- DL manuals

- Rational

- Grill

- SCC Line

- Training Manual

Rational SCC Line Training Manual

Summary of SCC Line

Page 1

-1- training manual diagnostic and troubleshooting scc line selfcooking center - combi master edition 11-2006.

Page 2: Training

-2- training manual diagnostic and troubleshooting scc line edition 11-2006 general hints: isolate the appliance from mains supply before opening the appliance when working with chemicals, i.E. Aggressive cleaning materials always wear protective clothing, goggles and gloves! After maintenance / rep...

Page 3

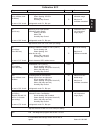

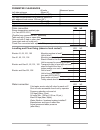

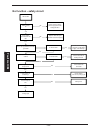

-3- part 2: topic: scc technique page: 1. Scc overlay 2. Scc self cooking control until software 01-07-12 3. Scc combi steamer mode until software 01-07-12 4. Scc self cooking control since software 02-01-01 5. Scc combi steamer mode since software 02-01-01 6. Scc programming, cleanjet 4. Scc princi...

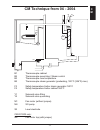

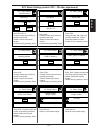

Page 4: Cm Technique From 04 - 2004

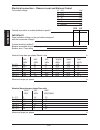

-4- s c m steam hot air combi steam low temperature steam finishing cool down cabinet temperature display cabinet temperature setting timer core temperature time - core temperature display time - core temperature setting cm technique from 04 - 2004.

Page 5: Cm Technique From 04 - 2004

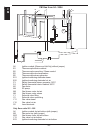

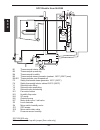

-5- s c m b1 b3 f4 m4 y1 y2 b2 m1 s2 b5 f3 cm technique from 04 - 2004 b1 thermocouple cabinet b2 thermocouple quenching / steam control b3 thermocouple core temperature b5 thermocouple steam generator (preheating, 180°c (356°f) max) f3 safety temperature limiter steam generator 160°c f4 safety temp...

Page 6

-6- s c m water level control steam generator v ac s2 m4 y1 y2 b2 s2 b5 f3 center s2 ==> ground: 2 - 6v ac: water level too low steam heating must switch off solenoid valve fi lling y1 on center s2 ==> ground: 0v ac: water level reached steam heating can switch on solenoid valve fi lling y1 switched o...

Page 7

-7- s c m y1 y2 b2 b1 °c / °f t (sec) b2 - 2 b2 - 1 b1 - 100°c(212°f) 70°c (158°f) 1. Filling of interior cabinet based on time and temperature control of b1 cabinet sen- sor 2. After steam saturation inside cabinet steam will also fi ll quenching chamber 3. Depending on the frequency of tempera- tur...

Page 8: Key Code Cm From 04 - 2004

-8- s c m key code cm from 04 - 2004 clen clen clen sc calc a) cool down cabinet below 60°c b) spray inside cabinet with rational cleaner c) close cabinet door d) select „cool down e) press core temperature key for 10 sec. F) „clen“ will show in cabinet temperature display g) press timer key 1x; cle...

Page 9: Key Code Cm From 04 - 2004

-9- s c m 100°c 212°f a) select any mode c) press timer and core temperature key simultaneously for 10 sec. Until ==> d) display changes from °c to °f or vice versa e) release both keys key code cm from 04 - 2004 notes: 4. Changing temperature display from °c to °f.

Page 10: 42.00.004

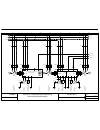

-10- s c m x7 x19 x20 f1 f2 transformer 0,1 at 2 at 1 1 x7 x19 x20 x18 x23 x31 rs 485 x8 x12 x26 x27 x32 x24 x30 rs 232 x63 x3 x4 x6 x2 x50 2 at 1 2 3 4 on of f 1 1 1 1 1 1 1 f6.1 f6.1 2 at 2 at x16 x16 f6 f6 42.00.004 42.00.047 x2 b3 core temperature x3 b1 interior cabinet x4 b2 quenching / steam c...

Page 11: Motor For Cm 40.00.274

-11- s c m motor for cm 40.00.274 jumper 40.01.581 is used on fl oor model 201 and 202 for top position motor only! Jumper is not used on models 61 - 102 with one motor only! (service 34 will be shown!) led jumper reason 1x motor doesn’t start, no changing signal from hallsensor 2x voltage too low on...

Page 12

-12- s c m mode: steam 100°c (212°f) temp. Preset, not adjustable function step select steam mode select time or core temperature close cabinet door check water level inside steam generator preheat steam generator, if b5 is below 85°c (185°f); timer starts after successful preheating steam supply up...

Page 13

-13- s c m mode: low temperature steam temp. Range 30-99°c (86-210°f) function step select vario steam mode (temp. Setting 30-99°c (86-210°f)) select time or core temperature close cabinet door check water level inside steam generator preheat steam generator, if b5 is below 85°c (185°f); timer start...

Page 14

-14- s c m mode: combination temp. Range 30-300°c (86-572°f) function step select combination mode (temp. 30-300°c (86-572°f)) select time or core temperature close cabinet door check water level inside steam generator preheat steam generator, if b5 is below 85°c (185°f); timer starts after successf...

Page 15

-15- s c m mode: finishing temp. Range 30-300°c (86-572°f) function step select finishing (recom. Temp. 100-140°c (212-284°f)) select time or core temperature close cabinet door check water level inside steam generator preheat steam generator, if b5 is below 85°c (185°f); timer starts after successf...

Page 16

-16- s c m mode: hot air temp. Range 30-300°c (86-572°f) function step select hot air (temp. 30-300°c (86-572°f)) select time or core temperature close cabinet door timer starts at once hot air supply until set temperature inside cabinet is reached quenching (set to 90°c/194°f) responsible sensor re...

Page 17: Function Test

-17- s c m x7 x19 x20 f1 f2 transformer 0,1 at 2 at 1 1 x7 x19 x20 x18 x23 x31 rs 485 x8 x12 x26 x27 x32 x24 x30 rs 232 x63 x3 x4 x6 x2 x50 2 at 1 2 3 4 on of f 1 1 1 1 1 1 1 f6.1 f6.1 2 at 2 at x16 x16 f6 f6 42.00.004 42.00.047 1 2 3 4 on switch unit on on operator pcb set dip switch 1 to „on“ posi...

Page 18

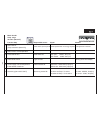

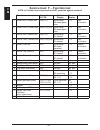

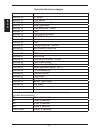

-18- s c m description software version b1 cabinet sensor b2 quenching sensor b3 core sensor b5 steam generator sensor pcb temperature s3 door contact s2 water level steam generator steam elements 0 - off; 1 - 50%; 2 - 100% hot air elements 0 - off; 1 - 50%; 2 - 100% speed fan motor top speed fan mo...

Page 19

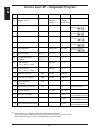

-19- s c m service level: rt -- running time rt # rt 1 rt 2 rt 3 rt 4 rt 5 rt 6 rt 7 rt 8 rt 9 rt 10 rt 11 rt 12 rt 13 description total s3 door openings total time y1 valve fi lling total time y2 valve quenching total time m4 sc-pump total time steam heating time total time hot air heating time tota...

Page 20

-20- s c m service level: se -- basic settings select desired step with timer dial (fan motor and heating elements are automatically off) activate selected step with timer key steam heating time since last sc-automatic press time and core key simultaneously for 5 seconds to set steam heating time to...

Page 21

-21- s c m adjusting speed of blower motor steam (+/ -10%) (after blower speed adjustment the original rpm is shown in the temp. Display, the changed rpm is shown in the time display) press time key, keep it pressed and adjust displayed rpm with timer dial se9 = min rpm; se10 = start rpm; se11 = max...

Page 22

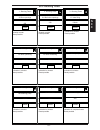

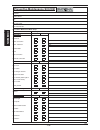

-22- s c m function connection i/o pcb cabinet display time display comment f1 steam 50%, electric unit x24:(1-2) actual temp. B5 steam gene- rator 1 / 0 gas: no function f2 steam 100%, electric unit x24:(1-2)+(5-6) actual temp. B5 steam gene- rator 1 / 0 gas: no function f3 hot air 50%, electric un...

Page 23

-23- s c m service level: f -- function test note: in function test components are not protected against overload! Connection i/o pcb bus bus bus bus bus bus bus bus bus cabinet dispaly actual blower rpm actual blower rpm actual blower rpm actual blower rpm actual blower rpm actual blower rpm actual...

Page 24

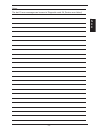

-24- s c m since software version c1-07-01 the last 10 error messages are shown. Er when timer key is pressed the error code will be displayed, i.E. Er1 3 b1 cabinet sensor defective er2 14 y1 filling solenoid defective er3 -- -- er10 since software version c1-07-01 the last 16 gas error messages ar...

Page 25

-25- s c m int. Cab. Display h2o chng timer display e1 e2 e3 e4 e5 e6 e7 e8 e9 e10 e11 e12 e 12 e13 e14 e15 e16 e17 e18 e19 e20 e21 e22 e23 e24 timer display open pol int. Cab. Display (e -press core temp. Key) 1 st 1 co 2 st 2 co 1_ 2_ 1xx 2xx 3xx 1xx 2xx 3xx failure explanation h2o open change pol...

Page 26

-26- s c m s2 b1 b3 f4 m4 y1 y2 b2 m1 b5 f3 m8 m9 y11 y12 a5 b11 b12 cm gas from 04 - 2004 a5 ignition module (steam and hot air) (without jumper) b1 thermocouple interior cabinet b2 thermocouple quenching / steam control b3 thermocouple core temperature b5 thermocouple steam generator b11 ignition/...

Page 27

-27- s c m identifi cation of the different gas burners / gas blowers: cm 201 - 202 cm 61 - 62 - 101 - 102 steam blower (ignition box fi tted) hot air blower top (ignition box not fi tted) hot air blower bottom (ignition box fi tted) ignition box of hot air blower, bottom (201-202): jumper must only be ...

Page 28

-28- s c m sequence of events of steam / hot air burner (scc as well as cm) if no flame detected => new ignition sequence. After 5 th ignition without success => reset 16 24 19 20 17 18 10 11 14 15 speed of bur ner blower motor in u/min 21 22 23 26 27 6 7 8 9 0 1 4 5 8 4 3 2 1 25 12 13 f l a m e c u...

Page 29

-29- s c m check gas type / gas conversion: cm gas from 04-2004 select any mode and cooking time open control panel set dip switch 1 on pcb to „on“ position with timer dial select: „se“ = settings: activate „settings“ by pressing core temperature key; display changes to „se1“ with timer dial select:...

Page 30

-30- s c m changing installation altitude: cm gas from 04-2004 se a) b) c) d) e) f) g) h) i) j) k) l) m) n) 6250 select any mode and cooking time open control panel set dip switch 1 on pcb to „on“ position with timer dial select: „se“ = settings. Activate „settings“ by pressing core temperature key;...

Page 31

-31- s c m flue gas analysis: cm gas from 04-2004 before you carry out a fl ue gas analysis check input gas fl ow pressure when burner is running • switch on unit. Select any mode and cooking time. Wait till burner works • check input gas fl ow pressure • see correct values of input fl ow pressure on se...

Page 32

-32- s c m select position f19 with timer dial and enter „steam min“ with timer key. Activate position f19 with core temperature key; note: in this position core temp. Key is used as a switch and will automatical- ly deactivate after 4 minutes.“ carry out a co 2 measurement to cross-check co 2 value...

Page 33

-33- s c m input gas flow pressure adjustment of co 2 - screw input gas flow pressure adjustment of co 2 - screw input gas flow pressure adjustment of co 2 - screw 61 18 - 25 mbar 3,9 mm 18 - 25 mbar 3,8 mm 62 18 - 25 mbar 3,4 mm 18 - 25 mbar 3,5 mm 101 18 - 25 mbar 3,3 mm 18 - 25 mbar 3,3 mm 102 18...

Page 34

-34- s c m changing gas blower speed (max, start, min rpm): cm gas from 04-2004 (as from software c-06-03): note: this setting shall only be done by specially trained and rational approved technicians. Se a) b) c) d) e) f) g) h) i) j) k) l) m) n) o) p) q) 6250 open cabinet door select any mode open ...

Page 35

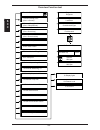

-35- s s c c scc control panel notes:.

Page 36

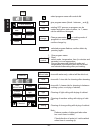

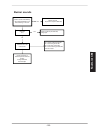

-36- s s c c 1 2 3 4 1 2 3 4 1 2 3 4 back to previous level help guide line for selected setting cleanjet, haccp, delta t, e1/2 store selected setting start time, cds, descaling, settings selection of core temperature searing notes: selfcooking control mode - level 1 selfcooking control mode - level...

Page 37: 200°C

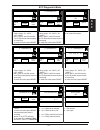

-37- s s c c combi steamer mode functions settings 1 2 3 4 1 2 3 4 1 2 3 4 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% 200°c duration cds cleanjet haccp start time settings 10:24 english am/pm 24 h h:m m:s 08/22/03 22.08.03 °c / °f prog 1 2 3 4 1 2 3 4 service typ haccp prog english h:m m:s am/pm 24...

Page 38

-38- s s c c 1 2 3 4 1 2 3 4 1 2 3 4 large roast potato product pan fries egg dishes/desserts poultry bakery products fish finishing side dishes help: guide line for selected setting; practical hints for product to be used in the respective scc cooking process back to previous level cleanjet, haccp,...

Page 39: 200°C

-39- s s c c setting of humidity setting of cabinet temperature setting of time setting of core temperature moistening setting of fan speed (lowest level=intermittent) cool down service key (after setting dip switch #1) 1 2 3 4 1 2 3 4 combi steamer mode functions settings 1 2 3 4 1 2 3 4 1 2 3 4 0%...

Page 40

-40- s s c c 1 2 3 4 1 2 3 4 delete prog new level control copy change clean manual cleanjet select program name with central dial give program name (blank - between _ and @ existing scc process or program can be copied and get an index number, i.E. 1; name can be edited and changed; change paramete...

Page 41

-41- s s c c notes:.

Page 42

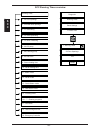

-42- s s c c b1 b6 f4 p1 m3 s4 m4 m6 s11 y1 y2 y3 b2 m1 s2 m7 s12 b4 b5 f3 b1 thermocouple interior cabinet b2 thermocouple quenching b4 thermocouple humidity b5 thermocouple steam generator (preheat, 180°c (356°f) max) b6-b11 thermocouples core temperature f3 safety thermostat steam generator 160°c...

Page 43

-43- s s c c notes:.

Page 44

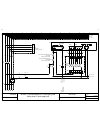

-44- s s c c x 7 x 8 x 1 x 51 x 54 x 53 x 09 x 10 x 5 x 2 x 6 x 4 x 50 a2 scc pcb a3 add on pcb x 52 x 2 3v on led 1 2 3 x 3 rs 232 battery x 12 x 11 x7 200 - 240v input to i/0 switch x8 buzzer x12 level electrode x11 humidity fl ap motor / micro switch add on x1 p1 pressure sensor add on x2 b6-11 th...

Page 45

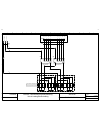

-45- s s c c ultraventvent . 230v input energy optimising sicotronic y1 fi lling y2 quenching y3 moistening sc pump cleanjet pump measuring points i/o pcb scc (40.00.049) wires of pcb edge connectors are pointing to component side of pcb! Motor drain valve micro switch drain valve 12 v dc ssr ssr pul...

Page 46: Motor For Scc / Cm

-46- s s c c motor for scc / cm jumper 40.01.581 is used on fl oor model 201 and 202 for top position motor only! Jumper is not used on models 61 - 102 with one motor only! (service 34 will be shown!) led jumper reason 1x motor doesn’t start, no changing signal from hallsensor 2x voltage too low on m...

Page 47

-47- s s c c notes:.

Page 48

-48- s s c c mode: wet heat (98-103°c (208-218°f), set temperature) function step select wet heat (temp 98-103°c (208-218°f)) select time or core temperature close cabinet door check water level inside steam generator preheat steam generator, if b5 is below 85°c (185°f); timer starts after successfu...

Page 49

-49- s s c c mode: low temperature steam; (30-97°c (85-207°f), set temperature) function step select wet heat (temp 30-97°c (85-207°f) select time or core temperature close cabinet door check water level inside steam generator preheat steam generator, if b5 is below 85°c (185°f); timer starts after ...

Page 50

-50- s s c c mode: forced steam104-130°c (219-266°f), set temperature) function step select wet heat (temp 104-130°c (219-266°f)) select time or core temperature close cabinet door check water level inside steam generator preheat steam generator, if b5 is below 85°c (185°f); timer starts after succe...

Page 51

-51- s s c c mode: combi steam 141-300°c (286-572°f), set temp. Function step select wet and dry heat (temp 141-300°c (286-572°f)) select time or core temperature close cabinet door check water level inside steam genera- tor preheat steam generator, if b5 is below 85°c (185°f); timer starts after su...

Page 52

-52- s s c c mode: finishing (30°-140°c (85-284°f), set temp. Function step select wet and dry heat (temp. 30-140°c, 85-284°f) select time or core temperature close cabinet door check water level inside steam genera- tor preheat steam generator, if b5 is below 85°c (185°f); timer starts after succes...

Page 53

-53- s s c c mode: dry heat 30°-300°c (86-572°f), set temp. Function step select dry heat temp. 30-300°c (86-572°f) select time or core temperature close cabinet door timer starts counting down heat up cabinet with hot air until set temperature quenching (set to 90°c/158°f) responsible sensor reed s...

Page 54

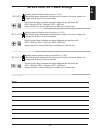

-54- s s c c 1 2 3 4 switch on unit set dip 1 on operator pcb to „“on““ position press service key on the displays the following available service - modules will be shown window 1 diagnostic window 2 running times window 3 basic settings window 4 function test activate selected service module by pus...

Page 55

-55- s s c c notes:.

Page 56

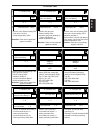

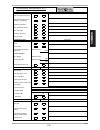

-56- s s c c diagnostic running times basic settings function test 1 - diagnostic cabinet b1 130°c 345°c act max 160°c 32 min scc diagnostic mode overview diagnostic 1 - cabinet b1 2 - quenching b2 3 - not used 4 - humidity b4 5 - steam generator b5 6-11 - core temp b6-11 12 - temperature 13 - level...

Page 57

-57- s s c c scc diagnostic mode 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 - diagnostic cabinet b1 130°c 345°c act max“ - temp. Range: -30 - 340°c (-22 - 644°f) - 900°c (655°c until sw version 01-07-08) broken thermocouple or loose plug - to reset max value press rese...

Page 58

-58- s s c c 15 - diagnostic clima p1 - b4 - rpm default out 0,48v 2,24v b4 85% rpm 145°c 1850 default: 0,4-0,55v at standard speed: out ca. 1,3 - 1,6v combi 200°c (392°f) out ca. 1,5 - 1,9v steam 100°c (212°f) out ca. 2.5 - 3,0v hot air 60°c (140°f) 18 - diagnostic hot air 0% 50% 100% 21 - diagnost...

Page 59

-59- s s c c notes: starting with software version 01-07-09 the entire information of the service level can be downloaded to memory stick when dip switch 1 is set to „1“. 1 2 3 4 1 2 3 4 25 - diagnostic gas error history gas 1 0: 09:10.05 9:17 32 - since software version 01-07-09 indication of the l...

Page 60

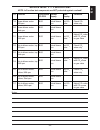

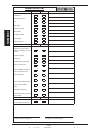

-60- s s c c diagnostic running times basic settings function test 1 - running times s3 door openings 219 1 2 3 4 1 2 3 4 running times 1 - s3 door openings 2 - s12 ball valve openings 3 - y1 valve fi lling 4 - y2 valve quenching 5 - y3 valve moistening 6 - m4 sc pump 7 - m6 cleaning pump 8 - m7 ball...

Page 61

-61- s s c c 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 2 - running times s12 ball valve openings 238 quantity counter reset possible 5 - running times y3 valve moistening 48min indication in minutes reset possible 8 - running times m7 ball valve 55min indication in minu...

Page 62

-62- s s c c 10 - running times hot air heating time 4hrs indication in complete houres reset possible 13 - running times combi steam mode 4hrs indication in complete houres reset not possible 16.1-6 - running times cleaning program 4hrs indication in complete houres reset not possible 16.1 - rinse ...

Page 63

-63- s s c c notes:.

Page 64

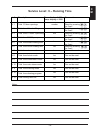

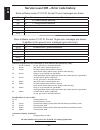

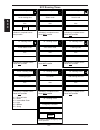

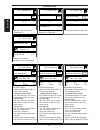

-64- s s c c diagnostic running times basic settings function test basic setting gas type nath - g20 17 - ip address 18 - subnet mask 19 - gateway address 20 - ip address 21 - server ip address 22 - subnet mask 23 - plate á la carte (weight of plate) sw 02-01 24 - plated banquet (weight of plate) sw...

Page 65

-65- s s c c 2 - basic setting gas type 3b/p - 3p- a12/13 - nat.H - nat.L - confi rm adjustment by touch on „store“ icon. - corresponding blower speeds are automatically selected and loaded. - unit must be switched off and on to store new setting! 5 - basic setting gas blower speed steam rpm start rp...

Page 66

-66- s s c c 1 2 3 4 1 2 3 4 1 2 3 4 10 - basic setting sc automatic 45sec (20-90sec) sc pump duration 60min (20-120min) steam heating time - activation by touch on dial icon - adjust duration with dial - confi rm adjustment by touch on dial icon 12 - basic setting show mode on - off - activation by ...

Page 67

-67- s s c c 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 scc basic settings (switch off - on after adjustment) 1 2 3 4 1 2 3 4 1 2 3 4 17 - basic setting ip address edit 168.65.8.217 - press „edit“ - change number and confi rm by pressing central dial - „delete“ erases last entered number - confi ...

Page 68

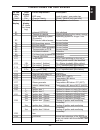

-68- s s c c diagnostic diagnose running times laufzeiten basic settings grundeinstellungen function test funktionstest 5 - function test fan motor top start speed 4 1800 rpm actual speed 1800 rpm 19 display lights 20 exhaust hood 21 sicotronic 1 2 3 4 1 2 3 4 function test 1 steam (dampf) 50% (gas ...

Page 69

-69- s s c c 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 2 - function test steam 100% (gas: see below) 0 - 1 temperature b5 103°c - electric and gas units: steam heating 100%; - indication gas units (window 2): „steam gas-burner“ - actual temperature of b5 attention: part...

Page 70

-70- s s c c 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 10 - function test solenoid moistening y3 0 - 1 activation of solenoid valve moistening y3 13 - function test drain valve motor m7 direction 1 -2 end switch s12 1 - 0 direction 1: clockwise direction 2: counter clockwise 14 - funct...

Page 71

-71- s s c c 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 18 - function test interior light 0 - 1 - activation of interior cabinet light 21 - function test sicotronic 0 - 1 - relay on pcb 19 - function test display light - testing of all display lights by pushing and holding start key. The different ligh...

Page 72

-72- s s c c overview service messages service 10 sc pump service 11 cds sensor service 12 cds sensor no signal service 13 steam generator service 14 level electrode - water service 15 free service 16 pcb with old sofware service 17 eeprom faulty service 18 free service 19 free service 20 thermocoup...

Page 73

-73- s s c c service 11 (cds sensor) maintenance needed - appears for 30 sec. After switch on - display can be cancelled by touch - water level o. K. - level electrode is working - too many pulses from cds sensor - check electrode or water leaka- ge through check valve service 14 maintenance needed ...

Page 74

-74- s s c c service messages scc 1 2 1 2 1 2 1 2 1 2 1 2 1 2 1 2 1 2 1 2 1 2 1 2 service 23 (short circuit ssr steam) no function switch unit off - since sw 01-07-09 only! - display at once when: temp. B5 raises above 100°c (212°f) for 60sec. Without energy demand - intermittent buzzer 30 sec - uni...

Page 75

-75- s s c c notes: the last 10 error messages can be seen in diagnostic mode 24 „service error history“.

Page 76

-76- s s c c calibration scc step 1 10 in case of „13“ check: 20 (min: 4x20sec; max: 4x180sec) in case of „20“ check: 30 (4x 30 sec) in case of „50“ check: 40 (max. 800 sec) in case of „11“ check: 50 (40 sec) unit status: basic conditions o.K?: continue with step 10 measurement: offset diff. Pressur...

Page 77

-77- s s c c step 60 (min: 4x20sec; max: 4x180sec) in case of „20“ check: 70 (4x 30 sec) in case of „60“ check: 75 (min 80sec max 1000 sec) in case of „12“ check: 90 (min 360sec max 1000 sec) 100 (min: 4x20sec; max: 4x60sec in case of „20“ check: 110 (4x 30sec) step 90,100 and 110 will run 1x for ea...

Page 78

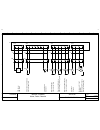

-78- s s c c m6 m6 m6 m6 s12 s12 1 2 3 4 5 6 control drain valve 54.00.357 notes:.

Page 79

-79- s s c c notes:.

Page 80

-80- s s c c s2 b5 b1 b6 f4 p1 m3 s4 m4 m6 s11 y1 y3 y2 b2 m1 b4 f3 m7 s12 m8 m9 a5 y12 y11 b12 b11 a5 ignition module b1 thermocouple interior cabinet b2 thermocouple quenching b4 thermocouple humidity b5 thermocouple steam generator b6 thermocouple core temperature b11 ignition/monitoring electrod...

Page 81

-81- s s c c notes:.

Page 82

-82- s s c c identifi cation of the different gas burners / gas blowers: scc 201 - 202 scc 61 - 62 - 101 - 102 steam blower (ignition box fi tted) hot air blower top (ignition box not fi tted) hot air blower bottom (ignition box fi tted) ignition box of hot air blower, bottom (201 - 202): jumper must on...

Page 83

-83- s s c c sequence of events of steam / hot air burner (scc as well as cm) if no flame detected => new ignition sequence. After 5 th ignition without success => reset 16 24 19 20 17 18 10 11 14 15 speed of bur ner blower motor in u/min 21 22 23 26 27 6 7 8 9 0 1 4 5 8 4 3 2 1 25 12 13 f l a m e c...

Page 84

-84- s s c c check gas type - gas conversion : scc gas from 04 - 2004 whenever working on any gas component like: gas valve, gas blower and / or changing connected type of gas, a detailed fl ue gas analysis must be done using adequate co and co2 measuring equipment! This shall only be done by trained...

Page 85

-85- s s c c adjustment of installation altitude above sea level scc gas from 04 - 2004 note: the altitude settings of 0-499 and 500-999m are identical. Therefore resetting of installation altitude needs to be done only when installing above 1000m (3280ft) or below sea level (i.E. Red sea) a) - swit...

Page 86

-86- s s c c before you carry out a fl ue gas analysis check input gas fl ow pressure when burner is running • switch on unit. Select any mode and cooking time. Wait till burner works • check input gas fl ow pressure • see correct values of input fl ow pressure on serial plate • if necessary adjust gas ...

Page 87

-87- s s c c flue gas analysis: scc gas ab 04 - 2004 1 2 3 4 14 - function test gas steam blower start/stop max co2 fc xxx see list 5,5 rpm h) i) j) k) l) m) n) o) p) q) r) s) t) u) v) press key and select „min“ speed. Activate the burner with the „start“ key. Note: start key is used as a switch and...

Page 88

-88- s s c c input gas flow pressure adjustment of co 2 - screw input gas flow pressure adjustment of co 2 - screw input gas flow pressure adjustment of co 2 - screw 61 18 - 25 mbar 3,9 mm 18 - 25 mbar 3,8 mm 62 18 - 25 mbar 3,4 mm 18 - 25 mbar 3,5 mm 101 18 - 25 mbar 3,3 mm 18 - 25 mbar 3,3 mm 102 ...

Page 89

-89- s s c c a) - switch unit on - open control panel - set dip switch 1 on pcb to „on“ position b) at basic settings select i.E. Position 5 - gas blower steam c) the factory stored blower speed is shown at max, start und min. D) to change the rpm of max, start and min, select the desired step. E) s...

Page 90: Common

S -90- common flash scc software the actual software version can be downloaded from: www/rational-ag.De/service/technical_documentation/scc-line/software software update by usb-stick usb stick must be formatted in fat (fat16) format. Note: most standard usb flash stick are not suitable for scc flash...

Page 91

-91- s s c c notes:.

Page 92: Common

S -92- common changing pcb (pcb defectice) eeprom data faulty (no display of serial number, type) service 17 standard software update green led on main pcb on? Isolate unit from power supply (disconnect control fuses) check pcb transformer primary and secondary voltage (12vac) and plug connectors ch...

Page 93: Common

S -93- common notes:.

Page 94: Common

S -94- common software update cm units with flash-box 87.00.037 for downloading unit software from pc to cm fl ash box the program „megaload“ must be installed on the pc. This program is available on the rational service internet page under: „technical documentation/software update scc-line/cm“. For ...

Page 95: Common

S -95- common copying unit software from pc to cm flash-box - open lid of the flash-box 1. - set dip - switch 2 to „on“. (other switches remain in the off position) 2. Connect rs 232 adapter cable (item 2) to flash-box and to the selected interface (e. G. Com 1) of the pc 3. Start program megaload a...

Page 96

-96- fault tree: changing pcb / changing eeprom / fault "e1" changing pcb software update unit displays "e1" new eeprom to be connected to pcb with unknown sw version or software version before c1-06-05 isolate unit from power supply (disconnect control fuses) fault type: 1 fault type: 2 or 3 reconn...

Page 97: Common

S -97- common how to update cm units via pc to update a cm unit of new generation you have to use a software called „megaload“. To install the software on your pc, you just have to excecute the “setup.Exe” and follow the installation instructions on your screen. After mega- load installation please ...

Page 98: Common

S -98- common the descaler pump 60.70.409 (230v) and 60.70.497 (110v) must only be used to fi ll chemical part number: 6006.0110 into steam generators of equipment bearing either of the following marks on the data plate: warning! When working with chemicals, i.E. Aggressive cleaning materials, al- wa...

Page 99: Common

S -99- common lean the cabinet door close and fi ll the above mentioned quantity of descaler at 10 sec intervals into the steam generator note: descaling liquid can react very violently with the scale inside the steam generator! Should any foam appear at the steam inlet port stop fi lling and wash the...

Page 100: Common

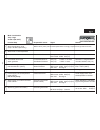

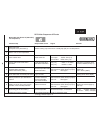

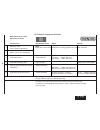

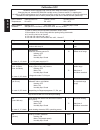

S -100- common rational installation / commissioning checklist scc / cm to be completed individually for each rational combi installation. This checklist has to be completed and returned within 14 days of installation / commission to validate warranty. Customer: address: telefone: __________________...

Page 101: Common

S -101- common perimeter clearances all units measured space left side minimum 50mm (2”) left side 201/202 electric unit min. 500 mm (20“) left side recommended for all units for service or with adjacent heat source 500 mm (20“) rear side 50mm (2”) right side 50mm (2”) drain connection yes no steam ...

Page 102: Common

S -102- common electrical connection – observe local and national codes! Connected voltage l1 – l2 volt l1 – l3 volt l2 – l3 volt l1 - n volt l2 - n volt l3 - n volt n - ground volt yes no ground connection to mains distribution panel? Important!! Does indicated voltage on the unit data correspond w...

Page 103: Common

S -103- common gas connection – observe local and national codes! Yes no required diameter and fi nal connection of individual gas line to each combi: all gas units minimum 3/4” individual gas shut off valve installed for each unit? Shut off valve accessible from front by operator? List type of gas c...

Page 104: Common

S -104- common customer: address street: city: area (zip) code: unit serial number: 1.Installation placement water connection water treatment sedimentfilter drain gas connection electrical connection 2.Door door lock door catch door hinges / screws door contact trolley gasket 2.1 mobile trolley cast...

Page 105: Common

S -105- common 4. Bottom group water connections leak tight retracting mechanism drain gasket floor model drain connection quenching / drain box drain valve scc 5. Gas specific parts burner burner blower emission analysis co co2 according list measured value: visual inspection flue vent 6. Electrica...

Page 106: Common

S -106- common inspections list 8. Control panel control panel gasket control panel dials mode switch temperatur control timer function core probe function led-indicators pcb visual check 9. Function test diagnostic program function test humidity control / flap motor drain, drain valve scc cleanjet ...

Page 107: Common

S -107- common notes:.

Page 108: Common

S -108- common water info because of continuous examinations of systems for water treatment we would like to offer you a few information on some different systems. The given statements are only related to rational units. If you already have made experiences with systems for water treatment, we would...

Page 109: Common

S -109- common notes:.

Page 110: Common

S -110- common scc fault list - troubleshooting 1. Service 10 2. Service 11 3. Service 25 4. Service 26 - 27 5. Gas - service 34 6. No function 7. No steam 8. Pcb change 9. Gas - reset, polarity 10. Descaling 11. Service 12 12. Buzzer sounds cm fault list - troubleshooting 1. No function 2. No steam...

Page 111: Fault List Scc

-111- s fault list scc service 10 unit shows service 10 activate function test level electrode of the steam generator did not recognise a reduction of the water level during last sc-automatic info select step 8 sc pump m4 and touch "start" key pump active, water is pumped off short circuit level ele...

Page 112: Fault List Scc

-112- s fault list scc service 11 indication service 11 shown every time unit is switched on water supply from cds to steam generator leaking eliminate leak actual measured filling volume above reference volume of steam generator info check valve in the water supply line to the steam generator. Valv...

Page 113: Fault List Scc

-113- s fault list scc service 25 activate cleanjet- pump (m6) in the function test. Is pump running? Output voltage of i/o pcb x18 3/4 present cleanjet pump does not or not enough deliver enough water (loss of pressure during cleanjet). Typical indication: the running time of the program will be ex...

Page 114: Fault List Scc

-114- s fault list scc service 26 service 27 activate ball valve in the function test. Micro switch ball valve in permanent closed position. Unit out of order indication service 26 every time unit is switched on info output voltage at i/o pcb x25 7/8 (12v dc) present? Check motor ball valve, micro s...

Page 115: Fault List Scc

-115- s fault list scc service 34 disconnect and reconnect bus cable of the indicated faulty part. Failure eliminated? Bus failure indication of the faulty knot with the following code (combination of different faults possible): - 1: i/o pcb - 2: bottom motor - 4: top motor - 8: top ignition box - 1...

Page 116: Fault List Scc

-116- s fault list scc no function - safety chain no function power supply ok? Check main fuse of the power supply and earth leakage breaker fuse f1/f2 and contactor k1 ok? Replace defective part and find reason for tripping press dry up protector of steam generator no no is unit on now check steam ...

Page 117: Fault List Scc

-117- s fault list scc no or to low steam production humid cooking mode is selected but no/not enough steam is visible door closed ? Close door, check door contact switch is the water tap symbol flashing on the display? Yes emergency humidity control active indication ? Press function, service and f...

Page 118: Fault List Scc

-118- s fault list scc changing pcb (pcb defectice) eeprom data faulty (no display of serial number, type) service 17 standard software update green led on main pcb on? Isolate unit from power supply (disconnect control fuses) check pcb transformer primary and secondary voltage (12vac) and plug conn...

Page 119: Fault List Scc

-119- s fault list scc "reset" indication (gas units) check polarity unit shows "reset" does the connected gas type comply with the gas type on the name plate? Reason: flame monitoring does not work after ignition info gas supply open external ventilation system on yes convert unit to connected gas ...

Page 120: Fault List Scc

-120- s fault list scc indication descaling /service 12 unit shows "descaling of steam generator necessary" (indication comes up every time unit is switched on and remains for 2 minutes) touch function key: degree of scale is shown activate and run descaling program. At the end of the program the ne...

Page 121: Fault List Scc

-121- s fault list scc buzzer sounds buzzer sounds for 30 seconds after fault identification and every time unit is switched on. Activate diagnostic program step 1 - 11 check which thermocouple shows actual values > 654°c, this indicates, that the corresponding "thermo couple is broken" reason: any ...

Page 122: Fault List Cm

-122- s fault list cm no function - safety circuit no function power supply ok check main fuse of the power supply and earth leakage breaker fuses f1/f2 and contactor k1 ok? Replace defective part and find reason for tripping press dry up protector of steam generator no no is unit on now? Check stea...

Page 123: Fault List Cm

-123- s fault list cm no steam wet cooking mode is activated but no steam is visible door closed? Close door and/or check door contact switch indication h2o open? Yes indication e16 or e17? E16: temperature sg>180°c check for scale build up e17: temperature sg water tap open? Sediment filter at wate...

Page 124: Fault List Cm

-124- s fault list cm fault tree: changing pcb / changing eeprom / fault "e1" changing pcb software update unit displays "e1" new eeprom to be connected to pcb with unknown sw version or software version before c1-06-05 isolate unit from power supply (disconnect control fuses) fault type: 1 fault ty...

Page 125: Fault List Cm

-125- s fault list cm buzzer sounds buzzer sounds intermittently after fault identification and after switching on the unit. Reason of fault: a ny thermo couple is defective check connector of thermocouple for sufficient contact. Change defective thermocouple. Indication e3 or e4 or e5 or e6? E3 = i...

Page 126: Fault List Cm

-126- s fault list cm indication "e13" (sc-automatic) unit shows e13 activate function test level electrode of the steam generator did not recognise a reduction of the water level during last sc-automatic info select step f14 sc pump m4 by pressing timer key, activate function with core temper. Key ...

Page 127: Fault List Cm

-127- s fault list cm indication "res" (= reset) chng pol (check polarity) unit shows "res" does the connected gas type comply with the gas type on the name plate? Reason: flame monitoring does not work after ignition info gas supply open external ventilation system yes - convert unit to connected g...

Page 128: Common

S -128- common notes:.

Page 129: Common

S -129- common notes:.

Page 130

Deckblatt elektrische dokumentation, cover sheet for electrical documentation die elektrische dokumentation besteht aus: 1. Diesem deckblatt, 2. Dem schaltplan und 3. Der legende der elektrischen bauteile the electric documentation contains: 1. This cover sheet, 2. The wiring diagram and 3. The bill...

Page 131

76-00011 0 version Überblick cm101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 8 30.04.2004 modul 3 klima plus, fühler humidity control, sensors blatt 3 page modul 2 heißluftheizung/dampfheizung hot air heating/steam heating blatt 2 page modul 1 sicherheitskette, sp.-versorgun...

Page 132

76-00011 0 version modul 1 sicherheitskette, sp.-versorgung pcb safety chain, power supply pcb cm101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 1 30.04.2004 k1 n/o 1 2 3 4 5 6 w17 a4 pcb k1 n/o 14 13 x7 1 1 gy bn rd f3 sicherheitstemperaturbegrenzer 160°c/320°f safety tempera...

Page 133

76-00011 0 version modul 2 heißluftheizung/dampfheizung hot air heating/steam heating cm101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 2 30.04.2004 k 1 :5 / 1 .0 8 1 x0 w16 awg 12 k 1 :1 / 5 .0 0 k 1 :3 / 1 .0 8 og bk vt thermoelement dampfgenerator thermocouple steam generat...

Page 134

76-00011 0 version modul 3 klima plus, fühler humidity control, sensors cm101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 3 30.04.2004 a4 pcb s2 n ive auelek tr ode w a te r lev el s ens or w5 gy wh wh ye/gn x12 1 1 x73 2 2 2 2 1 1 3 3 3 3 4 4 4 4 b1 t h erm oelem ent garraum ...

Page 135

76-00011 0 version modul 4 wasser water, drain, cleanjet cm101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 4 30.04.2004 a4 pcb w3 wh bu wh bu y1 m a g n etv entil- füllen s o le noid v a lv e filling a1 a2 x19 3 3 x30 1 1 1 1 2 2 y2 m a g n e tv ent il-a blös c hung s o le n o...

Page 136

76-00011 0 version modul 5 lüftermotor fan motor, cooling fan cm101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 5 30.04.2004 1.08 / 2.00 / k1:1 1.08 / n 1.08 / pe 1.08 / k1:13 1.08 / k1:a2 bk bu ye/gn bn bu m11 kü hl lü ft er co ol ing fan m 1 ~ a2 a1 m5 kü hl lü ft er co ol i...

Page 137

76-00011 0 version modul 6 summer, eeprom buzzer, eeprom cm101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 6 30.04.2004 a4 pcb w9 wh wh x8 1 1 x47 1 t2 su m m e r bu z z e r 2 2 2 x50 ext erne e p r om 1 1 2 2 eeprom 3 3 4 4 0 0 1 2 3 4 5 6 7 8 9.

Page 138

76-00011 0 version modul 7 option options cm101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 7 30.04.2004 a4 pcb x20 sicotronic system sicotronic system 1 1 1: frei 2: frei 3 :nu llle it e r ( d ) 4: g e rät e in (a) 5 :ei ngang si c ot roni c (c ) 6 :h ei z ungs anf orderung (...

Page 139

Positionsliste bill of material name name artikelnr. Item number artikelbezeichnung item description module modul Änderungsdatum 2004-04-02 11:36:57 name cm101e dokument-nr. 78-00022 erzeuger schd spannung 3nac 400/415v 50-60hz version 0 seite 1 von 1 a4 42.00.004 bedienplatine cm operator pcb cm mo...

Page 140

76-00017 0 version modul 2 heißluftheizung/dampfheizung hot air heating/steam heating cm202e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 2 30.04.2004 k 1 :5 / 1 .0 8 w16 awg 8(4x) vt r1 6x3kw 18kw d1 1 2 t h er m oel e m ent d a m pf gene rat or t h er mocoupl e s team gene rat...

Page 141

76-00017 0 ve rsion modul 5 lüfter motor f an motor, c ooling fan c m202e 3nac 400v 50- 60h z e rstellt von created by da tum da te blatt p age pa 5 30.04. 2004 1.08 / k 1:13 bn 77 66 55 44 33 22 1.08 / 2. 00 / k 1:1 1.08 / n 1.08 / p e 1.08 / k 1:a 2 bu t4 t raf o 12v t ran sf o rm e r 1 2v ~ - 12v...

Page 142

76-00011 3 version modul 1 sicherheitskette, sp.-versorgung pcb safety chain, power supply pcb index f 3nac400v 50-60hz erstellt von created by datum date blatt page schd 1 16.01.2006 k1 n/o 1 2 3 4 5 6 w17 a4 pcb k1 n/o 14 13 x7 11 gy bn rd f3 sicherheitstemperaturbegrenzer 160°c/320°f safety tempe...

Page 143

Deckblatt elektrische dokumentation, cover sheet for electrical documentation die elektrische dokumentation besteht aus: 1. Diesem deckblatt, 2. Dem schaltplan und 3. Der legende der elektrischen bauteile the electric documentation contains: 1. This cover sheet, 2. The wiring diagram and 3. The bill...

Page 144

76-00050 0 version Überblick cm 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 8 30.04.2004 modul 3 klima plus, fühler humidity control, sensors blatt 3 page modul 2 heißluftheizung/dampfheizung hot air heating/steam heating blatt 2 page modul 1 sicherheitskette, sp.-ver...

Page 145

76-00050 0 version modul 1 sicherheitskette, sp.-versorgung pcb safety chain, power supply pcb cm 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 1 30.04.2004 z1 entstörfilter electronic noise filter w0 k1 n/o 1 2 bk bk bk 3 4 bu bu bu g n /y e g n /y e bk bu f1 6,3a f2 6...

Page 146

76-00050 0 version modul 2 heißluftheizung/dampfheizung hot air heating/steam heating cm 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 2 30.04.2004 1.08 / k1:14 1.08 / k1:a2 1.09 / pe 1.08 / k1:a1 bn bu ye/gn rd g a s ge bl äse ( h l1) ga s b lo w e r m8 1 m ~ n l1 pe g...

Page 147

76-00050 0 version modul 3 klima plus, fühler humidity control, sensors cm 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 3 30.04.2004 a4 pcb s2 n ive auelek tr ode w a te r lev el s ens or w5 gy wh wh ye/gn x12 1 1 x73 2 2 2 2 1 1 3 3 3 3 4 4 4 4 b1 t h erm oelem ent ga...

Page 148

76-00050 0 version modul 4 wasser water, drain, cleanjet cm 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 4 30.04.2004 a4 pcb w3 wh bu wh bu y1 m a g n etv entil- füllen s o le noid v a lv e filling a1 a2 x19 3 3 x30 1 1 1 1 2 2 y2 m a g n e tv ent il-a blös c hung s o ...

Page 149

76-00050 0 version modul 5 lüftermotor fan motor, cooling fan cm 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 5 30.04.2004 1.09 / k1:1 1.09 / k1:3 2.08 / pe 2.08 / m5:~ 2.08 / m5:n 2.08 / a5/m1 2.08 / a5/pcb bk bu gn/ye bn bu m11 kü hl lü ft er co ol ing fan m 1 ~ a2 a...

Page 150

76-00050 0 version modul 6 summer, eeprom buzzer, eeprom cm 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 6 30.04.2004 a4 pcb w9 wh wh x8 1 1 x47 1 t2 su m m e r bu z z e r 2 2 2 x50 ext erne e p r om 1 1 2 2 eeprom 3 3 4 4 0 0 1 2 3 4 5 6 7 8 9.

Page 151

76-00050 0 version modul 7 option options cm 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 7 30.04.2004 a4 pcb x23 dunstabzug extractor hood 1 1 2 2 3 3 0 0 1 2 3 4 5 6 7 8 9.

Page 152

Positionsliste bill of material name name artikelnr. Item number artikelbezeichnung item description module modul Änderungsdatum 2004-04-01 11:23:09 name cm101g dokument-nr. 78-00036 erzeuger schd spannung 1nac230v 50-60hz version 0 seite 1 von 1 a4 42.00.004 bedienplatine cm operator pcb cm modul 8...

Page 153

76-00054 0 ve rsion modul 2 h eißluftheizung/d ampfheizung hot air heating/steam heating c m 201/202 g 1nac 230v 50- 60h z e rstellt von created by da tum da te blatt p age pa 2 03.05. 2004 1.08 / k 1:14 1.08 / k 1:a 2 1.09 / p e 1.08 / k 1:a 1 g a sg eb lä se ( h l2 ) g a sb lo w e r m10 1 m ~ n l1...

Page 154

76-00054 0 ve rsion modul 5 lüfter motor f an motor, c ooling fan c m 201/202 g 1nac 230v 50- 60h z e rstellt von created by da tum da te blatt p age pa 5 03.05. 2004 1.09 / k 1:1 1.09 / k 1:3 2.08 / p e 2.08 / t4:~ 2.08 / t4:n bn bu t4 12 v t ra fo ~ - 12v 0v 0v 200v 208v 220v 230v 240v 250v 2.08 /...

Page 155

Positionsliste bill of material name name artikelnr. Item number artikelbezeichnung item description module modul Änderungsdatum 2004-04-19 16:21:09 name cm202g dokument-nr. 78-00114 erzeuger schd spannung 1nac230v 50-60hz version 0 seite 1 von 2 a4 42.00.004 bedienplatine cm operator pcb cm modul 8...

Page 156

Positionsliste bill of material name name artikelnr. Item number artikelbezeichnung item description module modul Änderungsdatum 2004-04-19 16:21:09 name cm202g dokument-nr. 78-00114 erzeuger schd spannung 1nac230v 50-60hz version 0 seite 2 von 2 w5 40.01.542 kabel:niveauelektrode cable water level ...

Page 157

Deckblatt elektrische dokumentation, cover sheet for electrical documentation die elektrische dokumentation besteht aus: 1. Diesem deckblatt, 2. Dem schaltplan und 3. Der legende der elektrischen bauteile the electric documentation contains: 1. This cover sheet, 2. The wiring diagram and 3. The bill...

Page 158

76-00003 0 version Überblick scc101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 8 05.05.2004 modul 3 klima plus, fühler humidity control, sensors blatt 3 page modul 2 heißluftheizung/dampfheizung hot air heating/steam heating blatt 2 page modul 1 sicherheitskette, sp.-versorgu...

Page 159

76-00003 0 version modul 1 sicherheitskette, sp.-versorgung pcb safety chain, power supply pcb scc101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 1 05.05.2004 k1 n/o 1 2 bk 3 4 og 5 6 vt w17 a2 operator pcb k1 n/o 14 13 x7 1 1 gy rd bn f3 sicherheitstemperaturbegrenzer 160°c/3...

Page 160

76-00003 0 version modul 2 heißluftheizung/dampfheizung hot air heating/steam heating scc101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 2 05.05.2004 k 1 :5 / 1 .0 8 1 x0 w16 awg 12 k 1 :1 / 5 .0 0 k 1 :3 / 1 .0 8 og bk vt thermoelement dampfgenerator thermocouple steam genera...

Page 161

76-00003 0 version modul 3 klima plus, fühler humidity control, sensors scc101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 3 05.05.2004 a2 operator pcb w8 wh wh wh wh x11 1 1 x48 1 s4 e n d s c halt er k lappenm ot or e n d p o sitio n sw itch fla p mo to r 2 2 2 3 3 3 m3 k la...

Page 162

76-00003 0 version modul 4 wasser water, drain, cleanjet scc101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 4 05.05.2004 a1 i/o-pcb w2 wh pe wh x15 2 2 x28 1 1 s11 c d s- sen s o r cds -s e n s o r gnd in signal hall 1 1 2 2 3 3 3 3 w6 wh wh wh wh x25 1 1 x45 1 s12 e n d sch a...

Page 163

76-00003 0 version modul 5 lüftermotor fan motor, cooling fan scc101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 5 05.05.2004 1.08 / 2.00 / k1:1 1.08 / n 1.08 / pe 1.08 / k1:13 1.08 / k1:a2 bk bu ye/gn bn bu m11 kü hl lü ft er co ol ing fan m 1 ~ a2 a1 m5 kü hl lü ft er co ol ...

Page 164

76-00003 0 version modul 6 garraumbeleuchtung, summer, zentrales einstellrad, eeprom scc101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 6 05.05.2004 a1 i/o-pcb w11 bn bu x13 1 1 x49 1 h1 g a rr aum beleuc ht ung in terior c abinet light 2 2 2 a2 operator pcb w9 wh wh x8 1 1 x4...

Page 165

76-00003 0 version modul 7 option options scc101e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 7 05.05.2004 a1 i/o-pcb x20 sicotronic system sicotronic system 1 1 1: f re i 2: f re i 3 :nu llle it e r ( d ) 4 :g e rät e in (a) 5 :ei ngang si c ot roni c (c ) 6 :h e iz ungs anf o...

Page 166

Positionsliste bill of material name name artikelnr. Item number artikelbezeichnung item description module modul Änderungsdatum 2004-04-19 13:22:11 name scc101e dokument-nr. 78-00111 erzeuger schd spannung 3nac400/415v 50-60hz version 0 seite 1 von 2 a1 40.00.049 i/o-pcb i/o-pcb modul 8 a2 42.00.00...

Page 167

Positionsliste bill of material name name artikelnr. Item number artikelbezeichnung item description module modul Änderungsdatum 2004-04-19 13:22:11 name scc101e dokument-nr. 78-00111 erzeuger schd spannung 3nac400/415v 50-60hz version 0 seite 2 von 2 w10 40.00.210 kabel:trafo-bedienplatine cable tr...

Page 168

76-00016 0 version modul 2 heißluftheizung/dampfheizung hot air heating/steam heating scc202e 3nac400v 50-60hz erstellt von created by datum date blatt page pa 2 30.04.2004 k 1 :5 / 1 .0 8 w16 awg 8(4x) vt r1 6x3kw 18kw d1 1 2 t h er m oel e m ent d a m pf gene rat or t h er mocoupl e s team gene ra...

Page 169

76-00016 0 ve rsion modul 5 lüfter motor f an motor, c ooling fan s c c 202e 3nac 400v 50- 60h z e rstellt von created by da tum da te blatt p age pa 5 30.04. 2004 1.08 / k 1:13 bn 77 66 55 44 33 22 1.08 / 2. 00 / k 1:1 1.08 / n 1.08 / p e 1.08 / k 1:a 2 bu t4 t raf o 12v t ran sf o rm e r 1 2v ~ - ...

Page 170

Deckblatt elektrische dokumentation, cover sheet for electrical documentation die elektrische dokumentation besteht aus: 1. Diesem deckblatt, 2. Dem schaltplan und 3. Der legende der elektrischen bauteile the electric documentation contains: 1. This cover sheet, 2. The wiring diagram and 3. The bill...

Page 171

76-00006 0 version Überblick scc 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 8 05.05.2004 modul 3 klima plus, fühler humidity control, sensors blatt 3 page modul 2 heißluftheizung/dampfheizung hot air heating/steam heating blatt 2 page modul 1 sicherheitskette, sp.-ve...

Page 172

76-00006 0 version modul 1 sicherheitskette, sp.-versorgung pcb safety chain, power supply pcb scc 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 1 05.05.2004 z1 entstörfilter electronic noise filter w0 k1 n/o 1 2 bk bk bk 3 4 bu bu bu gn /y e gn /y e bk bu f1 6,3a f2 6,...

Page 173

76-00006 0 version modul 2 heißluftheizung/dampfheizung hot air heating/steam heating scc 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 2 05.05.2004 1.09 / k1:14 1.09 / k1:a2 1.09 / pe 1.09 / k1:a1 bn bu ye/gn rd g a s ge bl äse ( h l1) ga s b lo w e r m8 1 m ~ n l1 pe ...

Page 174

76-00006 0 version modul 3 klima plus, fühler humidity control, sensors scc 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 3 05.05.2004 a2 operator pcb w8 wh wh wh wh x11 1 1 x48 1 s4 e n d s c halt er k lappenm ot or e n d p o sitio n sw itch fla p mo to r 2 2 2 3 3 3 m...

Page 175

76-00006 0 version modul 4 wasser water, drain, cleanjet scc 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 4 05.05.2004 a1 i/o-pcb w2 wh pe wh x15 2 2 x28 1 1 s11 c d s- sen s o r cds -s e n s o r gnd in signal hall 1 1 2 2 3 3 3 3 w6 wh wh wh wh x25 1 1 x45 1 s12 e n d...

Page 176

76-00006 0 version modul 5 lüftermotor fan motor, cooling fan scc 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 5 05.05.2004 1.09 / k1:1 1.09 / k1:3 2.08 / pe 2.08 / m5:~ 2.08 / m5:n 2.08 / a5/m1 2.08 / a5 / i/o-pcb bk bu gn/ye bn bu m11 kü hl lü ft er co ol ing fan m 1...

Page 177

76-00006 0 version modul 6 garraumbeleuchtung, summer, zentrales einstellrad, eeprom scc 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 6 05.05.2004 a1 i/o-pcb w11 bn bu x13 1 1 x49 1 h1 g a rr aum beleuc ht ung in terior c abinet light 2 2 2 a2 operator pcb w9 wh wh x8 ...

Page 178

76-00006 0 version modul 7 option options scc 101/102 g 1nac230v 50-60hz erstellt von created by datum date blatt page pa 7 05.05.2004 a1 i/o-pcb x23 dunstabzug extractor hood 1 1 2 2 3 3 a2 operator pcb 0 0 1 2 3 4 5 6 7 8 9.

Page 179

Positionsliste bill of material name name artikelnr. Item number artikelbezeichnung item description module modul Änderungsdatum 2004-04-01 08:28:37 name scc101g dokument-nr. 78-00031 erzeuger schd spannung 1nac230v 50-60hz version 0 seite 1 von 2 a1 40.00.049 i/o-pcb i/o-pcb modul 8 a2 42.00.002 be...

Page 180

Positionsliste bill of material name name artikelnr. Item number artikelbezeichnung item description module modul Änderungsdatum 2004-04-01 08:28:37 name scc101g dokument-nr. 78-00031 erzeuger schd spannung 1nac230v 50-60hz version 0 seite 2 von 2 w15 40.00.215 kabel:feuerungsautomat - gasgebläse ca...

Page 181

76-00051 0 ve rsion modul 2 h eißluftheizung/d ampfheizung hot air heating/steam heating s c c 201/202 g 1nac 230v 50- 60h z e rstellt von created by da tum da te blatt p age pa 2 30.04. 2004 1.09 / k 1:14 1.09 / k 1:a 2 1.09 / p e 1.09 / k 1:a 1 g a sg eb lä se ( h l2 ) g a sb lo w e r m10 1 m ~ n ...

Page 182

76-00051 0 ve rsion modul 5 lüfter motor f an motor, c ooling fan s c c 201/202 g 1nac 230v 50- 60h z e rstellt von created by da tum da te blatt p age pa 5 30.04. 2004 1.09 / k 1:1 1.09 / k 1:3 2.08 / p e 2.08 / t4:~ 2.08 / t4:n bn bu t4 12 v t ra fo ~ - 12v 0v 0v 200v 208v 220v 230v 240v 250v 2.08...

Page 183: Common

S -129- common notes:.

Page 184

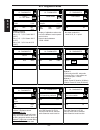

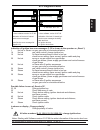

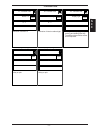

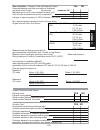

Scc service reference 1 2 5 - activated 3 4 6 5 7 8 operating buttons 1 function key 2 display scc functions 3 haccp protocol - download 4 service key - de-scaling - empty steam generator (with door open) - display type / software - download diagnostic (since 01-07-09) service error code: service 10...

Page 185

Cm service reference 1 2 3 4 5 6 key code cm (scc line) a: cleaning program select cool down with "1" press key "5" for 10 sec. „clen“ is shown in temperature display press key "4" 1x; b: de-scaling program select cool down with "1" press key "5" for 10 sec. „clen“ is shown in temperature display se...

Page 186

Rational ag iglinger straße 62 d- 86899 landsberg a. Lech tel.: ++ 49 - 81 91/ 32 70 fax: ++ 49 - 81 91/ 2 17 35 www.Rational-ag.Com rational ag tel: ++ 49-81 91-32 70 fax: ++ 49-81 91-2 17 35 rational uk tel: ++ 44-15 82-48 03 88 fax: ++ 44-15 82-48 50 01 e-mail: rational@rational-uk.Co.Uk rational...