Th is manual is intended only for use by a qualifi ed heating installer/technician. Read and follow this manual, all supplements and related instructional information provided with the boiler. Install, start and service the boiler only in the sequence and methods given in these instructions. Failure...

2 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual the mestek 200 i condensing cast iron boiler operation overview th e 200 i is a cast iron boiler designed and constructed to allow full condensing operation. Th...

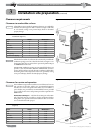

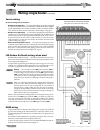

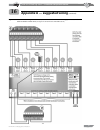

3 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual the mestek 200 i condensing cast iron boiler 200 i components components gas valve pressure/temperature gauge jacket cast iron section assembly inlet air fi lte...

4 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual hazard icons you will fi nd the following icons throughout this manual. (english/french) the warning icon indicates a hazard that can cause severe personal inju...

5 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual read before beginning the installation codes and standards boiler compliances th e 200i has been design certifi ed by csa for use with natural and propane gas u...

6 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual boiler ratings and specifi cations 2 boiler model units 200i notes afue (doe seasonal effi ciency) % 92.7 1 csa input (max) btuh kw 200,000 58.6 2 csa input (mi...

7 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual installation site preparation boiler location requirements do not install the boiler unless the location meets all of the requirements in this box. Failure to c...

8 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual installation site preparation (continued) clearance requirements clearances to combustible surfaces all installations must provide the minimum clearances to com...

9 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual figure 3 air opening options for combustion air drawn from boiler room installation site preparation (continued) combustion air requirements air ducted to boile...

10 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual figure 4 relief valve piping prepare the boiler remove the boiler from the crate cold weather handling — th e boiler jacket includes plastic parts. If the boil...

11 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual water piping th e 200i boiler requires a continuous minimum water fl ow for proper operation. Th e circulator for the boiler must be sized to overcome the head...

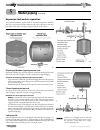

12 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual water piping (continued) figure 6 diaphragm or bladder-type expansion tank suggested piping figure 7 closed-type expansion tank suggested piping expansion tank...

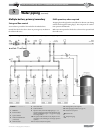

13 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual water piping (continued) figure 8 suggested piping — single boiler — zone valve zoning — two-pipe or series loop (left), or primary/secondary piping (right) l ...

14 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual water piping (continued) figure 9 suggested piping — single boiler — circulator zoning — two-pipe or series loop (left), or primary/secondary piping (right) zo...

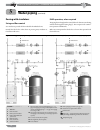

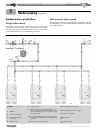

15 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual water piping (continued) figure 11 suggested piping — multiple boilers — primary/secondary piping, reverse-return boiler headers multiple boilers, primary/seco...

16 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual water piping (continued) figure 12 suggested piping — multiple boilers — parallel-fl ow piping, reverse-return headers multiple boilers, parallel fl ow sizing ...

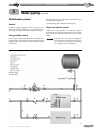

17 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual water piping (continued) figure 13 suggested piping — boilers connected to chilled water systems chilled water systems general provide the piping components sh...

18 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual gas piping figure 14 connecting gas supply line failure to adhere to the following could result in severe personal in- jury, death or substantial property dama...

19 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual gas piping (continued) table 3 gas fl ow capacity for black iron pipe iron pipe size (inches) pipe length, equivalent feet (length plus allowance for fi ttings...

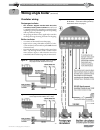

20 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual wiring a single boiler 7 figure 15 electrical connection board (see item 10, page 3 for location — also see the wiring summary illustrations on the next pages)...

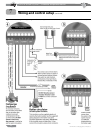

21 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual wiring single boiler (continued) 7 figure 19 circulator wiring terminal strip (see figure 15 for location) — also see the wiring summary illustrations on the n...

22 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual wiring single boiler (continued) 7 figure 20 indoor air reset wiring to iar terminals with 4-wire zone valves and no zone controller (see figure 21a for termin...

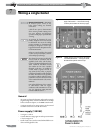

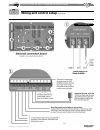

23 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual figure 21a 200i wiring summary (see boiler manual and control manual text for additional information) wiring and control setup (continued) 7 also see page 20

24 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual figure 21b 200i wiring summary (see figure 21 for locations) (see boiler manual and control manual text for additional information) wiring and control setup (c...

25 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual figure 22 heat net display during standby (no call for heat) — pressing the down key on the keypad changes the display as shown control setup 8 before control ...

26 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual control setup (continued) 8 recommended settings th e following recommendations should cover most single-boiler applications. Th e sett ings covered in this ma...

27 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual control setup (continued) 8 5. Th e factory default sett ing is on, or iar enabled. If the boiler is wired for iar, then leave the sett ing at on. 6. To change...

28 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual vent piping (and air piping when used) all 200i boilers must be vented using only the materials listed in the 200i vent/air manual. Th e vent installation must...

29 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual condensate drain line figure 23 connecting a condensate drain line fill the condensate trap before installing the condensate line, you must fi ll the condensat...

30 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual fill and test the system failure to adhere to the following could result in boiler section failure, resulting in potential for severe personal injury, death or...

31 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual fill and test the system (continued) antifreeze antifreeze for hydronic systems contains propylene glycol and an inhibitor. With- out the inhibitor the glycol ...

32 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual starting the boiler failure to adhere to the following could result in severe personal injury, death or substantial property damage. Accessibility th e boiler ...

33 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual measure the air piping length and note the number of fi tt ings. Make sure the air piping complies with the 200i vent/air manual. Verify ventilation openings t...

34 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual figure 24b boiler sequence of operation, fault states and smartcycle control display information figure 24a smartcycle control display during operation startin...

35 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual figure 25 operating instructions (for starting boiler only — follow manual instructions to check boiler operation and adjust as needed) starting the boiler (co...

36 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual illustration 26 en francaise . . . Starting the boiler (continued) 12.

37 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual figure 27 flue gas sampling hole figure 28 electrical panel starting the boiler (continued) turn the boiler off turn off the boiler on/off switch and allow the...

38 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual figure 29 throttle adjustment and fl ame window adjust gas valve throttle setting allow combustion to stabilize allow the boiler to operate 15 minutes, or as n...

39 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual figure 30 removing boiler jacket top figure 31 gas valve adjustments starting the boiler (continued) when is low fi re adjustment required? Adjust the gas valv...

40 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual starting the boiler (continued) figure 32 throttle adjustment and fl ame window measure fl ame current electrical shock hazard — th e electrical box contains l...

41 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual annual start-up th e boiler and system must be inspected, started and serviced at least annually by a qualifi ed service technician. Follow all procedures spec...

42 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual maintenance 13 handling ceramic fi ber and fi berglass materials the 200i boiler contains some ceramic fi ber and fi berglass materials. Ceramic fi ber materia...

43 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual cleaning the air fi lter turn the boiler on/off switch off . Remove the three thumb screws that secure the fi lter access plate (see figure 33). Remove the fi ...

44 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual accessing the burner if the fi lter enclosure and blower inlet show signs of drywall dust, construction debris or other deposits, you may need to inspect the b...

45 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual maintenance (continued) 14 notes.

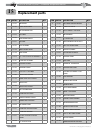

46 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual replacement parts 15 item part no. Description qty 1 20-1022 tridicator 1 2 03-1752 right jacket panel 1 3 60-5625 abs side medallion 1 4 42-5238 off label 1 5...

47 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual replacement parts (continued) 15.

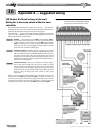

48 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual appendix a — suggested wiring 16 figure a1 indoor air reset wiring to iar terminals with 3-wire zone valves and no zone controller (see figure 21a for terminal...

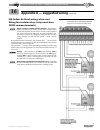

49 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual appendix a — suggested wiring (continued) 16 figure a2 indoor air reset wiring to iar terminals with 3-wire zone valves and no zone controller (see figure 21a ...

50 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual iar (indoor air reset) wiring, when used wiring for typical zone controller heat demand terminal connections — th e end switch leads from the controller must c...

51 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual figure a3 indoor air reset wiring to iar terminals, heat demand and dhw demand using typical zone controller for either circulators or zone valves (see figure ...

52 p/n 42-9470 11/07 copyright 2007 mestek, inc. Cast iron condensing boiler cast iron condensing boiler — installation and operation manual start-up & service history installation and start-up (complete before leaving installation site) start-up date boiler model serial number installer/start-up co...