- DL manuals

- Rauch

- Controller

- quantron e

- Operator's Manual

Rauch quantron e Operator's Manual

5900660-

e

-en-0909

QUANTRON-E

OPERATOR MANUAL

Please read carefully

before using the machine!

Store carefully for future

use!

This Operator Manual should be consi-

dered as part of the machine. Suppliers

of new and second-hand machines are

obliged to indicate in writing that the

Operator Manual has been delivered

with the machine.

Translation of the original

operating manual

Summary of quantron e

Page 1

5900660- e -en-0909 quantron-e operator manual please read carefully before using the machine! Store carefully for future use! This operator manual should be consi- dered as part of the machine. Suppliers of new and second-hand machines are obliged to indicate in writing that the operator manual has...

Page 2

Preface dear customer your purchase of the control unit quantron e for the axis fertiliser spreader indicates your confi- dence in our products. Thank you! We want to justify your trust. You have purchased a powerful and reliable control unit.Control unit however, if any problems occur: our customer...

Page 3

Table of contents 1 preface technical improvements 1 user instructions 3 1.1 about this operator manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1.2 information on layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 4

Table of contents 2 4.7 field data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62 4.7.1 select field file. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62 4.7.2 creating a new field file . . ...

Page 5

User instructions 3 1 1 user instructions 1.1 about this operator manual this operator manual is a component of the control unit quantron e. The operator manual contains important instructions for the safe, correct and economical operation and maintenance of the control unit. Your attention will hel...

Page 6

User instructions 1 4 danger levels in the safety precautions the danger level is identified by the signal word. The danger levels are classified as follows: n danger type and source of the danger this note warns of a danger posing an immediate threat to the health and life of people. Ignoring this ...

Page 7

User instructions 5 1 1.2.2 instructions and procedures steps that the operator must carry out are shown as a numbered list. 1. Instruction for action step 1 2. Instruction for action step 2 instructions that only have one step are not numbered. The same applies for ac- tion steps that do not have a...

Page 8

User instructions 1 6.

Page 9

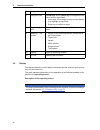

Layout and function 7 2 2 layout and function 2.1 overview of the axis versions supported function/options axis q axis w ground speed dependent spreading axis 20.1 q axis 30.1 q axis 40.1 q weighing spreader axis 30.1 w axis 40.1 w axis 50.1 w electrical adjustment of drop point axis 50.1 w.

Page 10

Layout and function 2 8 2.2 layout of the control unit - overview figure 2.1: control unit quantron e no. Designation function 1 control panel keys for operation of the unit and the display for ope- rating screens. 2 v24 data port serial interface (rs232) with lh 5000 and asd protocol, designed for ...

Page 11

Layout and function 9 2 2.3 controls, keys figure 2.2: control panel on front of unit notice the operator's manual describes the functions of the control unit quantron e as of software version 3.30.00. No. Designation function 1 start / stop starts and stops spreading. 2 clear / reset clear an input...

Page 12

Layout and function 2 10 2.4 display the display shows the current status information and the selection and input op- tions for the control unit. The most important information on the operation of the fertiliser spreader is dis- played in the operating screen. Description of the operating screen 7 n...

Page 13

Layout and function 11 2 figure 2.3: display on the control unit (using the operating screen as an example) the icons and displays in the example have the following meaning: no. Icon / display meaning (in the example) 1 operating mode shows the current operating mode. Auto km/h uses the radar signal...

Page 14

Layout and function 2 12 2.5 structural overview of menu fertiliser settings hopper configuration fast emptying field data system/t est main menu 7-pin 8-pin w eigh volume metre counter kg remaining (kg, ha, m) application rate (kg/ha) t ractor (km/h) choose new file brightness/contrast languages di...

Page 15

Attachment and installation 13 3 3 attachment and installation 3.1 requirements for the tractor before installing the control unit, check to make sure your tractor meets the fol- lowing requirements: minimum voltage 11 v is essential at all times, even if multiple consumers are connected simultaneou...

Page 16

Attachment and installation 3 14 3.2.2 7-pin plug connector the control unit receives the impulses for the current traverse speed via the 7-pin socket (din 9684-1/iso 11786. To do so, the 7-pin to 8-pin cable (accessory) is connected to the ground speed sensor at the plug connector. 3.3 connecting t...

Page 17

Attachment and installation 15 3 carry out the installation in the following order. Select a suitable position in the tractor cabin (in the driver's field of view) to attach the control unit. Install the control unit with the bracket in the tractor cabin. Connect the control unit to the 7-pin socket...

Page 18

Attachment and installation 3 16 standard schematic terminal diagram: figure 3.3: schematic terminal diagram quantron e (machine cable) [1] rs232 serial interface [2] 39-pin machine connector [3] battery [4] option (level sensor left/right) [5] 3-pin plug connector as per din 9680 / iso 12369 [6] 8-...

Page 19

Attachment and installation 17 3 wheel sensor schematic terminal diagram: figure 3.4: schematic terminal diagram quantron e (machine cable) [1] rs232 serial interface [2] 39-pin machine connector [3] battery [4] option (level sensor left/right) [5] 3-pin plug connector as per din 9680 / iso 12369 [6...

Page 20

Attachment and installation 3 18 machine cable schematic terminal diagram: figure 3.5: schematic terminal diagram quantron e (machine cable) [1] rs232 serial interface [2] 39-pin machine connector [3] battery [4] option (level sensor left/right) [5] 3-pin plug connector as per din 9680 / iso 12369 [...

Page 21

Attachment and installation 19 3 3.4 preparation of metering slide the axis 20.1 q, axis 30.1 w, axis 30.1 q, axis 40.1 w, axis 40.1 q and axis 50.1 w fertiliser spreader have an electronic slide control for adjusting the spreading volume. Figure 3.6: preparation of the metering slide (example) n ca...

Page 22

Attachment and installation 3 20

Page 23

Operation quantron e 21 4 4 operation quantron e 4.1 switching on the control unit requirements: the control unit is correctly connected to the fertiliser spreader and the tractor ( 3.3: connecting the control unit, page 14 ). The voltage is at least 11 v. Notice the operator manual describes the fu...

Page 24

Operation quantron e 4 22 switch on: press the on/off switch. after a few seconds, the start interface appears on the control unit. then the boot menu is displayed for a few seconds. then the operating screen appears. Figure 4.1: start quantron e [1] on/off switch.

Page 25

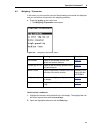

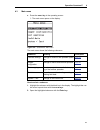

Operation quantron e 23 4 4.2 weighing - tripcounter in this menu you can have the values of the spreading work carried out displayed and you can perform functions for the weighing operation. Press the kg key on the control unit. the weighing-tripcounter menu opens. Figure 4.2: weighing-tripcounte...

Page 26

Operation quantron e 4 24 4.2.1 trip counter you can find values for the completed spreading work (time, area, distance) with this menu. Figure 4.3: trip counter menu [1] display of spread amount since the last reset [2] display of spread area since the last reset [3] display of spread distance sinc...

Page 27

Operation quantron e 25 4 4.2.2 remaining fertiliser volume in the kg rest menu, you can call up the remaining fertiliser volume in the hop- per. The menu shows the possible area (ha) and distance (m) that can be spread with the remaining fertiliser volume. Both displays are calculated based on the ...

Page 28

Operation quantron e 4 26 entering the remaining fertiliser volume when refilling (not with weighing spreader): 1. Switch from the weighing-tripcounter menu to the kg rest menu. the remaining fertiliser volume from the last spreading process appears in the display. 2. Fill the hopper. 3. Input the...

Page 29

Operation quantron e 27 4 4.2.3 weigh quantity in this menu you can weigh the fertiliser volume contained in the hopper and set the parameters for controlling the flow factor. Figure 4.5: weigh quantity menu [1] weighed volume in the hopper [2] filling options [3] weigh remnant (only displayed for t...

Page 30

Operation quantron e 4 28 when weighing the volume ensure that: the fertiliser spreader is at a standstill, the pto shaft is switched off, the fertiliser spreader is horizontal and off the ground. The tractor is at a standstill the quantron e is switched on. Weighing the fertiliser volume in the hop...

Page 31

Operation quantron e 29 4 working with the weighed fertiliser quantity, topping up the hopper: 1. Tare the scales. See 4.2.4: machine tare, page 30 . 2. Select the fertiliser type. See 4.4.6: fertiliser chart, page 44 . 3. Fill the hopper. 4. Weigh the fertiliser quantity in the hopper. See 4.2.3: w...

Page 32

Operation quantron e 4 30 4.2.4 machine tare in this menu, set the weighing value for the empty weighing spreader to 0 kg. When taring the scales ensure that: the hopper is empty, the fertiliser spreader is at a standstill, the pto shaft is switched off, the fertiliser spreader is horizontal and off...

Page 33

Operation quantron e 31 4 4.3 main menu press the menu key in the operating screen. the main menu opens on the display. Figure 4.8: quantron e main menu the main menu shows the following submenus. How to select a submenu: 1. Highlight the submenu with the black bar in the display. The highlight ba...

Page 34

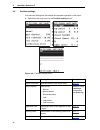

Operation quantron e 4 32 4.4 fertiliser settings you make the settings for the fertiliser and spreader operation in this menu. Switch from the main menu to the fertiliser settings menu. Figure 4.9: fertiliser settings menu submenu meaning/possible values description name of fertiliser selected fert...

Page 35

Operation quantron e 33 4 calibration start request submenu for executing the cali- bration test. Page 38 spreading disc type selection list: s2 s4 s6 s8 s10 s12 selection using arrow keys confirmation with enter key drop point l input of the left-hand drop point: the dis- play is only for informati...

Page 36

Operation quantron e 4 34 how to select a submenu: 1. Highlight the submenu with the black bar in the display. The highlight bar can be moved up and down with the arrow keys. 2. Open the highlighted submenu with the enter key. 4.4.1 application rate in this menu you can enter the desired target valu...

Page 37

Operation quantron e 35 4 4.4.2 working width you can set the working width (in metres) in this menu. Figure 4.11:working width menu entering the working width: 1. Switch from the fertiliser settings menu to the working width menu the working width currently set appears on the display. 2. Input th...

Page 38

Operation quantron e 4 36 4.4.3 flow factor the flow factor is within the range of 0.4 to 1.9. The following applies under the same basic conditions (km/h, working width, kg/ha): if the flow factor is increased the metering weight is reduced. If the flow factor is reduced the metering weight is incr...

Page 39

Operation quantron e 37 4 3. Confirm the input by pressing the enter key. the new value is saved in the operator panel. 4. Press the esc key to return to the previous menu or press the menu key to return to the operating screen. See also 4.5.2: auto / man mode, page 50 . Resolving problems with th...

Page 40

Operation quantron e 4 38 4.4.4 calibration test in this menu, you can determine the flow factor on the basis of a calibration test and save it in the control unit. Run the calibration test: before spreading for the first time. If the fertiliser quality has changed greatly (moisture, high dust conte...

Page 41

Operation quantron e 39 4 figure 4.14:working speed menu 4. Confirm the input by pressing the enter key. the new value is saved in the operator panel. the prepare calibration test screen opens. Figure 4.15:prepare calibration test screen [1] icon above function key f4 to select right spreading s...

Page 42

Operation quantron e 4 40 running calibration test: 2. Press the start/stop button. the opening slide of the previously selected part width is opened. The ca- libration test is started. the run calibration test screen is displayed. Figure 4.16:running calibration test operating screen [1] displa...

Page 43

Operation quantron e 41 4 figure 4.17:input collected weight menu n warning risk of injury from rotating machine components contact with rotating machine components (shafts, hubs) may cause bruises, abrasions and crushing injuries. Body parts or objects may be caught or pulled in. disengage the pt...

Page 44

Operation quantron e 4 42 recalculate flow factor 1. Weigh the spread fertiliser amount. 2. Input the weight of discharged fertiliser in the input field of the input collected weight menu. See also 4.9.2: input of values using the cursor keys, page 76 . 3. Confirm the input by pressing the enter key...

Page 45

Operation quantron e 43 4 4.4.5 drop point (l+r) when the quantron e is connected to an axis 50.1 w fertiliser spreader, the drop point is actuated and adjusted electrically. 1. Switch from the fertiliser settings menu to the drop point l menu. 2. Determine the position for the drop point from the f...

Page 46

Operation quantron e 4 44 4.4.6 fertiliser chart you can create and manage fertiliser charts in this menu. Create new private fertiliser chart you have the option of creating up to 60 private fertiliser charts in the control unit. 1. Switch from the fertiliser settings menu to the fertiliser chart m...

Page 47

Operation quantron e 45 4 7. Confirm the name input with the f4 key (ok). the name of the fertiliser chart is saved in the operator panel. the fertiliser settings menu is displayed again. The steps for specifying the other parameters are described in the section : edit fertiliser chart, page 45 ...

Page 48

Operation quantron e 4 46 4.5 hopper configuration you make the settings for the tractor and the fertiliser spreader in this menu. Switch from the main menu to the hopper configuration menu. Figure 4.20:hopper configuration menu how to select a submenu: 1. Highlight the submenu with the black bar in...

Page 49

Operation quantron e 47 4 4.5.1 speed calibration the speed calibration is the basic requirement for an exact spreading result. Fac- tors such as tyre size, a different tractor, all-wheel drive on or off, slippage be- tween tyres and ground, ground characteristics and tyre pressure influence the spe...

Page 50

Operation quantron e 4 48 recalibrating the speed signal: you can overwrite an existing profile or create a profile in an empty memory lo- cation. 1. Highlight the desired memory location with the function key below it in the tractor (km/h) menu. 2. In the tractor (km/h) menu, highlight the new cali...

Page 51

Operation quantron e 49 4 the number of impulses of the speed signal must still be specified below. If you know the exact number of impulses you can enter it directly: 7. Highlight the imp/100m submenu and press the enter key. the impulses menu is displayed for manual input of the number of im- pu...

Page 52

Operation quantron e 4 50 4.5.2 auto / man mode by default you operate in auto mode. The control unit automatically controls the actuators as specified by the speed signal. Only work in manual mode if: there is no speed signal (radar or wheel sensor not available or defective), seed auger or seeds (...

Page 53

Operation quantron e 51 4 a) select auto km/h + auto kg: 1. Switch on the control unit quantron e. 2. Switch from the hopper configuration menu to the auto/man operation menu. 3. Highlight the auto km/h + auto kg selection field. 4. Press the enter key. the weigh quantity window appears. 5. Case a...

Page 54

Operation quantron e 4 52 5. Highlight the action carried out in the display: refill: continue spreading with the same fertiliser. The flow factor setting is retained. The remaining fertiliser volume is increased by the refilling volume new fertiliser: flow factor set to 1.0 and a new flow factor re...

Page 55

Operation quantron e 53 4 automatic mode with static weighing (auto km/h + stat. Kg) the auto km/h + stat. Kg operating mode is recommended for spreading on uneven hilly terrain and/or for low application rates. Automatic flow factor regula- tion does not take place during spreading. However, you ca...

Page 56

Operation quantron e 4 54 b) procedure when spreading with auto km/h + stat. Kg: 1. Each time you switch on the quantron e, use the kg button to switch to the weigh quantity menu and weigh the volume of fertiliser using refill or new fertiliser. See 4.2.3: weigh quantity, page 27 2. Press the enter ...

Page 57

Operation quantron e 55 4 automatic mode (auto km/h) a) select auto km/h: 1. Switch on the control unit quantron e. 2. Switch from the hopper configuration menu to the auto/man operation menu. 3. Highlight the auto km/h selection field. 4. Press the enter key. the operating mode setting is saved. ...

Page 58

Operation quantron e 4 56 b) procedure when spreading with auto km/h: 1. Carry out the fertiliser settings: application rate (kg/ha) working width (m) 2. Pour the fertiliser in. 3. Carry out a calibration test to determine the flow factor or take the flow factor from the fertiliser chart and enter i...

Page 59

Operation quantron e 57 4 manual operation (man km/h) 1. Switch from the hopper configuration menu to the auto/man operation menu. 2. Highlight the man km/h selection field. the forward speed menu is displayed. 3. Input the value for the forward speed during spreading. Confirm the input by pressin...

Page 60

Operation quantron e 4 58 the metering slide opening can be changed manually during spreader operation in the man scale mode. Requirement: the metering slides are open (activation with the start/stop key). In the man scale operating screen, the symbols for the part widths are filled in black. Figure...

Page 61

Operation quantron e 59 4 4.5.3 +/- appl. Rate in this menu, you can specify a percentage volume change for the normal spreading type. The basis (100 %) is the pre-set value of the dispensing slider opening. Figure 4.26:+/- appl. Rate (%) menu specifying weight reduction: 1. Switch from the hopper c...

Page 62

Operation quantron e 4 60 4.6 fast emptying the fast emptying menu can be selected to clean the machine after spreading or to discharge the remaining weight quickly. Switch from the main menu to the fast emptying menu. Figure 4.27:fast emptying menu [1] metering slide opening display [2] icon for fa...

Page 63

Operation quantron e 61 4 run fast emptying: 1. Use the function button to select the desired part width. the selected part width is shown as a symbol in the display. 2. Press the start/stop button. fast emptying is started. 3. To stop fast emptying, press the start/stop button again. 4. Press t...

Page 64

Operation quantron e 4 62 4.7 field data in this menu you can create and save up to 200 operating data files. Switch from the main menu to the field data menu. Figure 4.28:field file menu 4.7.1 select field file you can re-select a previously saved field file and proceed with this. The data al- read...

Page 65

Operation quantron e 63 4 4.7.2 creating a new field file 1. In the field data menu, select the create new file entry and press the enter key. the display shows a window for entering the file name or a note. Input of text into the operator panel is described in section 4.9.1: text input, page 75 ....

Page 66

Operation quantron e 4 64 2. Select the field data start field and press the enter key. recording starts. the field data start display changes to field data stop. the operating screen displays the recording icon. Figure 4.30:recording symbol 3. Press the esc key to return to the previous menu ...

Page 67

Operation quantron e 65 4 4.7.4 stopping recording 1. Switch from the field data menu to the current field data. 2. In the current field data select the field data stop field and press the enter key. the recording is stopped. the field data stop display changes to field data start. 3. Press the ...

Page 68

Operation quantron e 4 66 4.8 system / test this menu is used to created the test and system settings for the control unit. Switch from the main menu to the system / test menu. Figure 4.31:system/test menu pages 1 and 2 submenu meaning description brightness / contrast display setting. Modification ...

Page 69

Operation quantron e 67 4 how to select a submenu: 1. Highlight the submenu with the black bar in the display. The highlight bar can be moved up and down with the arrow keys. 2. Open the highlighted submenu with the enter key. 4.8.1 setting language in the control unit quantron e there are 2 differe...

Page 70

Operation quantron e 4 68 4.8.2 display config. The display fields in the operating screen of the control unit can be configures as required. You can assign both display fields with the following values if desired: ground speed flow factor (ff) time ha trip kg trip m trip kg rest m rest ha rest figu...

Page 71

Operation quantron e 69 4 4.8.3 test / diagnosis in the test/diagnosis menu you can monitor the function of certain sensors/ac- tuators. 1. Switch from the system/test menu to the submenu test/diagnosis. 2. Highlight the desired function and press the enter key. the display shows the status of the...

Page 72

Operation quantron e 4 70 figure 4.35:test/diagnosis;example: weighing cells [1] current fertiliser volume in left hand hopper [2] fill level left, in percent [3] fill level right in percent figure 4.36:test/diagnosis; example: voltage [1] current operating voltage [2] functional range of the sensor...

Page 73

Operation quantron e 71 4 4.8.4 data transmission data transmission takes place using various data protocols. Figure 4.38:data transmission menu importing operating data (pc to quantron e) requirements: use the data stick supplied. Do not alter the directory structure on the data stick. The data is ...

Page 74

Operation quantron e 4 72 figure 4.39:importing and exporting operating data 4. Press the enter key. a message appears indicating that the current data will be deleted. Figure 4.40:message prior to deletion of the files 5. Press the start/stop button. the bar indicates the progress of the transm...

Page 75

Operation quantron e 73 4 the consequences of importing the operating data are as follows: all operating data currently stored in the quantron e is overwritten. If you have defined the application rate on the pc, the application rate is au- tomatically transferred and immediately activated in the fe...

Page 76

Operation quantron e 4 74 4.8.5 service notice an input code is required for settings in the service menu. These settings can only be modified by authorised service personnel. As a general rule, we recommend that all settings in this menu are carried out by authorised service personnel..

Page 77

Operation quantron e 75 4 4.9 special functions 4.9.1 text input in some menus freely editable text can be input. Figure 4.43:text input menu [1] input field [2] delete the complete input [3] arrow keys for navigation through the character field [4] enter key to confirm input [5] function key for te...

Page 78

Operation quantron e 4 76 overwrite character: a single character can be overwritten by another character. A single character cannot be deleted. 5. Move the cursor by using the arrow keys to the position of the character to be deleted in the input field. 6. Replace the character by selecting the des...

Page 79

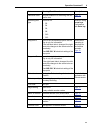

Alarm messages and possible causes 77 5 5 alarm messages and possible causes various alarm messages can be displayed on the control unitquantron e display. 5.1 meaning of alarm messages no. Message in display meaning possible cause 1 error in the metering direction. The actuator for the metering dev...

Page 80

Alarm messages and possible causes 5 78 10 min.Setting = 2.00 max.Setting = 50.00 reference to the range of values for the working width. Value entered is not permitted. 11 min.Setting = 0.40 max.Setting = 1.90 reference to the value range of the flow factor. Value entered is not permitted. 12 error...

Page 81

Alarm messages and possible causes 79 5 5.2 clear fault / alarm 5.2.1 acknowledging alarm message: an alarm message is highlighted in the display and displayed with a warning icon. Figure 5.1: alarm message (example: fertiliser settings) acknowledging alarm message: 1. Correct the cause of the alarm...

Page 82

Alarm messages and possible causes 5 80 acknowledging alarm message: 1. Proceed as described in the previous paragraph. 2. Switch the control unit quantron e off (on/off) and then restart it. 3. Switch to the weigh quantity menu using the kg button. 4. Select the function new fertiliser. 5. Press th...

Page 83

Special equipment/options 81 6 6 special equipment/options no. Illustration name 1 empty message sensor for axis 2 ground speed sensor for quantron e 3 y cable rs232 for data exchange (e. G. Gps, n sensor, etc.) 4 system tractor cable set for quantron e axis 12 m axis w 12 m.

Page 84

Special equipment/options 6 82 5 gsp cable and receiver 6 telimat sensor 7 suction cup bracket for quantron e no. Illustration name.

Page 85

Guarantee and warranty 83 7 7 guarantee and warranty rauch units are manufactured with modern production methods and with the greatest care and are subject to numerous inspections. Therefore rauch offers a 12-month warranty subject to the following conditions: the warranty begins on the date of purc...