- DL manuals

- Raven

- Control Systems

- SCS 450

- Installation & Service Manual

Raven SCS 450 Installation & Service Manual

Summary of SCS 450

Page 1

Scs 450 serial interface installation & service manual.

Page 2: Disclaimer

While every effort has been made to ensure the accuracy of this document, raven industries assumes no responsibility for omissions and errors. Nor is any liability assumed for damages resulting from the use of information contained herein. Raven industries shall not be held responsible or liable for...

Page 3

Table of contents manual no. 016-0159-831 i chapter 1 important safety information................................................. 1 important safety information ..................................................................................................... 1 hydraulic safety ...................

Page 4

Table of contents ii scs 450 serial interface installation & service manual console programming ............................................................................................................. 28 data entry ...................................................................................

Page 5: Notice

Chapter 1 manual no. 016-0159-831 1 chapter 1 important safety information important safety information read this manual and the operation and safety instructions included with your implement and/or controller carefully before installing the scs 450 serial interface system. • follow all safety infor...

Page 6: Danger

Chapter 1 2 scs 450 serial interface installation & service manual thoroughly bleed the nurse tank hose and all other system lines prior to disassembling the flow meter, fittings, and hoses, especially in the case of anhydrous ammonia. Hydraulic safety • raven industries recommends that appropriate ...

Page 7: Notice

Chapter 2 manual no. 016-0159-831 3 chapter 2 introduction introduction congratulations on your purchase of the raven scs (sprayer control system) 450 serial interface! The raven scs 450 is designed to provide uniformity of spray applications, regardless of the vehicle’s speed. Utilizing a computer-...

Page 8

Chapter 2 4 scs 450 serial interface installation & service manual unit definitions and conversions unit of measure definitions unit of measure conversions to convert the meter cal value into the a unit of measure, divide the original number printed on the flow meter label by the desired conversion ...

Page 9

2 manual no. 016-0159-831 5 introduction calculating machine’s calibration values calculate the boom cal value broadcast spraying calculate the boom cal value in inches [cm] by multiplying the number of tips by the spacing between the tips. Be sure to write down these figures for future reference wh...

Page 10

Chapter 2 6 scs 450 serial interface installation & service manual phoenix 10 speed sensors only the initial speed cal value for phoenix 10 speed sensors is 785 [200]. After the initial console programming has been performed, this value may be adjusted to optimize the system’s performance. Wheel dri...

Page 11

2 manual no. 016-0159-831 7 introduction calculate the meter cal value no calculation of the meter cal value is necessary, since the flow meter calibration value is stamped on the tag attached to each flow meter. Locate this number and write it down for future reference when programming the console....

Page 12

Chapter 2 8 scs 450 serial interface installation & service manual calculate the rate 1 and rate 2 cal values determine the application rate at which the chemical is to be sprayed, and then consult with your raven dealer to verify that the spray nozzles are capable of applying at that rate. To deter...

Page 13

2 manual no. 016-0159-831 9 introduction for example: based on these calculations and a psi of 30, tip xr8004 should be selected since it comes closest to providing the desired output. Verifying flow rate limits the flow rate of spray must be within the specified range for the flow meter being used....

Page 14

Chapter 2 10 scs 450 serial interface installation & service manual.

Page 15

Chapter 3 manual no. 016-0159-823 11 chapter 3 calibration card introduction located on the next page is a card that may be used to record the machine’s calibration values. Write the calibration numbers in pencil so that they may be revised if necessary. Cut on the dotted line, fold, and insert the ...

Page 16

Chapter 3 12 scs 460 serial interface installation & service manual.

Page 17

Chapter 4 manual no. 016-0159-831 13 chapter 4 installation sensor installation raven radar speed sensor note: raven industries recommends the installation of a large, heavy mounting bracket (p/n 107-0159- 693) on the machine’s frame for mounting the radar speed sensor. Figure 1. Radar mounting loca...

Page 18

Chapter 4 14 scs 450 serial interface installation & service manual 3. Use a level to verify that the selected mounting bracket location is parallel to the ground. 4. Bolt the mounting bracket to the machine. Figure 2. Radar mounting 5. Bolt the radar to the mounted bracket using the supplied mounti...

Page 19

4 manual no. 016-0159-831 15 installation rim drilling for six hole wheel stud patterns - optional this section is required only on wheels that do not have pre-punched mounting holes. If your machine has the pre-punched mounting holes, proceed to the mounting the wheel drive speed sensor section on ...

Page 20

Chapter 4 16 scs 450 serial interface installation & service manual figure 6. Switch assembly installed note: the switch assembly does not need to pivot with the wheel. 4. Loosely mount the switch assembly to the wheel axle with the supplied hardware, positioning it so that as the wheel rotates, the...

Page 21

4 manual no. 016-0159-831 17 installation flow meter installation mounting the flow meter figure 8. Flow meter installation diagram note: all flow through the flow meter must go to the boom sections only. Ensure there are no return, agitation, or sparge lines to the tank or pump after the flow meter...

Page 22

Chapter 4 18 scs 450 serial interface installation & service manual control valve installation install the control valve figure 9. Control valve installation diagram note: this plumbing schematic applies only to applications of 3 gpm [11 lit/min] or greater. For flow less than 3 gpm [11 lit/min], th...

Page 23

4 manual no. 016-0159-831 19 installation alternate bypass line plumbing system figure 10. Alternate bypass line plumbing system diagram note: this plumbing schematic applies only to applications of less than 3 gpm [11 lit/min]. For flow of 3 gpm [11 lit/min] or greater, the motorized control valve ...

Page 24: Caution

Chapter 4 20 scs 450 serial interface installation & service manual console and cabling installation 1. Mount the scs 450 console to a secure area inside the machine’s cab. Note: the scs 450 console should be mounted in the machine’s cab so that the machine operator has easy access to it. 2. Connect...

Page 25

4 manual no. 016-0159-831 21 installation figure 11. Console cabling diagram.

Page 26

Chapter 4 22 scs 450 serial interface installation & service manual install the remote switch - optional an optional remote switch may be installed if the console is mounted in a location that is not easily accessible. A remote switch may include a foot switch or a toggle switch on the joystick. To ...

Page 27

Manual no. 016-0159-831 23 installation battery connections note: if the system will not be used for an extended period of time (for example, two weeks), be sure to disconnect the scs 450 battery wires. If the wires are not disconnected and the scs 450 is only turned off, the system will continue to...

Page 28

Chapter 4 24 scs 450 serial interface installation & service manual.

Page 29

Chapter 5 manual no. 016-0159-831 25 chapter 5 console programming and calibration important: the scs 450 console requires the selection of volume rate (us, si, or tu), speed sensor type (sp1 or sp2), and valve type (c-sd - standard valve, c-f - fast valve, c-fc - fast close valve, c-p - pwm valve, ...

Page 30

Chapter 5 26 scs 450 serial interface installation & service manual console features figure 2. Scs 450 serial console select s m anua l or fully au to matic con trol manu al ov errid e co nt ro l prov ides th e cap ability of spo t ap plicat ion t u rns t h e co nso le p o w e r on or o ff t o g g l...

Page 31

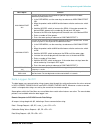

5 manual no. 016-0159-831 27 console programming and calibration button definitions calibration buttons the calibration buttons are used to enter data into the console when calibrating the system. Refer to the table below for the button names and functions. Function buttons the function buttons are ...

Page 32

Chapter 5 28 scs 450 serial interface installation & service manual console programming data entry note: data must be entered for all booms and for each of the variables. If a boom is not in use, enter 0 as the value for that boom. 1. Press the number key that corresponds with the variable to be cha...

Page 33

Manual no. 016-0159-831 29 console programming and calibration 9. Use the arrow keys to advance to the remaining booms and enter the data for each boom. Note: if a boom is not being used, enter 0 for the boom length. 10. Press the speed cal button and enter the appropriate speed cal value for the ty...

Page 34

Chapter 5 30 scs 450 serial interface installation & service manual 7. Enter the adjusted speed cal value. 8. Recheck the new speed cal value by repeating the steps above. Refining the speed cal value - phoenix 10 speed sensors only the initial speed cal value when using the phoenix 10 speed sensor ...

Page 35

Manual no. 016-0159-831 31 console programming and calibration programming additional system data although it is not required for system operation, data may be entered in the vol tank and time submenus. Vol tank 1. Press the vol tank button. 2. Press enter. 3. Enter the estimated volume of product i...

Page 36

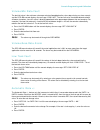

Chapter 5 32 scs 450 serial interface installation & service manual system features data menu pressing the data menu button displays the menu options by name and the default setting. Use the arrow keys to scroll through the menu options. Menu option function print field begin sends data through the ...

Page 37

Manual no. 016-0159-831 33 console programming and calibration data logger on/off the data logger uses communication strings to pass data through the serial port based on the values entered in data logger trigger value and data logger trigger units. Whenever a value or console switch is changed, dat...

Page 38

Chapter 5 34 scs 450 serial interface installation & service manual scs 450 console to remote computer data strings all request strings begin with $r, indicating a raven communication string. The 124 value indicates the last three digits of the programmed chip part number in the console, and f is th...

Page 39

Manual no. 016-0159-831 35 console programming and calibration volume/min rate fault the low limit value is the minimum volume per minute allowed before the valve stops closing, an alarm sounds, and the scs 450 console displays the message “low limit.” the low limit value should be determined with a...

Page 40

Chapter 5 36 scs 450 serial interface installation & service manual control valve delay and valve advance the control valve delay feature allows the user to set a delay between the time the booms are turned on and when the console begins to control the flow rate. The delay is active if the time betw...

Page 41

Manual no. 016-0159-831 37 console programming and calibration entering data in the data lock mode 1. Press the button of the variable to be edited. 2. Press enter. A message prompting for the data-lock code will appear. 3. Enter the data-lock code. If the code is correct, e will appear on the displ...

Page 42

Chapter 5 38 scs 450 serial interface installation & service manual shift the decimal place 1. Press the meter cal button. 2. Press the self test button. 3. Enter the flow meter calibration value stamped on the identification tag. 4. Press enter. Unshift the decimal place 1. Press the meter cal butt...

Page 43

Chapter 6 manual no. 016-0159-831 39 chapter 6 initial system setup and testing initial system setup after all components of the system have been installed and the console has been programmed, the scs 450 is ready to be set up. Complete the following steps to set up the scs 450 system. Note: this pr...

Page 44

Chapter 6 40 scs 450 serial interface installation & service manual note: if the rate and minimum pressure cannot be achieved, consider modifying the plumbing into the alternate by-pass plumbing system configuration. Refer to the alternate bypass line plumbing system section on page 19. Alternate by...

Page 45

6 manual no. 016-0159-831 41 initial system setup and testing initial system field test note: this procedure applies only to applications of 3 gpm [11 lit/min] or greater. For flow less than 3 gpm [11 lit/min], refer to the alternate bypass plumbing initial system field test section for the alternat...

Page 46

Chapter 6 42 scs 450 serial interface installation & service manual.

Page 47: Danger

Chapter 7 manual no. 016-0159-831 43 chapter 7 preventative maintenance & troubleshooting general preventative maintenance preventative maintenance is extremely important to ensure the long life of your machine and the scs 450 system. The following preventative maintenance measures should be taken o...

Page 48

Chapter 7 44 scs 450 serial interface installation & service manual d. Spin the turbine to confirm that it spins freely with very little drag inside the turbine hub. 4. Adjust the turbine hub if necessary. This should be done whenever the transducer assembly is replaced or the turbine stud is adjust...

Page 49

Manual no. 016-0159-831 45 preventative maintenance & troubleshooting 7 recalibrating the flow meter note: this procedure should be performed when the tank is filled with water, not chemicals. 1. Enter a meter cal value of 10 [38] into the console. 2. Enter a total volume value of 0 into the console...

Page 50

Chapter 7 46 scs 450 serial interface installation & service manual speed sensor cables testing speed sensor extension cables note: verify that the console is in the sp1 speed sensor mode while testing the cable. 1. Disconnect the extension cable from the speed sensor assembly cable. Figure 2. Speed...

Page 51

Manual no. 016-0159-831 47 preventative maintenance & troubleshooting 7 troubleshooting console issues issue corrective action the console is on, but there are no lights lit up on the console. 1. Check the fuse on the back of the console. 2. Check the battery connections. 3. Check the operation of t...

Page 52

Chapter 7 48 scs 450 serial interface installation & service manual rate control issues the speed is inaccurate or unstable. (wheel drive speed sensor) 1. Check the speed sensor. C. Run a speed check on a hard surface road. D. If the speed is accurate, move the speed sensor to a different wheel and ...

Page 53

Manual no. 016-0159-831 49 preventative maintenance & troubleshooting 7 cannot vary the rate in automatic or manual operation. 1. Check the cabling to the motorized control valve for breaks in the line. 2. Verify the cable connections are clean. 3. Verify that there is voltage to the valve connector...

Page 54

Chapter 7 50 scs 450 serial interface installation & service manual.

Page 55

Chapter 8 manual no. 016-0159-831 51 chapter 8 replacement parts.

Page 56

Chapter 8 52 scs 450 serial interface installation & service manual.

Page 57

Index manual no. 016-0159-831 53 c console programming and calibration console features 26 button definitions 27 console identification 25 console programming 28 changing initial console programming 30 data entry 28 initial console programming 28 programming additional system data 31 system features...

Page 58

Index 54 scs 450 serial interface installation & service manual.

Page 59: Raven Industries

Raven industries will not assume any expense or liability for repairs made outside our facilities without written consent. Raven industries is not responsible for damage to any associated equipment or products and will not be liable for loss of profit or other special damages. The obligation of this...

Page 60

Notice: this document and the information provided are the property of raven industries, inc. And may only be used as authorized by raven industries, inc. All rights reserved under copyright laws. Raven industries toll free (u.S. And canada): (800)-243-5435 applied technology division or outside the...