air handler.) comments ___________________________________________________________________________ m. Operational checks: miscellaneous ___ do...

Page 156: Warning

4000-s eries i nstallation , o peration and s ervice m anual 148 of 154 section 26: rapid ® 4000-series start-up procedures: evaporative cooler customer: ________________________________ technician: _______________________________ start-up co: ______________________________ date: ___________________...

Page 157

Section 26: rapid ® 4000-s eries s tart -u p p rocedures : e vaporative c ooler 149 of 154 d. Conductivity control (control package #2) a conductivity controller monitors the electrical conductance of the cooling water. If the conductivity of the cooling water exceeds the front panel setpoint, the c...

Page 158

4000-s eries i nstallation , o peration and s ervice m anual 150 of 154 appendix i: burner firing rate calibration high fire adjustments note: the modulating/regulator valve is located on the gas train. See gas train drawing for location of valve. In order to set the high fire gas pressure correctly...

Page 159

Section 27: t he rapid ® 4000-s eries w arranty 151 of 154 section 27: the rapid ® 4000-series warranty rapid engineering llc will pay for: within 24 months from date of purchase by buyer or 27 months from date of shipment by rapid engineering llc (whichever occurs first), replacement parts will be ...

Page 160

4000-s eries i nstallation , o peration and s ervice m anual 152 of 154.

Page 161

Section 27: t he rapid ® 4000-s eries w arranty 153 of 154.

Page 162

4000-s eries i nstallation , o peration and s ervice m anual 154 of 154.