Raptor 30 V2 User Manual

1

INTRODUCTION

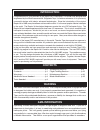

CONTENTS

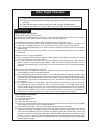

WARNING

This radio controlled helicopter is not a toy. It is a sophisticated piece of equipment and

is designed for hobby use only. If not properly assembled and operated, it is capable of

causing property damage and bodily harm to both the operator and/or spectators. Thunder

Tiger and its duly authorized distributors assume no liability for damage that could occur

from the assembly and/or use/misuse of this product.

AMA INFORMATION

Operating a model helicopter requires a high degree of diligence and skill. If you are a

newcomer to the hobby, it is best to seek help and guidance from accomplished model

helicopter pilots. This will greatly speed up the learning process and have you flying

successfully in a reasonable time. We also would strongly urge you to join the Academy

of Model Aeronautics. The AMA is a non-profit organization that provides its members

Congratulations on your purchase of the Raptor 30 V2 helicopter. This model was designed and

engineered by the World-renowned Mr. Shigetada Taya. It combines elements of his previously

successful designs with today's advanced technologies. Since the introduction of the original

Raptor 30 in 1998, many have been sold around the world. It is the most popular 30-size helicopter

in the world. The Raptor 30 has helped beginners master the art of RC helicopter flying. The

Raptor 30 has helped experienced pilots learn new 3-D maneuvers. This is truly a versatile model

helicopter for everyone. We did not just sat on our laurel, our team of engineers and test pilots

have collected feedbacks from around the world and have now made the Raptor 30 an even better

helicopter. We made new molds and tooling for new parts. Many area have subtle changes to

increase strength and durability.

As one of the largest R/C manufacturers in the world, Thunder Tiger has spared no expense to

bring you this incredible new machine. All production parts are manufactured by use of the most

modern technology available and meets or exceeds the standards as set forth by ISO-9001.

In the last few years we have spend time and resource to develop a new Thunder Tiger PRO-

39H(R) ring engine for the Raptor 30 V2 and for other 30-size helicopters. The new PRO-39H(R)

has much better transition characteristics than the Pro 36H ABC engine. The needles are easy

to set. The ring design eliminates the criticalness of ABC engines. You will find the new 39H

engine produce more power than any other available 30-size engines. Together, the new Raptor

30 V2 and the PRO 39H(R) engine will provide you with many hours of enjoyment. Thank you

again for purchasing our fine products.

Introduction......................................... p.1

Contents..............................................p.1

Warnings............................................. p.1

Additional Items Needed..................... p.3

Tools Needed...................................... p.3

Assembling Section............................ p.4

Flight Training Section........................ p.22

Maintenance Section.......................... p.30

Blade Modification............................. p.35