- DL manuals

- Ravenheat

- Boiler

- HE Primary AAA

- Instructions For Use Installation And Servicing

Ravenheat HE Primary AAA Instructions For Use Installation And Servicing

Supplied By www.heating spares.co Tel. 0161 620 6677

Technical and illustative data are not binding and can be modifi ed without prior notice.

The descriptions and illustrations in the present booklet are for guideline purposes only.

RAVENHEAT MANUFACTURING LTD, CHARTISTS WAY, MORLEY, LEEDS, LS27 9ET

TEL. 0044( 0)113 252 7007 - FAX: 0044 (0)113 238 0229

Website : www.ravenheat.co.uk - E-mail : sales@ravenheat.co.uk

Instructions for Use

Installation and Servicing

To be left with the user

HIGH EFFINCENCY

CONDENSING

PRIMARY BOILER

HE Primary AAA

HE Primary AAA

Natural Gas (G20) I

2H

- II

2H3+

G.C. No. 47-581- 05

05

LPG (G30-G31) I

3+

- II

2H3+

G.C. No. 47-581- 06

06

Summary of HE Primary AAA

Page 1

Supplied by www.Heating spares.Co tel. 0161 620 6677 technical and illustative data are not binding and can be modifi ed without prior notice. The descriptions and illustrations in the present booklet are for guideline purposes only. Ravenheat manufacturing ltd, chartists way, morley, leeds, ls27 9e...

Page 2

Supplied by www.Heating spares.Co tel. 0161 620 6677 condensing system innovation central heating boiler this new super high effi cient boiler is designed to meet heating requirements at super high effi ciency, unheard of only a few years ago position the appliance is extremely versatile as it can b...

Page 3

Supplied by www.Heating spares.Co tel. 0161 620 6677 4 table of contents sections 1 2 3 4 5 6 7 8 9 10 11 introduction design principles and operating sequence tecnical data general requirements installation commissioning servicing instructions faul finding electrical system diagram exploded parts d...

Page 4

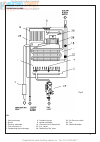

Supplied by www.Heating spares.Co tel. 0161 620 6677 5 operating scheme key 1 - heat exchanger 3 - burner 4 - sensing electrode 5 - flue restriction rin 6 - condensing heat exchanger 8 - condensing trap 9 - ignition electrode 18 - overheat cut-off thermostat 22- c.H. Sensor 26 - modulating gas valve...

Page 5

Supplied by www.Heating spares.Co tel. 0161 620 6677 6 section 1 introduction 1.1 the csi primary is a gas fi red room sealed fan assisted condensing heating boiler suit- able for fully pumped open vented or sealed system central heating and domestic hot water systems. 1.2 the provision of stored do...

Page 6

Supplied by www.Heating spares.Co tel. 0161 620 6677 7 bs 5440:2 ventilation (for gas appliances of rated input not exceeding 60 kw) dd 189:1990 discharge of condensate health & safety document no. 635 the electricity at work regulations1989 the manufacturer’s notes must not be taken, in any way, as...

Page 7: He Primary Aaa

Supplied by www.Heating spares.Co tel. 0161 620 6677 8 section 3 technical data he primary aaa table 1 natural gas (g 20) І 2h - П 2h3+ nominal heat input net qms 22.6 kw minimum heat input net 11.6 kw nominal heat output 22.3 kw minimun heat output condensing 23.9 kw nominal heat output 11.4 kw min...

Page 8: He Primary Aaa

Supplied by www.Heating spares.Co tel. 0161 620 6677 9 he primary aaa table 1/a lpg (g 30 - g 31) І 3p - П 2h3+ nominal heat input net qms 22.6 kw minimum heat input net 11.6 kw nominal heat output 22.3 kw minimun heat output condensing 23.9 kw nominal heat output 11.4 kw minimum heat output condens...

Page 9

Supplied by www.Heating spares.Co tel. 0161 620 6677 a smaller size than the boiler inlet gas connection should not be used the complete installation must be tested for soundness as described in the above code n b: if the gas supply for the boiler serves other appliances ensure an adequate sup ply i...

Page 10

Supplied by www.Heating spares.Co tel. 0161 620 6677 note the fl ue must be terminated in a place not likely to cause a nuisance 4.6.2 a concentric vertical fl ue kit is available, for fl ueing applications up to a maximun height of 40 metres. For further details see vertical fl ue installation inst...

Page 11

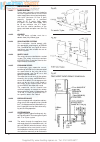

Supplied by www.Heating spares.Co tel. 0161 620 6677 12 water system 4.8.2.1 water system for an open (vented) system the boiler must be supplied from an unrestricted water supply taken from a feed and expan- sion tank (minimum 22 litre 5 gall) capacity situated at a maximum height of 27 5 metre (90...

Page 12

Supplied by www.Heating spares.Co tel. 0161 620 6677 13 the sta tic head available from the cistern should be adequate to provide the initial system design pressure. The cold feed pipe from the cistern should include a non-return valve, and a stop-valve with an automatic air vent connected be - twee...

Page 13

Supplied by www.Heating spares.Co tel. 0161 620 6677 the system may be fi lled through a self contained unit comprising of a cistern pres- sure booster pump if required and if neces- sary an automatic pressure reducing valve or fl ow restrictor the cistern should be sup- plied through a temporary co...

Page 14

Supplied by www.Heating spares.Co tel. 0161 620 6677 should exceed 110 litres, an additional ves sel should be installed on the return to the combination boiler from the heating system (fig 7) guidance on vessel sizing is given in (table 3). Reference should be made to british gas publications «mate...

Page 15

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 12 fig. 13 fig. 14 16 optional extras: straight header box containing (fig 13) : 57 - straight header 59 - rubber seal Ø 60 66 - flue gas sample point flue extension box containing(fig 14) 1000 mm fl ue extension duct as an extra cost only wh...

Page 16

Supplied by www.Heating spares.Co tel. 0161 620 6677 17 fig. 18.

Page 17

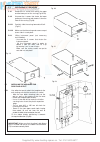

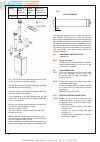

Supplied by www.Heating spares.Co tel. 0161 620 6677 18 5.4 positioning of the boiler 5.41 remove the 4 screws that secure the upper and the lower part of the casing(fig.19-20). 5.4.2 unscrew the 4 screws that fasten the lower grating on the casing and remove it from the sides of the casing (fig.20)...

Page 18: Important

Supplied by www.Heating spares.Co tel. 0161 620 6677 intake and exhaust terminal components 19 5.5.2 locate the rubber Ø 100 and Ø 60 into the fl ue elbow header (fig 30). - cut the inner fl ue duct (60 mm) at right - angles to a length equal to w + 264 mm insert from cut end reassemble the two tube...

Page 19

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig 37 20 5.5.4 insert the fl ue assembly into the wall, being careful to make sure that the outer air duct comes fl ush to the inner surface of the wall. 5.5.5 lift the boiler on to the wall (fig 34), locating onto the top coach bolts fit the two...

Page 20

Supplied by www.Heating spares.Co tel. 0161 620 6677 21 5.5.9 each extension length extends the pipe by approximately 1000 mm long up to a maxi mum of two extensions. Pipeline length can be established using the instructions in section 5.5 for rear fl ue outlets and section 5.7 for side fl ue outlet...

Page 21

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig.39 l l l l 22 5.7.2 positioning the elbow towards the required direction (fig 30). 5.7.3 locate the rubber Ø 60 into the elbow. (fig 30) . 5.7.4 - if the standard duct furnished with the boiler is too long (position of the boiler from the wall...

Page 22

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig 41 l l l l = 3.0m max plus vertical flue kit l = 3.0m max plus vertical flue kit l = 2.25m max (2 in line 45° bend max) plus vertical flue kit 23 inline flue bend - 1680 mm must be deducted from overall length for each 90° bend obtuse flue ben...

Page 23

Supplied by www.Heating spares.Co tel. 0161 620 6677 model model no of fl ue extensions overall max fl ue length distance to centre of fl ue from back wall he primary 3 4 metre 200 mm 24 cut a 105 mm diameter hole through the ceiling and/ or roof, at the point previously marked. Fit a roof fl ashing...

Page 24

Supplied by www.Heating spares.Co tel. 0161 620 6677 25 5.13 electrical connections 5.13.1 important: electricity supply must be as specifi ed in clause (sect. 4.10). - when controls external to the appliance are required, design of the external electrical circuits should be undertaken by a competen...

Page 25

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 48 26 6.5 setting the system design pressure 6.5.1 the design pressure must be a min 1 bar and max 1.5 bar these fi gures are read off the pressure gauge. - the actual reading should ideally be 1 bar + the height in metres to the highest poin...

Page 26

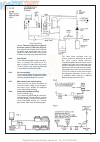

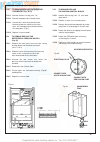

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 50 fig. 51 instrument panel key 77 - upstream pressure inlet 81 - downstream pressure outlet 104 - gas valve modulator 110 - min. Regulator nut 111 - max regulator nut 114 - electrical connections modulator 115 - electrical connections power ...

Page 27

Supplied by www.Heating spares.Co tel. 0161 620 6677 28 6.7 check the gas pressure at the burner now check the gas pressure at the burner is equal to 10.5 ± 0.5 mbar . Lpg check gas pressure inlet (37mbar propane - 29 mbar butane). To do this proceed as follows - press to off on/off switch (fig. 50)...

Page 28

Supplied by www.Heating spares.Co tel. 0161 620 6677 29 - the operation of the boiler including the use and adjustment of all system controls which should be fully explained to the householder this then ensures the greatest possible fuel economy consistent with household requirements of both heating...

Page 29

Supplied by www.Heating spares.Co tel. 0161 620 6677 30 7.2.6.1 to remove condensate trap (sect 5.4) pull forward the trap (fig 90). Unscrew the earth wire, and the sensor replace in reverse order 7.2.7 examine the fan for any mechanical damage, check to ensure free running of the fan wheel clean th...

Page 30

Supplied by www.Heating spares.Co tel. 0161 620 6677 31 7.8.8 disconnect unions for two heating (right side of boiler) water pipelines (fig.59). 7.8.9 unscrew the ring that fasten the heat exchanger to the combustion chamber.(fig.59). 7.9.5 remove burner (sect. 7.15). Remove top insulation pieces at...

Page 31

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 58 32 fig. 56 fig. 57.

Page 32

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 59 33 7.10.2 detach the wire from electrode and then unscrew the nut that secures it to the burner and remove .(fig.61). 7.10.3 replace with new electrode in reverse order. 7.14 to remove/replace the injectors fig.62-63). 7.14.1 remove the fr...

Page 33

Supplied by www.Heating spares.Co tel. 0161 620 6677 34 fig. 60 fig. 61 fig. 62 fig. 63.

Page 34

Supplied by www.Heating spares.Co tel. 0161 620 6677 35 7.25 to remove/replace the ignition/control board 7.25.1 remove front casing (sect. 7.3 and lower gratin panel. 7.25.2 remove 2 screw to instrument panel. 7.25.3 remove the plastic box protection by unclip ping it from its 4 locating pins (2 ea...

Page 35

Supplied by www.Heating spares.Co tel. 0161 620 6677 36 section 8 fault finding stat to maximum ensure external controls calling for heat (room stat/time clock/trv).

Page 36

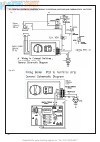

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 9 electrical system diagram fig. 94 37.

Page 37

Supplied by www.Heating spares.Co tel. 0161 620 6677 38 9.0 general schematic diagram wiring to external switches and thermostats volt free fig. 95 fig. 95.1.

Page 38

Supplied by www.Heating spares.Co tel. 0161 620 6677 9.1 wiring to “y” and “s” plan installations using an external programmer “ y “ plan 39 “ s “ plan fig.96 fig.97.

Page 39

Supplied by www.Heating spares.Co tel. 0161 620 6677 8.0 installation instructions for twin flue pipe (eccentric flue duct system) 40 important these instructions must be read in conjunction with the main installation and servicing instructions as with all fl ues the kits must be installed taking du...

Page 40

Supplied by www.Heating spares.Co tel. 0161 620 6677 41 discard this orifi ce plate and re-fi t the f1 ori- fi ce plate ensuring that the venturi tube has been re-fi tted, making sure this is securely lo- cated into the locating peg locate the sealing washer fi xing the twin fl ue header as illustra...

Page 41

Supplied by www.Heating spares.Co tel. 0161 620 6677 42 item description part no 1 2 3 4 5 6 7 8 9 10 csi fl ue adaptor gasket and screws straight pipe eccentric vertical terminal 90º slow bend 45º bend air inlet terminal (plastic) 80 mm exhaust terminal (stainless steel) 80 mm pitch roof slate flat...

Page 42

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 10 exploded parts diagram 43.

Page 43

Supplied by www.Heating spares.Co tel. 0161 620 6677 44 ravenheat he primary aaa condensing boiler short list of spare parts ravenheat g.C. Pos. Part. No. Part. No. Description 1 0001cop01010/0 depression chamber cover 2 0012ven03005/1 fan 3 0002sca06006/0 condensing heat exchanger 4 0001cop06005/0 ...

Page 44

Supplied by www.Heating spares.Co tel. 0161 620 6677 45 ravenheat g.C. Pos. Part. No. Part. No. Description 31 0012cav06020/0 cable for spark-sensing electrode 32 0003uge03005/0 371297 nozzle Ø 1,25 for natural gas 32.1 0003uge01011/0 e23-755 nozzle Ø 0.75 for lpg 33 0013gua03035/0 371273 gasket 32 ...

Page 45

Supplied by www.Heating spares.Co tel. 0161 620 6677 46 chartists way, morley, leeds, ls27 9et telephone : 0044(0)113 252 7007 tfax : 0044(0)113 238 0229 website : www.Ravenheat.Co.Uk e-mail : sales@ravenheat.Co.Uk ravenheat reserves the right to make changes and improvements in our products which m...

Page 46

Supplied by www.Heating spares.Co tel. 0161 620 6677 47 the code of practice for the installation, commissioning & servicing of gas central heating installation, commissioning and service record log book name address tel no. Customer details important company name installation date address tel no. I...

Page 47

Supplied by www.Heating spares.Co tel. 0161 620 6677 48 48 gblb second edition 01.03.02 does the heating and hot water system comply with the appropriate building regulations? Yes has appliance and associated equipment been installed and commissioned in accordance with the manufacturer’s instruction...