- DL manuals

- Rauch

- Spreader

- 18.1

- Operator's Manual

Rauch 18.1 Operator's Manual

OPERATOR MANUAL

5900854-

d

-en-0910

AXEO

2.1/6.1/18.1

Please read carefully

before using the machine!

Store carefully for future

use!

This Operator Manual should be consi-

dered as part of the machine. Suppliers

of new and second-hand machines are

obliged to indicate in writing that the

Operator Manual has been delivered

with the machine.

Translation of the original

operating manual

Summary of 18.1

Page 1

Operator manual 5900854- d -en-0910 axeo 2.1/6.1/18.1 please read carefully before using the machine! Store carefully for future use! This operator manual should be consi- dered as part of the machine. Suppliers of new and second-hand machines are obliged to indicate in writing that the operator man...

Page 2

Preface dear customer, by purchasing the single-disc spreader of the axeo series you have shown confidence in our product. Thank you. We want to justify your trust. You have purchased a powerful and reliable ma- chine. Our customer service is always at your disposal, should any problems arise. Pleas...

Page 3

Contents i preface technical improvements 1 intended use and eu conformity 1 1.1 intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1.2 declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

Contents ii 4 machine data 21 4.1 manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 4.2 versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 4.3 specifications o...

Page 5

Contents iii 7.7 using the fertiliser chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 7.7.1 information on the fertiliser charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 7.7.2 fertiliser chart for grit (3/5 mm) . . . . . . . . . ...

Page 6

Contents iv 10 faults and possible causes 103 11 list of available accessories 105 11.1 electric remote control (metering slider and spreading width limiter). . . . . . . . .105 11.2 hydraulic remote control (metering slider). . . . . . . . . . . . . . . . . . . . . . . . . . . . .105 11.3 hopper ex...

Page 7

Intended use and eu conformity 1 1 1 intended use and eu conformity 1.1 intended use the single-disc spreader axeo may only be used in accordance with the infor- mation given in this operating manual. The single-disc spreader axeo is constructed exclusively for the following appli- cations (intended...

Page 8

Intended use and eu conformity 1 2 1.2 declaration of conformity in accordance with 2006/42/eg, appendix ii, no. 1 a rauch - landmaschinenfabrik gmbh, landstr. 14, 76547 sinzheim, germany we hereby declare that the product: single-disc spreader of the series axeo type: axeo 2.1, axeo 6.1, axeo 18.1 ...

Page 9

User instructions 3 2 2 user instructions 2.1 about this operating manual this operating manual is a constituent part of the single-disc spreaderaxeo. The manual contains important instructions for safe, correct and economical use and maintenance of the single-disc spreader. Adherence to the manual ...

Page 10

User instructions 2 4 2.3 notes on text descriptions 2.3.1 instructions and procedures steps that the operator must carry out are shown as a numbered list. 1. Instruction for action step 1 2. Instruction for action step 2 instructions involving only one step are not numbered. The same applies for ac...

Page 11

Safety 5 3 3 safety this chapter contains basic safety instructions as well as working and traffic reg- ulations for using the axeo single-disc spreader. All instructions in this chapter must be observed in order to work with and operate the single-disc spreader safely. There are additional warnings...

Page 12

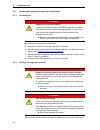

Safety 3 6 warning severity level the degree of danger is indicated by the signal word, and the levels are classified as follows: n danger type and source of danger this advice warns of a danger posing an immediate threat to the health and life of persons. Ignoring this warning will result in very s...

Page 13

Safety 7 3 3.2 general information on the safety of the machine the axeo single-disc spreader is designed and manufactured to the state-of- the-art in technology and the generally accepted rules of engineering. Neverthe- less, operation and maintenance of the machine may pose a risk to life and limb...

Page 14

Safety 3 8 3.3.3 accident prevention safety and accident prevention regulations are governed by law in every country. The machine owner is responsible for ensuring compliance with the legal regula- tions in force in each country. The following instructions must also be observed: never permit unsuper...

Page 15

Safety 9 3 3.4.3 filling the single-disc spreader never fill the spreader while the tractor engine is running. Prevent an uninten- tional start of the tractor's engine by removing the ignition key. Use auxiliary equipment (e.G. Bucket loader, feed screw conveyor, silo) to fill the hopper of the sing...

Page 16

Safety 3 10 3.4.5 operation if the single-disc spreader malfunctions, stop the machine immediately and secure it. Have the fault repaired immediately by qualified technicians. Never climb onto the spreader when it is running. Operate the spreader only with the safety guard fitted in the hopper. The ...

Page 17

Safety 11 3 3.5 use of the spreading material incorrect selection or use of spreading material may cause serious injury or envi- ronmental damage. When selecting the spreading material, inform yourself about its effects on persons, the environment, and the machine. Follow the directions of the sprea...

Page 18

Safety 3 12 3.7 service and maintenance service and maintenance work involves additional hazards that do not occur dur- ing operation of the machine. Take particular care when carrying out maintenance and repair work. Work very carefully and with awareness of danger. 3.7.1 qualifications of maintena...

Page 19

Safety 13 3 only remove blockages in the spreader hopper with the machine at a stand- still, and never use your hands or feet. Only use a suitable tool. To prevent blockages, always use the safety guard when filling the hopper. Before cleaning the spreader with water, steam or other cleaning agents,...

Page 20

Safety 3 14 3.8.2 road travel with the single-disc spreader handling, steering, and braking performance of the tractor are affected by the at- tached spreader. For example, the high permissible load capacity will reduce the weight on the tractor's front axle, and may affect its steering. Be aware of...

Page 21

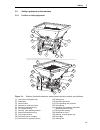

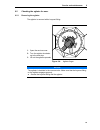

Safety 15 3 3.9 safety equipment on the machine 3.9.1 position of safety equipment figure 3.1: position of protective devices, warning and instruction notices, and reflectors [1] instruction note agitator stop [2] nameplate [3] serial number [4] retainer for cable and hoses [5] maximum payload warni...

Page 22

Safety 3 16 3.9.2 function of protective devices the safety equipment is deigned to protect your health and life. Only operate the single-disc spreader with effective protective devices. [1] drive shaft guard figure 3.2: drive shaft guard description function protective screen in hopper prevents bod...

Page 23

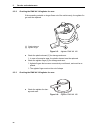

Safety 17 3 figure 3.3: retainer for cable and hoses [1] retainer for cable and hoses 3.10 warning and instruction stickers there are various warning and instruction notices attached to the axeo single- disc spreader (for attaching to the machine, see figure 3.1 ). The warning and instruction sticke...

Page 24

Safety 3 18 3.10.1 warning stickers read operating manual and safety instructions. Read the operating manual and the safety instructions before putting the machine into operation. The operating manual explains in detail how to operate the spreader and contains valuable information on operation, care...

Page 25

Safety 19 3 3.10.2 instruction stickers and nameplate pto speed the rated speed of the pto shaft is 540 rpm. Agitator stop the agitator must be stopped when the metering slid- ers are closed. Maximum payload of 800 kg on the axeo2.1 maximum payload of 1000 kg on the axeo6.1 maximum payload of 1800 k...

Page 26: 120 Nm

Safety 3 20 3.11 lighting system with rear and side reflectors the lighting equipment must be attached as specified, and must always be in op- erating condition. Lights must not be covered or obscured by dirt. The axeo 18.1 single-disc spreader is factory-fitted with regulation rear and side indicat...

Page 27

Machine data 21 4 4 machine data 4.1 manufacturer rauch landmaschinenfabrik gmbh landstr. 14 d-76547 sinzheim germany phone: +49 (0) 7221 / 985-0 fax: +49 (0) 7221 / 985-200 technical service centre rauch landmaschinenfabrik gmbh post box 1162 d-76545 sinzheim germany phone: +49 (0) 7221 / 985-250 f...

Page 28

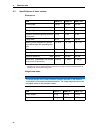

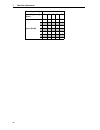

Machine data 4 22 4.3 specifications of basic version dimensions: weights and loads: data axeo 2.1 axeo 6.1 axeo 18.1 overall width 100 cm 120 cm 150 cm overall length 87 cm 95 cm 121 cm filling height (basic version) 96 cm 123 cm 128 cm distance of centre of gravity from low- er link point 40 cm 40...

Page 29

Machine data 23 4 4.4 specifications for extensions and extension combinations axeo series single-disc spreaders can be operated with different combinations of extensions. Capacity, dimensions, and weights will change, depending on the combination used. Extension axeo 2.1 ax 100 change in capacity 1...

Page 30

Machine data 4 24.

Page 31

Transport without tractor 25 5 5 transport without tractor 5.1 general safety instructions read the following instructions before transporting the single-disc spreader: the spreader may only be transported without the tractor if the hopper is empty. The operation may only be carried out by suitable,...

Page 32

Transport without tractor 5 26.

Page 33

Commissioning 27 6 6 commissioning 6.1 acceptance of the single-disc spreader when taking delivery of the single-disc spreader, check and make sure that the scope of delivery is complete. The standard equipment includes 1 single-disc spreader axeo 2.1,axeo 6.1 or axeo 18.1 1 operating manual for sin...

Page 34

Commissioning 6 28 6.3 hitching the single-disc spreader to the tractor 6.3.1 preconditions check the following specific requirements: are both the tractor and the spreader safe to operate? Does the tractor comply with the mechanical, hydraulic, and electrical require- ments? (see „tractor requireme...

Page 35

Commissioning 29 6 hitching instructions: hitching the axeo 2.1/6.1 to the tractor with class ii linkage is only possible with class i clearance and the use of reducing sleeves. Hitching the axeo 18.1 to the tractor with class iii linkage is only possible with class ii clearance and the use of reduc...

Page 36

Commissioning 6 30 determining the hitching height the data specified for hitching height refers to the distance from the bottom edge of the spreading disc when the spreader is mounted horizontally. For the axeo spreader it is given as 55 cm (dimension a). Determine the hitching height by measuring ...

Page 37

Commissioning 31 6 6.4 fitting the pto shaft depending on version, the axeo single-disc spreader can be fitted with a gear- box for driving the spreading disc and the agitator. Depending on design, the spreader may be equipped with different universal drive shafts: universal drive shaft with full pr...

Page 38

Commissioning 6 32 6.4.2 fitting and removing the pto shaft fitting: 1. Checking the installed position. the end of the shaft with the tractor symbol must face the tractor's pto. the locking screw of the drive shaft guard is released. The drive shaft guard is in the removal position. N danger da...

Page 39

Commissioning 33 6 instructions for removal: remove the universal drive shaft in reverse order of attachment. Do not use the safety chain to suspend the universal drive shaft. Store uncoupled universal drive shaft on the retainer provided. 4. Slide drive shaft guard with hose clamp over the univer- ...

Page 40

Commissioning 6 34 6.5 connect the electric actuators (version e/h) depending on version, up to 3 electric actuators can be fitted to the axeo single- disc spreader: one actuator for the electric metering slider (version e), one or two actuators for the electric adjustment of the spreading width (av...

Page 41

Commissioning 35 6 notice the control units can be connected in series via an additional 12 v connection in the tractor (see figure 6.10 ). Precise instructions are provided in the installation instructions for the control unit. Figure 6.8: series connection of several control units.

Page 42

Commissioning 6 36 6.6 connecting the hydraulic drive (version h-100/200, e-100/200, q-100/200) depending on the version, the axeo single-disc spreader can be fitted with a hy- draulic motor to drive the spreading disc and the agitator. You will need a single-acting control valve and a free return o...

Page 43

Commissioning 37 6 6.7 connecting the hydraulic slider control (version h) a single-acting hydraulic cylinder with a return spring is used on the axeo single- disc spreader: oil pressure closes, spring force opens. The hydraulic slider actuation is connected to the tractor via a hydraulic hose. A si...

Page 44

Commissioning 6 38 6.9 filling the spreader hopper instructions for filling the spreader hopper only fill the spreader hopper when it is hitched to the tractor. When determining the maximum permissible load weight, bear in mind the specific weight (kg/l) of the spreading material. This will depend o...

Page 45

Commissioning 39 6 6.10 parking and unhitching the single-disc spreader the spreader can be parked safely on the frame. General instructions for parking the spreader the spreader may only be parked on a firm, level surface. Only park the spreader with an empty hopper. Relieve the load on the hitchin...

Page 46

Commissioning 6 40 opening the metering slider: 1. Close the metering slider fully using the control valve. 2. Set the volume end stop to the maximum value. 3. Open the metering slider fully using the control valve. the hydraulic cylinder is at the end stop. the return spring remains under tensi...

Page 47

Machine adjustments 41 7 7 machine adjustments 7.1 overview of adjustment possibilities n danger hazard from running engine adjusting the single-disc spreader with the engine running may cause serious injuries from the mechanical components and ejected spreading material. wait until all rotating p...

Page 48

Machine adjustments 7 42 the setting elements are used to adjust the spreading parameters of the spreader. Parameter meaning description spreading vol- ume adjustment of spreading volume by altering the opening of the metering slider. Page 45 spreading pat- tern adapting the working width and spread...

Page 49

Machine adjustments 43 7 7.2 adjusting the spreading disc or agitator speed 7.2.1 pto drive the speeds for spreading disc and agitator are given in the spreading table. 7.2.2 hydraulic motor drive on spreaders with hydraulic drive, the speed is set using the flow control valve. The values to be set ...

Page 50

Machine adjustments 7 44 adjustment values for 200 cm 3 hydraulic motor handwheel setting on the flow control valve speed in rpm spreading ma- terial 3 65 3,5 110 4 160 4,5 200 grit 5 250 salt and sand 6 325 fertiliser 7 390 fertiliser 8 445 fertiliser 9 510 10 570 handwheel setting on the flow cont...

Page 51

Machine adjustments 45 7 7.3 adjusting the application rate notice the single-disc spreaders axeo 2.1 q, axeo 6.1 q and axeo axeo 18.1 q have an electronic slider actuation for adjusting the application rate. The electronic slider actuator is described in a separate operating manual for the quantron...

Page 52

Machine adjustments 7 46 spreading volume is determined by the opening of the metering slider, which is adjusted using the number scale on the scale plate. The operator moves the pointer to the position specified beforehand in the spreading table or from a calibration test. That is the end stop posi...

Page 53

Machine adjustments 47 7 7.4 adjusting the drop point adjusting the drop point serves to adapt to various different spreading materials and spreading patterns. The drop point is adjusted using the letter scale on the scale plate. The operator moves the end stop to the position determined beforehand ...

Page 54

Machine adjustments 7 48 7.5 adjusting the spreading width limiter the spreading width limiter permits different spreading widths of approx. 0.8 to 8 m to be adjusted for a mounting height of approx. 55 cm (see “determining the mounting height”, page 30 ). Depending on the equipment of your spreader...

Page 55

Machine adjustments 49 7 adjustment: figure 7.4: limiting the spreading width [1] setscrew [2] setting lever with scale 1. Loosen the setscrew [1] on the spreading width limiter. 2. Move the adjustment lever [2] to the desired position. Adjustment lever upwards: spreading width increased. Adjustment...

Page 56

Machine adjustments 7 50 7.6 adjusting a spreading pattern 7.6.1 symmetric and asymmetric spreading pattern depending on type and condition of the spreading material, an asymmetric loca- tion of the spreading pattern can be created (spreading volume different on the left and right-hand sides). This ...

Page 57

Machine adjustments 51 7 7.6.2 sharp limitation of the right-hand spreading edge for a sharp limitation on the right-hand spreading edge, the spreading pattern must be adjusted to left-hand asymmetric spreading, as seen in the direction of travel. In order to obtain an even spreading pattern you mus...

Page 58

Machine adjustments 7 52 notes on adjustment for sharp limitation of the spreading pattern at the right-hand spreading edge with volume balancing and even spreading material distribution: determine the adjustment values for your spreading material (fertiliser chart). Lower the right-hand spreading w...

Page 59

Machine adjustments 53 7 figure 7.11: spreading density right in direction of travel white arrow: spreading disc's direction of rotation grey arrow: adjustment of the spreading vanes in the direction opposite to the spreading disc's rotation 3. Move the spreading vanes backwards in the direction opp...

Page 60

Machine adjustments 7 54 increasing the spreading density on the left-hand side in direction of travel 1. Note the spreading disc's direction of rotation. See figure 7.10 . 2. Remove the screws of the spreading vanes with the associated nuts and washers. Figure 7.12: spreading density left in direct...

Page 61

Machine adjustments 55 7 7.7 using the fertiliser chart 7.7.1 information on the fertiliser charts the values in the fertiliser charts have been determined on the spreading mate- rial test system. The spreading materials specified have been purchased from the manufacturers or from dealers. Experienc...

Page 62

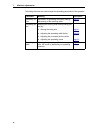

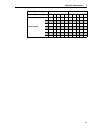

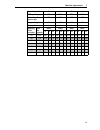

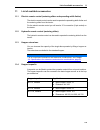

Machine adjustments 7 56 7.7.2 fertiliser chart for grit (3/5 mm) adjustment values for the metering slider end stop: pto speed: n = 450 rpm spreading disc speed: 200 rpm drop point e flow factor: 1.35 hopper height: b = 33 cm agitator type: rwk ax 160 one-sided delivery slider: 0 spreading width [m...

Page 63

Machine adjustments 57 7 spreading width [m] 6 8 spreading density [g/m 2 ] 100 150 200 250 300 100 150 200 250 300 speed [km/h] 3 23 27 31 36 39 26 31 37 40 43 6 31 38 43 49 – 37 43 52 – – 10 40 49 60 – – 45 – – – – 15 49 60 – – – – – – – – 20 60 – – – – – – – – – 25 – – – – – – – – – – 30 – – – – ...

Page 64

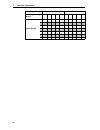

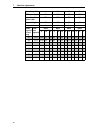

Machine adjustments 7 58 7.7.3 fertiliser chart for sand adjustment values for the metering slider end stop: pto speed: n = 540 rpm spreading disc speed: 230 rpm drop point j flow factor: 0.78 hopper height: b = 33 cm agitator type: rwk ax 180 one-sided delivery slider: 0 spreading width [m] 1 2 spr...

Page 65

Machine adjustments 59 7 7.7.4 fertiliser chart for rock salt adjustment values for the metering slider end stop: pto speed: n = 540 rpm spreading disc speed: 230 rpm drop point f flow factor: 1.22 hopper height: b = 33 cm agitator type: rwk ax 220 one-sided delivery slider: 0 spreading width [m] 1 ...

Page 66

Machine adjustments 7 60 spreading width [m] 6 8 spreading density [g/m 2 ] 5 10 20 30 40 5 10 20 30 40 speed [km/h] 3 – – 11 12 13,5 – 10 11,5 13,5 14,5 6 – 10,5 13,5 15,5 17,5 10 11,5 15 17,5 19,5 10 10,5 12,5 16 19 22 11,5 13,5 18 22 25,5 15 11,5 14,5 19 23 26,5 12,5 16 22 26,5 29,5 20 12,5 16 22...

Page 67

Machine adjustments 61 7 7.7.5 fertiliser chart for refined salt adjustment values for the metering slider end stop: pto speed: n = 540 rpm spreading disc speed: 230 rpm drop point f flow factor: 1.38 hopper height: b = 33 cm agitator type: rwk ax 220 one-sided delivery slider: 0 spreading width [m]...

Page 68

Machine adjustments 7 62 spreading width [m] 5 spreading density [g/m 2 ] 5 10 20 30 40 speed [km/h] 3 – – 7 8 9,5 6 – 7 9,5 11 12,5 10 6,5 8,5 11,5 13,5 15,5 15 7,5 10,5 13,5 16 18,5 20 8,5 11,5 15,5 18,5 21,5 25 9,5 12,5 17 20,5 23,5 30 10,5 13,5 18,5 22,5 26.

Page 69

Machine adjustments 63 7 7.7.6 fertiliser chart for fertiliser basatop sport compo npk: 20 - 5 - 10 fertiliser density: 1.10 kg/l one-sided delivery slider: 5 application rate in kg/ha agitator type: rwk ax 140 spreading width 5 6 7 8 pto speed (rpm) 540 540 750 1000 spreading disc speed: rpm 230 23...

Page 70

Machine adjustments 7 64 cornufera npk, günther npk: 20 - 5 - 8 fertiliser density: 1.10 kg/l one-sided delivery slider: 5 application rate in kg/ha agitator type: rwk ax 140 spreading width 5 6 7 8 pto speed (rpm) 540 750 750 1000 spreading disc speed: rpm 230 325 325 430 hopper height: 33 33 33 33...

Page 71

Machine adjustments 65 7 40 48,2 723 578 482 603 482 402 516 413 344 452 362 301 41 50,3 754 603 503 629 503 419 539 431 359 471 377 314 42 52,4 785 628 524 655 524 436 561 449 374 491 393 327 43 54,4 817 653 544 681 544 454 583 467 389 510 408 340 44 56,5 848 678 565 707 565 471 606 484 404 530 424...

Page 72

Machine adjustments 7 66 entec avant, compo npk: 12 - 7 - 6 fertiliser density: 1.13 kg/l one-sided delivery slider: 5 application rate in kg/ha agitator type: rwk ax 140 spreading width 5 6 7 8 pto speed (rpm) 540 540 750 1000 spreading disc speed: rpm 230 230 325 430 hopper height: 33 33 33 33 dro...

Page 73

Machine adjustments 67 7 44 69,4 1041 833 694 868 694 579 744 595 496 651 521 434 45 71,9 1079 863 719 899 719 599 770 616 514 674 539 449 46 74,1 1111 889 741 926 741 617 794 635 529 694 555 463 47 76,2 1143 915 762 953 762 635 817 653 544 715 572 476 48 78,4 1176 941 784 980 784 653 840 672 560 73...

Page 74

Machine adjustments 7 68 floranid n32, compo npk: 32 % n fertiliser density: 0.52 kg/l one-sided delivery slider: 5 application rate in kg/ha agitator type: rwk ax 140 spreading width 3 4 5 6 pto speed (rpm) 540 750 1000 1000 spreading disc speed: rpm 230 325 430 430 hopper height: 33 33 33 33 drop ...

Page 75

Machine adjustments 69 7 39 27,8 695 556 463 521 417 347 417 333 278 347 278 232 40 28,8 720 576 480 540 432 360 432 346 288 360 288 240 41 29,5 739 591 492 554 443 369 443 354 295 369 295 246 42 30,3 757 606 505 568 454 379 454 363 303 379 303 252 43 31,0 776 620 517 582 465 388 465 372 310 388 310...

Page 76

Machine adjustments 7 70 floranid permanent, compo npk: 16 - 7 - 15 fertiliser density: 1.01 kg/l one-sided delivery slider: 5 application rate in kg/ha agitator type: rwk ax 140 spreading width 5 6 7 8 pto speed (rpm) 540 750 750 1000 spreading disc speed: rpm 230 325 325 430 hopper height: 33 33 3...

Page 77

Machine adjustments 71 7 floral, calcium-ammonium nitrate npk: 27% n fertiliser density: 1.07 kg/l one-sided delivery slider: 5 application rate in kg/ha agitator type: rwk ax 140 spreading width 5 6 7 8 9 pto speed (rpm) 540 750 1000 1000 1000 spreading disc speed: rpm 230 325 430 430 430 hopper he...

Page 78

Machine adjustments 7 72 43 60,2 903 722 602 753 602 502 645 516 430 564 452 376 502 401 334 44 62,6 939 751 626 783 626 522 671 537 447 587 470 391 522 417 348 45 65,0 975 780 650 813 650 542 696 557 464 609 488 406 542 433 361 spreading width 5 6 7 8 9 pto speed (rpm) 540 750 1000 1000 1000 spread...

Page 79

Machine adjustments 73 7 kornkali, k + s gmbh npk: 40% k, 6% mgo fertiliser density: 1.15 kg/l one-sided delivery slider: 5 application rate in kg/ha agitator type: rwk ax 140 spreading width 4 5 6 7 pto speed (rpm) 540 540 850 1000 spreading disc speed: rpm 230 230 370 430 hopper height: 33 33 33 3...

Page 80

Machine adjustments 7 74 43 55,4 1039 831 693 831 665 554 693 554 462 594 475 396 44 57,6 1079 863 720 863 691 576 720 576 480 617 493 411 45 59,7 1119 896 746 896 716 597 746 597 498 640 512 426 46 61,3 1149 919 766 919 735 613 766 613 511 656 525 438 47 62,8 1178 942 785 942 754 628 785 628 524 67...

Page 81

Machine adjustments 75 7 lawn floranid npk compo npk: 20 - 5 - 8 fertiliser density: 0.90 kg/l one-sided delivery slider: 5 application rate in kg/ha agitator type: rwk ax 140 spreading width 5 6 7 pto speed (rpm) 540 750 100 spreading disc speed: rpm 230 325 430 hopper height: 33 33 33 drop point l...

Page 82

Machine adjustments 7 76 thomaskali, k + s gmbh npk: 10% p - 15% k fertiliser density: 1.35 kg/l application rate in kg/ha agitator type: rwk ax 140 spreading width 5 6 7 8 pto speed (rpm) 540 750 1000 1000 spreading disc speed: rpm 230 325 430 430 hopper height: 33 33 33 33 drop point j j k k meter...

Page 83

Machine adjustments 77 7 41 65,0 974 780 650 812 650 541 696 557 464 609 487 406 42 67,2 1008 807 672 840 672 560 720 576 480 630 504 420 43 69,5 1042 834 695 869 695 579 744 596 496 651 521 434 44 71,7 1076 861 717 897 717 598 769 615 512 673 538 448 45 74,0 1110 888 740 925 740 617 793 634 529 694...

Page 84

Machine adjustments 7 78 7.8 calibration test for precise control of the spreading quantity we recommend running a new cali- bration test every time you change spreading material types. Carry out a calibration test: before spreading for the first time. If the quality of the spreading material change...

Page 85

Machine adjustments 79 7 7.8.2 run calibration test requirements: the metering slider is closed. Pto and tractor engine are switched off and locked to prevent accidental starting. An adequately sized container is ready for collecting the discharged material. The container's empty weight is known. Us...

Page 86

Machine adjustments 7 80 implementation: 1. Install the agitator specified in the calibration table for the specific spreading material. See 7.7: using the fertiliser chart, page 55 . 2. Fill the hopper. 3. Lay a sheet or place a container under the spreader for collecting the spread- ing material. ...

Page 87

Spreading work 81 8 8 spreading work 8.1 general information the modern technology and design of our single-disc spreaders, and exhaustive, continuous testing in our own spreading material test facilities ensure that you will have a perfect spreading pattern. Our machines are manufactured with great...

Page 88

Spreading work 8 82 select the pto and spreading disc speeds so that the spreading width is ob- tained without leaving deposits on the spreading disc. Lower pto and spreading disc speeds reduce the wear of agitator and spreading disc. Particularly hard spreader material types, e.G. Grit, increase th...

Page 89

Spreading work 83 8 8.3 spreading sequence the intended use of the single-disc spreader includes the observance of service, maintenance, and repair instructions specified by the manufacturer. Therefore, spreading operations always include the preparation and cleaning/mainte- nancework. Carry out spr...

Page 90

Spreading work 8 84 8.4 spreading grit observe the following when spreading grit: use the rwk ax 160 agitator for spreading grit. When spreading grit, a pto speed of 450 rpm and a disc speed of 200 rpm are adequate. Disengage the pto drive before transport trips. Engage the pto drive slowly at low t...

Page 91

Spreading work 85 8 8.5 spreading sand or moist salt observe the following when spreading sand or moist salt: use the rwk ax 180 agitator when spreading sand or moist salt. Do not exceed the maximum pto speed of 540 rpm or a spreading disc speed of 230 rpm. Disengage the pto drive before transport t...

Page 92

Spreading work 8 86 8.6 spreading dry salt observe the following when spreading dry salt: use the rwk ax 220 agitator when spreading sand or moist salt. Do not exceed the maximum pto speed of 540 rpm or a spreading disc speed of 230 rpm. Disengage the pto drive before transport trips. Disengage the ...

Page 93

Spreading work 87 8 8.7 spreading granulated fertiliser observe the following when spreading granulated fertiliser: use the rwk ax 140 agitator for spreading granulated fertiliser. Do not exceed the maximum pto speed of 540 rpm or a spreading disc speed of 230 rpm. Disengage the pto drive before tra...

Page 94

Spreading work 8 88 8.8 discharging residual material in order to retain the value of your spreader and its spreading performance, we recommend emptying the hopper immediately after each use. 1. Disengage the pto drive and switch off the tractor's engine. 2. Place a sheet under the spreader to catch...

Page 95

Service and maintenance 89 9 9 service and maintenance 9.1 safety service and maintenance work involves additional hazards that do not occur dur- ing normal operation of the machine. Take particular care when carrying out maintenance and repair work. Work very carefully and with awareness of danger....

Page 96

Service and maintenance 9 90 9.2.2 checking the bolted joints bolted joints have been tightened to the specified torque and locked at the facto- ry. Vibrations and shocks, in particular during the initial operating hours, can loos- en bolted joints. With a new fertiliser spreader, check all bolted j...

Page 97

Service and maintenance 91 9 9.4 metering slider adjustment check that the metering slider opens smoothly before every working season, and during the season if necessary. Disconnecting the return spring and actuating cylinder: in order to check the metering slider adjustment, the mechanism must be f...

Page 98

Service and maintenance 9 92 5. Push the metering slider against the pin, and lock it in this position by tighten- ing the setscrew. the end stop on the lower scale plate (metering scale) is positioned at scale value 24. If the position does not match, the scale must be reset. To adjust: the meter...

Page 99

Service and maintenance 93 9 9.5 checking the agitator for wear 9.5.1 removing the agitator the agitator is secured with a bayonet fitting. 1. Open the service cover. 2. Turn the agitator clockwise up to the end stop. 3. Lift out the agitator upwards. Figure 9.4: agitator finger notice the agitator ...

Page 100

Service and maintenance 9 94 9.5.2 checking the rwk ax 140 agitator for wear if the spreading material no longer flows out of the outlet evenly, the agitator fin- ger must be replaced. Check the plastic element [1] for damage and wear. in case of excessive wear, the plastic element must be replace...

Page 101

Service and maintenance 95 9 9.5.4 checking the rwk ax 180 agitator for wear check the plastic element [1] for damage and wear. in case of excessive wear, the plastic element must be replaced. Check the agitator fingers 2 for damage and wear. agitator fingers that are worn excessively could brea...

Page 102

Service and maintenance 9 96 9.5.5 checking the rwk ax 220 agitator for wear check the plastic element [1] for damage and wear. in case of excessive wear, the plastic element must be replaced. Check the agitator fingers 2 for damage and wear. agitator fingers that are worn excessively could brea...

Page 103

Service and maintenance 97 9 9.5.6 checking the thrust ring for wear instructions for fitting the thrust ring: align the groove with the outlet. Make sure that the thrust ring is seated on the baseplate. Check the thrust ring for damage and wear. Figure 9.9: thrust ring.

Page 104

Service and maintenance 9 98 9.5.7 checking the stop ring in the hopper for wear 9.6 replacing spreading vanes worn spreading vanes can be replaced. Determining the spreading vane type: replacing a spreading vane: check the stop ring in the hopper for damage and wear. Figure 9.10: stop ring in the h...

Page 105

Service and maintenance 99 9 figure 9.11: remove the spreading vane screws 1. Remove the self-locking nuts on the spreading vane and remove the spread- ing vane. 2. Mount the new spreading vane on the spreading disc. Make sure you have the correct spreading vane type. Figure 9.12: use new self-locki...

Page 106

Service and maintenance 9 100 9.7.2 checking the oil level the gearbox is maintenance-free and does not need to be lubricated under nor- mal conditions. Preconditions: the single-disc spreader must be horizontal to check the oil and to add oil. Pto drive and tractor engine are stopped, the ignition ...

Page 107

Service and maintenance 101 9 9.8 lubrication chart lubrication points lubricant notes drive shaft grease see manufacturer's manual. Metering slider, one-sided delivery slider grease, oil ensure smooth movement, and grease regularly. Upper and lower hitch balls grease grease regularly. Joints, bushe...

Page 108

Service and maintenance 9 102.

Page 109

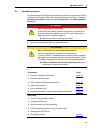

Faults and possible causes 103 10 10 faults and possible causes n gefahr risk of injury and accident from omitted or inadequate trou- bleshooting. Delayed or incorrect repairs by unqualified persons may result in incalculable risks with negative consequences for persons, the machine, and the environ...

Page 110

Faults and possible causes 10 104 blockage of metering outlets through: lumps of spreading ma- terial, damp fertiliser, miscellane- ous impurities (leaves, straw, sack residues) clear blockages. Proceed as follows: 1. Park tractor, remove ignition key. 2. Open metering slider. 3. Place catch basin u...

Page 111

List of available accessories 105 11 11 list of available accessories 11.1 electric remote control (metering slider and spreading width limiter) the electric remote control can be used to operate the spreading width limiter and the metering slider from the tractor. For the electric remote control yo...

Page 112

List of available accessories 11 106 11.5 spreader apron 11.6 agitators 11.6.1 rwk ax 140 11.6.2 rwk ax 160 spreader apron dimensions in cm (w x h) application sts 2 120 x 100 basic unit: axeo 2.1 basic unit: axeo 6.1 sts 6 150 x 100 basic unit: axeo 2.1 basic unit: axeo 6.1 sts 16 180 x 125 basic u...

Page 113

List of available accessories 107 11 11.6.3 rwk ax 180 11.6.4 rwk ax 220 11.7 adapter for mounting to cat. 1n hitch this adapter enables the axeo 2.1 single-disc spreader to be mounted on a trac- tor unit with cat. 1n hitch. The rwk ax 180 agitator is for sand and damp salt. Figure 11.3:agitator rwk...

Page 114

List of available accessories 11 108 11.8 additional lighting blo 18 this lighting is fitted as standard to the axeo 18.1 single-disc spreader. The axeo 2.1 and axeo 6.1 spreaders can be fitted with the lighting as an option. 11.9 universal drive shaft with ratchet clutch the ratchet safety clutch l...

Page 115

Axle load calculation 109 12 12 axle load calculation 12.1 calculation of the total weight n caution overload danger mounted units on the front or rear three-point linkage must not cause the approved total weight to be exceeded. The front axle of the tractor must always be loaded with at least 20 % ...

Page 116

Axle load calculation 12 110 you will need the following data for the calculation: [1] see tractor operator's manual [2] see equipment price list and/or operator's manual [3] measuring character [unit] meaning calculation by t l [kg] unladen weight of tractor. [1] t v [kg] front-axle load of the unl...

Page 117

Axle load calculation 111 12 rear-mounted unit or front-rear combinations calculation of minimum ballast at front g v min enter the calculated minimum ballast requirement in the table. G vmin g h c d + ( ) • t v b 0 2 t l b • • , + • – ( ) a b + ------------------------------------------------------...

Page 118

Axle load calculation 12 112 12.2 axle loads table tyre load capacity enter double the value (two tyres) of the approved tyre load capacity (for example, see tyre man- ufacturer's documentation) in the table. Actual value from calculation approved value from operator's manual twice approved tyre loa...

Page 119

Disposal 113 13 13 disposal 13.1 safety n warning environmental pollution due to unsuitable disposal of hy- draulic and gear oil hydraulic oil and gear oil are not fully biodegradable. Therefore, oil must be prevented from entering the environment in an uncon- trolled manner. spilled oil may only ...

Page 120

Disposal 13 114 13.2 disposal the following points apply without restriction. The precautions laid down as a re- sult of national regulations must be observed implicitly. 1. All components, auxiliary and operating substances must be removed from the single-disc spreader by specialist personnel. Here...

Page 121

Guarantee and warranty 115 14 14 guarantee and warranty rauch equipment is manufactured using modern production methods and with the greatest care, and is subjected to numerous inspections. Therefore, rauch offers a 12-month warranty under the following conditions: the warranty period begins on the ...