- DL manuals

- Raven

- Control Systems

- SCS-330

- Installation & Service Manual

Raven SCS-330 Installation & Service Manual

Summary of SCS-330

Page 1

Installation & service manual scs 330

Page 2

N o t i c e the use of the suspension type fertilizers and lime slurries will significantly reduce the life of the plastic parts in the flow meter and motorized control valve. Check the rotor and inlet hub assembly in the flow meter frequently for worn parts. Excessive wear can affect accuracy. Do n...

Page 3

1 table of contents symbol definition .............................................................................................................................................. 2 introduction ...........................................................................................................

Page 4

2 symbol definition meter cal conversions meter cal conversions meter cal conversions meter cal conversions meter cal conversions to convert the meter cal number simply divide the original number (number printed on flow meter label) by the desired conversion factor. For example: for example: for exa...

Page 5

3 introduction the raven scs 330 (sprayer control system) is designed to improve the uniformity of spray applications automatically. Its performance relies on the installation and preventive maintenance of the complete sprayer. It is important that this installation and service manual be reviewed th...

Page 6

4 installation 1. Mounting the raven radar speed sensor see appendix 1 for wheel drive speed sensor installation instructions. See appendix 2 for speedometer drive speed sensor installation instructions. For mounting the radar, the following guidelines will assure proper installation: it is suggeste...

Page 7

5 2. Mounting the flow meter l) l) l) l) l) mount the flow meter in the area of the boom valves per figure 4 . All flow through the flow meter must go to booms only, i.E. No return line to tank or pump after flow meter. 2) 2) 2) 2) 2) mount flow meter horizontal to the ground. Use the bracket to sec...

Page 8

6 4. Mounting the console and cabling l) l) l) l) l) mount the console to secure support inside the cab of the vehicle. 2) 2) 2) 2) 2) connect the control cable to the plug in the back of the console. Route the cable out of the vehicle cab. (flow meter extension cables are available from your dealer...

Page 9

7 battery connections figure 6 figure 6 figure 6 figure 6 figure 6.

Page 10

8 console features important: important: important: important: important: this console requires selection of us us us us us (acres), si si si si si [hectares], or tu tu tu tu tu {1,000 sq. Ft.} area; sp1 sp1 sp1 sp1 sp1 (wheel drive, etc.) or sp2 sp2 sp2 sp2 sp2 (radar) speed sensor; and c-sd c-sd c...

Page 11

9 console calibration 1. Calculating "boom cal" 1) 1) 1) 1) 1) broadcast spraying: calculate the width of each boom in inches [cm] by multiplying the number of tips times the spacing. Write these boom widths down for future reference when programming the console. Figure 7 2) 2) 2) 2) 2) band sprayin...

Page 12

10 2. Calculation of radar "speed cal" note: note: note: note: note: numbers in brackets [ ] are metric equivalents. 1) 1) 1) 1) 1) reset console according to the instruction manual. 2) 2) 2) 2) 2) complete "initial console programming" in the installation and service manual for your console. Select...

Page 13

11 3. Calculating "meter cal" the flow meter calibration number is stamped on the tag attached to each flow meter. Write down this number for future reference when programming the console computer. To convert original meter cal from gallons to desired units of measure (oz, lbs, or liters per area), ...

Page 14

12 flow meter model flow range rfm 5 0.05-5 gpm [0.2-18.9 lit/min] rfm 15 0.3-15 gpm [1.1-56.8 lit/min] rfm 55/55a 1-55 gpm [3.8-208 lit/min] rfm 100 3-100 gpm [11.4-379 lit/min] rfm 200/200 poly 15-200 gpm [56.8-757 lit/min] rfm 400 25-400 gpm [94.6-1514 lit/min] verifying flow rate limits: verifyi...

Page 15

13 complete the entry by again depressing the enter key. Depress the keys correspond- ing to the number you wish to enter (i.E. "7","4","3"). The numbers will be dis- played as they are entered. Depress the key in which you wish to enter data. Depress the enter key. An "e" will illuminate in the dat...

Page 16

14 1. Initial console programming when you first turn on console power after all installation procedures have been completed, the console will display "us" in the display window. This means you must "calibrate", or program, the console before it can be operated. This is a one-time operation which do...

Page 17

15 5) 5) 5) 5) 5) display c-sd (standard valve), or c-fc (fast close valve). A) a) a) a) a) depressing momentarily steps the display from c-sd to c-fc. B) b) b) b) b) depressing momentarily steps the display from c-fc to c-sd. 6) 6) 6) 6) 6) selecting c-sd or c-fc. A) a) a) a) a) to select c-sd or c...

Page 18

16 2. Other display features see appendix 9 for detailed outline of each console key and what features are located under them. 1) 1) 1) 1) 1) to display the set operating modes for units of measure (us, si, tu), speed sensor type (sp1, sp2), and valve type (c-sd, c-fc), depress for 5 seconds and con...

Page 19

17 3. Self test feature self test allows speed simulation for testing the system while the vehicle is not moving. Enter the simulated operating speed by depressing the key labelled for 5 seconds. Display will show "-test-". If 6 mph [9.6 km/h] is desired, enter 6.0 [9.6] (see console programming). V...

Page 20

18 6. Automatic rate +/- this feature sets the increment at which flow is increased or decreased in the auto mode of operation. Select rate +/- for product by depressing for 7 seconds. The display will show "delt". Enter the desired amount for +/-. Example: example: example: example: example: if flo...

Page 21

19 9. Valve cal to display current valve cal setting, depress dey labled for 5 seconds. Valve cal number will show in data display. 10. Control valve delay depress key labelled for 5 seconds. "dlay" will be displayed. The control valve delay number is a 4 digit number. The first didgit in the contro...

Page 22

20 13. Enter mode sequence with activated data-lock 1) 1) 1) 1) 1) depress the console key that you wish to enter data into and depress . 2) 2) 2) 2) 2) "code" message will appear in the display. Enter your activated code number and depress . If code is correct, "e" will appear in display and consol...

Page 23

21 initial system field test 1) 1) 1) 1) 1) drive down field or road at target speed with sprayer booms off, to verify speed readout on console. 2) 2) 2) 2) 2) turn master switch and boom switches to on. Place the off/man/auto switch to auto. Increase or decrease speed by one mph [2 km/h]. The syste...

Page 24

22 appendix 1 wheel drive speed sensor installation and calibration procedure 1. Mounting wheel drive speed sensor the wheel drive speed sensor consists of two magnets, a switch assembly with cable, and mounting hardware. Sequence of mounting speed sensor: l) l) l) l) l) select a non-driven wheel (l...

Page 25

23 2. Rim drilling instructions for wheel drive speed sensor magnets on wheels which do not have pre-punched mounting holes, proceed as follows: note: note: note: note: note: if only two magnets are to be mounted; drill two holes 180° from each other. Rims with a four or eight hole stud patterns: ri...

Page 26

24 3. Calculating "speed cal" 1) 1) 1) 1) 1) place a chalk mark or tape onto the vehicle tire that the speed sensor mounted to it as shown below. 2) 2) 2) 2) 2) mark the initial spot on the ground. 3) 3) 3) 3) 3) drive vehicle straight ahead counting 10 full revolutions of the wheel. The mark must s...

Page 27

25 appendix 2 speedometer drive speed sensor installation and calibration procedure 1. Mounting the speedometer drive speed sensor 1) 1) 1) 1) 1) remove the existing speedometer cable from the back of the vehicle speedometer. Pull cable through fire wall into engine compartment. 2) 2) 2) 2) 2) insta...

Page 28

26 2. Calculating "speed cal" 1) 1) 1) 1) 1) complete "initial console programming" before doing this procedure. 2) 2) 2) 2) 2) enter “0” in key labelled . 3) 3) 3) 3) 3) enter a speed cal of 306 [78] in key labelled . 4) 4) 4) 4) 4) drive 1 mile [1 km]. Caution: caution: caution: caution: caution: ...

Page 29

27 appendix 3 alternate by-pass line plumbing system figure 11 figure 11 figure 11 figure 11 figure 11 initial system set-up plumb the system as shown in figure 11. Adjust as follows: install polarity reversal jumper in motorized control valve cable (p/n 115-0159-415). 1) 1) 1) 1) 1) fill tank with ...

Page 30

28 8) 8) 8) 8) 8) verify that each boom valve operates and that no nozzles are plugged by operating the boom on/off switches. 9) 9) 9) 9) 9) place all boom on/off switches to on. 10) 10) 10) 10) 10) hold the flow control switch to inc position for approximately 12 seconds. This assures motorized con...

Page 31

29 appendix 4 procedure to test speed sensor extension cables verify that the console is in the sp1 speed sensor mode while testing the cable. Disconnect extension cable from speed sensor assembly cable. Hold extension cable connector so that keyway is pointing in the 12 o’clock position. Procedure ...

Page 32

30 appendix 5 procedure to test flow meter cables disconnect cable from flow sensor. Hold flow sensor cable so that the keyway is pointing in the 12 o’clock position: procedure to check cable: procedure to check cable: procedure to check cable: procedure to check cable: procedure to check cable: 1) ...

Page 33

31 appendix 6 flow meter maintenance and adjustment procedure 1) 1) 1) 1) 1) remove flow meter from sprayer and flush with clean water to remove any chemicals. Nh nh nh nh nh 3 3 3 3 3 warning: warning: warning: warning: warning: thoroughly bleed nurse tank hose and all other system lines prior to d...

Page 34

32 appendix 7 procedure to re-calibrate flow meter 1) 1) 1) 1) 1) enter a meter cal number of 10 [38] in the key labelled . 2) 2) 2) 2) 2) enter a total volume of 0 in the key labelled . 3) 3) 3) 3) 3) switch off all booms. 4) 4) 4) 4) 4) remove a boom hose and place it into a calibrated 5 gallon [1...

Page 35

33 appendix 8 remote switch option figure 12 figure 12 figure 12 figure 12 figure 12 the remote switch when installed is in parallel the master switch; therefore switching on the remote switch or or or or or the master switch will energize the boom valves..

Page 36

34 appendix 9 hidden features the scs 330 console is equipped with many hidden features. Several console keys have multiple features located under them. The amount of time a key is held down determines the feature that will be displayed. The display will flash the coded name of the feature that is b...

Page 37

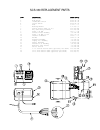

Scs 330 replacement parts item item item item item description description description description description raven part # raven part # raven part # raven part # raven part # 1 master switch 412-2011-037 2 boom switch 412-2011-038 3 off/man/auto switch 412-2011-052 4 inc/dec switch 412-2011-053 5 k...

Page 39: Raven Industries

Raven industries will not assume any expense or liability for repairs made outside our facilities without written consent. Raven industries is not responsible for damage to any associated equipment or products and will not be liable for loss of profit or other special damages. The obligation of this...

Page 40

Notice: this document and the information provided are the property of raven industries, inc. And may only be used as authorized by raven industries, inc. All rights reserved under copyright laws. Scs 330 installation & service manual (p/n 016-0159-524 rev e 2/09) raven industries toll free (u.S. An...