- DL manuals

- Rato

- Engine

- RV160

- Service Manual

Rato RV160 Service Manual

Summary of RV160

Page 1

Rv160 rv170 service manual chongqing rato power co., ltd.

Page 2: Content

Content content 1. Introduction ................................................................................................................ 1 1-1 parts description......................................................................................................... 1 1-2 specifications.........

Page 3

Content 4-3 dismounting chart ................................................................................................... 26 4-4 gasoline engine ........................................................................................................ 27 4-4-1recoil starter / fan cover ..........

Page 5: 1. Introduction

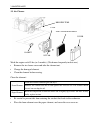

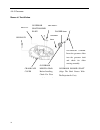

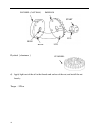

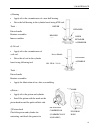

1. Introduction 1 1. Introduction 1-1 parts description spark plug start handle oil dipstick muffle r air cleaner fuel tank cover.

Page 6

1. Introduction 2 1-2 specifications model item rv160 rv170 l×w×h(not including crankshaft output terminal) 395×348×282(mm) 395×348×282(mm) dry weight 12.1kg or 13.7kg 12.5kg or 13.7kg engine type single cylinder horizontal,4-stroke, ohv displacement 163cc 173.2cc bore × stroke 68mm×45mm 70mm×45mm t...

Page 7

1. Introduction 3 connecting rod small end i.D big end i.D big oil clearance small end side clearance 18.005-18.020 30.020-30.033 0.040-0.063 0.1-0.7 18.052 30.066 0.12 1.1 crankshaft crankshaft pin o.D 29.970-29.980 29.92 valve valve clearance stem o.D guide i.D stem clearance seat width spring fre...

Page 8

1. Introduction 4 cylinder head sleeve i.D 72 71.165 cylinder head warpage - 0.10 piston skirt o.D. Piston–to-cylinder clearance piston pin bore i.D. Piston pin o.D piston pin-to-piston pin bore clearance 69.985 0.015-0.050 18.002-18.008 17.994-18.00 0.002-0.014 69.845 0.12 18.048 17.954 0.08 piston...

Page 9

1. Introduction 5 carburetor main jet float height pilot screw opening #65 13.7 2-5/8turns -- -- -- spark plug gap 0.7-0.8 -- spark plug cap resistance 3.75-6.25kΩ -- ignition coil resistance air gap primary coil secondary coil (at flywheel) 0.8-1.0 Ω 5.9-7.2 kΩ 0.35~0.45mm -- -- --.

Page 10: 2. Dimension And Torque

2. Dimension and torque 6 2. Dimension and torque 2-1 dimension.

Page 11

2. Dimension and torque 7 2-2 the position of installing hole 2-3 pto installing drawing p1 shaft p2 shaft p1 shaft p2 轴 seat face seat face.

Page 12

2. Dimension and torque 8 p3 shaft p26 shaft p27 schaft p28 schaft seat face seat face seat face seat face.

Page 13

2. Dimension and torque 9 p29 shaft seat face.

Page 14

2. Dimension and torque 10 2-4 torque value items fasteners torque value (n·m) connection-rod bolt m7×1.0 12±1 governor gear bolt m6×12 10±2 crankcase cover bolt m8×50 26±1 spark plug m14-1.25 18±2 cylinder head bolt m8×50 26±1 rotation shaft bolt m8 × 1.25 24±2 rotation shaft locked nut m6 × 0.5 10...

Page 15

2. Dimension and torque 11 2-5 standard torque value fasteners specification torque value(n·m) bolt, nut 5mm bolt, nut 4.5-6 6mm bolt, nut 8-12 8mm bolt, nut 18-25 10mm bolt, nut 29-34 12mm bolt, nut 49-59 4mm screw 1.5-2.6 5mm screw 3.5-5 6mm screw 7-11 5mm flange bolt 3.6-6.9 6mm screw 7-11 5mm fl...

Page 16: 3. Maintenance

3. Maintenance 12 3. Maintenance 3-1 maintenance schedule frequency item each time first month or 20 hrs each season or 50 hrs every 6 month or 100 hrs each year or 300 hrs engine oil oil level check √ replace √ √ air cleaner check √ clean replace √ oil alert system check √ spark plug clean, adjust ...

Page 17

3. Maintenance 13 when the temperature in your area is in the frame of the above chart, you can use other viscosity of engine oil. Check method 1. Remove the dipstick and clean it. 2. Reinsert the dipstick into the oil filling hole without screwing it, and check oil level. 3. If the oil level is too...

Page 18

3. Maintenance 14 3-3 air cleaner wash the engine each 50 hrs (or 3 months). (wash more frequently in dust area) remove the air cleaner cover and take the element out. Change the damaged element. Clean the element before reusing. Clean the element: foam element wash the element with detergent and dr...

Page 19

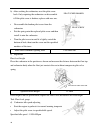

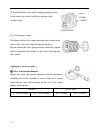

3. Maintenance 15 spark plug cap spark plug socket wrench 0.70~0.80mm side electrode 3-4 wash the strainer don’t smoke or use fire near the flammable solvent. A) fill the fuel into the container b) remove the fuel tube, screw the strainer bolt off. C) check the strainer for damage and clean the stra...

Page 20

3. Maintenance 16 e) to avoid cross-threading, first, screw in spark plug by hand, then tighten with a spark plug wrench to compress the gasket. F) if a new spark plug is used, more twist 1/2 turns after compressing the gasket. G) if reinstalling the used spark plug, just more twist 1/8-1/4 turns. S...

Page 21

3. Maintenance 17 after the cylinder head cover is removed, engine oilmay flow. Be sure to wipe up any flowed oil. B) pull the starting rope lightly and set the piston at top dead center of the compression stroke (insert a feeler gauge between the rocker arm and valve to measure the valve clearance)...

Page 22

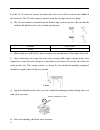

3. Maintenance 18 governor support throttle valve governor arm nut m6 clearance too big: intake and exhaust valve opening delay will shorten the intake and exhaust time, lower the opening height of the valve and change normal distributing phase to result in power lowering from the intake lack and ex...

Page 23

3. Maintenance 19 4. Disassembling and servicing 4-1 troubleshooting 4-1-1 starting difficult trouble cause remedy n or m al cyl inder c om pr es si o n n or m al spa rk pl ug spa rk som et hi ng w rong w it h t he f uel sys tem . Fuel suppl y i s n ot sm oot h or no fuel suppl y. There is no enough...

Page 24

20 if still can’t starting, have the engine to our authorized dealer for repairing. ● spark plug testing make sure there is no spilled fuel outside the engine and that the spark plug isn’t dipped with fuel. when testing the spark plug, never hold the high- tension line of the spark plug with wet...

Page 25

3. Maintenance 21 turn the fuel cock to “off” position, and drain the gasoline of the carburetor. remove the spark plug and spark plug cap pull the recoil starter grip to drain the gas in the cylinder. install the spark plug cap. put the control lever to “low” position. pass negative pol...

Page 26

22 4-1-3 speed unstable trouble cause remedy knocking sound piston, cylinder or piston ring is worn excessively. Replace the worn piston pin and piston pin hole are worn excessively. Replace piston or piston pin tie rod small head is worn excessively. Replace tie rod roller bearing for crankshaft ma...

Page 27

3. Maintenance 23 4-1-5 gasoline engine is overheat trouble cause remedy g as ol ine engi ne i s o ver heat oil insufficient in the gasoline refill engine oil exhaust pipe blocked up clean exhaust pipe shroud leaking repair damaged part cooling fins blocked by foreign matter clear cooling fins conne...

Page 28

24 4-2 preparation of servicing 4-2-1 safety precautions indicate a possibility of invalid warranty and personal or equipment damage if instructions are not followed. Please pay special attention to the following: 1. Strictly set the engine according to the regulated power on the nameplate. Do not o...

Page 29

3. Maintenance 25 12. Safe warning label: please carefully read warning label before operating. Our company will not assume any responsibility, for person hurt, or equipment damaged caused by disregarding this warning label. 4-2-2 special tools tool name application note float lever gauge 1. Valve g...

Page 30

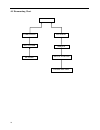

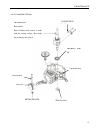

26 4-3 dismounting chart engine muffler carburetor flywheel air cleaner shroud recoil starter engine housing.

Page 31

3. Maintenance 27 4-4 gasoline engine 4-4-1recoil starter / fan cover removal : bolt m5×16 engine cover recoil starter grip fuel cover nut m6-8 clip recoil starter case rope shroud stud m6×88 recoil starter spring return spring drive cam drive guide locking screw spring.

Page 32

28 cutout groove wear gloves and eye protection during disassembly, and take care not to allow the return spring to come out. Installation instruction ① pass the recoil starter rope through the rope in the recoil starter pulley and make a figure-eight knot at the rope end. Check the rope foe wearing...

Page 33

3. Maintenance 29 ⑥ pass the recoil starter rope through the recoil starter case and recoil starter grip, and make a figure-eight knot at the rope end. ⑦ pull the recoil starter rope lightly to check the drive cam for function..

Page 34

30 4-4-2 muffler removal / installation disassemble the muffler as shown on the figure. The muffler can produce carbon deposits in the long time operation and seriously trouble the exhaust system. To get the best performance, the muffler must be periodically removed the carbon deposits. Lightly tap ...

Page 35

3. Maintenance 31 4-4-3 fuel tank a) removal / installation the fuel tank does not require general maintenance, but, sometimes the dusts and vapor will trouble the fuel system, so that, periodically washing it with lubrication oil and gasoline is required. Don’t smoke and use fire near the flammable...

Page 36

32 remove the fuel tube, screw the fuel strainer bolt off and remove the fuel tank. Clean the fuel tank and dry it thoroughly. After cleaning, install the strainer on the fuel tank and connect the fuel tube. Check the fuel tank for leak. Install the engine housing, fuel tank cover, recoil starter gr...

Page 37

3. Maintenance 33 breathe tube notice check for damage of the air cleaner and install. Note the installation direction, view from the air cleaner side. Before installing the breather tube, check for deterioration or damage. Replace if necessary. Pay attention to connect the beveled end smaller to th...

Page 38

34 4-4-5 governor removal / installation oil block pin 8×14 bolt m6×12 governor shaft holder plate washer 6mm governor driven gear: before installing, check for wear and damage of the gear. Washer 6mm governor holder shaft (align the shaft groove with the projection in case). Governor slider: insert...

Page 39

3. Maintenance 35 governor lever ( insert the left end into vertical hole of the throttle valve) throttle valve return spring (hook the left end hook into the hole of the throttle valve shaft. Projection.) governor assy. Nut m6 fixing bolt bolt m5×16 bolt m6×28 choke lever(hook the left end into upp...

Page 40

36 4-4-6 carburetor at high altitude, the standard carburetor air-fuel mixture will be excessively rich. Output power will decrease, and fuel consumption will increase. Engine performance can be improved by installing a smaller diameter main fuel jet in the carburetor and readjusting the pilot screw...

Page 41

3. Maintenance 37 wash the carburetor in the clean place, first, clean the outside surface, and wash the inside the parts with special carburetor detergent or industrial gasoline. Exception for washing impurities, also wash the gasoline colloid on the part surface. Blow the washed parts clean with c...

Page 42

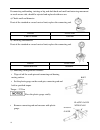

38 a) carburetor disassembly: loosen the drain bolt and completely drain the fuel out before installing carburetor. No fire. Float pin float valve pilot screw carburetor (clean with compressed air before installation) ) float ( after installation, check for operation by lightly pushing with a finger...

Page 43

3. Maintenance 39 o-ring idle speed jet carburetor body o-ring check the float valve, float seat and float spring for wear. Clean with compressed air before installation. Clean with compressed air before installation. Clean with compressed air before installation. Apply light coat of oil to the o-ri...

Page 44

40 pilot screw broken pilot screw float level gauge b) after washing the carburetor, reset the pilot screw back. Only repairing the carburetor can disassemble it.If the pilot screw is broken, replace with new one. Disassemble the broken pilot screw from the carburetor. Put the spring onto the replac...

Page 45

3. Maintenance 41 4-4-7 flywheel ①removal: a) holding the flywheel with a commercially available strap wrench, remove the nut (m14). B) disassemble the starter cut and impeller. C) remove with a commercially available flywheel puller. Do not hit the flywheel with a hammer. Avoid the magnet section w...

Page 46

42 flywheel(aluminum) d) apply light coat of the oil to the threads and surface of the nut, and install the nut loosely. Torque:52n.M hole hole lug lug start er cup flywheel (cast iron) impeller flywheel.

Page 47

3. Maintenance 43 clearance 0.35-0.45mm ignition coil fly wheel ③ignition coil a) remove the fuel tank, air cleaner, carburetor and recoil starter assy. B) measure the clearance between the ignition coil and flywheel with the feeler. C) adjust the clearance of the ignition and flywheel. D) adjusting...

Page 48

44 check the ignition coil (primary side) measure the resistance of the primary coil by attaching one ohmmeter lead to the ignition coil’s primary terminal while touching the other tester lead to the iron core primary side resistance value:0.8-1.0Ω (secondary side) measure the resistance of the seco...

Page 49

3. Maintenance 45 4-4-8 cylinder head / valve 1) removal / installation ① remove the muffler ② remove the air cleaner ③ remove the recoil starter and shroud ④ remove the carburetor and insulator valve head intake valve exhaus t valve push rod lifter valve guide guide seal spring retainer valve adjus...

Page 50

46 pin(10×14) gasket cylinder head installation : before installation, remove any carbon deposits from the combustion chamber and inspect the valve seats. Measure the cylinder compression after reassembly. Bolt(M8×50) loosen and tighten the bolts in a crisscross pattern in 2 or 3 steps. Torque:26n.M...

Page 51

3. Maintenance 47 cylinder head intake valve reassembly: don’t interchange with the exhaust valve. In:25mm ex:24mm be careful not to damage the valve stem when installing. Exhaust valve reassembly: before installation, remove carbon deposits and inspect the valve. Intake valve guide exhaust valve gu...

Page 52

48 projections head cover gasket ⑤ install the head cover gasket aligning the projection of the head cover gasket with the projection of the cylinder head. ⑥ valve spring retainer push down on the valve spring and move the retainer to the side so that valve stem slips through the side hole. Do not r...

Page 53

3. Maintenance 49 ② valve spring free length measure the free length of the valve springs. If out of the standard or service limit. Please replace the spring. Standard service limit 34.0mm 32.5mm ③ valve guide inspect: a) inspect the valve guide for smooth, scratch and damaged in the inner surface, ...

Page 54

50 valve guide driver valve guide installation height 11mm clip valve guide driver be careful to avoid damaging the cylinder head when driving out the valve guides. C) install the new valve guides from the valve spring side of the cylinder head. Exhaust side: drive the exhaust valve guide until the ...

Page 55

3. Maintenance 51 e) check the valve guide bore, it should be straight, round and centered in the valve guide, insert the valve and check operation. If the valve does not operate smoothly, the guide may have been bent during installation. Replace the valve guide if it is bent or damaged. F) check th...

Page 56

52 0.8mm use the 32°-45°cutters to narrow and adjust the valve seat so that it contacts the middle of the valve face. The 32°cutter removes material from the top edge (contact too high). D) the 45°cutter removes material from the bottom edge (contact too low). Be sure that the width of the finished ...

Page 57

3. Maintenance 53 4-4-9 crankshaft / piston bolt torque:12n·m connection rod cap crankshaft reassembly: push in firmly until contact is made with the rearing surface. Be careful not to damage the oil seal. Piston seal 25×38×7 bearing 6205 p6 crankcase piston pin piston pin clip.

Page 58

54 connection rod reassembly: make sure that the longer end marked is toward the piston head with the “▽” “▽”mark marker mark 120° top rin g second ring oil ring piston pin clip cutout ①disassembly: a) piston install with the maker mark facing upward as shown. Do not interchange the top ring and the...

Page 59

3. Maintenance 55 driver handle retainer assembler bearing 6205 inner retainer assembler c) bearing apply oil to the circumference of a new ball bearing. Drive the ball bearing in the cylinder barrel using 6205 tool. Tools: driver handle retainer assembler inner assembler d) oil seal: apply oil to t...

Page 60

56 defects, piston top for burn and cracks. If damaged, replace. Clean the carbon deposit clean the deposit round the piston top and cylinder neck before checking, first soak the carbon deposit with kerosene, and then clean with meter scraper or metal brush. A) piston skirt o.D measure the piston sk...

Page 61

3. Maintenance 57 check with piston converting in the cylinder, and inserting feeler between piston skirt bearing face and wall, then pull the feeler out, if feeling resistance and smoothly out, the thickness of the feeler shall be considered as piston-cylinder clearance. D) piston ring side clearan...

Page 62

58 bolt if connecting rod bending, twisting or big end shaft bush and small end outer ring movement or crack on one side, should be rejected and replaced with new one. A) check small end diameter if out of the standard or exceed service limit, replace the connecting rod. Standard service limit 18.00...

Page 63

3. Maintenance 59 standard service limit 0.040-0.063mm 0.12mm if the clearance exceeds the service limit, replace the connecting rod and recheck the clearance. ⑤camshaft check the camshaft is main driving part of the train valve mechanism, which control the intake and exhaust valves opening and clos...

Page 64

60 poor lubrication will result in camshaft abnormal wearing, such as, oil viscosity low, impurity too much, and recycling oil little can’t let the camshaft surface forming complete oil film to make the camshaft surface seriously worn in the high speed rubbing stat. Second, installing precision prob...

Page 65

3. Maintenance 61 timing gear will be damaged in gear worn, gear face peeling off, and gear teeth broken. The engagement clearance is bigger due to gear wearing, the noise is bigger. If the timing gear is damaged, please replace with new one. Please replace the gear with a new set to ensure the enga...

Page 66

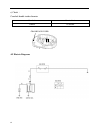

62 c) check: camshaft handle inside diameter standard service limit 14.0mm 14.048mm 4-5 electric diagrams crankcase cover.