- DL manuals

- Ravenheat

- Boiler

- Little Star LS 100

- Installation And Servicing Instructions

Ravenheat Little Star LS 100 Installation And Servicing Instructions

Supplied By www.heating spares.co Tel. 0161 620 6677

ELECTRONIC IGNITION - AUTOMATIC MODULATING BOILER

WITHOUT TIMER

LS 80 G.C. N

o

4758129 (NAT.) - 4758131 (LPG)

LS 100 G.C. N

o

4758133 (NAT.) - 4758135 (LPG)

NATURAL GAS (G20) -I

2H -

II

2H3+

LPG (G30 - G31) - I

3+-

II

2H3+

Fanned Combination Boiler

Listed by The United Kingdom Water

Fitting Byelaws Scheme

WITH TIMER

LS 80T G.C. N

o

4758130 (NAT.) - 4758132 (LPG)

LS 1OOT G.C. N

o

4758134 (NAT.) - 4758136 (LPG)

NATURAL GAS (G20) - I

2H

-

II

2H3+

LPG (G30 - G31) - I

3+-

II

2H3+

INSTALLATION AND SERVICING INSTRUCTIONS

TO BE LEFT WITH USER

Technical and illustrative data are not binding and can be modified without prior notice.

The descriptions and illustrations in the present booklet are for guideline purposes only.

RAVENHEAT MANUFACTURING LTD., CHARTISTS WAY, MORLEY, LEEDS, LS27 9ET. -TELEPHONE (0113) 252 7007

Summary of Little Star LS 100

Page 1

Supplied by www.Heating spares.Co tel. 0161 620 6677 electronic ignition - automatic modulating boiler without timer ls 80 g.C. N o 4758129 (nat.) - 4758131 (lpg) ls 100 g.C. N o 4758133 (nat.) - 4758135 (lpg) natural gas (g20) -i 2h - ii 2h3+ lpg (g30 - g31) - i 3+- ii 2h3+ fanned combination boile...

Page 2

Supplied by www.Heating spares.Co tel. 0161 620 6677 the little star - automatic modulating boiler for central heating and domestic hot water the new small super high efficiency turbo-modulating boiler is designed to meet domestic hot water and central heating requirements at super high efficiency, ...

Page 3

Supplied by www.Heating spares.Co tel. 0161 620 6677 sections: table of contents introduction 2 3 4 5 6 7 8 9 10 11 general layout fig. 1 design principles and operating sequence technical data general requirements installation commissioning servicing instructions fault finding electrical system dia...

Page 4

Supplied by www.Heating spares.Co tel. 0161 620 6677 operating fig. 2 scheme key 1 - heat exchanger 2 - heat exchanger for d.H.W. Water 3 - burner 4 - ignition electrode 5 - flue restriction ring 6 - elbow header 7 - electronic ignition 8 - twin header 9 - detection electrode 10 - straight header 12...

Page 5

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 1 introduction 1.1 the ravenheat boiler is for the use of cen- tral and domestic hot water combined in one unit. It is fitted with an automatic domestic hot water priority valve. A winter/summer selector switch is fitted to the left hand s...

Page 6

Supplied by www.Heating spares.Co tel. 0161 620 6677 2.4 2.4.1 domestic hot water mode, the heat exchanger in the d.H.W. Circuit is a stainless steel plate heat exchanger water 2.4.4 when d.H.W. Is no longer called for the boil- er automatically returns to the central heat- ing mode. 2.4.5 to water,...

Page 7: Natural Gas (G 20)

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 3 technical data table 1 natural gas (g 20) i 2h nominal heat input net qms 26.1 kw minimum heat input net nominal heat output minimum heat output 13.5 kw 24.1 kw 11.6 kw gas rate max 2.6 m 3 /h after 10 minutes min 1.3 m 3 /h inlet pressu...

Page 8: Lpg (G 30 - G 31) I

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 3 technical data table 1/a lpg (g 30 - g 31) i 3+ nominal heat input net qms 26.1 kw minimum heat input net 13.5 kw nominal heat output 24.1 kw minimum heat output 11.6 kw gas rate max g 31 0.95 m 3 /h g 30 0.79 m 3 /h after 10 minutes min...

Page 9: Ls 100 (T)

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 3 technical data ls 100 (t) table 3 natural gas (g 20) i 2h - ii 2h3+ nominal heat input net qms 31.4 kw minimum heat input net 13.0 kw nominal heat output 29.0 kw minimum heat output 11.2 kw gas rate max 3.2 m 3 /h after 10 minutes m i n ...

Page 10: Ls 100 (T)

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 3 technical data ls 100 (t) table 4 lpg (g 30 - g 31) ii 2h3+ -i 3+ nominal heat input net qms 31.4 kw minimum heat lnput net 13.0 kw nominal heat output 29.0 kw gas rate max g 31 1.24 m 3 /h g 30 0.95 m 3 /h after 10 minutes inlet pressur...

Page 11

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 4 general requirements the manufacturer’s notes must not be tak- 4.0 safety en, in any way, as overriding statutory oblig- ations. Gas safety (installation and use) regulations, 1994 and amended 2000. Important.These appliances are ce cer-...

Page 12

Supplied by www.Heating spares.Co tel. 0161 620 6677 4.4 important notice 4.4.1 if the combination boiler is to be fitted in a timber framed building it should be fitted in accordance with the british gas publication guide for gas installations in timber frame housing reference dm2. If in doubt advi...

Page 13

Supplied by www.Heating spares.Co tel. 0161 620 6677 note: 4.6.2 4.7 4.7.1 fig. 6a the flue must be terminated in a place not likely to cause a nuisance. A concentric vertical flue kit is available for flueing applications up to a maximum height of 4 metres. For further details see vertical flue ins...

Page 14

Supplied by www.Heating spares.Co tel. 0161 620 6677 4.8.4 4.8.5 4.8.6 draining tap these must be located in. Accessible posi- tions to permit the draining of the whole system. The taps must be at least 15 mm nominal size and manufactured in accor- dance with bs 2870 1980 fig. 7 a i r r e l e a s e ...

Page 15

Supplied by www.Heating spares.Co tel. 0161 620 6677 sizing of additional expansion vessels: table 3 deduct from the value given in the table the 7 litre vessel supplied. Note: this pressure can be increased up to 1.5 bar to suit static head situations, see item 10, other appliance instructions in t...

Page 16

Supplied by www.Heating spares.Co tel. 0161 620 6677 4.8.10 4.9 4.9.1 4.10 4.10.1 hard water areas 5.2 delivery if the. Area of installation is recognised as hard water, it is recommended that a suit- able water treatment device is installed in the mains. 5.2.1 the appliance will arrive on site in t...

Page 17

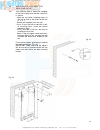

Supplied by www.Heating spares.Co tel. 0161 620 6677 5.4 positioning of the boiler 5.4.1 unscrew the 2 screws that fasten the lower grating on the casing and remove it the casing (fig. 20). 5.4.2 - remove the 4 screws that secure in the top, 2 in the bottom the casing (fig. 19). - carefully slide th...

Page 18

Supplied by www.Heating spares.Co tel. 0161 620 6677 5.5 installingthe appliance for rear flue outlet 5.5.1 use adhesive tape to attach the template to the wall, making sure that the centre line is vertical. - mark the two boiler fastening holes on the wall as well as the centre of the flue d u c t ...

Page 19

Supplied by www.Heating spares.Co tel. 0161 620 6677 5.5.3 if the standard duct furnished with the boil- er is too long it can be shortened. Note: should it be necessary to cut the flue, always cut equal amounts from both inner and outer pipes. Always cut the end furthest from the terminal. Cut end ...

Page 20

Supplied by www.Heating spares.Co tel. 0161 620 6677 5.5.4 5.5.5 5.5.6 insert the flue assembly into the wall, being careful to make sure that the outer air duct comes flush to the inner surface of the wall. Lift the boiler on to the wall (fig. 34), locat- ing onto the top coach bolts, and tighten a...

Page 21

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 37 5.6 5.6.1 5.7 5.7.1 completing boiler installation reassemble the outer casing (sect 5.4) proceeding in this order 1) fit the casing. 2) refit the lower grating (sect. 5.4). Installing the appliance for side flue outlet (fig. 39) -attach t...

Page 22

Supplied by www.Heating spares.Co tel. 0161 620 6677 5.7.6 insert the flue assembly into the wall, mak- ing sure it will not interfere when fixing the boiler on the wall. 5.7.7 lift the boiler on the wall. Locate onto the top coach bolts. Fit the lower coach bolts and tighten all two securing bolts....

Page 23

Supplied by www.Heating spares.Co tel. 0161 620 6677 position min. Distance mm n above roof level (to base of terminal) 300 p from adjacent wall to flue 300 q from internal corner to flue 300 s from facing terminal 1,200 m horizontally from a vertical terminal to a wall 300 before proceeding with in...

Page 24

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 44 . Starting at the appliance end, assemble the exten- sion duct sections, making each inner and outer (flue) joint by inserting the spigot end into the socket end of the next tube. Make sure that the entire flue is adequately supported. Use...

Page 25

Supplied by www.Heating spares.Co tel. 0161 620 6677 5.13 electrical connectlons 5.13.1 the electricity supply must be as specified in clause (sect. 4.10). - when controls external to the appliance are required, design of the external electrical circuits should be undertaken by a competent person. I...

Page 26

Supplied by www.Heating spares.Co tel. 0161 620 6677 6.5 6.6 6.7 setting the system design pressure the design pressure must be a min. 1 bar and max. 1.5 bar. These figures are read off the pressure gauge. - the actual reading should ideally be 1 bar + the height in metres to the highest point of th...

Page 27

Supplied by www.Heating spares.Co tel. 0161 620 6677 instrument panel fig. 50

Page 28

Supplied by www.Heating spares.Co tel. 0161 620 6677 6.9.1 6.10 6.11 detach one of the wires going to modu- 6.12 s e t t i n g c e n t r a l h e a t i n g g a s lator 104 (fig. 51) and make the boiler pressure the boiler comes set operate just as was done for checking at mid position rating for use ...

Page 29

Supplied by www.Heating spares.Co tel. 0161 620 6677 once the process of commissioning the boiler is complete, the commissioning engineer must com- plete his section in the benchmark log book. 6.13 checking the flue system 6.13.1 the flue system should be visually checked for soundness. Check all fi...

Page 30

Supplied by www.Heating spares.Co tel. 0161 620 6677 key 6 - main burner 11- chamber cover 10- combustion chamber 12- air restriction ring 13- flue gas exhaust hood 17- heat exchanger 19- air pressure switch 2 4 - main burner 27 - auto air vent valve 31- seal 37- gasket 48 x 42 x 1 38- connection pi...

Page 31

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 7 servicing instructions 7.2.2 7.1 servicing ravenheat are a member of the benchmark initiative and fully supports the aims of the programme. Benchmark has been instruct- ed to improve the standards of installation and commissioning of cen...

Page 32

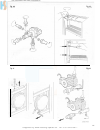

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.6 7.6.1 7.6.2 7.6.4 7.7 7.7.1 7.7.2 7.7.3 7.7.4 7.7.5 7.7.6 7.8 7.8.1 7.8.2 7.8.4 7.8.5 7.8.8 7.8.9 7.8.11 7.8.12 7.8.13 to remove/replace the fan important: when replacing a heat assembly (fig. 58) exchanger new seals must be used. Remove front...

Page 33

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 63 fig. 60 fig. 64 7.10 to replacethe electrodes (fig. 66) 7.10.1 remove front casing (sect. 7.3). Remove combustion chamber front cover (sect. 7.4). Fig. 61 7.10.2 detach the wire from electrode and then unscrew the screw that secures it to ...

Page 34

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.14 to remove/replace the main injectors 7.14.1 remove the front panel of the casing and the combustion chamber front cover (sect. 7.3 & 4). 7.14.2 unscrew the union (fig. 70) 7.14.3 unscrew the 4 screws securing the injector manifold to the burn...

Page 35

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.15 to remove/replace the main burner 7.15.1 remove the front panel of the casing and the combustion chamber front cover (sect. 7.3 & 7.4). 7.15.4 r e m o v e t h e i n j e c t o r s m a n i f o l d a s described in sect. 7.14. 7.15.5 remove the ...

Page 36

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.19 7.19.1 7.19.2 7.19.3 7.19.4 7.19.5 7.19.6 7.20 7.20.1 7.20.2 7.20.3 7.20.4 7.21 7.21 .1 7.21.2 7.21.3 7.21.4 7.21.5 7.22 7.22.1 to remove/replace the heating control and domestic hot water control remove the casing (sect. 7.3) lower the instr...

Page 37

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.25 to remove/replace the pump (fig. 88) 7.25.1 remove the casing (sect. 7.3) and lower the instrument panel (sect. 7.19.1). 7.25.2 7.254 7.25.5 remove lower grill of the casing (sect. 5.4.2 & 5), lower the electric box (sect. 7.16.2 & 3). Detach...

Page 38

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.27 7.27.1 7.27.3 7.27.4 7.27.5 7.27.6 fig. 82 to remove/replace the central heating and/or hot water con- trol thermistor remove the casing (sect. 7.3) and lower the instrument panel (sect. 7.19.1 for dhw). Remove the wires that connect the ther...

Page 39

Supplied by www.Heating spares.Co tel. 0161 620 6677 7.29.4 7.29.6 7.29.7 7.29.8 7.30 7.30.1 7.30.2 7.30.3 7.30.4 7.31 7.31.1 7.31.2 7.31.3 7.31.4 7.31.5 7.31.6 7.32 7.32.1 7.32.2 7.32.3 close the on/off valves for the central heat- ing circuit and drain the water from the boil- er drain point (fig....

Page 40

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 89 fig. 91 fig. 92 fig. 93 4 1.

Page 41

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 8 fault finding central heating switch on select “winter” central heating stat to maximum ensure external controls calling for heat (room stat/tune clock/trv).

Page 42

Supplied by www.Heating spares.Co tel. 0161 620 6677 fault finding domestic hot water before continuing it may be necessary to see central heating fault finding. Select only (summer) domestic hot water. Open domestic hot tap close to appliance. Boiler not operational on timer (integral) switch on/se...

Page 43

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 9 electrical system diagram fig. 94 44.

Page 44

Supplied by www.Heating spares.Co tel. 0161 620 6677 sectlon 10 important 10.0 installation instructions for t w i n f l u e p i p e ( e c c e n t r i c f l u e duct system) important: correct ls 80 (t) 75 mm (nat. Gas) - 74 mm (lpg), ls 100 (t) 78 mm (nat. Gas) - 77 mm (lpg) must be fitted. As with...

Page 45

Supplied by www.Heating spares.Co tel. 0161 620 6677 90” m/f bend consisting of: 90” elbow with ‘0’ ring side f 80 mm dia ‘0’ ring 135” m/f bend consisting of: 135” elbow with ‘0’ ring side f 80 mm dia’0’ ring vertical eccentric flue exhaust duct fig. 2.8 figures 2.8, 3.8 and 4.8 show the versatilit...

Page 46

Supplied by www.Heating spares.Co tel. 0161 620 6677 fig. 3.8 fig. 4.8 exhaust/suction system with two separate rated 80 diam pipes - exhaust on flat or sloping roof, suction from vertical wall. Maximum distance d = i + e + t = total exhaust/inlet pipe = 27 metre. Exhaust terminal must not be cut. M...

Page 47

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 1 exploded parts diagram 48.

Page 48

Supplied by www.Heating spares.Co tel. 0161 620 6677 section 12 ravenheat short list of spare parts pos. Ls 80 (t) part. No. 1 0014pan09005/0 2 00121nt0900510 4 ool2pot05005/0 5 0007ter0301010 6 0001 cam09005/0 7 0014man06015/0 a 00061dr0900510 9 0007ter05005/0 10 0014vet01005/0 11 0001 c0p09010/0 1...

Page 49

Supplied by www.Heating spares.Co tel. 0161 620 6677 ravenheat short list of spare parts continued pos. Ls 80 (t) part. No. G.C. Ls 100 (t) g.C. Part. No. Part. No. Part. No 36 37 36 39 40 44 46 51 58 59 60 60.1 60.2 61 65 69 79 82 87 5018046 0013gua01045/0 0010tvb009055/0 0012fuso5015/0 0012can0900...

Page 50: Telephone: (0113) 252 7007

Supplied by www.Heating spares.Co tel. 0161 620 6677 chartists way, morley, leeds, ls27 9et. Telephone: (0113) 252 7007 tfax: (0113) 238 0229.