- DL manuals

- Rational

- Cookers

- CombiMaster Plus series

- Installation Manual

Rational CombiMaster Plus series Installation Manual

Summary of CombiMaster Plus series

Page 1

Selfcookingcenter ® combimaster ® plus combimaster ® original installation manual.

Page 2: Contents

2 contents contents unit type 4 1 introduction 5 1.1 about this manual 5 1.2 warnings used 7 1.3 warranty 8 2 safety instructions 9 3 installation instructions 11 4 unit transportation 13 5 setting up the unit 16 5.1 unit dimensions 16 5.2 minimum distances 18 5.3 securing the unit 22 5.3.1 tabletop...

Page 3: Contents

3 8 gas connection 48 9 exhaust gas connection 53 10 wastewater connection 55 11 ventilation, technical data, heat dissipation 58 12 initial start-up 60 13 options 63 14 conversion tables 72 contents.

Page 4: Unit Type

4 unit type _____________________________________ ______________________________________ ______________________________________ _____________________________________ dealer installer specify for all queries: appliance model unit no.: set to gas type: your unit was checked by: unit type unit type.

Page 5: 1 Introduction

5 1 introduction 1 introduction 1.1 about this manual > this installation manual is part of and shipped with the unit, and contains information on its safe installation. > read this installation manual completely before installing the unit. > this installation manual must be kept available to instal...

Page 6: 1 Introduction

6 1 introduction this manual applies to the following units: > all selfcookingcenter® we units > selfcookingcenter® xs > all combimaster® plus units abbreviations used in this manual: product name abbreviation used selfcookingcenter® we scc selfcookingcenter® xs scc combimaster® plus cmp appliance s...

Page 7: 1 Introduction

7 1 introduction 1.2 warnings used danger hazardous situation that may result in severe injury or death. Warning hazardous situation that could potentially result in serious injury or death. Caution hazardous situation that could result in minor injury. Caution fire hazard! Caution danger of burns! ...

Page 8: 1 Introduction

8 1 introduction 1.3 warranty exceptions to the warranty include > damage to glass, light bulbs and gaskets, > damage resulting from improper use, installa- tion, maintenance, repair or descaling, > use of the unit for purposes other than those for which it is intended, > modifications or technical ...

Page 9: 2 Safety Instructions

9 2 safety instructions 2 safety instructions incorrect installation > incorrect installation, service, maintenance or cleaning of this unit can result in damage, injury or death, as can modifications to the unit. Read the installation manual carefully prior to installation. Unit usage > the unit ma...

Page 10: 2 Safety Instructions

10 2 safety instructions operating personnel > this unit must not be used by children or by persons with reduced physical, sensory or mental capabilities, or by persons with insuf- ficient experience and/or knowledge, unless such persons are under the supervision of another person who takes responsi...

Page 11

11 3 installation instructions 3 installation instructions standards > local and country-specific standards and reg- ulations regarding the installation and opera- tion of commercial cooking appliances must be observed at all times. > in all other countries, the corresponding country-specific standa...

Page 12

12 3 installation instructions air filter maintenance: > the unit automatically detects dirty air filters. It will display a service prompt instructing you to clean or replace the air filter. > never operate the unit without the air filter. When replacing the air filter, please note: tabletop units ...

Page 13: 4 Unit Transportation

13 4 unit transportation 4 unit transportation caution risk of injury! Unit may tip over. When transporting: secure the unit against tipping. 21, 22: are top heavy. Caution risk of injury! Note unit weights. Use lifting aids. Wear safety shoes. Weight (without packaging) 60 61 62 11 12 21 22 scc ele...

Page 14: 4 Unit Transportation

14 4 unit transportation transporting unit with pallet: x note required door width: appliance size 60 61 62 11 12 21 22 x [mm] 880 920 1120 920 1120 950 1150 x [inch] 34 3/4 36 1/4 44 1/8 36 1/4 44 1/8 37 1/2 45 1/4 transporting unit without pallet: i notice risk of damage to the unit! Only floor un...

Page 15: 4 Unit Transportation

15 4 unit transportation i notice risk of damage to the unit! Tabletop units not secured with a pallet should only be transported using carrying straps. Note required entrance width: appliance size 60 61 62 11 12 21 22 x [mm] 630 845 1045 845 1045 925 1145 x [inch] 24 6/8 33 1/4 41 1/8 33 1/4 41 1/8...

Page 16: 5 Setting Up The Unit

16 5 setting up the unit 5 setting up the unit 5.1 unit dimensions x y z x y z x y z.

Page 17: 5 Setting Up The Unit

17 5 setting up the unit width x 60 61 62 11 12 21 22 scc, cmp [mm] 657 847 1069 847 1069 879 1084 scc, cmp [inch] 25 7/8 33 3/8 42 1/8 33 3/8 42 1/8 34 5/8 42 5/8 depth y 60 61 62 11 12 21 22 scc, cmp [mm] 623 843 1043 843 1043 909 1114 scc, cmp [inch] 24 1/2 33 1/4 41 1/8 33 1/4 41 1/8 35 3/4 43 7...

Page 18: 5 Setting Up The Unit

18 5 setting up the unit 5.2 minimum distances i notice unit overheating may cause material and unit damage! If the ambient temperature to the left of the unit becomes too high, it may trigger an emer- gency shutdown of the unit. I notice unit overheating may cause material and unit damage! Do not i...

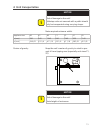

Page 19: 5 Setting Up The Unit

19 5 setting up the unit recommendation at least 20” [500 mm] away from left side of the unit so that service work can be performed. 500 mm /20" minimum distance to other units minimum 14” [350 mm] distance between left side of the unit and heat sources. 350 mm/ 14” heat shield to reduce thermo load...

Page 20: 5 Setting Up The Unit

20 5 setting up the unit minimum distance to ceiling caution fire hazard! Keep minimum clearance between unit and ceiling. Gas units: recommended 16” (400 mm) clearance from unobstructed rear exhaust pipes and any surface collecting grease or flammable material. Left side view minimum clearance 16“ ...

Page 21: 5 Setting Up The Unit

21 5 setting up the unit electric units: recommended 10” (254 mm) clearance from unobstructed rear vent pipes and any surface col- lecting grease or flammable material. Left side view electric unit minimum clearance 10“ if steam from the venting pipe cannot be direct- ed into an exhaust hood or a ve...

Page 22: 5 Setting Up The Unit

22 5 setting up the unit condensation breaker this clearance space is sufficient to install a condensation breaker so that exhaust air can be directed into non-critical areas. Other i notice unit malfunction! Avoid steam or grease sources near the cool- ing air filter. Moisture intake may result in ...

Page 23: 5 Setting Up The Unit

23 5 setting up the unit unit sizes 61, 62, 11, 12 > place the unit onto the stand. Catching the feet of the unit in place using the locating pins on the stand..

Page 24: 5 Setting Up The Unit

24 5 setting up the unit > level the unit using the unit feet. +/- 10 mm gas appliances: warning risk of damage / injury! Secure the gas unit against movement. Installing onto an original oven stand: > use the mounting kit (article number 8700.0317) to attach the stand to the floor, either with scre...

Page 25: 5 Setting Up The Unit

25 5 setting up the unit a appliance size 61 / 11 62 / 12 a [mm] 745.5 965.5 a [inch] 29 3/8 38 i notice oven stand mounting kit is not included in delivery and must be ordered separately. > insert the oven stand into the foot locks and set the stand up horizontally in the installation location. Sec...

Page 26: 5 Setting Up The Unit

26 5 setting up the unit > secure the retaining plates to the installation site using screws and dowels or nuts and bolts. I notice oven stand foot locks are not included in delivery and must be ordered separately. Movable oven stands/base units: i notice oven stand foot locks are included in delive...

Page 27: 5 Setting Up The Unit

27 5 setting up the unit lorem ipsum.

Page 28: 5 Setting Up The Unit

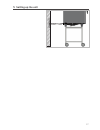

28 5 setting up the unit 5.3.2 floor units make sure the unit is level. 10 mm secure the unit against movement. The enclosed mounting kit may be used to do this. 64,5 mm 2 5/8" a appliance size 21 22 a [mm] 732.5 937.5 a [inch] 28 7/8 37.

Page 29: 5 Setting Up The Unit

29 5 setting up the unit if using the mounting kit, push the floor unit into the foot locks. Mobil oven racks make sure the mobile oven rack is positioned level within the unit. I notice incorrectly aligning the oven rack may cause the unit to malfunction (e.G., during cleaning)..

Page 30: 5 Setting Up The Unit

30 5 setting up the unit make sure there is 7 7/8” [200 mm] distance between the upper edge of the entry ramp and the floor with the unit feet. 200 mm (7 7/8“) max 4° check the cooking cabinet door seal: valid for scc > activate the “rinse without tabs” cleaning program, > observe for excess leakage...

Page 31: 5 Setting Up The Unit

31 5 setting up the unit drain troughs in front of floor units: position flat plates over the trough in front of the mobile oven rack. Handle storage the included holder provides a convenient place to store the mobile oven rack handle during cooking. Remove the left side panel to mount the holder. I...

Page 32: 5 Setting Up The Unit

32 5 setting up the unit nsf cover panel for hygiene reasons and in accordance with nsf standard 4 and din en 203-3, a cover panel must be installed over the drain valve and clean- ing pump on units 21 and 22. This cover is included with the unit. I notice this does not apply to 21, 22 mobile units..

Page 33: 6 Electrical Connection

33 6 electrical connection 6 electrical connection danger electrocution hazard! High voltage. Observe local and nema/nec regulations during installation! Warning danger to life! Incorrect connection may result in electric shock! Note color coding of wires! Color coding of wires: yellow/green = elect...

Page 34: 6 Electrical Connection

34 6 electrical connection caution improper installation can lead to personal inju- ry or property damage! Customer: provide accessible all-pole discon- nect unit with at least 3 mm contact separation (disconnect switch or circuit breaker). If unit must be connected to an earth leakage circuit break...

Page 35: 6 Electrical Connection

35 6 electrical connection units 12, 21 and 22 electro: maximum connection impedance at the grid con- nection point is 0.09Ω. The cross-sections of the connection lines depend on current consumption and local regu- lations. Special voltage available on request. 6.2 electrical units each unit should ...

Page 36: 6 Electrical Connection

36 6 electrical connection i notice connection to a residential type gfi (ground fault interrupter) of insufficient leakage current is not advisable. Random and or nuisance trips of the breaker could result..

Page 37: 6 Electrical Connection

37 6 electrical connection 6.4 power supply cable i notice in order to avoid hazards, the mains power cable may only be replaced by the manufactur- er, its customer service representative or simi- larly qualified service personnel. I notice non-functioning unit ! Tighten mains lead connection. Use c...

Page 38: 6 Electrical Connection

38 6 electrical connection 6.5 equipotential bonding (physical earth ground) a connection site for optional equipotential bonding is located on the bottom or the back of the unit. 60: 61, 62, 11, 12: 21, 22:.

Page 39: 6 Electrical Connection

39 6 electrical connection 6.6 voltage conversion 208/240v units all electric units and 62/102/202 gas units are set to 208v ex works. They can be converted to 240v. To convert from 208v to 240v proceed as follows: > disconnect unit from mains > remove left side panel and open operator panel. > set ...

Page 40: 6 Electrical Connection

40 6 electrical connection 61-22: s 13 440/480 v units units are set to 480v ex works, but can be con- verted to 440v. To convert from 480v to 440v proceed as follows: > disconnect unit from mains > remove left side panel and open operator panel. > remove adapter cable w22 from input trans- former t...

Page 41: 6 Electrical Connection

41 6 electrical connection 6.7 connection values scc, cm_p electrical units appliance size 60 61 62 11 12 21 22 power [kw] / current consumption [a] input voltage 2 ac 208v 5,7 / 27.5 11,1 / 53,4 2 ac 240v 5,7 / 31.5 11,1 / 61,5 3 ac 208v 5,7 / 16.5 11,1 / 30,8 22,1 / 61,4 19 / 52,8 37 / 102,7 38 / ...

Page 42: 6 Electrical Connection

42 6 electrical connection fuse [a] 60 61 62 11 12 21 22 2 ac 208v 50 60 2 ac 240v 50 70 3 ac 208v 30 35 70 60 125 125 200 3 ac 240v 30 40 80 75 150 150 250 3 ac 440v 20 35 30 60 60 100 3 ac 480v 25 40 35 70 70 110 awg [x] 60 61 62 11 12 21 22 2 ac 208v 8 4 2 ac 240v 8 4 3 ac 208v 12 8 3 4 2 1 4/0 3...

Page 43: 7 Water Connection

43 7 water connection 7 water connection the unit complies with all relevant regulations (svgw, kiwa, wras). 7.1 prerequisites > the user must supply each unit with its own water supply tap. > rinse the water supply line before connecting the unit to water! > water pressure 21 - 87psi, 43psi recom- ...

Page 44: 7 Water Connection

44 7 water connection 7.2 unit water connection unit size 60: 1 unit sizes 61, 62, 11, 12: 1 2 3 unit sizes 21, 22: 3 2 1 water connection legend 1 = 3/4” common water supply line. (cold water up to 30°c [86°f]) 61, 62, 11, 12, 21, 22: if split water connection: 2 = 3/4” cold water supply line (max....

Page 45: 7 Water Connection

45 7 water connection i notice unit size 60 is single water connection only. All others are for split water connection. I notice all units are provided with bsp to garden hose thread adapter(s) in starter kit. Article number: 50.00.790 i notice the manufacturer recommends preventative inspection be ...

Page 46: 7 Water Connection

46 7 water connection regarding water and sewer connections, espe- cially those regarding installation of water intake points. Only usa (not valid for can) in most cases, water connections do not require additional filters or water treatment. Filtration and/or water treatment (a, b, c, d) may be nec...

Page 47: 7 Water Connection

47 7 water connection important for treated water connections: to increase filter capacity, split the water con- nection like shown in chapter 7.2 into cold and treated water inputs (not possible with size 60 units) - remove the common water supply line. I notice unit size 60 is single water connect...

Page 48: 8 Gas Connection

48 8 gas connection 8 gas connection caution danger to life! Connecting incorrectly may result in burns or fire. Observe local regulations. Danger poisoning hazard! Make sure that factory settings conform with actual connection conditions: > perform exhaust gas analysis when first commissioning stea...

Page 49: 8 Gas Connection

49 8 gas connection i notice any gas equipement like connectors, fittings and regulators must be designed to supply the required amount of gas. Pipe diameter in accordance with local regulations > at least ¾” id (interior diameter) for 61-201 > at least 1” id (interior diameter) for 202 gas connecti...

Page 50: 8 Gas Connection

50 8 gas connection gas connection 61, 62, 11, 12 ¾“ pipe ¾“ main gas line shut off left side view quick connect gas line i. E. Dormont 36“ ¾“ gas connection 21, 22 ¾“ pipe for 201 1“ pipe for 202 ¾“ for 201 1“ for 202 main gas line shut off left side view quick connect gas line i. E. Dormont 36“ ¾“...

Page 51: 8 Gas Connection

51 8 gas connection notes danger gas connections must only be set up by locally authorized gas technicians! Set up the gas connection line in accordance with the rated thermal load specified on the type label. I notice unit malfunction! If line pressure deviates from connection flow pressure, contac...

Page 52: 8 Gas Connection

52 8 gas connection gas consumption gas type required connection flow pres- sure wobbe index [mj/m 3 ] maximum consumption at rated thermal load (15°c, 1013mbar) wi ws 61 62 11 natural 6,5 -10,0 in/wc 45,67 50,72 49,44 ft 3 /h 49000 btu/hr 107,35 ft 3 /h 106000 btu/hr 82,98 ft 3 /h 83500 btu/hr prop...

Page 53: 9 Exhaust Gas Connection

53 9 exhaust gas connection 9 exhaust gas connection danger asphyxiation hazard! Combustion products (co and co 2 ) prevent unacceptable concentrations of harm- ful combustion products within the installation room. Set up the unit under conditions of adequate ventilation. Observe instructions given ...

Page 54: 9 Exhaust Gas Connection

54 9 exhaust gas connection maintenance as per the specified standards, we recommend gas components undergo annual maintenance. After maintenance or repair work: > check that the compensation tube is posi- tioned correctly. > check the gas supply line components for leaks. Exhaust gas and room volum...

Page 55: 10 Wastewater Connection

55 10 wastewater connection 10 wastewater connection i notice use only steam temperature-resistant pipes for wastewater drainage (e.G. Copper, stainless steel or schedule 80 pvc). Do not use hoses. > unit complies with all relevant regulations (svgw, kiwa, wras). > welding a drain pipe onto the unit...

Page 56: 10 Wastewater Connection

56 10 wastewater connection unit size 60 min. 3°/5% Ø 40 mm (1½”) unit sizes 61, 62, 11, 12 > avoid bends attached immediately at unit. > provide 8 - 10” before a bend. Weight of piping not to be placed on unit drain air gap per local code clamped to stand approx. 24“ 3x45° 2“ copper pipe 8 - 10”.

Page 57: 10 Wastewater Connection

57 10 wastewater connection floor units > floor units can only use floor drains Ø 50 mm (2”) 70 mm (2 3/4“) max. 1 m (3 ft.) min. 3°/5% i notice the average height of the water drainage pipe is 2 3/4” [70 mm]. Options > additional riser tube to reduce steam escap- ing from drain pipe with open drain...

Page 58

58 11 ventilation, technical data, heat dissipation 11 ventilation, technical data, heat dissipation on-site ventilation: when installing an externally vented exhaust hood, observe the following: > comply with all local regulations and stan- dards (nfpa 96; gas combi or electric combi where applicab...

Page 59

59 11 ventilation, technical data, heat dissipation technical data noise emissions value: water jet protection: ipx5 thermal load - scc units [kj/h]: electrical units 60 61 62 11 12 21 22 latent: 1.020 2.050 3.450 3.450 6.350 6.850 10.900 sensitive: 1.350 2.450 4.450 4.450 7.750 8.850 14.000 gas app...

Page 60: 12 Initial Start-Up

60 12 initial start-up 12 initial start-up warning scalding hazard! To avoid scalding, when working with liquids or foods that become liquid when heated to higher temperatures, only use containers that are easy to monitor. (din: iec 60335-2-42). The “max. Rack height for containers with liquid” safe...

Page 61: 12 Initial Start-Up

61 12 initial start-up self test when first commissioning a new unit, start a one-time self-test. This test serves to adjust the unit to its specific ambient conditions. It runs automatically, and takes between 45 and 65 minutes depending on the size of the unit; if an ultravent is in use, the test ...

Page 62: 12 Initial Start-Up

62 12 initial start-up danger poisoning hazard! Gas units: perform exhaust gas analysis after self-test. Scc: press “start” cmp: press “prog/start”.

Page 63: 13 Options

63 13 options 13 options left and right heat shields (not suitable for combi-duo and ultravent) if it is not possible to keep the left side (or right, on unit sizes 61 and 11) of the unit a sufficient distance away from heat sources, an additional heat shield can reduce thermal loads. I notice a cle...

Page 64: 13 Options

64 13 options adjusting height on unit sizes 61, 62, 11, 12 if units of these sizes do not have sufficient ground clearance, ground clearance can be increased using longer foot bases (4” [110 mm]). To do this, simply replace the standard foot bases with longer ones. Article number: foot extension: 1...

Page 65: 13 Options

65 13 options height adjustable transport trolley for mobile oven rack when using a mobile oven rack and a mobile oven rack transport trolley, height differences can be compensated by using an adjustable transport trolley. Appliance size 61, 11 62, 12 article number: 60.60.188 60.70.160

Page 66: 13 Options

66 13 options raising floor units if ground clearance underneath floor units is too low, use foot extensions to increase the height of the unit by 2 3/4” [70 mm]. Article number: 60.21.179 (1x) article number: 60.70.407 (set of 4) i notice scalding hazard! The topmost rack rail may then be higher th...

Page 67: 13 Options

67 13 options floor unit entry ramps if the ground is not level in the mobile oven rack entry area on floor units, use an entry ramp to compensate this. The plate feet are adjustable by +/-1/2” [+/-10 mm]. The entry ramp is attached to the right feet of the unit using the ramp clamps. Appliance size...

Page 68: 13 Options

68 13 options condensation breaker i notice unit malfunction! Extending the ventilation pipe without using a condensation breaker can cause the unit to malfunction. Installing a condensation breaker and the includ- ed pipes can divert steam escaping from the exhaust pipe into non-critical areas, or ...

Page 69: 13 Options

69 13 options reducing excessive steam emissions an additional riser pipe can be attached to the ventilation pipe to reduce excess steam emis- sions. Holes must be drilled into this extra vent pipe where air is sucked in and condensates the steam. 8 mm 1/8" Ø 1/8“ [8 mm] 4“ [100 mm ].

Page 70: 13 Options

70 13 options wall mount unit sizes 60 and 61 only the two units named above can be attached to the wall using a wall mount. I notice be sure to follow the corresponding modifica- tion instructions when performing wall instal- lations. Appliance size 60 61 article number: 60.30.968 60.70.963.

Page 71: 13 Options

71 13 options interfaces scc come with an ethernet interface as part of their standard equipment. An cat-5 ethernet cable must be used to connect to a network. Connection location: unit size 60: on the rear of the unit unit sizes 61-22: on the underside of the unit a detailed description on connecti...

Page 72: 14 Conversion Tables

72 14 conversion tables 14 conversion tables °dh °f °e ppm mmol/l gr/ gal(us) mval/kg 1 °dh 1 1.79 1.25 17.9 0.1783 1.044 0.357 1 °f 0.56 1 0.70 10.0 0.1 0.584 0.2 1 °e 0.8 1.43 1 14.32 0.14 0.84 0.286 1 ppm 0.056 0.1 0.07 1 0.01 0.0584 0.02 1 mmol/l 5.6 0.001 0.0007 100 1 0.00058 2 1 gr/gal (us) 0....

Page 73

73 3 installation instructions kpa mbar psi inch/wc 0.1 1 0.0147 0.4014 0.2 2 0.0294 0.8028 0.3 3 0.0441 1.2042 0.4 4 0.0588 1.6056 0.5 5 0.0735 2.0070 0.6 6 0.0882 2.4084 0.7 7 0.1029 2.8098 0.8 8 0.1176 3.2112 0.9 9 0.1323 3.6126 1 10 0.147 4.0140 1.2 12 0.1764 4.8168 1.4 14 0.2058 5.6196 1.6 16 0...

Page 74: 14 Conversion Tables

74 14 conversion tables.

Page 75: 14 Conversion Tables

75 14 conversion tables.

Page 76

80.02.362 · v-13 · 04/2017 · r ts · dja us a rational canada inc. 2410 meadowpine blvd. Unit 107 l5n 6s2 mississauga canada tel. +1 877 728 4662 fax +1 905 567 2977 info@rational-online.Ca rationalcanada.Com rational usa inc. 1701 gold road suite c-120, commercium rolling meadows, il 60008 united st...