- DL manuals

- Rato

- Offroad Vehicle

- RT150ST-A

- Service Manual

Rato RT150ST-A Service Manual

Summary of RT150ST-A

Page 1

Rt150st-a service manual chongqing rato power co., ltd. Rt150st-a 维修手册 重 庆 润 通 动 力 有 限 公 司.

Page 2: Warning

Brief introduction to four-wheeled cross-country vehicle model rt150st-a four-wheeled cross -country vehicle, model rt150st-a is a full road condition vehicle which can be driven on every kinds of road conditions such as sand beach, grassland, forest,village, construction site country road , this ma...

Page 3: Content

Content chapter i general description 1 section 1 description ..........................................................................................................................................1 section 2 special tools, instruments and meters .....................................................

Page 4

Section 3 maintenance and adjustment of vechicle body ............................ .......................................... 21 (i)wear inspection of front&rear brake ........................................................................................................ 21 (ii)adjustment of front ...

Page 5

(i) removal steps................................................................. ....................................................... 50 (ii) inspection steps .................................................................................................................................... 51 ...

Page 6: Chapter

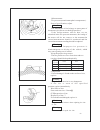

Chapter i general description section 1 description 1. Front wheel 2. Fuel cock 3. Cushion 4. Rear wheel 5. Exhaust silencer 6. Rear fender 7. Front fender 8. Bumper 9. Left lever of rear brake 10. Left switch unit 11. Fuel tank cover 12. Throttle grip 13. Right lever of front brake caution: the atv...

Page 7

Section 2 special tools, instruments and meters for the above tools, you can select with reference to special tools of the same type of vehicle. -2- (i) special tools special tools is the necessary tools used for accurately adjustment and assembly, it is helpful to prevent the maintenance defects an...

Page 8

(ii) instruments and meters the following instruments and meters can be selected with reference to the same type of vehicle. Speedometer of engine multimeter ignition timing meter spark tester of spark plug barometer ignition checker measuring tool of gasoling dial indicator -3-.

Page 9

Section 3 identification code, label of model and engine n0. Section 4 points for attention in maintenance identification code it is engraved in the left or right side of front supporting main take of engine of frame. Engine n0. The engine no. Engrave on the narrow point position -4- identification ...

Page 10

4. Clip 4.1before assembling, be sure to check all the clips carefully.Use a new one after remov- ing the clip of piston pin. When mounting clip ring ① make the sharp face ② on the opposite position of impacted face ③ of clip.(see left fig) 5.Locking washer /shim and location pin 5.1when reassemblin...

Page 11

7.Check of electirc parts 7.1 check the rust, dirt and moisture etc. Of connector, if there is moisture, please blow it dry and clear the rust and dirt. 7.2 the eclectolyte inside the battery is a kind of corrosive, when operation exercise shall be taken not to let the electrolyte splash on the body...

Page 12

B. If joint is slack, bend the plug pin upward, then connect with connector plug(see fig7.5) 7.6 before mounting new fuse, check if the load of fuse of components is right, especially for the portion being burned broken regularly, then mount the fuse having proper current value. 7.7wire connector ha...

Page 13: Section 5 Specification

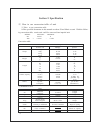

Section 5 specification (i) how to use conversion table of unit (1)how to use conversion table all the specified documents in this manual are taken si and metric as unit. With the follow- ing conversion table, metric unit could be conversed into imperial unit. Metric multiply imperial mm 0.03937 in ...

Page 14

Ii.Basic specification -9- item item specification specification dimension: overall length 1730mm overall width 1060mm overall height 1160mm height of cushion 830mm axle base 1100mm min.Ground clearance 100mm min.Turning radius 2500±100 mm basic weight: engine oil(with full tank) 160±5 kg engine typ...

Page 15

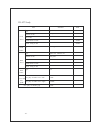

Iii.Atv body -10- item standard limit front wheel front brake rear wheel rear brake brake lever and brake pedal free play of throttle grip type material of rim size of tire radial runout of rim lateral swing of rim type type material of rim size of tire radial runout of rim lateral swing of rim type...

Page 16

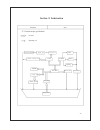

-11- section 6 electrical diagram of atv.

Page 17

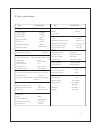

-12- section 7 requirements for torque of fastener (i) general torque specification general torque specification (standard screw) this table is screw locking specification drawn up by international standard association. In order to avoid the twist or unbalancing phe- nomenon when locking screw. Plea...

Page 18: Section 8 Lubrication

-13- section 8 lubrication (i) general torque specification :pressure :splashing oil standard item piston/cylinder piston pin connecting rod valve automatic centrifugal clutch crank camshaft rocker bearing sprocket chamber branch valve fine filter spindle driving shaft middle gearbox oil pump rough ...

Page 19

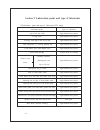

Section 9 lubrication point and type of lubricants (i)lubrication point and type of lubricants(atv body) lubrication point lip of oil seal (full) o-ring (full) steering shaft(upper end,lower end) ball connection of steering pushing rod front wheel fork (ball-shaped joint) front wheel bearing dust-pr...

Page 20

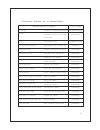

(ii)lubrication point and type of lubricants(engine) -15- lip of oil seal all bearing o-ring stem end of intake and exhaust valve fastener of cylinder head outside surface of piston pin outside surface of piston.Piston ring clutch upper cam plate guide rod inner hole of upper cam plate unit steel ba...

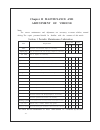

Page 21: Adjustment Of Vehicle

Chapter ii maintenance and adjustment of vehicle note: the correct maintenance and adjustment are necessary to ensure vehicles, normal driving.The repair personnel should be familiar with the contents of this article. Section 1 periodic maintenance/lubrication item valve spark plug air filter carbur...

Page 22

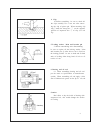

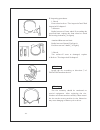

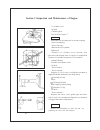

Section 2 diassembly and assembly of cushion, fender and fuel tank -17- lock lever lock lever ( ) cushion 1.Disassembly (1) place the vehicle on the horizontal ground. (2) disassemble the cushion pull the cushion lock lever upward, then raise the tail part of cushion. By that, you can disassemble th...

Page 23

-18- caution should disconnect the negative wire fistly. (4)take out the battery. (5)disassemble the rear fender. 2.Installation operate according to reverse procedure of “disassembly”.Pay attention to following points: (1)install: rear fender (2)install: battery battery negative wire positive wire ...

Page 24

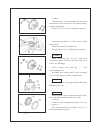

(3)install the cushion -19- caution insert the support plug of cushion into the plug seat on the frame, then press down the cushion. (iii)front fender 1. Disassembly: (1) place the vehicle on the horizontal ground. ( 2)disassembly the front carrier ① ( 3 ) d i s a s s e m b l y t h e b u m p e r p r...

Page 25

-20- (iv)fuel tank 1.Disassembly (1)place the vehicle on the horizontal ground (2)disassemble the cushion (3)remove the front fender and rear fender (4)remove the fuel tank bolt (5)pull the fuel cock lever to “off”position (6)remove the fuel inlet pipe caution place a cloth on the engine to absorb t...

Page 26

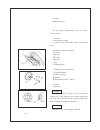

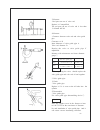

Section 3 maintenance and adjustment of vechicle body caution caution -21- (i)wear inspection of front&rear brake 1.Check the front brake (1)brake the vehicle with front brake (2)check: .Wear indication .If the wear indication reach the wear limit mark,replace the brake shoe assy. Refer to section“f...

Page 27

-22- 2.Adjustment adjusting procedure of free clearance of right lever: .Loosen the locking nut,and rotate the cable adjsuting screw clockwise to reduce the tension of front brake cable. .Pick up the front wheel from ground, and rotate the two front wheels, and ensure the two front brake’s brake for...

Page 28

(iii)inspection of steering system 1.Place the vehicle on the flat ground 2.Check: .Clamp seat of steering vertical column and sliding bearing on the lower end of steering vertical column, upper &lower and front &rear moving steering bar if the clearance is too large, replace the sliding bearing 3.C...

Page 29

-24- (iv)adjustment of toe-in of front wheel 1.Rest the motorcycle on the flat ground 2.Measurement: .Toe-in .Adjust if out of specification .Adjustment steps of toe-in. .Mark the centers of tire thread of two front wheel. .Lift the front end of motorcycle to keep the front wheel from force. .Faster...

Page 30

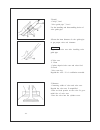

-25- inspecion of front/rear shock absorber 1. Rest the motorcycle on the flat ground 2. Inspection (1) front/rear shock absorber if scraped/damaged replace the front/rear shock absorbe (2) oil leakage if the heary oil leakage of front/rear shock absorbers is found, replace it. 3.Inspection .Operati...

Page 31

-26- (vi) inspection of tire warning this motorcycle adopted the low pressure tire,so correct filling pressure and keeping the proper pressure is very important. .Tire characterics 1)quality characterics of tire will affect the driving reliability of atv. The following types of tires reliability by ...

Page 32

Standard min max front normal temperature tire pressure rear 20kpa( 0. 20kgf/ cm 2 ) 17kpa( 0. 17kgf/ cm 2 ) 23kpa( 0. 23kgf/ cm 2 ) 25kpa( 0. 25kgf/ cm 2 ) 22kpa( 0. 22kgf/ cm 2 ) 28kpa( 0. 28kgf/ cm 2 ) keep the rim in balance when replacing the rim or tire. Never attempt to repair the rim. Warnin...

Page 33

Section 4 maintenance and adjustment of electrical appliance caution caution warning -28- (i)inspection of battery warning: the electrolyte is dangerous article, whitch includes sulphuric acid, so it is poisonous and corrosive. .Please operate by the following steps: a.Avoid the body touching the el...

Page 34

Small size test instrumentation: 9/n.Yu-03112 caution -29- caution 4.Inspection of battery if damaged, replace it 5.Installment of battery 6.Connect .Battery electrode(positiove electrode negative electrode) first connect the positive electrode 7. Installment: a.Battery clamp plate b.Cushion (ii)ins...

Page 35

-30- caution caution caution (iii)replacement of taillight lamp 1.Cut off .Connecting wire terminal of taillight 2.Removel .Unit of taillight 3.Take out the lens 4.Removal the lens seat rotate countercolockwise when taking out the lens. Caution when removing the light tail hold the front side of the...

Page 36

Caution caution -31- 3.Installment of fuse cover (iv)replacement of headlight lamp 1.Cut off .Connecting wire terminal of headlight 2.Removel .Unit of headlight 3.Take out the lens 4.Removal the lens seat rotate countercolockwise when taking out the lens . Caution when removing the light head hold t...

Page 37

-32- 7.Connect .Light seat caution make sure that the projective part on the lamp is engaged with the comex groove on the light seat. 8.Install the lens to the light seat. 9.Installment .Headlight caution install the rubber hole-guard ring of the headlight connecting wire column to the headlight. 10...

Page 38

Section 5 maintainace and adjustment of engine caution -33- (Ⅰ)clean of air filter 1.Remove cushion front fender rear fender fuel tank 2. Remove the air filter box cover, air filter components. Never start the engine without filter, otherwise the piston and cylinder will be overworn. 4.Inspection a....

Page 39

Caution -34- 6.Installment: a.Install the foam filter core to the foam supporting cylinder to combine a air filter assy. B. Install the air filter assy. C.Install the air filter cover. Make sure that the close fit surface of air fiter is engaged with the close fit surface of air filter box, and the ...

Page 40

Caution caution -35- (iii)adjustment of idle speed 1.Rest the vehicle on the flat ground 2.Start the engine and prewarm it at the speed of 1000-2000r/min, after several minutes, increase the engine speed to 4000-5000r/min. 3.Set the specified idle speed through adjusting the throttle adjusting screw...

Page 41

Warning caution -36- (v)adjustment of speed limitator: the speed limitator can limit the throttle in full opening condition when the throttle grip is pulled to the max position, screwing the adjuster inward can stop increasig the speed. 1.Adjust speed limiting length@ adjustment steps: a.Loosen the ...

Page 42

-37- (i)when the mark on the rotor is align with the mark on the crankcase,the two arms must have clearance. (ii)if there is not clearnance, turn the crankcase a circle by counterclockwise to meet the above requirement. 3)measuer the valve clearance with plug gauge. Adjust the clearance if it is out...

Page 43

4.Mount correct timed ignition meter on connection line of spark plug cap 5.Inspection of ignition timing. Inspection steps: a.Take off plug b.Start the engine, and make the engine run at 1450r/min-1550r/min idle speed. When the engine is running, the machine, oil maybe splash out, so be careful to ...

Page 44

4.Take off pressure gauge 5. Mount spark plug, torque of mount is 175n.M (ix).Inspection of oil quantity of engine compression force(the machine oil has been filled in the cylinder) compressure read piston or piston ring is worn or damaged read is highter than one before filling read is equal to one...

Page 45

Caution caution warning -40- b.Turn out the dipstick ①entirely, and clean it, then insert it¢Ùback into oil hole. C.Take out the dipstick ① to check if the oil level is between the max. Value and the min.Value . D.If the oil quantity is too small, fill some engine oil to make the oil quantity get to...

Page 46

Warning -41- 6.Inspection one of parts of o-ring ①, compressure spring② ,rough filter ③,fine filter ④is damaged,repalce it. 7.Cleaning clean the compressure spring② , filter③ ,filter ④, filter plug of crankcase⑤and filter net cap with cleaner. 8.Coat the engine oil on the o-ring slightly. 9.Install ...

Page 47

Section 1 front wheel and front brake technical parameter warning chapter iii repair and maintenance of vehicle body ① ser no. 1 2 3 4 5 6 7 item parameter at21 ×7-10 5.5× 10 20kpa(standard value) 17kpa(min vlaue) 23kpa(max value) 2mm 2mm 2mm 2mm 16mm tire specification rim dimension run-out tire ai...

Page 48

① ② ① ② ③ ⑤ ⑥ ④ -43- 3)disassmeble split pin① , slotted nut② ,plain washer ③,front brake ④ and gasket ⑤. 4)disassmeble adjusting nut① , pin② , spring ③, circlip ④ spring⑤and circlip⑥. 5)remove the front brake cable and front brake air pipe. 6)disassemble brake shoe assy ① and front cover assy ②. 7)d...

Page 49

Warning caution -44- ii.Inspecting procedures 1.Check front wheel:refer to “tire inspection”and “hub inspection”of chapter2. 2.Measure radial run-out of front wheel:if exceeding the specified limit, replace the front wheel or check the bearing clearance(①in figure) attached:rim run-out limit: radial...

Page 50

Caution ① -45- 4.Check friction wafer:polish the surface needing polishment with rough sand paper. 5.Measure thickness of friction wafer of brake: if it does not conform to specified thickness, replace it . Attached: thicknes of friction wafer of brake:4.0mm wear limit :2.0mm if the worn thickness o...

Page 51

Caution caution caution -46- 9.Check if the bearing ①of front brake hub runs out in brake hub or front wheel runs out when rotating, replace the bearing. If the oil seal ②is worn or damaged, replace it. Replacing procedures of front wheel bearig and oil seal wash the outer side of brake hub remove t...

Page 52

When installing the friction indicating sheet ② onto the brake cam shaft ① , should make the convext part (@)of friction indicating sheet corresponding with concave part ( )of brake cam shaft. Make the punching mark on brake cam shaft ① corresponding with punching mark of brake cam arm. Warning caut...

Page 53

Should use new and complete split pin. Caution warning -48- 4.Install brake shoe assy do not apply lubricating grease on brake friction wafer. 5.Connect a.Front brake air pipe. B. Connect the front brake cable with brake cover. 6.Install (as shown in figure) ①circlip ②spring ③ circlip ④spring ⑤pin ⑥...

Page 54

-49- 9.Installment: when installing the front wheel① , the fastening torque of connecting nut②of front and rear wheels is 55n.M. The rotation direction of front wheel (a) is the arrow direction marked on the tire. 10.Adjustment free clearance of front brake cable refer to the “adjustment of front br...

Page 55

Section 2 rear wheel/rear brake/rear wheel axle -50- (i) removal steps 1. Rest the motorcycle on a flat ground 2. Stop up the front wheel with wood, then put a proper supporting article under the frame so as to lift the rear wheel and make the rear wheel leave the earth. In order avoid the parts fal...

Page 56

-51- 6. Dismantle the rear disk brake plate 7. Dismantle of rear disk brake bracket caution take out the rear wheel axle from the end of rear wheel axle bushing and gear box with soft hammer warning during taking out the rear wheel axle, in order to protect the thread and gear groure from damage, do...

Page 57

-52- 5.Inspection of rear wheel axle ① a:if the rear wheel axle is heavily scraped or broken, replace it. B.If the thread or gear groove on the rear wheel axle is worn or damaged, replace it. 6. Measurement the radial runout of the pisition @on the rear wheel axle, if out of specification, repalce i...

Page 58

Section 3 steering operation system ① -53- (i)removal steps of steering bar 1.Removal handle bar decration cover 2.Removal front brake cable remvoal throttle grip assy 3.Removal after stopping the vehicle, remove the rear brake assembly①. 4.Removal ①steering bar pipe ②lower holder of steering bar.

Page 59

Caution -54- (ii)removal steps of steering vertical column welding 1.Plain move .The locking part of locking pad as shown 2.Removal .Bolt .Locking washer.Clip assy 3.Remocal install the steering vertical column with split pin nut washer 4.Removal split pin nut tension rod① ① when removing the tensio...

Page 60

Warning -55- (iii)inspection content 1.Check if the steering bar is cracks、 bent or damaged. If it is, replace it. 2.Inspect if the steering vertical column welding assy is bent or damaged. If it is, replace it in order to avoid decreasing the performance of steering vertical column, if it is bent d...

Page 61

Caution -56- 6.Adjustment assembly length of tension rod adjustment steps of tension rod assembly length loosen the connecting nut (a).(b) adjusting the assembly length of tension rod by rotating the tension rod. A t t a c h e d : te n s i o n r o d a s s e m b l y l e n g t h @:297mm (a)right-hand ...

Page 62

Warning caution -57- 2.Lubricate the steering vertical column holder ① and seal ring② during installing the steering vertical column welding. 3. Installment install the seal ring ① to the steering vertical column welding, then install bushing② , finally install the steering vertical column holders ③...

Page 63

7.Mounting split pin ① warning caution warning -58- don’t loosen the nut after the torque is fixed.If the nut recess is not correspondance with split pin hole on the double -screw bolt, tighten the nut to align them. Always use new split pin 8.Tighting after mounting the washer,nut, split pin under ...

Page 64

Warning caution warning -59- (v)installation steps of steering bar 1.Install the lower holding seat① , steering tube ② and upper holding seat ③. When tightening the bolt of holding seat, make ensure the even of clearance . Attached:bolt torque:20nm 2.Install the throttle grip unit the projection ①of...

Page 65

Section 4 front shock absorber and front wheel fork -60- (i)disassembly: 1.Take off front feder, front wheel. 2.Take off split pin, nut and steering rod ball pin assembly. 3 . D i s m a n t l e t h e b o l t o f t h e f r o n t shockabsorker. 4.Take off the bolt under the front shock absorber nut of...

Page 66

Warning -61- d:move the left/right front wheel fork up and down to check its vertical clearance. If the vertical moving is tight, limited or uneven, replace the bushing sub-assembly or whole front wheel fork. 8.Take off nut, bolt, left/right front wheel forkand bushing sub-assembly. (ii)inspection s...

Page 67

Warning caution -62- if the left/right front wheel fork welding is bent,don’ t strighten it seriously in order to avoid reducing its performance. 4. Check the bushing sub- assembly , if it is worn or damaged, replace it. (iii)installment steps the opposit steps of “ disassembly” is the mounting step...

Page 68

Caution caution warning -63- 3.Mount left/right front seat assy 4.Fix the nut of left/right front seat assy. Attached: nut torque :25nm 5.Mount the split pin don’t loosen the nut after marking the standard torque.If the recess on the nut is not correspondence with split pin hole on the bolt,correct ...

Page 69

Caution warning -64- don’t loosen the nut after markingthe standard t o r q u e . I f t h e r e c e s s o n t h e n u t i s n o t correspondence with the split pin on the bolt, correct it by fixing the nut. Must use new split pin③ 9. Mount front brake cap assy brake shoe assy front brake hub and fro...

Page 70

Section 5 rear shock absorber and rear wheel fork -65- 1. Take of cushion/rear fender/drive sprocket 2. Take off rear shock absorber check: a. If rear shock absorker is leakage, if any,replace it b. If rear shock absorber is bent or damaged,if any, replace it. C. Pull the spring up and down to check...

Page 71: Section 1 Inspect Switch

Chapter iv electric appliance section 1 inspect switch pocket multimeter remark -66- (i)inspect switch inspect if the circuit between wire end is on w i t h p o c k e t m u l t i m e t e r. I f t h e r e i s a n y failure,replace the switch. .Adjust the multimeter to “ 0” before inspecting .Adjust t...

Page 72

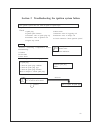

Section 2 troubleshooting the ignition system failure if the ignition system does not work(no spark or spark stops) 1.Spark plug 2.Ignition park clearance 3.Resistance value of spark plug cap 4.Resistance value of ignition coil 5.Engine stop switch step: check: 6.Main switch 7.Resistance value of tr...

Page 73

2.Ignition spark clearance .Remove the spark plug cap from spark plug .Connect as shown in figure ① spark testing instrument ② spark plug cap ③ spark plug .Rotate the main switch to “on” .Check the ignition spark clearance. .Press down the starting switch to start the engine. And increase the spark ...

Page 74

.Inspect if the resistance of primary coil con- forms to specification .Inspect if the secondary coil resitance conforms to specification primary coil resistance at 20℃(68°f)0.43~0.5Ω secondary coil resistance at 20℃(68°f)4.6-7.6kΩ all conform to specification normal normal 6.Main switch refer to “c...

Page 75

8.Resistance value of charge coil .Remove the corresponding connector of charge coil from cable. .Connect the mulitester( Ω×100 )to wire end of charge coil multitester pen (+) → yellow/green wire end ① multitester pen (-) → yellow/green wire end ② coil resistance value at 20℃(68°f)450~550 Ω inspect ...

Page 76

Section 3 running of starting circuit the starting circuit of this vehicle include start- ing motor, cut-off relay, rear brake switch and neutral switch. If the main switch is in position, the startig motor could be operated only at the following conditions: ① battery ② start motor ③ start relay ④ c...

Page 77

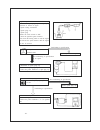

Section 4 troubleshooting electric starting system if starting motor doesn’t work remark .Remove the following parts before troubleshooting 1)cushion 2)fuel tank 3)front fender .Use the following special tool to troubleshoot pass pass 2.Battery .Check the battery condition voltage of open circuit at...

Page 78

4.Power off relay .Remove the relay from cable .Connect portable multitester (Ω×1)and battery (12v) to wire end of power off relay battery end(+) → red/white wire end ① battery end(-) → green/yellow wire end ② multitester pen(+) → red/white wire end ① multitester pen(-) → blue/white wire end ③ .Insp...

Page 79

Replace main switch replace rear brake switch replace handlebar switch (left) connect the whole starting system correctly incorrect incorrect incorrect incorrect incorrect correct correct correct correct 7.Neutral switch 6.Main switch 8.Rear brake switch 9.Starting switch 10.Circuit connection .Chec...

Page 80

Section 5 check starting motor 1.Check .Reverser not clean→ clean with #600 sand paper 2.Ensure .Reverser diameter @ not conforming to specification → change the startig motor 3.Measure .Mica cut sheet not conform to specification → scrape the mica with square scraper mica cut sheet:0.7mm(0.028 in) ...

Page 81

5.Measure .Length @of brush (every one) out of specification → replace it 6.Measure .Brushing spring force fatigue/out of specification → replace whole device length of brush:10mm(0.39 inches) range of wear: brushing spring force:326~970g(3.2~3. 8n) 7.Check .Oil sealing .Bushing .O-ring wear/damage ...

Page 82

Section 6 no charging in the battery steps check: 1.Safety 2.Battery 3.Charging voltage 4.Startor coil 5.Coupling of circuit (whole charging system) .Repair with following special toolings 1.Safety refer to “nspection of switch” 2.Battery .Check battery condition correct pass 3.Charging voltage .Con...

Page 83

.Start the engine and accelerate to 2000r/m or so. Charging voltage:14-15v at 2000r/m remark: use battery with full capacity 4.Resistance value for startor coil .Take out the lighting coil of ac magneto from in- serter .Connect pocket multiconeter to stator coil(1) pocket multimeter(+)→white termina...

Page 84

Section 7 troubleshooting if the headlight or taillight is not work steps check: 1.Safety 2.Battery 3.Main switch 4.Lamp switch 5.Coupling of wires(for entire lighting system) pocket multimeter:p/n yu-03112 1.Safety refer to “inspection of switch” pass 2.Battery .Check the battery condition voltage ...

Page 85

* 4.Switch for lamps refer to “inspection of switch” correct incorrect if the lamp switch is failure replace the switch of handle(left) poor coupling connect whole lighting system correctly. 5.Coupling of wires .Check the wire compling or whole lighting sys- tem correct check the returning condition...

Page 86

Section 8 inspection of lighting system (i) if the taillight is out of work 1.Bulb and bulb socket .Check if the bulb and bulb socket is correct 2.Voltage .Connect the pocket tester (dc 20v)to the terminal of taillamp. Multimeter (+)→blue terminal ① multimeter (-)→black terminal ② meet specification...

Page 87: Chapter V Engine

Chapter v engine section 1 disassembly of engine -82- (i)remove the engine from finished atv 1.Remove .Cushion .Front&rear carrier .Bumper 2.Remvoe .Front panel .Front fender .Rear fender .Right&left main footrest 3.Oil draining screw out oil draining screw plug. Drain off the lubricating oil of the...

Page 88

Caution -83- place the throttle cock grip on “off”postion,and remove: .Throttle cable .Oil pipe .Hoop .Carburetor, carburetor seat and hook hitch assy. Before disassembling, drain off the gasoline of the carburetor float cabinet firstly. Wrap the overflow pipe with cloth to absorb the splashed gasol...

Page 89

11. Disassembly of engine remove the engine unit from lift side 9.Dismantle the engine connecting plate 10.Dismantle the driving sprocket (ii) disassembly of engine -84-.

Page 90

1.Remove .Cylinder head cover 2.Remove .Bolt .Shroud assy ① 3. Remove .Spark plug ① -85-.

Page 91

5.Remove .Camshaft holder 4.Remove .Pipe comp inlet① 6.Remove .Bolt .Camshaft assy -86- ①.

Page 92

-87- ① ③ ③ ③ ② ④ ⑤ 7.Remove .Cylinder head ① .Cylinder head gasket ② .Location pin ③ .Oil seal ④ .Lower guide plate ⑤(exhaust side) 8.Remove .Bolt .Chain tensioner .Gasket 9.Remove ① .Cylinder body assy ② .Location pin ① ② ②.

Page 93

① ① ③ ② 10.Remove .Circlip ① .Piston pin ② .Piston unit ③ 11.Remove .Motor unit start 12.Remove .Left crankcase cover .Gasket .Pin 13.Remove .Pulley set driven -88-.

Page 94

14.Remove .Pulley set drive 16.Remove .Bolt .Cover assy fan 15.Remove .Transmission belt 17.Remove .Bolt .Fan comp cooling -89-.

Page 95

18.Remove .Nut .Fly wheel comp .Stator comp 19.Remove .Bolt .Cover right crank case .Gasket 20.Remove .Bolt .Crank case comp right 21.Remove .Shaft comp crank -90-.

Page 96

22.Remove .Bolt .Cover mission .Gear .Shaft drive .Shaft comp counter .Gear find .Circlip -91-.

Page 97

Section 2 inspection and maintenance of engine remove the deformation of valve rod end ① by polishing the valve end with oilstone. Caution caution -92- 1.Cylinder cover 1)clean .Carbon eposit use circular scraper ① please do not use sharp tool to avoid scraping .Nut of spark plug .Valve seat ring .B...

Page 98

3)measure .Rod part run-out of valve rod replace it if unqualified the rod part run-out of valve rod is less than (0.03mm0.0012in) 4)measure .Clearance between valve rod and valve guide pipe clearance=a-b inner diameter of valve guide pipe a valve rod diameter b repalce the valve or valve guide pipe...

Page 99

3)install .Circlip ①(new) .Valve guide pipe ②(new) use the installing and disassembling device of valve guide pipe 4)ream the inner diameter of valve guide pipe to get proper valve rod clearance. Regrind the valve race after installing valve guide pipe 4.Valve race 1).Clean .Carbon deposit(valve rau...

Page 100

.Press the valve on through valve guide pipe to leave clear trace on the valves. .Remove the valve from cylinder cover .When the valve contancts with valve race, the redle is marked on the valve form vavle race, then can measure the contacting width of valve and valve race. Valve race correcting pro...

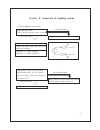

Page 101

The contacting part b is the middle of valve face. But the width is too narrow the contacting part c is too narrow, and on the upper edge of valve face d the contacting part is too narrow and on the bottom of valve. 5)grind .Valve face .Valve race should grind the valve face and valve race after cor...

Page 102

.Pain molybdenum disulfide oil on the valve rod part. .Place the valve into the cylinder cover .Rotate the valve to grind in with seat fully on the valve face, then clean the dirty .Repeat procedure until the contacting width of valve face and valve seat in order to get the best grinding quality, yo...

Page 103

2)measure .Installing pressure of valve spring if unqualified, replace the inner and outer spring totally. 6.Seal check of valve 1)installation of valve lubricate .Valve rod part ① .Valve rod oil seal ② install .Valve spring seat ①(lower part) .Oil seal of valve rod ② .Valve ③ .Inner spring ④ of val...

Page 104

Must install the long pitch end of all valve spring upward. 2)check the valve seal if there is leakage on the valve face, repair again and regrind or replace the valve and regrind. Inspecting procedure of valve seal .Inject the clean solvent ① into intake way and exhaust way respectively. .Check the...

Page 105

8.Valve rocker and rocker shaft 1)check .Rocker hole .Contacting surface with distribution cam if over worn, replace it 2)check .Rocker shaft surface replace or check lubrication if there is bent, scratch or discoloration 3)measure .Measure inner diameter of valve rocker hole replace it if unqualifi...

Page 106

9.Timing chain check .Timing chain replace it if the chain is stretched, or not flex- ible or broken. 10.Timing sprocket and crankshaft sproket check .Crankshaft sproket (on crankshaft) if there is wear and damaged, replace the sproket and chain totally 11.Guide plate 1)check .Lower guide plate ① (e...

Page 107

13.Cylinder and piston 1)check .Carbon deposit (from piston top to ring slot) 2)check .Surface of cylinder and piston rebore cylinder or replace cylinder and piston if there is vertical scratch. 3)measure .Clearance between cylinder and piston measuring method is as following .Measuring the inner di...

Page 108

If out of specification, rebore or replace the cylinder and piston (replace in a set) .Measure the diameter “p” of piston lower part with micrometer, is the measuring position if out of specification. Replace the piston and piston ring as a set at the same time. .Calculate the mating cylinder cleara...

Page 109

2)measurement .Closed clearance of piston ring .Install the piston ring to the cylinder,pull for- ward about 20mm(0.8 in),then pull the piston ring with piston top to make it vertical with cyl- inder wall. .Use feeler gauge ① if out of specification replace a set of ring you cannot measure the close...

Page 110

Piston pin 1)inspection .If the color is changed, or indent is found,re- place piston pin, then inspect the lubrication system. 2)measurement: .Outer diameter @ (piston pin) out of specification,replace it 3)measurement: .Inner diameter of piston pin out of specification,replace it 4)measurement .Cl...

Page 111

15.Crankshaft 1)measurement .Dimension a of crankshaft assy if out of specification replace it or repair it .Side clearance d of big head of connecting rod if out of specification, replace it or repair it max side clearance 0.35mm-0.65mm(0.014-0.026 in) .Runout e of big head of connecting rod if out...

Page 112

Main points of reassembly of crankshaft: the oil traces on crankshaft ① and crank pin ② should be connected correctly, the malpo- sition of two oil traces should be with in 1mm (0.04 in) 16.Drive belt check if the transmission belt worn or not and replace it whenever necessany 17.Shaft drive to chec...

Page 113

19.Shaft comp counter to check if the gears of the counter shaft are worn out or heve any cracks and replace it whenever necessary. -108- 20.Bearing and oil seal 1)inspection .Bearing if jammed in operation or there are pits and dammagd,replace it. 2)inspection .Oil seal if damaged or worn replace i...

Page 114: Judgment

Chaptervi vehicle ordinary trouble and judgment -109- trouble caution the following trouble, not including all possible troubles, is a help for trouble guide .Please refer to relevent contents for the inspection, adjustment and replacement of parts. ( i )starting trouble/difficulty 1.Fuel system ( 1...

Page 115

-110- ( 2 )piston and piston ring .Improper piston ring installation .Piston ring is worn and out of elasticity .Piston is damaged or crack ( 3 )valve, camshaft and crank shaft .Valve didnt closed entirdly .Improper match between valve and valve seat .Wrong port timing .Valve spring is damaged .Valv...

Page 116

-111- ( 4 ) driving system .Claw of gear end is worn ( v ) clutch slips ( 1 ) clutch .Improper adjustment of clamp plate release rod clearance of clutch .Clutch spring is loosen (primary clutch and / secondary clutch ) .Clutch spring is fatigue (primary clutch and/secondary clutch ) .Friction disc i...

Page 117

-112- .Improper installation of steering pillar bearings .Holding seat of steering pillar or sealing ring is damaged .Rod is bent .Spherical connection is bent (3) wheel tyre .Uneven pressure on two sides of tyre .Wrong tyre pressure .Uneven tyre wear (4) front/rear tyre .Deformed run .Loosen bearin...

Page 118

Our group reserve the right to change structure, dimension and parameter of the vehicle’s parts without additional notice..