- DL manuals

- Rato

- Engine

- R160

- Service Manual

Rato R160 Service Manual - Contents

CONTENTS

1. INTRODUCTION ···················································································· 1

1-1 PARTS DESCRIPTION ······································································ 1

1-2 SPECIFICATION ·············································································· 2

1-3 SERVICE LIMIT ·············································································· 5

2. DIMENSIONS AND TORQUE ·································································· 19

2-1 ENGINE DIMENSIONS ···································································· 19

2-1-1 R100 ························································································· 19

2-1-2 R160/R180/R200/R210/R225 ······················································ 19

2-1-3 R270/R280/R300 ····································································· 20

2-1-4 R390/R420/R440 ····································································· 21

2-2 TORQUE VALUES ········································································· 22

2-2-1 torque values ·········································································· 22

2-3 STANDARD Torque valueS ······························································· 24

3. MAINTENANCE ··················································································· 25

3-1. Maintenance schedule ······································································ 25

3-2 engine oil ······················································································ 26

3-3 Air cleaner ····················································································· 27

3-4 Cleaning of the fuel filter ··································································· 27

3-5 spark plug cleaning and ····································································· 28

adjusting ···························································································· 28

3-6 valve clearance adjustment ································································· 28

3-7 governor ······················································································· 29

4. DISASSEMBLING AND SERVICING ························································· 30

4-1 Troubleshooting ·············································································· 30

4-1-1 Hard starting ·········································································· 30

4-1-2 Engine lacks power ····································································· 2

4-1-3 Speed is unstable ······································································· 3

4-1-4 Motor is unable to start ································································ 3

4-1-5 Exhaust gas color is abnormal ························································ 4

Summary of R160

Page 1

Gasoline engine r100-r440 horizontal shaft service manual chongqing rato power manufacturing corporation.

Page 2

This manual contains information about how to perform routine maintenance and how to do troubleshooting. Keep this manual handy, so you can refer to it at any time. This service manual describes correct methods for maintaining this equipment. If any personal casualty or equipment damage is caused du...

Page 3

Safety messages your safety and the safety of others are very important. We have provided important safety messages in this manual and on the generator. Please read these messages carefully. A safety message alerts you to potential hazards that could injure you or others. Each safety message is prec...

Page 4: Contents

Contents 1. Introduction ···················································································· 1 1-1 parts description ······································································ 1 1-2 specification ···········································································...

Page 5

4-1-6 unable to ignite ········································································· 4 4-1-7 oil alert system malfunction ·························································· 5 4-1-8 gasoline engine is overerheated ····································· 5 4-2 preparation of servicin...

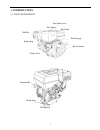

Page 7: 1. Introduction

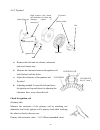

1 1. Introduction 1-1 parts description throttle grip fuel tank recoil starter muffler spark plug choke lever air cleaner fuel tank cover start handle drain plug oil dipstick.

Page 8

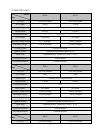

2 1-2 specification model items r100 r160 l×w×h 310×290×320mm 390×320×345mm dry weight 8.8 kg 15.5kg engine type 4-stroke, ohv, single cylinder displacement 98 cm3 163cm3 compression ratio 8.5±0.3:1 bore×stroke 56×40 mm 68×45mm maximum output power 1.8/3600 rpm 3.4kw/3,600rpm maximum torque 4.7n·m/2...

Page 9

3 dry weight 16.5 kg 16.5kg engine type 4-stroke, ohv, single cylinder displacement 212 cm3 223cm3 compression ratio 8.5±0.3 bore×stroke 70×55 mm 70×58mm maximum output power 4.2/3600 rpm 4.4kw/3,600rpm maximum torque 12n·m/2500rpm 13n·m/2,500rpm cooling system forced air-cooled ignition system tran...

Page 10

4 compression ratio 8.2:1 8:1 bore×stroke 80×60mm 88×64mm maximum output power 6kw/3,600rpm 7.6kw/3,600rpm maximum torque 18n·m /2,500rpm 23n·m /2,500rpm cooling system forced air-cooled ignition system transistorized magneto ignition(tci) spark plug bpr6es(ngk),nhsp ld f7rtc,f7tc lubrication system...

Page 11

5 1-3 service limit 1-3-1 r100 parts item standard value service limit gasoline engine maximum speed (no load) cylinder compression 3850rpm 0.9mpa(1400rpm) -- cylinder cylinder bore i.D. 56-56.015mm 56.165 cylinder head warpage -- 0.1 piston skirt o.D. Piston-to-cylinder clearance piston pin bore i....

Page 12

6 ex journal o.D 29.4mm 12.966-12.986mm 29.2 12.91 crankcase cover camshaft holder i.D. 13.0-13.018mm 13.048 1-3-2 r160/r200 parts item standard value service limit gasoline engine maximum speed (no load) cylinder compression 3750-3810rpm ≧ 1.17mpa(1400rpm) -- -- cylinder cylinder bore i.D. 68.0mm 6...

Page 13

7 spring free length 34.0mm 32.5mm camshaft cam height in ex journal o.D 27.7mm 27.75mm 13.984mm 27.45mm 27.50mm 13.916mm crankcase cover camshaft holder i.D. 14.0mm 14.048mm carburetor main jet float height pilot screw opening 0.85 13.7±1.5mm 2-1/8 circle -- -- -- spark plug gap 0.7-0.8mm -- spark ...

Page 14

8 big end oil clearance small end side clearance 0.040-0.063mm 0.1-0.7mm 0.12mm 1.1mm crankshaft crankshaft pin o.D 29.98mm 29.92mm valve valve clearance stem o.D guide i.D stem-to-guide clearance seat width spring free length in ex in ex in/ex in ex 0.15±0.02mm 0.20±0.02mm 5.48mm 5.44mm 5.50mm 0.02...

Page 15

9 piston pin bore i.D. Piston pin o.D. Piston pin-to-piston pin bore clearance 18 .002mm 18.0mm 0.002-0.014mm 18.048mm 17.954mm 0.06mm piston rings ring side clearance: top /second ring oil ring ring end gap: top /second ring oil ring ring width: top /second/oil ring 0.015-0.045mm -- 0.2-0.4mm 0.15-...

Page 16

10 air gap secondary coil 5.9-7.1kΩ 0.4-0.6mm -- -- 1-3-5 r270 parts item standard service limit engine maximum speed (no load) cylinder compression 3150-3180rpm ≧ 1.37mpa(1400rpm) -- -- cylinder head sleeve i.D. 77-77.017mm 77.17mm cylinder head warpage -- 0.10mm piston skirt o.D. Piston-to-cylinde...

Page 17

11 1-3-6 r280 parts item standard service limit engine maximum speed (no load) cylinder compression 3750-3850rpm 1.1mpa(1400rpm) -- -- cylinder head sleeve i.D. 78.0-78.015mm 78.17mm cylinder head warpage -- 0.10mm piston skirt o.D. Piston-to-cylinder clearance piston pin bore i.D. Piston pin o.D. P...

Page 18

12 rod big end i.D big end oil clearance big end side clearance 33.225-33.239mm 0.013-0.03mm 0.25-0.65mm 33.27mm 0.12mm 1.0mm crankshaft crankshaft pin o.D 33.175-33.185mm 33.12mm valves valve clearance stem o.D. Guide i.D. Stem clearance seat width spring free length in ex in ex in/ex in ex 0.10-0....

Page 19

13 piston skirt o.D. Piston-to-cylinder clearance piston pin bore i.D. Piston pin o.D. Piston pin-to-piston pin bore clearance 79.975-79.985mm 0.015-0.04mm 15 .002-15.008mm 14.992-14.998mm 0.004-0.016mm 79.85mm 0.12mm 15.242mm 14.95mm 0.08mm piston rings ring side clearance: first/ second oil ring e...

Page 20

14 spark plug cap resistance 9.5-10.5kΩ -- ignition coil resistance air gap primary coil secondary coil 0.6-0.9Ω 5.6-6.9kΩ 0.3-0.5mm -- -- -- 1-3-8 r390 parts item standard service limit engine maximum speed (no load) cylinder compression 3750-3810rpm ≧ 1.37mpa(1400rpm) -- -- cylinder head sleeve i....

Page 21

15 1-3-9 r420 parts item standard service limit engine maximum speed (no load) cylinder compression 3750-3850rpm 1.2mpa(1400rpm) -- cylinder head sleeve i.D 90-90.015mm 90.17mm cylinder head warpage -- 0.10mm piston skirt o.D. Piston-to-cylinder clearance piston pin bore i.D. Piston pin o.D piston p...

Page 22

16 ring width: first/second oil 3.7-3.9 mm 2.95-3.15 mm 1.37mm 2.0mm connecting rod small end i.D big end i.D big end oil clearance big end side clearance 20.011-20.022 mm 36.025-30.039 mm 0.25-0.65 mm 0.013-0.03 mm 20.07mm 36.07mm 0.12mm 1.0mm crankshaft crankshaft pin o.D 35.975-35.985 mm 35.92mm ...

Page 23

17 head cylinder head warpage -- 0.10mm piston skirt o.D. Piston-to-cylinder clearance piston pin bore i.D. Piston pin o.D piston pin-to-piston pin bore clearance 91.96-91.97 mm 0.03-0.055 mm 20.002-20.008 mm 19.992-19.997 mm 0.004-0.016 mm 91.85mm 0.27mm 20.042mm 19.95mm 0.08mm piston rings ring si...

Page 24

18 pilot screw opening -- -- spark plug gap 0.7-0.8mm -- spark plug cap resistance 9.5-10.5kΩ -- ignition coil resistance air gap primary coil secondary coil 0.6-0.9Ω 5.6-6.9kΩ 0.3-0.5mm -- -- --.

Page 25: 2. Dimensions And Torque

19 2. Dimensions and torque 2-1 engine dimensions 2-1-1 r100 2-1-2 r160/r180/r200/r210/r225.

Page 26

20 2-1-3 r270/r280/r300

Page 27

21 2-1-4 r390/r420/r440

Page 28

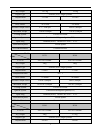

22 2-2 torque values 2-2-1 torque values ser. No. Part model part description and specifications torque value connecting components 1 oil drain plug r100 r160-r225 r270-r440 m10×1.5×15 8.8-a m10×1.5×15 8.8-a m12×1.5×18 8.8-a 22±2 oil drain plug-flat washer-crankcase 2 oil sensor r100 r160-r225 r270-...

Page 29

23 subassembly r270-r440 -- head subassembly 10 spark plug r100-r440 m14×1.25 28±2 spark plug-cylinder head subassembly 11 cylinder shroud r100 r160-r210 r270-r4440 m6×10 8.8-a m6×8 8.8-a m6×12 8.8-a 10±2 cylinder shroud-cylinder head subassembly 12 lower shield r100 r160-r225 r270-r440 -- m6×16 8.8...

Page 30

24 r270-r440 m6×30 8.8-a 2-3 standard torque values item specifications torque valve n·m kg·m standard torque 5mm bolt, nut 5.5 0.55 6mm bolt, nut 10 1.0 8mm bolt, nut 21 2.4 10mm bolt, nut 37.5 3.75 12mm bolt, nut 55 5.5.

Page 31: 3. Maintenance

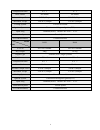

25 3. Maintenance 3-1. Maintenance schedule good maintenance is essential for safe, economical, and trouble-free operation. It will also help reduce air pollution. Exhaust gas contains poisonous carbon monoxide. Shut off the engine before performing any maintenance. If the engine must be running dur...

Page 32

26 3-2 engine oil ● oil change 1 )dismount the oil filler cap and oil drain bolt to drain dirty oil. 2 )tighten the oil drain plug see 2-2-1maintenance standard 3 )add the clean oil from the filler neck. R100 oil capacity 0.35l r160/r180/r200/r210/r225 oil capacity 0.6l r270/r300/r390/r420 oil capac...

Page 33

27 3-3 air cleaner dual element type 1 ) remove the nut, air cleaner cover and wing nut. Remove polyurethane and paper elements. 2 ) clean polyurethane with detergent, then, blow it dry with compressed air or squeeze it dry. Dip the element in clean oil, then, forcefully squeeze it dry and install i...

Page 34

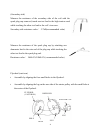

28 valve rocker arm valve lock 3-5 spark plug cleaning and adjusting 1 )remove carbon or other deposits with a stiff wire brush. Check gasket for damage. 2 ) measure plug gap between center electrode and side electrode with a spark plug feeler. If necessary, adjust the gap by bending the side electr...

Page 35

29 and valve to measure valve clearance. 4 ) if adjustment is necessary, proceed as follows: a .hold the rocker arm pivot and loosen the valve lock nut b .turn the rocker arm pivot to obtain the specified clearance. C .fix the rocker arm pivot with a spanner, then tighten the lock nut. D .recheck va...

Page 36

30 4. Disassembling and servicing 4-1 troubleshooting 4-1-1 hard starting trouble cause remedy normal cylinder compression normal spark plug spark something wrong with the fuel system. Fuel supply is not smooth or there is no fuel supply. There is no enough fuel in fuel tank and fuel cock is closed....

Page 37

31 al fuel supply system. Normal high –tension cord spark. Spark plug is in poor conditions too much carbon deposit and dirt around electrodes. Clear away. Electrodes are burned badly or insulators are damaged. Replace spark plug. Improper electrode gap. Adjust to proper value. High-tension cord wit...

Page 38

2 turn the fuel cock to “off” position, and drain the gasoline of the carburetor. Remove the spark plug and spark plug cap. Pull the recoil start handle to drive off the gas out of the cylinder. Install the spark plug cap. Put the control lever to “low” position. Put negative pole (thread) of the sp...

Page 39

3 drain the oil of the fuel tank. Drain the gasoline by loosening the fuel drain plug of the carburetor. Remove the spark plug cap and spark plug and install the cylinder pressure meter. Forcibly pull the recoil starter several times and measure compression force (≥0.4mpa) 4-1-3 speed is unstable tr...

Page 40

4 trouble cause remedy 1.Check the battery connection improper connection correct the connection 2. Check battery wrong gasoline engine, or battery is charged insufficiently, battery is stored long without being used, and pole plate’s sulphation is eroded. Check or replace rectification circuit, cha...

Page 41

5 side electrode of spark plug has dropped out replace spark plug high-tension cord has dropped out weld it on ignition coil is punctured or short-circuited replace ignition coil stop engine wire is located on engine body find out the meeting position, separate them and insulate others cylinder is s...

Page 42

6 gasoline engine is overheated oil insufficient or wrong oil/gasoline ratio add engine oil exhaust pipe is blocked clean exhaust pipe shroud is leaking repair damaged part cooling fins are blocked by foreign matter clear cooling fins cooling fan is loose and malfunctioning reinstall it well connect...

Page 43

7 walls or other equipment, keep away from inflammables such as gasoline, matches and so on to avoid possibility of fire. 8. Refuel in a well-ventilated area with the engine stopped, and in places refueling or storing gasoline, no smoking and any flames or sparks. 9. Refuel the fuel tank not too muc...

Page 44

8 4. Trademark label 5. Throttle control label 6. Air cleaner maintenance label 7. Choke lever, fuel cock label 8. Oil grade label.

Page 45

9 9. Oil filling label.

Page 46

10 4-2-2 special tools tool name application note 1. Float level gauge 2. Valve guide driver 3. Retainer assembler 4. Assembler handle 5. Inner retainer assembler 6. Diamond lap 45 0 7. Diamond lap 32 0 8. Flywheel driver 9. Bearing extractor 10. Valve guide reamer carburetor float level inspection....

Page 48

46 4-3 disassembling chart engine air cleaner carburetor recoil starter shroud flywheel starter motor.

Page 49

47 4-4 engine a . disassembly, reassembly engine switch (engine equipped with oil alert device) control box (only used for automatic starter) lead support (2) assembling: insert it into fan cover ignition coil lead (black) starter relay lead white lead oil level switch lead (yellow) oil level switch...

Page 50

48 4-4-1 recoil starter notice: wear gloves and eye protection during disassembling, and take care not to allow the return spring to come out ① insert the recoil starter rope through the groove in the recoil starter reel and make a figure-eight knot at the rope end ② hang the side hook of the recoil...

Page 51

49 groove groove . Set the recoil starter coil spring’s outside hook to the groove of the recoil starter reel. . Set the starter drive cam on the recoil starter reel, and install the return spring on the recoil starter reel while hooking it to the side of the driving cam. . Install the spring, drivi...

Page 52

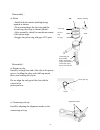

50 ignition coil flywhhel clearance 0.4-0.6 (mm) 4-4-2 flywheel a) remove the fuel tank, air cleaner, carburetor and recoil starter assy. B) measure the clearance between the ignition coil and flywheel with the feeler. C) adjust the clearance of the ignition and flywheel. D) adjusting method: loosen...

Page 53

51 flywhhl (cast iron) hole hole impeller lug lug starter cup (secondary side) measure the resistance of the secondary side of the coil with the spark plug cap removed, touch one test lead to the high tension cord while touching the other test lead to the coil’s iron core. Secondary side resistance ...

Page 54

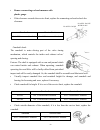

52 4-4-3 air cleaner collar b air cleaner cover air cleaner element air cleaner grid air cleaner element (paper) air cleaner element (polyurethane) noise silencer (only for silence) elbow seal air cleaner elbow disassembly/reassembly: ·remove and install with the choke lever and fuel valve in the on...

Page 55

53 oil bath type wing nut air cleaner cover air cleaner element (polyurethane) air cleaner grid elbow packing collar air cleaner case oil capacity: 60cc reassembly: after cleaning with solvent, fill with clean oil and install air cleaner elbow disassembly/reassembly: ·remove and install with the cho...

Page 56

54 4-4-4 carburetor a .disassembly/reassembly governor rod throttle return spring disassembly: unhook the throttle return spring. Pull the carburetor forward to a point where the groove in the governor rod lines up with the governor rod, and lift the rod out of its hole. Reassembly: after pulling fu...

Page 57

55 b .disassembly/reassembly ·remove the drain plug and drain the carburetor before disassembling ·prohibit fire. Choke lever fuel cock reassembly: check for top wear or spring wear before installation. Float valve oil cup drain bolt oil cup bolt after assembly, check for any sign of fuel leakage. R...

Page 58

56 float level gauge inspection ●float level height place the carburetor in the position as shown and push the float in by finger and measure the distance between the float top and carburetor body (float height). Specified float height see 1-3maintenance standard if the float height is out of specif...

Page 59

57 4-4-5 cylinder head /valve 1) removal/ installation remove the fuel tank remove the air cleaner remove the recoil starter and shroud remove the carburetor and insulator spark plug: clean and adjust spark plug before installation stud stud pin cylinder head gasket breather tube bolt assembly disas...

Page 60

58 valve spring retainer : push down on the valve spring and move the retainer to the side so that valve stem slips through the side hole do not remove the valve spring retainers while the cylinder head is installed to the cylinder, or the valves will drop into the cylinder. 2 )inspect/service/repai...

Page 61

59 valve guide driver valve guide inspect : a) inspect the valve guide for smoothness, scratch and damage in the inner surface, and matching between the valve guide and cylinder cover for fastness. B) use the valve guide reamer, ream the valve guides to remove any carbon deposits before measuring. I...

Page 62

60 valve guide installation height clip valve guide driver replacement: a) chill the replacement valve guides in the freezer section of a refrigerator for about an hour. B) drive the valve guide out of the combustion chamber side using valve guide driver. Notice: be careful to avoid damaging the cyl...

Page 63

61 correct incorrect reamer : for best results, be sure the cylinder head is at room temperature before reaming valve guides. A) coat the reamer and valve guide with cutting oil. B) rotate the reamer clockwise through the valve guide for the full length of the reamer. Continue to rotate the reamer c...

Page 64

62 valve seat : a) thoroughly clean the combustion chambers and valve seats to remove carbon deposits. Apply a light coat of red lead powder or erasable color painting to the valve faces. Insert the valves, and then press the valve several times forcefully. Be sure the valve does not rotate on the s...

Page 65

63 4-4-6 crankshaft/piston balancing shaft bearing oil seal piston piston pin piston pin clip oil sensor bolt camshaft crankshaft: reassembly : push it in firmly until contact is made with the bearing surface. Be careful not to damage the oil seal bolt crankcase bearing governor arm bolt crankcase c...

Page 66

64 oil dipstick oil filter cap crankcase cover gasket (don’t reuse) pin bearing seal ring sealing ring bolt oil seal (don’t damage the edge of the oil seal when reassembling crankcase cover ) pin (fix the governor arm with pin after installing ) spacer oil seal connection rod piston pin piston pin c...

Page 67

65 connecting rod reassembly: make sure that the longer end marked is toward the piston head’s side with the “ ” “ ”mark marker marking 120° first ring second ring oil ring piston pin clip cutout disassembly : a) piston • install with the marker marking facing upward as shown. • do not interchange t...

Page 68

66 piston check check the piston and cylinder for contacting, and check the groove for defects, piston top for burn and cracks. If any of them is damaged, replace it. Clean the carbon deposit clean the deposit round the piston top and cylinder neck before checking, first soak the carbon deposit with...

Page 69

67 c) piston-to-cylinder clearance difference between cylinder maximum diameter and piston skirt should be considered as piston-to-cylinder clearance. Notice: this clearance must be checked before and after repairing. Check with piston upside down in the cylinder, and inserting feeler between piston...

Page 70

68 bolt standard standard check connecting rod if connecting rod is bent or twisted, or its big end shaft hole and small end hole have apparent grooves, or have cracks on one side, the connecting rod should be rejected and replaced with a new one. A) check small end diameter if it is out of the stan...

Page 71

69 remove connecting rod and measure with plastic gauge. If the clearance exceeds the service limit, replace the connecting rod and recheck the clearance. Standard service limit see 1-3maintenance standard see 1-3maintenance standard camshaft check the camshaft is main driving part of the valve timi...

Page 72

70 camshaft wearing cause and its influence on engine performance: poor lubrication, caused by factors such as low oil viscosity, too many impurities, and little recycling oil, will result in camshaft abnormal wearing, making it hard for the camshaft surface to have a complete oil film, causing the ...

Page 73

71 4-4-7 starting control box a . disassembly/reassembly (only for starter) 6×12mm(2) screw control box silicon rectifier check : 7-8 blade type fuse (5a) reassembly: check for burn before installation.

Page 74

72 b .check ● engine switch check the continuity between lead and fan cover. Switch position continuity box installation bracket nut oil alert check: p.7-8 reassembly: install by aligning with the hole of the control plate control panel resetting button(1a) reassembly: be careful not to install the ...

Page 75

73 on no off yes ● engine switch (with oil alert) check the continuity between black lead and engine switch. Switch position continuity on no off yes ● switch (with starter) check continuity between leads when switch is kept at each position. Lead color switch position black/red (to grounding) black...

Page 76: Electric Diagram

74 yellow─ battery (-) (don’t connect the positive and negative poles wrongly ) ※don’t use the battery with over 6v, if so, bulb will break. ●connect the black/red and yellow leads to 6v battery or dry cell, check whether the alert lamp lights up. Black─ battery (+) yellow─ battery (-) (don’t connec...

Page 77

75 control box starter motor starter relay charging coil.

Page 78

76 chongqing rato power manufacturing corporation add:no. 99 jiujiang road, shuangfu district, chongqing china service hotline:400-681-9981 fox:023-85553450 postcode:402247 url:www.Rato.Cc e-mail: ratoservice@rato.Cc(consultation customer service) parts@rato.Cc (parts order).