Summary of CombiMaster CM

Page 1

Manual combimaster cm.

Page 2: Warning:

- 2 - warning: incorrect installation, adjustment, servicing, maintenance, cleaning, or unatmorised modifications to the appliance can result in damage, injury or death. Read the operating manual carefully before starting to use the appliance. For your safety: do not store or use any flammable gases...

Page 3: Dear Customer

- 3 - you have a 12 month warranty from the date of first use of your machine. The warranty excludes glass damage, light bulbs and gasket material as well as damage caused by improper use, maintenance, repair or scaling of components. Your rational ag our technical customer support service can be re...

Page 4: Dear Customer

- 4 - congratulations on the purchase of your new combimaster. Your decision to buy a new combimaster means that you now have a top-of-the-range combi steamer. Your combimaster will give you many years of reliable service thanks to its outstanding quality of finish and almost unlimited cooking poten...

Page 5: Table of Contents

General instructions / for your safety 6 features 10 controls 11 cooking techniques 12 control modes 13 moist heat mode 14 dry heat mode 16 combi-steam mode 19 vario-steam mode 21 finishing ® mode 23 working with the core temperature probe 2 cool down function 28 cleaning 29 servicing –steam generat...

Page 6: General

General instructions / for your safety keep this manual carefully so that it can always be consulted by anyone using the appliance. This appliance must only be used to cook food in catering establishments. Any other use does not conform to the use intended and is therefore consi- dered dangerous ope...

Page 7: Loading/removing

Loading/removing open appliance door slowly. . When it is opened the heating and fan wheel shut down automatically. The integral fan wheel brake is activated. The fan wheel runs on briefly. Do not touch the fan wheel do not insert containers or grids until the grid shelf has been properly secured an...

Page 8: Low Water

Appliance size max. Load size 6x1/1 gn 30 kg (max. 15 kg per rack) 10x1/1 gn 45 kg (max. 15 kg per rack) 20x1/1 gn 90 kg (max. 15 kg per rack) 6x2/1 gn 60 kg (max. 30 kg per rack) 10x2/1 gn 90 kg (max. 30 kg per rack) 20x2/1 gn 180 kg (max. 30 kg per rack) low water the indication h2o may appear on ...

Page 9: Cleaning

Cleaning • leave the appliance door slightly open if it is going to be idle for a prolonged period (e.G. Over- night). • do not clean unit with high-pressure cleaner • do not treat unit with acids or expose to acid fumes – this will damage the protective layer of stainless steel and units might disc...

Page 10: Features

Appliance serial number (visible only when door is open) draft diverter (optional) (gas appliances only) interior lighting appliance door with double glass pane door handle table-top units: one-handed operation with slam function floor models: one-handed operation unlocking device to open double gla...

Page 11: Controls

Controls info - 11 - moist heat (100 °c). Dry heat (30 °c to 300 °c). Combi-steam (30 °c to 300 °c). Control mode switch vario-steam (30 °c to 99 °c) finishing (30 °c - 300 °c) additional "cool down" function cabinet temperature display cabinet temperature dial heating mode display clock button (0 t...

Page 12: Moist Heat

Moist heat dry heat these two modes can be used either • individually or • in combination your appliance allows you to use virtually all the traditional cooking processes in just one cooker! Cooking techniques info - 12 - combi-steam.

Page 13: "moist Heat" Mode

"moist heat" mode the high-performance steam generator produces fresh steam. This is fed, unpressu- rised, into the cooking cabinet and is circu- lated at high speed by the fan. The paten- ted control system regulates the input of steam, supplying only as much as the food is actually able to absorb....

Page 14: "moist Heat"

"moist heat" the steam generator produces hygienic fresh steam. In this mode the cabinet temperature is set to a constant 100 °c. Cooking modes: steaming, stewing, blanching, poaching, simmering, vacuum cooking, thawing, preserving. 1 preheat until heating indicator light goes out 2 3 or work with t...

Page 15: Hints

Hints • to get the most out of your combi-master check daily the types of food which can be cooked together using "moist heat". Remember that fish, meat, vegetables, side dis- hes and fruit can be cooked together (as long as they are all being prepared by the same method). • cook potatoes in perfora...

Page 16: "dry Heat"

"dry heat" powerful heating elements heat the dry air. Cabinet temperature can be set to between 30 °c and 300 °c. Cooking methods: baking, roasting, grilling, deep-frying, gratinating, glazing. 1 preheat until heating indicator light goes out. 2 3 4 or work with the core temperatu- re probe 3 4 tar...

Page 17: Hints

Hints • cooking times cooking times will depend on product quality, weight and height. Do not overlo- ad grids or containers so that air can cir- culate evenly. • general notes on pan-frying - preheat to as high a temperature as possible (300 °c) to build up sufficient stored heat. - load as quickly...

Page 18: Dry Heat Mode

• baking preheat to baking temperature. For a full load you may need to select a higher preheating temperature. Baking temperature: approx. 20 to 25 °c lower than in a conventional oven. For rolls use only every second shelf. For frozen convenience products preheat to 300 °c. Defrost frozen rolls an...

Page 19: "combi-Steaming"

"combi-steaming" moist heat and dry heat modes are combined by a control system. This creates a hot, humid climate for especially intensive cooking. The temperature can be set to between 30 °c and 300 °c. Cooking modes: roasting, baking. 1 preheat until heating indicator light goes out. 2 3 4 or wor...

Page 20: Hints

Hints • do not place joints too close together to allow even cooking. • joints with rinds or larger joints should be stea- med for approximately 1/3 of the cooking time. • collect condensate in a container (additional rail) and make the gravy by adding it to the lightly roasted bones. • preparing sa...

Page 21: "vario-Steaming"

"vario-steaming" the steam generator produces hygienic fresh steam. Cabinet temperature can be variably set to between 30 °c and 99 °c. 1 preheat until heating indicator light goes out. 2 3 4 or work with the core temperatu- re probe 3 4 target actual sample dishes • mise en place blanching bacon an...

Page 22: Hints

Hints • "vario-steam" cooking times "moist heat" cooking times can be used as approximate values. As a general rule, the lower the cooking temperature the longer the cooking time. • approximate cabinet temperatures "vario-steaming": soup garnishes: 75 to 90 °c fish, shellfish and 65 to 90 °c crustac...

Page 23: „Finishing

„finishing ® “ a combination of moist heat and dry heat modes. This produces the ideal cooking climate, by preven- ting the food drying out and also the formation of unwanted puddles. Cabinet temperature can be set to between 30 °c and 300 °c. 1 preheat to operating temperature 2 we recommend a cabi...

Page 24: Hints

Hints • finishing utensils porcelain plates, earthenware, glass, silverware, copper pans, stainless steel, aluminium dishes (brought in). • banqueting service/tour groups reheat plates in the mobile plate rack. – large quantities in next to no time. – fast loading and unloading. – shorter serving ti...

Page 25: 19°C

The cooking process is regulated by measuring the core temperature of the food. Clean the core temperature probe before use and ensure at anbient temperature before use. Insert the core temperature probe into the thickest part of the food until the tip of the probe is at the centre of the food. Can ...

Page 26: Hints

Hints • when roasting meat for slicing set the core tem- perature approx. 5 °c lower, as the joint will continue to cook during the cool-down phase. For example: "roasting", core temperature – cooking time ratio. • to avoid holes (protein coagulation) in the pro- duct, cool the core temperature prob...

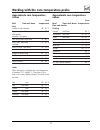

Page 27: Approximate Core Temperature

Approximate core temperature values core beef how well done temperature veal saddle of veal pale pink 58 - 65 °c leg of veal, well done 78 °c and topside noisettes, fricandeau loin with kidneys well done 75 - 80 °c roast veal/ well done 75 - 80 °c shoulder breast of veal well done 75 - 78 °c saddle ...

Page 28: Cool Down Function

You have been running your appliance at high tem- perature and you now want to carry on working at reduced cabinet temperature. Use the "cool down" function to cool the cabinet quickly and gently. 1 close door.. 2 3 open door.. Note close cabinet doors before selecting "cool down". Caution! • during...

Page 29: Cleaning Procedure

Cleaning procedure for hygiene reasons and to prevent malfunc- tions it is essential to clean the combi- steamer every day at close of work. Caution! • it is vital to wear the correct protective clothing (gloves, goggles and mask). • only use the hand spray piston made by the appliance manufacturer ...

Page 30: End

9 when the cleaning program has finished running rinse the appliance down, including behind the air baffle. 10 wipe cabinet and door gasket with a damp cloth, if necessary hinge back the inner pane and wipe it down as well. 11 close cabinet doors. To dry the cabinet "hot air" mode is auto- matically...

Page 31: Steam Generator Descaling

Your appliance is equipped with the patented auto- matic self clean system. Automatic self clean sig- nificantly extends the period between descaling intervals. The steam generator in your appliance still needs regular descaling, depending on water hardness and use. We recommend the following descal...

Page 32: Fill

Pumping out steam generator when pumping out has finished the display shows: you will be asked to top up with descaling fluid. 6 open cabinet doors 7 remove left grid shelf and air baffle from the cabinet. 8 replace the left grid shelf to secure the descaler hose. 9 screw the hose to the canister of...

Page 33

11 guide the hose into the steam inlet up to the mark shown on the hose. Fasten the hose to the left grid shelf with the wire hook. 12 very slowly fill with descaling fluid using the appliance manufacturer’s hand pump. Caution! • descaling fluid reacts with lime and can foam over. Electric appliance...

Page 34: End

13 remove descaling accessories from cabinet (hand pump and canister). 14 thoroughly rinse descaling fluid in cabinet and descaling accessories with water! 15 correctly replace air baffle and left grid shelf in cabinet and lock properly. 16 once 30 seconds have been indicated "door" appears on the d...

Page 35: End

If necessary you can discontinue the descaling pro- cess. Before filling with descaling fluid 1 please hold down the core temperature button for 10 seconds. Your appliance can now be used for cooking. After filling with descaling fluid 1 switch appliance off and wait for 4 seconds 2 switch appliance...

Page 36: 212 °F

Temperatures may be displayed in degrees celsius or degrees fahrenheit. Changing the celsius / fahrenheit display simultaneously press "clock" button and "core temperature" button and hold down for more than 10 seconds. Or 212 °f 100 °c appliance settings – celsius / fahrenheit - 36 -.

Page 37: Ans

Inspections which can be carried out by experienced staff technici- ans caution! • switch off the unit at the mains before opening the service doors and working on live components. • use only genuine spare parts made by the appliance manufacturer. Cleaning the air filter below the installation area ...

Page 38: Replacing The Door Gasket

Replacing the door gasket the door gasket comprises a vulcanised frame which slots into a guide on the cooking cabinet. If a gasket needs changing, pull the old gasket out of the guide. Clean any dirt from the guide rails. When fitting the gasket make sure the rectangular part of the gasket is inser...

Page 39: Appliance Options

- 39 - appliance options info draft diverter (gas appliances only) gas exhaust pipe diameter: 180 mm model 6x1/1 art. No. 70.00.356 model 6x2/1 art. No. 70.00.359 model 10x1/1 art. No. 70.00.348 model 10x2/1 art. No. 70.00.349 model 20x1/1 art. No. 70.00.352 model 20x2/1 art. No. 70.00.343 ultravent...

Page 40: Fault Indications

- 40 - fault indications heat shield for left side panel retrofitting a heat shield allows you to place a radiant heat source (e.G. Grill) near the left side panel. Model 6x1/1 art. No. 60.70.390 model 6x2/1 art. No. 60.70.392 model 10x1/1 art. No. 60.70.391 model 10x2/1 art. No. 60.70.393 model 20x...

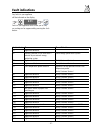

Page 41: E 11

Any faults in your appliance will be indicated on the display. Faults in your appliance which allow you to carry on cooking can be suppressed by pressing the clock button. E 11 fault indications - 41 - fault indication cause remedial action e1 appliance defective e2 heating switched off for more tha...

Page 42

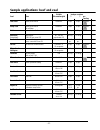

- 42 - sample applications: beef and veal suitable food hints gn container/grid fillet steak season, brush with oil combigrill ® rump steak season, brush with oil combigrill ® do not flatten sirloin season, brush with oil grid roast beef add mirepoix 90 - 150 mm (braised beef) Ø 80–100 mm, cover cns...

Page 43

- 43 - cooking process approx. Loading capacity 10x2/1 1st step 2nd step 3rd step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1 250 ° 36 pcs. 72 pcs. 60 pcs. 120 pcs. 240 pcs. 7 min. 260 ° 60 pcs. 120 pcs. 100 pcs. 200 pcs. 400 pcs. 8-10 min. 140 ° 160 ° 18 kg 36 pcs. 30 kg 60 kg 120 kg 10 min. Kt 56 ° 130-140 °...

Page 44

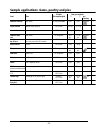

- 44 - sample applications: pork, mutton and lamb suitable food hints gn container/grid pork medallions season, brush with oil combigrill ® approx. 70 to 80 g escalopes au naturel, brush with oil combigrill ® pork chops browning fat, baking and roasting tray (breaded) pork carbonnade marinate, 40 mm...

Page 45

- 45 - cooking process approx. Loading capacity 10x2/1 1st step 2nd step 3rd step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1 250 ° 60 pcs. 120 pcs. 120 pcs. 240 pcs. 480 pcs. 8-10 min. 250 ° 60 pcs. 120 pcs. 100 pcs. 200 pcs. 400 pcs. 12-15 min. 200-220 ° 48 pcs. 96 pcs. 80 pcs. 160 pcs. 320 pcs. 15 min. 140-...

Page 46

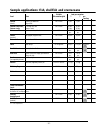

- 46 - sample applications: sausages and frozen food suitable food hints gn container/grid home-made sausage fill casing evenly, grid can be cooked hanging bavarian sausage to 2 meat hooks, iron grid heat bar and grid to secure sausages, to reheat 40 mm cns stuffing ffor mise en place cover with foi...

Page 47

- 47 - cooking process approx. Loading capacity 10x2/1 1st step 2nd step 3rd step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1 77 ° 180 pcs. 360 pcs. 300 pcs. 600 pcs. 1200 pcs. Kt 72 ° 80 ° 160 pcs. 420 pcs. 400 pcs. 800 pcs. 1600 pcs. Kt 75 ° 80 ° 180 pcs. 360 pcs. 300 pcs. 600 pcs. 1200 pcs. Kt 75 ° 80 ° 300...

Page 48

- 48 - sample applications: game, poultry and pies suitable food hints gn container/grid saddle of venison, lard, skewer 20 mm granit.Erare leg of venison debone, season, bard, tie cns 40 mm haunch of venison lard, marinate cns 40 mm saddle of hare lard, season 20 mm granite rare larded marinate, se...

Page 49

- 49 - cooking process approx. Loading capacity 10x2/1 1st step 2nd step 3rd step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1 220 ° 6 pcs. 8 pcs. 10 pcs. 20 pcs. 40 pcs. 25 min. 140-160 ° 18 kg 32 kg 30 kg 60 kg 120 kg 60-70 min. 140-150 ° 18 kg 36 kg 30 kg 60 kg 120 kg 80-100 min. 200-220 ° 24 pcs. 48 pcs. 40...

Page 50

- 50 - sample applications: fish, shellfish and crustaceans suitable food hints gn container/grid salmon salmon, put abdomen cns 20 mm (whole) flap outside salmon trout fillets, in serving dish, add cns 20 mm salmon steaks fumet or wine salmon soufflé darioles, cocottes, timbales grid halibut salt, ...

Page 51

- 51 - cooking process approx. Loading capacity 10x2/1 1st step 2nd step 3rd step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1 75 ° 2 pcs. 4 pcs. 3 pcs. 6 pcs. 12 pcs. Kt 67 ° 75 ° 6-8 min. 120 pcs. 240 pcs. 200 pcs. 400 pcs. 800 pcs. 80 ° 8-10 min. 90 pcs. 180 pcs. 150 pcs. 300 pcs. 600 pcs. 75 ° 60 pcs. 120 p...

Page 52

- 52 - sample applications: vegetables, side dishes suitable food hints gn container/grid broccoli frozen (fresh, perforated container, cns 65 mm plunge in iced water) perforated cauliflower cut rosettes cns 65 mm perforated brussels sprouts frozen, season when frozen, butter cns 65 mm just before s...

Page 53

- 53 - cooking process approx. Loading capacity 10x2/1 1st step 2nd step 3rd step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1 100 ° 15 kg 30 kg 25 kg 50 kg 100 kg 15 min. 100 ° 12 heads 24 heads 20 heads 40 heads 80 heads 18 min. 100 ° 15 kg 30 kg 25 kg 50 kg 100 kg 15 min. 100 ° 6 kg 12 kg 10 kg 20 kg 40 kg 8...

Page 54

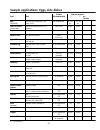

Sample applications: eggs, side dishes suitable food hints gn container/grid eggs time from glass misting (soft 7 min/ 65 mm perforated (hard boiled) / hard 15 min.) oeufs en cocotte load can be covered with foil or gn cns 20 mm (poached eggs) containers royale in tins or gn containers 65 mm unperfo...

Page 55

- 55 - cooking process approx. Loading capacity 10x2/1 1st step 2nd step 3rd step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1 100 ° 300 pcs. 600 pcs. 500 pcs. 1000 pcs. 2000 pcs. 12-15 min. 90 ° 60 pcs. 120 pcs. 100 pcs. 200 pcs. 400 pcs. 6-8 min. 85 ° 12 litre 24 litre 20 litre 40 litre 80 litre 30 min. 85 ° ...

Page 56

- 56 - leistungsbeispiele backwaren, brot, brötchen, dessert 1 suitable food hints gn container/grid apple strudel brush with milk, egg or sugar-water baking and roasting tray (strudel dough or perforated aluminium frozen brush with liaison if desired baking and roasting tray apple turnovers preheat...

Page 57

- 57 - cooking process approx. Loading capacity 10x2/1 1st step 2nd step 3rd step 6x1/1 6x2/1 10x1/1 20x1/1 20x2/1 170 ° 6 pcs. 12 pcs. 10 pcs. 20 pcs. 40 pcs. 40-50 min. 170 ° 60 pcs. 120 pcs. 100 pcs. 200 pcs. 400 pcs. 20 min. 180 ° 6 kg 12 kg 10 kg 20 kg 40 kg 12 min. 170-180 ° 6 shapes 12 shapes...

Page 58

- 58 - sample applications: pasty, bread, rolls, desserts 2 suitable food hints gn container/grid yeast cakes every 2nd rack 20 mm granite or baking and roasting tray yeast plaits 20 mm granite 500 g or perforated aluminium cheesecake every 2nd rack Ø 16 cm ring marble cake grease tins carefully, gr...

Page 59

- 59 - please note that quantities given always refer to a full load. In certain instances reducing the load can improve food quali- ty. Foods are natural products, cooking times and temperatures are intended as guides and should, if necessary, be adju- sted to suit the individual product. Cooking p...

Page 60: Rational International

Uk rational international 80.01.072 · v-01 · mediadesign and services · sf · 03/04.