- DL manuals

- Ravenheat

- Boiler

- Flue Boiler

- Installation And Servicing Instructions

Ravenheat Flue Boiler Installation And Servicing Instructions

Supplied By www.heating spares.co Tel. 0161 620 6677

CONDENSING FANNED FLUE BOILER

CSI SYSTEM

WITHOUT TIMER

NATURAL GAS (G20) (I

2H

) G.C.N

o

47 581 01 - CSI

LPG (G30-G31) (I

3+

) G.C.N

o

47 581 03 - CSI

Tested, certified and

service listed

Listed by The United Kingdom Water

Fitting Byelaws Scheme

WITH TIMER

NATURAL GAS (G 20) (I

2H

) G.C. N

O

47 581 02 - CSI

LPG (G 30 - G 31) (I

3+

) G.C.N

O

47 581 04 - CSI

INSTALLATION AND SERVICING INSTRUCTIONS

TO BE LEFT WITH USER

Technical and illustrative data are not binding and can be modified without prior notice.

The descriptions and illustrations in the present booklet are for guideline purposes only.

RAVENHEAT MANUFACTURING LTD., CHARTISTS WAY, MORLEY, LEEDS, LS27 9ET. -TELEPHONE (0113) 252 7007

Summary of Flue Boiler

Page 1

Supplied by www.Heating spares.Co tel. 0161 620 6677 condensing fanned flue boiler csi system without timer natural gas (g20) (i 2h ) g.C.N o 47 581 01 - csi lpg (g30-g31) (i 3+ ) g.C.N o 47 581 03 - csi tested, certified and service listed listed by the united kingdom water fitting byelaws scheme w...

Page 2

Supplied by www.Heating spares.Co tel. 0161 620 6677 condensing system innovation automatic modulating central heating boiler this new super high efficient turbo-modulating boiler is designed to meet heating requirements at super high efficiency, unheard of only a few years ago. Position the applian...

Page 3

Supplied by www.Heating spares.Co tel. 0161 620 6677 sections: 1 2 3 4 5 6 7 8 9 10 11 table of contents introduction design principles and operating sequence technical data general requirements installation commissioning servicing instructions fault finding electrical system diagram exploded parts ...

Page 4

Supplied by www.Heating spares.Co tel. 0161 620 6677 operating scheme fig. 2 key 1 - heat exchanger 10 - condensate sensor 3 - burner 12 - modulating gas valve 4 - ignition pilot burner 15 - heating control potentiometer 5 - flue restriction ring 16 - hot water control potentiometer 6 - condensing h...

Page 5

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 1 introduction 2.2.3 1.1 the ravenheat csi system boiler is a cen- tral heating system boiler which incorpora- tes a circulating pump, expansion vessel, safety valve, pressure gauge and electronic ignition. The boiler is equipped with a fr...

Page 6

Supplied by www.Heating spares.Co tel. 0161 620 6677 2.3.4 the boiler water temperature is automati- cally controlled by a built in thermostat. 2.3.5 interior space temperature is set by the room thermostat to be installed in the heat- ing system. The boiler already carries con- nection terminals fo...

Page 7: Natural Gas (G 20) I

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 3 technical data table 1 natural gas (g 20) i 2h nominal heat input net 24.8 kw minimum heat input net 13.0 kw nominal heat output 23.8 kw nominal heat output condensing 25.6 kw minimum heat output 11.7 kw minimum heat output condensing 13...

Page 8: Lpg (G 30 - G 31) I

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 3 technical data table 1/a lpg (g 30 - g 31) i 3+ nominal heat input net 24.8 kw minimum heat input net 13.0 kw (84,500 btu/h) (44.500 btu/h) nominal heat output nominal heat output condensing minimum heat output minimum heat output conden...

Page 9

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 4 general requirements 4.0 safety gas safety (installation and use) regulations, 1994, and amendments 1996. It is law that all gas appliances are installed and serviced by a corgi registered installer (identified by in accordance with the ...

Page 10

Supplied by www.Heating spares.Co tel. 0161 620 6677 4.4 important notice 4.4.1 if the combination boiler is to be fitted in a timber framed building it should be fitted in accordance with the british gas publication guide for gas installations in timber frame housing reference dm2. If in doubt advi...

Page 11

Supplied by www.Heating spares.Co tel. 0161 620 6677 note: 4.6.2 4.7 4.7.1 fig. 6a the flue must be terminated in a place not likely to cause a nuisance. A concentric vertical flue kit is available, for flueing applications up to a maximun height of 4.0 metres. For further details see vertical flue ...

Page 12

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 6c schematic ‘s’ plan 4.8.3 the water through the appliance heat exchanger circuit must exceed the min. 1.84 gals/min. (503 it/h) when the burner is firing. It is important to ensure that this rate is achieved when sections of the system are ...

Page 13

Supplied by www.Heating spares.Co tel. 0161 620 6677 sizing of additional expansion vessels: table 3 deduct from the value given in the table the 7 litre vessel supplied. Safety valve setting (bar) vessel charge pressure (bar) 3.0 0.5 1.0 1.5 initial system (bar) pressure total water content 01 syst...

Page 14

Supplied by www.Heating spares.Co tel. 0161 620 6677 reference should be made to british gas publications specifications for domestic central heating and hot water >> draining taps should be at least 1/2" in bsp nominal size and be in accordance with bs 2879. 4.8.9 installation to an existing centra...

Page 15

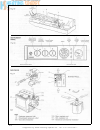

Supplied by www.Heating spares.Co tel. 0161 620 6677 5.2 delivery warning: 5.2.1 the appliance will arrive on site in two cartons maximum allowable flue length 2.5 m. Maximum no. 2x1000 mm. Flue duct extension used with standard flue box 1 of 2 containing (fig. 10 - 11): a) boiler fully assembled b)...

Page 16

Supplied by www.Heating spares.Co tel. 0161 620 6677.

Page 17

Supplied by www.Heating spares.Co tel. 0161 620 6677 5.4 54.1 5.4.2 5.4.3 5.4.4 5.4.5 5.4.6 5.5 5.5.1 positioning of the boiler - remove the 2 screws that secure the upper part of the front panel of the casing (fig. 19). - carefully slide the front panel a few milli- metres up towards the top of the...

Page 18

Supplied by www.Heating spares.Co tel. 0161 620 6677 5.5.2 locate the rubber 0 60 into the flue elbow header (fig. 30). 5.5.3 if the standard duct furnished with the boil- er is too long (the wall to go through is less than 680 mm. Thick) it can be shortened as follows: - remove the centering spring...

Page 19

Supplied by www.Heating spares.Co tel. 0161 620 6677 5.5.4 insert the flue assembly into the wall, being careful to make sure that the outer air duct comes flush to the inner surface of the wall. 5.5.5 lift the boiler on to the wall (fig. 34), locat- ing onto the top coach bolts. Fit the two lower c...

Page 20

Supplied by www.Heating spares.Co tel. 0161 620 6677 5.5.10 each extension length extends the pipe by approximately 1000 mm long up to a maximum of two extensions. Pipeline length can be established using the instructions in section 5.5 for rear flue outlets and section 5.7 for side flue outlets. Ex...

Page 21

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 39b key 63 - air intake duct extension 56 - sample point 64 - flue exhaust duct extension 57 - elbow header 65 - pipe centering spring 59 rubber seal 0 60 128 in line bend 5.7.2 positioning the elbow towards the required - reassemble the two ...

Page 22

Supplied by www.Heating spares.Co tel. 0161 620 6677 5.7.12 vertical flue instruction only inline flue bend - 1680 mm must be deducted from overall length for each 90” bend obtuse flue bend - 16130 mm must be deducted from overall length for each 135” bend the vertical flue kit is intended for use w...

Page 23

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 44 fig. 43 cut a 105 mm diameter hole through the ceiling and/or roof, at the point previously marked. Fit a roof flashing sleeve (7 fig. 43) to the roof, available from ravenheat manufacturing. Insert the vertical flue terminal assembly thro...

Page 24

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 48a fig. 48b schematic ‘y’ plan schematic ‘s’ plan fig. 49a posltlonlng of water and gas connections 24.

Page 25

Supplied by www.Heating spares.Co tel. 0161 620 6677 5.132 there are 2 electrical boxes, to gain access remove the front panel of the case as described in clauses (sect. 5.4.1) and the instrument panel as described in clauses (sect. 5.4.3). The terminals are easily visible on the front of the electr...

Page 26

Supplied by www.Heating spares.Co tel. 0161 620 6677 2 6.

Page 27

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 6 commissioning 6.1 6.2 6.2.1 6.3 6.4 6.5 6.7 each boiler has been through a rigorous operational procedure at our factory and should not require any further adjustment. If in the unlikely event of the appliance not operating correctly, pl...

Page 28

Supplied by www.Heating spares.Co tel. 0161 620 6677 6.11 - with the boiler operating use a screw driver (honeywell 9 mm spanner) to turn the nut 111 clockwise to increase pressure and anti-clockwise to decrease pressure. Note: lpg only the minimum pressure is factory set and sealed, and cannot be a...

Page 29

Supplied by www.Heating spares.Co tel. 0161 620 6677 exploded diagram of boiler body key 1 -window 2 plenum chamber cover 6 combustion chamber 7 - flue restriction ring 8 - flue gas exhaust hood 15 - connection pipe 18 - heat exchanger 24 - main burner 25 pilot burner 27 - auto air vent valve 28 - p...

Page 30

Supplied by www.Heating spares.Co tel. 0161 620 6677 6.16 handing over to the user 6.16.1 after completion of installation and commis- sioning of the system, the installer should hand over to the householder by taking the following actions: - hand the “user’s instructions” to the h o u s e h o l d e...

Page 31

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.2.6.1 7.2.7 7.2.8 7.2.9 7.3 7.3.1 7.4 7.4.1 7.4.2 7.4.3 7.4.4 7.6 7.6.1 7.6.2 7.6.4 removing and flushing out the exchanger. Inspect the siphonic condensate trap for a blockage. Any deposits should be flushed out (fig. 90). 7.6.5 7.6.5.1, to rem...

Page 32

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.8.4 7.8.5 remove the fan (sect. 7.6). Fig. 54 remove condensing heat exchanger (sect. 7.6.5). 7.8.6 7.8.8 7.8.9 remove the flue hood (sect. 7.7). Remove the automatic air vent (fig. 92). Disconnect unions for two heating (right side of boiler) w...

Page 33

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.10 to replace the electrode (fig. 66) 7.10.1 remove front casing (sect. 7.3). Remove combustion chamber front cover (sect. 7.4). Fig. 56 fig. 60 fig. 62.

Page 34

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 63 fig. 66 fig. 64 7.10.2 7.10.3 7.12 7.12.1 7.12.2 7.12.3 7.12.4 7.12.5 7.12.6 7.13 7.13.1 7.13.2 7.13.4 7.13.5 detach the wire from electrode and then unscrew the nut that secures it to the pilot burner assembly and remove. Replace with new...

Page 35

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.14 7.14.1 7.14.2 7.14.3 7.14.4 7.14.5 7.14.6 7.14.7 fig. 68 to remove/replace the main injec- fig. 69 tors remove the front panel of the casing and the combustion chamber front cover (sect. 7.3 & 4). Remove the pilot burner assembly as described...

Page 36

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.15 7.15.1 7.15.2 7.15.4 7.15.5 7.15.6 7.15.7 7.16 7.16.1 7.16.2 7.16.3 7.16.4 7.16.5 7.16.6 7.16.7 7.16.6 7.19 7.19.1 7.19.2 7.19.3 to remove/replace the main burner remove the front panel of the casing and the combustion chamber front cover (se...

Page 37

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.19.6 7.20 replace in reverse order. To remove/replace the main switch (fig. 82). 7.23 7.23.1 7.20.1 remove the front panel from the outer cas- ing (sect. 7.3) and lower the instrument panel (sect. 7.16.2 & 3), and remove the control box coyer (7...

Page 38

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.25.4 remove the terminal covers and detach the supply wires (fig. 88). 7.25.5 unscrew the two hexagonal nuts that fasten the pump to its pipes and remove the pump. Note: it may be necessary to loosen the flow pipe at the heat exchanger to replac...

Page 39

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 83 7.28 7.28.1 7.28.2 7.28.3 7.28.4 7.28.5 to remove/replace the central heating expansion vessel in the unlikely event of failure of the central heating expansion vessel it is recommend- ed a suitable expansion vessel be fitted external to t...

Page 40

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.30.3 unscrew the screw from its body, clean or replace. Replace in reverse order. 7.30.4 f i l l t h e s y s t e m a s d e s c r i b e d i n t h e (sect. 6.4 & 6.5) and check for leaks. 7.31 to remove/replace time clock ( f i g . 8 8 / a ) 7.31....

Page 41

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 90 fig. 91 fig. 93 41.

Page 42

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 8 fault finding central heating switch on stat to maximum ensure external controls calling for heat (room stat/time clock/trv) dhw stat 42.

Page 43

Supplied by www.Heating spares.Co tel. 0161 620 6677 boiler not operational on timer (integral) switch on/select “winter”/central heating stat to maximum/ensure external control calling for heat (room stat/trv) 43.

Page 44

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 9 electrical system diagram fig. 94 44.

Page 45

Supplied by www.Heating spares.Co tel. 0161 620 6677.

Page 46

Supplied by www.Heating spares.Co tel. 0161 620 6677 8.0 installation instructions for twin flue pipe (eccentric flue duct system) fig. 1.8 important these instructions must be read in conjunc- tion with the main installation and servicing instructions. As with all flues the kits must be installed t...

Page 47

Supplied by www.Heating spares.Co tel. 0161 620 6677 flue header as illustrated making sure that the inner aluminium exhaust locates firmly in the outlet spigot. Make sure that the screws are satisfactorily located through the gasket seal. Locate the 2 x 80 mm ‘0’ rings in the twin flue header.. Fig...

Page 48

Supplied by www.Heating spares.Co tel. 0161 620 6677 exhaust/suction system with two separate rated 80 dia. Pipes - exhaust on flat or sloping roof, suction from vertical wall. Maximum distance d = i + e + t = total exhaust/inlet pipe = 20 metre. Exhaust terminal must not be cut. Min inlet pipe dist...

Page 49

Supplied by www.Heating spares.Co tel. 0161 620 6677.

Page 50

Supplied by www.Heating spares.Co tel. 0161 620 6677 ravenheat csi system condensing fanned flue boiler short list of spare parts pos. 1 0014fro06005/0 2 0012com06005/0 4 0012pot05010/0 5 0007ter03010/0 6 0001 cam06005/0 7 0001 dia06005/0 8 5027055 9 0007ter05005/0 10 0014vet01005/0 11 0010tub05040/...

Page 51

Supplied by www.Heating spares.Co tel. 0161 620 6677 ravenheat g.C. Pos. Part. No. Part. No. Description 48 5012096 372856 nozzle 0,27 for natural gas 48.1 0003uge01005/0 e02-129 nozzle dm 0.22 x 1 lpg 50 5 0 2 1 0 5 0 372892 ignition electrode 51 0012cav06005/0 e23-739 cable for electrode 61 0002sc...

Page 52: Telephone: (0113) 252 7007

Supplied by www.Heating spares.Co tel. 0161 620 6677 chartists way, morley, leeds, ls27 9et. Telephone: (0113) 252 7007 tfax: (0113) 238 0229.