- DL manuals

- Ravenheat

- Boiler

- HE 120N

- Instructions For Use Installation And Servicingtion And Servicing

Ravenheat HE 120N Instructions For Use Installation And Servicingtion And Servicing

Supplied By www.heating spares.co Tel. 0161 620 6677

Technical and illustative data are not binding and can be modifi ed without prior notice.

The descriptions and illustrations in the present booklet are for guideline purposes only.

RAVENHEAT MANUFACTURING LTD, CHARTISTS WAY, MORLEY, LEEDS, LS27 9ET

TEL. 0044( 0)113 252 7007 - FAX: 0044 (0)113 238 0229

Website : www.ravenheat.co.uk - E-mail : sales@ravenheat.co.uk

Instructions for Use

Installation and Servicing

To be left with the user

HIGH EFFINCENCY - LOW NOX

CONDENSING

COMBINATION BOILER

HE 120N(T)

HE 120N(T)

Low Nox

Low Nox

HE 150N(T)

HE 150N(T)

Low Nox

Low Nox

Natural Gas (G20) I

2H

- II

2H3+

LPG (G30-G31) I

3+

- II

2H3+

G.C. No. XX-XXX-XX

Summary of HE 120N

Page 1

Supplied by www.Heating spares.Co tel. 0161 620 6677 technical and illustative data are not binding and can be modifi ed without prior notice. The descriptions and illustrations in the present booklet are for guideline purposes only. Ravenheat manufacturing ltd, chartists way, morley, leeds, ls27 9e...

Page 2

Supplied by www.Heating spares.Co tel. 0161 620 6677.

Page 3

Supplied by www.Heating spares.Co tel. 0161 620 6677 3 high efficency condensing system innovation automatic modulating boiler for central heating and domestic hot water this new super high effi cient turbo-modulating boiler is designed to meet domestic hot water and central heating requirements at ...

Page 4

Supplied by www.Heating spares.Co tel. 0161 620 6677 sections 1 2 3 4 5 6 7 8 9 10 11 12 introduction design and operating sequence technical data general requirements installation commissioning servicing instructions replacement of parts fault finding electrical system diagram alternative flue syst...

Page 5

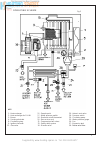

Supplied by www.Heating spares.Co tel. 0161 620 6677 5 key 1 - heat exchanger 2 - heat exchanger for d.H.W. 3 - burner 4 - sensing electrode 8 - condensing trap 9 - ignition electrode 12 - gas valve 15 - sample point 17 - water pressure switch 18 - overheat cut-off thermostat 20 - gas service cock 2...

Page 6

Supplied by www.Heating spares.Co tel. 0161 620 6677 6 etc ,with heating circuit fully charged so as to operate the low water sensor device the boiler will start in the same way as domestic hot water mode . As the heating sensor reaches temperature the fan speed modulates down. When starting, the fa...

Page 7

Supplied by www.Heating spares.Co tel. 0161 620 6677 7 2.4 domestic hot water mode 2.4.1 the heat exchanger in the d.H.W. Circuit is a stainless steel plate heat exchanger water to water, and domestic water is heated by converting the water in the central heating circuit. The transference of heat is...

Page 8: He 120N (T) Low Nox

Supplied by www.Heating spares.Co tel. 0161 620 6677 nominal heat input net qms 26.0 kw minimum heat input net 5.78 kw nominal heat output 25.7 kw nominal heat output condensing 28.8 kw minimum heat output 5.72 kw minimum heat output condensing 6.41 kw gas rate max 2.7 m 3 /h after 10 minutes min 0....

Page 9: He 120N (T) Low Nox

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 3 technical data he 120n (t) low nox table 1/a lpg (g 30 - g 31) І 3+ - П 2h3+ 9 nominal heat input net qms 26.0 kw minimum heat input net 5.78 kw nominal heat output 25.7 kw nominal heat output condensing 28.8 kw minimum heat output 5.72 ...

Page 10: He 150N(T) Low Nox

Supplied by www.Heating spares.Co tel. 0161 620 6677 10 nominal heat input net qms 32.0 kw minimum heat input net 8.0 kw nominal heat output 31.7 kw nominal heat output condensing 34.9 kw minimum heat output 7.93 kw minimum heat output condensing 8.73 kw gas rate max 3.4 m 3 /h after 10 minutes min ...

Page 11: He 150N (T) Low Nox

Supplied by www.Heating spares.Co tel. 0161 620 6677 11 nominal heat input net qms 32.0 kw minimum heat input net 8.0 kw nominal heat output 31.7 kw nominal heat output condensing 34.9 kw minimum heat output 7.93 kw minimum heat output condensing 9.06 kw gas rate max g31 1.3 m 3 /h g30 0.99 m 3 /h a...

Page 12

Supplied by www.Heating spares.Co tel. 0161 620 6677 12 the manufacturer’s notes must not be taken, in any way, as overriding statutory obligations. Important: these appliances are ce certificated for safety and performance. It is, therefore, important that no external control devices e.G. Flue damp...

Page 13

Supplied by www.Heating spares.Co tel. 0161 620 6677 13 4.6 flue system 4.6.1 the terminal should be located where dispersal of combustion products is not impeded and with due regard for the damage or discolouration that might occur to building products in the vicinity (see fig. 6). The terminal mus...

Page 14

Supplied by www.Heating spares.Co tel. 0161 620 6677 14 terminal position for fan assisted boiler (minimum distance) mm a - directly below an open window or other 300 opening (e.G. Air brick) b - below gutters, soil pipes or drain pipes 75 c - below eaves 150 d - below balconies or car port roof 200...

Page 15

Supplied by www.Heating spares.Co tel. 0161 620 6677 15 4.8.4 draining tap these must be located in accessible positions to permit the draining of the whole system. The taps must be at least 15 mm nominal size and manufactured in accordance with bs 2870 1980. 4.8.5 air release points these must be f...

Page 16

Supplied by www.Heating spares.Co tel. 0161 620 6677 16 b) where fitting of a make up vessel would be difficult, re pressurisation of the system can be done. See section on filling. If the capacity of the central heating system should exceed 110 litres, an additional vessel should be installed on th...

Page 17

Supplied by www.Heating spares.Co tel. 0161 620 6677 17 salamander corrosion guard salamander (eng) ltd tel: (0121) 3780952 /4508 4.8.10 hard water areas if the area of installation is recognized as hard water, it is recommended that a suitable water treatment device is installed in the mains. The w...

Page 18

Supplied by www.Heating spares.Co tel. 0161 620 6677 important :please, lubricate the internal part of the seals before being fitted. 18 type of flue system (all models) table 6 flue type c 13 c 33 c 53 1 flue diameter 60/100 80/125 60/100 80/125 80mm (concentric) (concentric) (concentric) (concentr...

Page 19

Supplied by www.Heating spares.Co tel. 0161 620 6677 plume management kit maximum length (mm) 6000 minimum length (mm) 500 equivalent length of 45° bend (mm) 500 equivalent length of 90° bend (mm) 1000 important : max fl ue length must not exceed 6 m with a horizontal concentric 60/100 fl ue of 3m (...

Page 20

Supplied by www.Heating spares.Co tel. 0161 620 6677 19 5.5 installing the appliance for rear flue outlet (fig.28-30-31-32) 5.5.1 use adhesive tape to attach the template to the wall, making sure that the centre line is vertical. - mark the two holes for to fix the hanging bracket on the wall as wel...

Page 21

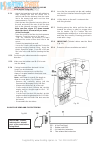

Supplied by www.Heating spares.Co tel. 0161 620 6677 intake and exhaust terminal components fig.31 20 important :please, lubricate the internal part of the seals before being fitted. Key 56 - flue adapter 58 - header gasket 59 - rubber seal Ø 60 61 - std fl ue exhaust duct 62 - terminal 63 - flue ex...

Page 22

Supplied by www.Heating spares.Co tel. 0161 620 6677 in line flue bend and flue extension fig.39b 128 - in line flue bend 59 - rubber seal Ø 60 63 - air intake duct extension 64 - flue exhaust duct extension important :please, lubricate the internal part of the seals before being fitted. 5.7 install...

Page 23

Supplied by www.Heating spares.Co tel. 0161 620 6677 l + l = 8m max fig. 41 straight flue straight flue offset flue offset flue l = 12.0 m max l = 12.0 m max l = 2.0 m max l = 2.0 m max plus terminal plus terminal (10 bend 90° max) (20 bend 45° max) plus terminal plus terminal fig. 42 5.7.10 vertica...

Page 24

Supplied by www.Heating spares.Co tel. 0161 620 6677 24 starting at the appliance end, assemble the extension duct sections, making each inner and outer (flue) joint by inserting the spigot end into the socket end of the next tube, making sure the seal rings are correctly located (fig. 44). Make sur...

Page 25

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig.46 25 5.9 gas connection (fig. 46) 5.9.1 a minimum working gas pressure of 20 mbar (8 in w.G.) must be available at the boiler inlet at full flow rate (37 mbar for propane, 29 mbar for butane). 5.9.2 fit gas service cock to the boiler via the ...

Page 26

Supplied by www.Heating spares.Co tel. 0161 620 6677 position of water and gas connections 26 fig. 49a 5.14 programmable timeclock instructions for use consult user’s guide. Instrument panel fig. 50 5.15 condensate drain connection 5.15.1 the condensate drain connection is between gas service cock a...

Page 27

Supplied by www.Heating spares.Co tel. 0161 620 6677 27 section 6 commissioning 6.1 each boiler has been through a rigorous operational procedure at our factory and should not require any further adjustment if in the unlikely event of the appliance not operating correctly, please turn to the fault f...

Page 28

Supplied by www.Heating spares.Co tel. 0161 620 6677 28 -turn control knob 4 (fig.50) down to its minimum setting. -push the power main switch to on (fig.50) -the digital display will show water set point temperature in central heating . -the fan start and after a few second the digital led display ...

Page 29

Supplied by www.Heating spares.Co tel. 0161 620 6677 29 6.10 checking the flue system 6.10.1 the flue system should be visually checked for soundness check all connections and fixings are secure and tight 6.11 checking the heating thermistor 6.11.1 allow the system to warm up and then turn the c.H t...

Page 30

Supplied by www.Heating spares.Co tel. 0161 620 6677 30 warning before the start of any servicing or replacement of components always isolate electricity supply to the appliance and always turn off the appliance gas supply at the gas service cock. Data badge position-lower left hand front panel. - t...

Page 31

Supplied by www.Heating spares.Co tel. 0161 620 6677 31 7.2.6 inspect the siphonic condensate trap for a blockage. Remove the cap at the base of the condensate trap. Remove any solid found. Remove the float to clean it. Any deposits should be flushed out. Reassemble and refit the condensing trap. Wh...

Page 32

Supplied by www.Heating spares.Co tel. 0161 620 6677 32 8.3 to remove/ replace the electrodes (fig.55) 8.3.1 remove the front casing panel (sect. 8.1.4). 8.3.2 remove the ignition and/or sensing lead plug . 8.3.3 unscrew the two securing screws and put them into a container so that they don’t get lo...

Page 33

Supplied by www.Heating spares.Co tel. 0161 620 6677 33 8.5 to remove/replace the burner (fig.57) 8.5.1 remove front casing (sect. 8.1.4). 8.5.2 unscrew and gently remove combustion chamber cover assembly with gas valve, fan ,burner and electrodes from combustion chamber.As in sect. 7.2.2 8.5.3 remo...

Page 34

Supplied by www.Heating spares.Co tel. 0161 620 6677 34 8.8.5 unscrew and gently remove combustion chamber cover assembly with gas valve, fan ,burner and electrodes from combustion chamber.As in sect. 7.2.2 8.8.6 remove the three screws, which fix the gas valve and venturi plate at the fan 8.8.7 rem...

Page 35

Supplied by www.Heating spares.Co tel. 0161 620 6677 8.13 to remove/replace plate to plate heat exchanger . 8.13.1 remove front casing (sect 8.1.4). 8.13.2 close off on/off valves for ch circuit and dhw circuit and drain the boiler and drain hot water from the lowest hot water tap . 8.13.3 unscrews ...

Page 36

Supplied by www.Heating spares.Co tel. 0161 620 6677 8.14 to remove/replace flue manifold . 8.14.1 remove front casing (sect 8.1). 8.14.2 unscrew and gently remove combustion chamber cover assembly with gas valve, fan ,burner and electrodes from combustion chamber.As in sect. 7.2.2 8.14.3 remove the...

Page 37

Supplied by www.Heating spares.Co tel. 0161 620 6677 8.19 to remove/replace overheat thermostat (fig.63). 8.19.1 remove front casing (sect 8.1.4) 8.19.2 remove the two wires that connect to the overheat thermostat. 8.19.3 remove the two screws securing the thermostat to the pipe and pull it out. 8.1...

Page 38

Supplied by www.Heating spares.Co tel. 0161 620 6677 38 8.23 to remove/replace timeclock 8.23.1 remove front casing (sect 8.1.4) and lower the instrument panel . 8.23.2 remove control board box cover. 8.23.3 pull the two securing clip that fasten the timeclock to the panel instrument, and pull it ou...

Page 39

Supplied by www.Heating spares.Co tel. 0161 620 6677 39 8.26 to remove/replace condensing trap (fig.66). 8.26.1 remove the casing (sect 8.1.4) and lower the instrument panel . 8.26.2 remove the securing clip and pull out the plastic pipe that connect the condensing trap at the heat exchanger. 8.26.3...

Page 40

Supplied by www.Heating spares.Co tel. 0161 620 6677 40 section 9 fault finding central heating before trying to operate the boiler make sure that: - all gas supply cocks are open and the gas supply has been purge of air. - the heating system pressure is at least 1 bar min to 1.5 bar max. - main swi...

Page 41

Supplied by www.Heating spares.Co tel. 0161 620 6677 41 fault finding domestic hot water before continuing it may be necessary to see central heating fault finding (sect.9) - all gas supply cocks are open and the gas supply has been purge of air. - the heating system pressure is at least 1 bar min t...

Page 42

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 10 electrical system diagram case off case off case off 42 fig. 94.

Page 43

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 95 important :please, lubricate the internal part of the seals before being fitted. 43 important these instructions must be read in conjunction with the main installation and servicing instructions as with all fl ues the kits must be installe...

Page 44

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 97 fig. 96 important :please, lubricate the internal part of the seals before being fitted. 44 exhaust/suction system with concentric pipes for fl at or sloping roofs. Extensions with two separate pipes ( fig.95 ). Maximum distance : t= l = 2...

Page 45

Supplied by www.Heating spares.Co tel. 0161 620 6677 important :please, lubricate the internal part of the seals before being fitted. 45 11.2 installation instructions for concentric 80/125 flue system l + l = 23.5m max straight flue straight flue 90° offset flue 135° offset flue l = 25 m max l = 25...

Page 46

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 12 spare parts 46 24 15 16 17 10 21 22 9 28 25 12 14 11 13 18 30 1 3 19 27 29 26 31 23 8 33 32 7 4 2 20 6 4 41 42 43 44.

Page 47

Supplied by www.Heating spares.Co tel. 0161 620 6677 47 ravenheat hei 120/150 (t) low nox hight effincency condensing combination boiler short list of spare parts ravenheat g.C. Pos. Part. No. Part. No. Description 1 0014pan11005/0 instrument panel 2 0012int09010/0 main - summer/winter switch 3 0012...

Page 48

Supplied by www.Heating spares.Co tel. 0161 620 6677 48 ravenheat g.C. Pos. Part. No. Part. No. Description 29 0002sca09030/0 heat exchanger for d.H.W. Csi120 29.1 0002sca09025/0 heat exchanger for d.H.W. Csi150 30 0012oro01010/0 digital timer 32 0012fus01010/0 internal fuse 315ma 33 0012fus01015/0 ...

Page 49

Supplied by www.Heating spares.Co tel. 0161 620 6677 cod 0017lib11011/0 - 10/2006 rev.1 chartists way, morley, leeds, ls27 9et telephone : 0044(0)113 252 7007 tfax : 0044(0)113 238 0229 website : www.Ravenheat.Co.Uk e-mail : sales@ravenheat.Co.Uk ravenheat reserves the right to make changes and impr...

Page 50

Supplied by www.Heating spares.Co tel. 0161 620 6677 the code of practice for the installation, commissioning & servicing of gas central heating installation, commissioning and service record log book name address tel no. Customer details important company name installation date address tel no. Inst...

Page 51

Supplied by www.Heating spares.Co tel. 0161 620 6677 gblb second edition 01.03.02 does the heating and hot water system comply with the appropriate building regulations? Yes has appliance and associated equipment been installed and commissioned in accordance with the manufacturer’s instructions? Yes...