- DL manuals

- Ravenheat

- Boiler

- CSI 85

- Installation And Servicing Instructions

Ravenheat CSI 85 Installation And Servicing Instructions

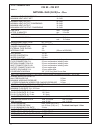

Summary of CSI 85

Page 3

3 condensing system innovation automatic modulating boiler for central heating and domestic hot water this new super high efficient turbo-modulating boiler is designed to meet domestic hot water and central heating requirements at super high efficiency, unheard of only a few years ago. Position the ap...

Page 4

Table of contents sections 1 2 3 4 5 6 7 8 9 10 11 introduction design principles and operating sequence tecnical data general requirements installation commissioning servicing instructions faul finding electrical system diagram exploded parts diagram list of spare parts page 6 6 8-9 6 15 26 30 39 4...

Page 5

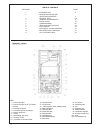

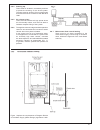

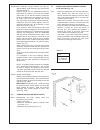

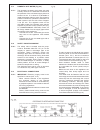

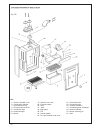

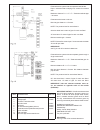

Key 1 - heat exchanger 2 - heat exchanger for d.H.W water 3 - burner 4 - sensing electrode 5 - flue restriction ring 6 - condensing heat exchanger 8 - condensing trap 9 - ignition electrode 10 - condensate sensor 12 - modulating gas valve 15 - heating control potentiometer 16 - hot water control pot...

Page 6

Section 1 introduction 1.1 the ravenheat boiler is for the use of central and domestic hot water combined in one unit. It is fitted with an automatic domestic hot water priority valve. A am / (winter/summer)selector switch is fitted to the left hand side of control panel.With the only (summer) positio...

Page 7

7 2.4 domestic hot water mode 2.4.1 the heat exchanger in the d.H.W. Circuit is built into the main heat exchanger, and domestic water is heated by converting the water in the central heating circuit the transference of heat is very high because the two fluids move in a counter direction flow to each ...

Page 8

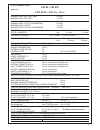

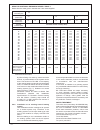

8 nominal heat input net qms 22.6 kw minimum heat input net 11.6 kw nominal heat output 22.3 kw nominal heat output condensing 23.9 kw minimum heat output 11.4 kw minumum heat output condensing 12.3 kw gas rate max 2.3 m3/h after 10 minutes min 1.2 m3/h inlet pressure 20 mbar burner pressure c.H. Ma...

Page 9

9 nominal heat input net qms 22.6 kw minimum heat input net 11.6 kw nominal heat output 22.3 kw nominal heat output condensing 23.9 kw minimum heat output 11.4 kw minumum heat output condensing 12.3 kw gas rate max g31 0.9 m 3 /h g30 0.7 m 3 /h after 10 minutes min 0.4 m 3 /h 0.3 m 3 /h internal pre...

Page 10

10 the manufacturer’s notes must not be taken, in any way, as overriding statutory obligations. Important: these appliances are ce certificated for safety and performance. It is, therefore, important that no external control devices e.G. Flue dampers, economisers etc., are directly connected to this...

Page 11

11 4.4 important notice 4.4.1 if the combination boiler is to be fitted in a timber framed building it should be fitted in accordance with the british gas publication guide for gas installations in timber frame housing reference dm2 if in doubt advice must be sought from the local gas supplier the c...

Page 12

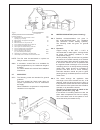

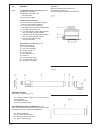

12 terminal position for fan assisted boiler (minimum distance) mm a - directly below an open window or other 300 opening (e.G. Air brick) b - below gutters, soil pipes or drain pipes 25 c - below eaves 25 d - below balconies or car port roof 25 e - from vertical drain pipes and soil pipes 25 f - fr...

Page 13

13 4.8.4 draining tap these must be located in accessible positions to permit the draining of the whole system. The taps must be at least 15 mm nominal size and manufactured in accordance with bs 2870 1980. 4.8.5 air release points these must be fitted at all high points where air will naturally col...

Page 14

14 b) where fitting of a make up vessel would be difficult, re pressurisation of the system can be done. See section on filling. If the capacity of the central heating system should exceed 85 litres, an additional vessel should be installed on the return to the combination boiler from the heating sy...

Page 15

15 salamander currosion guard salamander (eng) ltd tel: (0121) 3780952 /4508 4.8.10 hard water areas if the area of installation is recognized as hard water, it is recommended that a suitable water treatment device is installed in the mains. The water hardness can be determined by using the standard...

Page 16

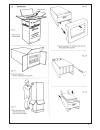

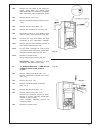

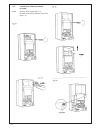

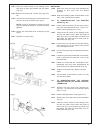

16 5.2 delivery 5.2.1 the appliance carton containing (fig 10) a) boiler fully assembled b) installation instructions and user instructions c) white paper template polythene bag containing a) 2-22 mm flanged copper tails complete with 3/4” brass nuts and washers b) 1-15 mm compression ball valve (wit...

Page 17

17.

Page 18

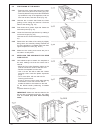

18 5.4 positioning of the boiler 5.4.1 - remove the 2 screws that secure the upper part of the front panel of the casing (fig 19). - carefully slide the front panel a few millimetres up towards the top of the appliance until it is free from its slot, and then lift off (fig. 20). 5.4.2 unscrew the 2 ...

Page 19

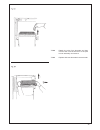

19 5.5.2 locate the rubber Ø 60 into the flue elbow header (fig 30). 5.5.3 if the standard duct furnished with the boiler is too long (the wall to go through is less than 680 mm thick) it can be shortened as follows: - remove the centering spring 65, the flue terminal to disengage inner flue duct - ...

Page 20

20 5.5.4 insert the flue assembly into the wall, being careful to make sure that the outer air duct comes flush to the inner surface of the wall 5.5.5 lift the boiler on to the wall (fig 34), locating onto the top coach bolts fit the two lower coach bolts and tighten all four securing bolts. 5.5.6 w...

Page 21

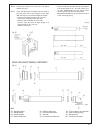

21 5.5.10 each extension length extends the pipe by approximately 1000 mm long up to a maximum of two extensions pipeline length can be established using the instructions in section 5.5 for rear flue outlets and section 5.7 for side flue outlets. Extensions must be installed with the widened end of ...

Page 22

22 5.7.2 positioning the elbow towards the required direction (fig. 30). 5.7.3 locate the Ø 60 into the elbow (fig. 30). 5.7.5 - if the standard duct furnished with the boiler is too long (position of the boiler from the wall to go through as illustrated in the drawing and wall thicknesses less than...

Page 23

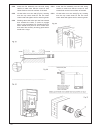

23 5.7.12 vertical flue instruction only inline flue bend - 1680 mm must be deducted from overall length for each 90° bend obtuse flue bend - 1680 mm must be deducted from overall length for each 135° bend the vertical flue kit is intended for use where a horizontal flue outlet is not possible or de...

Page 24

24 cut a 105 mm diameter hole through the ceiling and/or roof, at the point previously marked. Fit a roof flashing sleeve (7 fig. 43) to the roof, available from ravenheat manufacturing. Insert the vertical flue terminal assembly through the flashing plate from the outside fix the appliance to the w...

Page 25

25 5.11 domestic hot water (fig. 46) 5.11.1 the domestic hot water circuit does not need a safety valve but it is essential to ensure that the pressure of the cold water supply does not exceed 10 bar. If in doubt it is advisable to install a pressure reducing valve the minimum pressure needed to ope...

Page 26

5.14 programmable timeclock instructions for use consult user’s guide. Section 6 commissioning 6.1 each boiler has been through a rigorous operational procedure at our factory and should not require any further adjustment if in the unlikely event of the appliance not operating correctly, please turn...

Page 27

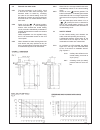

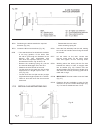

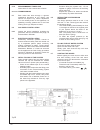

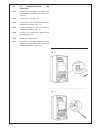

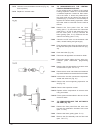

27 key 77 - upstream pressure inlet 81 - downstream pressure outlet 104 - gas valve modulator 110 - max. Regulator nut 111 - min. Regulator nut 114 - electrical connections modulator 115 - electrical connections.

Page 28

- turn control thermostat 4 up to its maximum setting - now the main burner should turn on with leak detection fluid test for gas soundness of all gas components and joints. - see paragraph 6.14 for regulating the heating circuit thermostat. Check gas mains pressure (fig. 52). Fit a gas pressure gau...

Page 29

6.13 checking the flue system 6.13.1 the flue system should be visually checked for soundness check all connections and fixings are secure and tight 6.14 checking the heating thermostat 6.14.1 allow the system to warm up and then turn the c.H thermostat to ensure the main burner modulates from “high...

Page 30

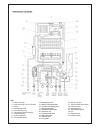

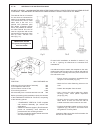

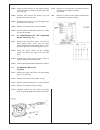

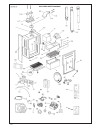

30 key 2 - plenum chamber cover 6 - combustion chamber 7 - flue restriction ring 8 - flue gas exhaust hood 15 - connection pipe 18 - heat exchanger 24 - burner 27 - auto air vent valve 28 - pressure switch 29 - seal 31 - seal 42- sight glass 44 - fan 46 - header gasket 50 - flue gas exhaust hood cov...

Page 31

31 6.16 handing over to the user 6.16.1 after completion of installation and commissioning of the system, the installer should hand over to the householder by taking the following actions: - hand the “user’s instructions” to the householder and explain his/her responsibilities under the “gas safety ...

Page 32

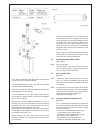

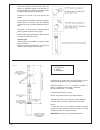

7.2.6 inspect the secondary condensate heat exchanger. Deposits can be cleared by removing and flushing out the exchanger inspect the siphonic condensate trap for a blockage any deposits should be flushed out (fig. 90) 7.2.6.1 to remove condensate trap (sect. 5.4). Pull forward the trap (fig. 90) un...

Page 33

33 7.8.2 remove the two sides of the casing by slightly lifting them and sliding them towards the top of the appliance, to release them from their upper suspension hooks 7.8.4 remove the fan (sect. 7.6). 7.8.5 remove condensing heat exchanger (sect. 7.6.5). 7.8.6 remove the flue hood (sect. 7.7). 7....

Page 34

34 7.10 to replace the electrode (fig.52b) 7.10.1 remove front casing (sect 7.3) remove combustion chamber from cover (sect 7.4).

Page 35

35 7.10.2 detach the wire from electrode and then unscrew the nut that secures it to the pilot burner assembly and remove 7.10.3 replace with new electrode in reverse order..

Page 36

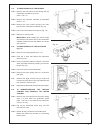

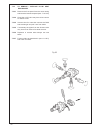

36 7.14 to remove/replace the injectors 7.14.1 remove the front panel of the casing and the combustion chamber front cover (sect. 7.3 & 4). 7.14.2 unscrew the union (fig. 70). 7.14.3 unscrew the 4 screw securing the injector manifold to the burner (fig. 71). 7.14.4 pull the manifold up and out from ...

Page 37

37 7.15 to remove/replace the burner 7.15.1 remove the front panel of the casing and the combustion chamber front cover (sect 7.3 & 7.4). 7.15.4 remove the injectors manifold as described insect. 7.14. 7.15.5 remove the two screws securing the main burner to the combustion chamber (fig 74). 7.15.6 p...

Page 38

38 7.19.6 replace in reverse order. 7.20 to remove/replace the main switch (fig. 82). 7.20 remove the front panel from the outer casing (sect. 7.3) and lower the instrument panel (sect. 7.16.2 & 3), and remove the control box cover (7.31.2/3). 7.20.2 pull off the switch knob. Remove the switch out f...

Page 39

39 7.25.3 close the on/off valves on the heating circuit and drain at drain point water from the boiler (fig. 93). 7.25.4 remove the wires that connect the pump (fig. 93). 7.25.5 unscrew the two hexagonal nuts that fasten the pump to its pipes and remove the pump. Note: it may be necessary to loosen...

Page 40

40 7.27.5 undo the nut and withdraw the sensor (fig. 81) from is pocket.) 7.27.6 replace in reverse order. 7.28 to remove/replace the central heating expansion vessel in the unlikely event of failure of the central heating expansion vessel it is recommended a suitable expansion vessel be fitted exte...

Page 41

41 7.29.4 close the on/off valves for the central heating circuit and drain the water from the boiler drain point (fig 93). 7.29.5 unscerw and remove the plastic cap that protects the valve vent hole 7.29.6 disconnect the unions 1 (fig 92) slightly turn and remove auto air vent 7.29.7 replace in rev...

Page 42

42 7.33 to remove / replace d.H.W. Heat exchanger 7.33.1 remove the front panel from the outer casing and lower the instrument panel (sect. 7.16.2 & 3) 7.33.2 close the on/off valve may have to be remove for easier acces. 7.33.4 unscrew the four nuts that connect the dhw heat exchanger and pull it o...

Page 43

43.

Page 44

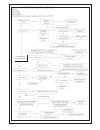

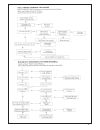

44 is fan running at maximum speed.

Page 45

45.

Page 46

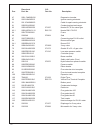

46 e tolleranze generali di lavorazione: uni iso 2768mk d denominazione collegament o elettrico circuit o technosystem per caldaia csi85 modulante 0012imp06006/0 c b a codice imp06006 tavola gerber rv data modifica firma disegnat o targa controllato durante pagina materiale scala note 0012imp06006/0...

Page 47

47 installation instruction for twin flue pipe (eccentric flue duct system) important these instructions must be read in conjunction with the main installation and servicing instructions as with all flues the kits must be installed taking due account of the current issue of bs 5440 parts 1 & 2 and ti...

Page 48

48 locate the sealing washer fixing the twin flue header as illustrated making sure that the ou- tlet spigot make sure that the screws are satis- factorily located through the gasket seal. Locate the 2 x 80 mm ‘o’ rings in the twin flue header. Figures show the versatility of this flueing system. Meas...

Page 49

49 exhaust/suction system with two separate rated 80 dia. Pipes - exhaust on flat or sloping roof, suction from vertical wall maximum distance d = i + e + t = total exhaust/inlet pipe = 20 metre exhaust terminal must not be cut. Min inlet pipe distance = 0.5 metre. Note: the pressure loss for each el...

Page 50

50 15.

Page 51

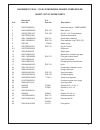

51 ravenheat csi 85 - csi 85 condensing fanned combi boiler short list of spare parts ravenheat g.C. Pos. Part. No. Part. No. Description 1 0014fr006005/2 instrument panel - timer model 2 0012com06005/0 e23-712 main switch 4 0012pot05010/0 e23-729 d.H.W. / c.H. Potentiometer 5 0007ter08010/0 overhea...

Page 52

52 ravenheat g.C. Pos. Part. No. Part. No. Description 47 0001 cam06010/0 depression chamber 50 0012can09005/2 ignition-sensing electrode 51 001 2cav08020/0 cable for spark-sensing electrode 61 0002sca06006/0 condensing heat exchanger 62 0003uge03005/0 371297 nozzle Ø 1,25 for natural gas 62.1 0003u...

Page 53

The code of practice for the installation, commissioning & servicing of gas central heating installation, commissioning and service record log book name adress tel no. Customer details important company name installer date adress tel no. Installer’s name corgi registration details reg no. Corgi id s...

Page 54

Gblb second edition 01.03.02 for the central hot water, measure and record: heat input kw maximum burner operating pressure mbar maximum operating water pressure bar cold water inlet temperature °c hot water outlet temperature °c water flow rate at maximum setting its/min for condensing boilers only...

Page 56

Cod 0017lib06006/0 - 06/2005.