- DL manuals

- Raymarine

- Marine Equipment

- EV-100

- Installation Instructions Manual

Raymarine EV-100 Installation Instructions Manual - Warning: Wheel Drive Clutch

24

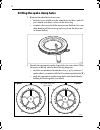

Autopilot steering direction

The autopilot steering direction defines which way the autopilot

applies helm when you press a course change key or when the boat

goes off course.

Check the autopilot steering direction as follows:

1.

Wheel Pilot:

Engage the wheel drive clutch by rotating the clutch

lever clockwise so it engages fully onto the locating pip.

WARNING: Wheel drive clutch

Always reach AROUND (not through) the wheel to operate the

wheel drive clutch lever.

2. Press the

+10

key. The helm should move to produce a turn to

starboard.

Engage the clutch

on the wheel pilot

Wheel pilot

81131_8.book Page 78 Thursday, October 7, 2004 11:03 AM

3. If the helm produces a turn to port, reverse the drive connections

on the back of the control unit.

D3568-2

+10°

Summary of EV-100

Page 1

Evolution wheel drive autopilot installation instructions english date: 0 5 -201 7 document number: 87287- 2 © 201 7 raymarine uk limited.

Page 2

81131_8.Book page 118 thursday, october 7, 2004 11:03 am.

Page 3: Important Information

Important information this handbook contains important information about installing, using and maintaining your new raymarine product. To get the best from the product, please read this handbook thoroughly. Warranty to register your new raymarine product, please take a few minutes to register on the...

Page 4: Emc Conformance

Your raymarine autopilot will add a new dimension to your boating enjoyment. However, it is the skipper’s responsibility to ensure the safety of the boat at all times by following these basic rules: • ensure that someone is present at the helm at all times, to take manual control in an emergency. • ...

Page 5: Emc Installation Guidelines

Emc installation guidelines all raymarine equipment and accessories are designed to the best industry standards for use in the recreational marine environment. Their design and manufacture conforms to the appropriate electromagnetic compatibility (emc) standards, but correct installation is required...

Page 6

81131_8.Book page 37 thursday, october 7, 2004 11:03 am.

Page 7: Parts Supplied

Parts supplied d5439-4 wheel drive parts clamp screw, m5 x 16 mm (x6) wheel drive pedestal bracket spoke clamp (x3) 16 mm spoke clamp insert (x3) 12 mm spoke clamp insert (x3) 6 mm drill bit 3 mm allen key 4 mm drill bit power cable 4.5 m (15 ft) bracket screw, no 10 x 3/4 in (x4) cable clip and scr...

Page 8

6 d5370-2 361 mm (14.2 in) diameter 228 mm (9.0 in) diameter 135 mm (5.3 in) 171 mm (6.7 in) [plus 60 mm (2.4 in) for cable clearance] motor tube: 48 mm (1.9 in) diameter wheel drive dimensions 28 mm (1.1 in) 152 mm (6.0 in) 154 mm (6.1 in) 81131_8.Book page 104 thursday, october 7, 2004 11:03 am di...

Page 9: Installation Stages

7 wheel drive (wheel pilots only) the raymarine wheel drive will fit 3, 4, 5, 6, 7 or 8 spoke wheels. It is designed to operate with steering systems with between 1 to 3.5 turns lock to lock. Installation stages installing the wheel drive involves four stages: 1. Drilling the spoke clamp holes in th...

Page 10

8 drilling the spoke clamp holes 1. Remove the wheel drive front cover: • the front cover is held onto the wheel drive by three ‘push-fit’ posts which sit in three sockets on the drive ring • to remove the cover, hold the motor in one hand and use your other hand to pull the cover up and away from t...

Page 11

9 note: the wheel drive is designed to work with 3 spoke clamps on 4 or 8 spoke wheels. For cosmetic reasons, however, you may want to fit an extra spoke clamp to the fourth spoke. Raymarine dealers can supply an extra spoke clamp (part number a18089). 3. Drill the appropriate spoke clamp holes usin...

Page 12

10 4. Align the cover with the wheel drive: • the two pre-drilled holes (marked with an arrow) must line up with their matching pair of threaded inserts on the drive ring (also marked with an arrow) • make sure that the other spoke clamp holes align with their threaded inserts note: the cover will o...

Page 13

11 securing the wheel drive to the wheel 1. Remove the wheel from the pedestal and place it on top of the drive unit, with the front of the wheel and drive both facing up. 2. Using the wheel drive template at the end of this book, select the correct set of spoke clamp inserts for your wheel: • measu...

Page 14: Motor Tube Location

12 attaching the pedestal bracket note: if your wheel is bulkhead or box pedestal mounted, you will need to obtain a bulkhead fitting kit (part number e15017) from your raymarine dealer. Fitting instructions are supplied with the kit. Motor tube location depending on the design of your pedestal and ...

Page 15

13 pedestal bracket – length and position note: if you are replacing an existing wheel drive, you need to: remove the old pedestal bracket, cut the new bracket pin to the correct length (see steps 2 and 3 below), then secure it in the standard orientation using the existing pedestal holes. 1. Fit th...

Page 16

14 note: you can install the pedestal bracket either way up. In the standard orientation the pin is at the bottom (below the mounting holes – see diagram). If obstructions on the pedestal prevent you from using the standard orientation, you can install the bracket so the pin is at the top (above the...

Page 17

15 8. When the pedestal bracket is correctly positioned and aligned, mark around the inside of the slots, then remove the bracket. 9. Use a center-punch to mark the center of each slot, then use the smaller supplied drill bit to drill a 4.0 mm ( 5 / 32 in) diameter hole. Note: drill at right angles ...

Page 18: Connecting to The Control

16 note: if the wheel is bent or the wheel drive is off center, the pin will move up and down in the back plate slot. As long as the pin does not hit the top or bottom of the slot, this pin movement will not affect the drive unit’s performance. 13. When you have checked alignment, fully tighten all ...

Page 19

17 2. Route the cable through the pedestal (or guard rail) and back to the control unit: • if the pedestal has a cable duct, use this for the drive cable to make sure that it cannot foul the steering mechanism 3. Run the drive cable back to the control unit and connect the two cores to the drive ter...

Page 20

Acu (control unit) connection a b + _ motor power d13589-1 to the acu wheel drive cable acu blue brown note: you can use the autopilot control head to change the motor phase: menu > setup > autopilot calibration > drive settings > motor phasing 18.

Page 21: Ensuring Correct Alignment

Rudder position sensor (wheel pilot) note: not all systems are supplied with a rudder sensor. It is available separately as part number m81105. The rudder position sensor connects directly to the boat’s tiller arm or quadrant. Installing the sensor involves five main steps: • ensuring correct alignm...

Page 22

Horizontal alignment when viewed from above (as shown in the illustration above): • the sensor arm must be between 75 mm (3 in) and 310 mm (12 in) from the tiller arm • with the rudder amidships, the sensor arm should be at 90° to the connecting rod and directly opposite the cable entry point on the...

Page 23: Location

Securing the sensor to the boat location mount the rudder position sensor on a suitable base alongside the rudder stock and tiller arm. Note: if necessary, you can install the sensor upside down. If you mount the sensor in this way, you must swap the red and green cable connections at the control un...

Page 24: Checking Alignment

Attaching the connector rod 1. Use a hacksaw to cut the threaded connector rod to length. 2. Screw the lock nuts onto the road and then the ball-pin sockets. 3. Press the sockets onto the pins on the sensor arm and tiller pin. Note: to give the precise rudder position, the rudder sensor has a built-...

Page 25: Setting-Up The

23 setting-up the system when you have installed the system, you need to check that the system is wired correctly and set up to suit your type of boat. This chapter provide instructions for the following post-installation procedures: functional test switch on 1. When you have installed your autopilo...

Page 26: Warning: Wheel Drive Clutch

24 autopilot steering direction the autopilot steering direction defines which way the autopilot applies helm when you press a course change key or when the boat goes off course. Check the autopilot steering direction as follows: 1. Wheel pilot: engage the wheel drive clutch by rotating the clutch l...

Page 27

25 6.2 check rudder sensor operation (if fitted) note: this procedure is only required if you have fitted a rudder position sensor to a wheel pilot system. If you have fitted a rudder position sensor to a wheel pilot, before commencing the initial sea trial you must make sure that it senses rudder m...

Page 28: Initial Sea Trial

26 initial sea trial when you have checked that the system is functioning correctly, you must complete the setup by taking the boat on a short sea trial to: • correct the compass deviation • adjust the heading alignment • check autopilot operation • adjust the rudder gain note : refer to your pilot ...

Page 29: 2.2 Using Auto Mode

27 2.2 using auto mode engaging the autopilot (auto mode) 1. Steady the boat on the required heading. 2. Wheel pilot: engage the wheel drive clutch by rotating the clutch lever clockwise (so the lever engages fully onto the locating pip). Warning: wheel drive clutch always reach around (not through)...

Page 30: Caution:

28 caution: autopilot course control makes it easier to sail a boat, but it is not a substitute for good seamanship. Always maintain a permanent watch, no matter how clear the sea appears to be. Disengaging the autopilot (standby mode) 1. Press standby . • the display shows the boat’s current compas...

Page 31: Maintenance & Fault Finding

29 maintenance & fault finding this chapter provides information about identifying common problems, maintaining your autopilot system and obtaining product support: fault finding all raymarine products are designed to provide many years of trouble-free operation. We also put them through comprehensi...

Page 32: General Maintenance

30 general maintenance wheel drive routine maintenance after each trip, flush inside the drive unit by inserting a hose pipe in the free slot on the back cover. The autopilot will not ‘talk’ to other seatalk instruments cabling problem – make sure all the cables are connected properly. Position info...

Page 33: Cleaning The Wheel Drive

31 cleaning the wheel drive caution: do not use mineral-based solvents (such as wd40) to lubricate or clean the wheel drive as they will damage the material. We recommend that you complete the following steps each season to prevent the build-up of salt on the wheel drive bearings and drive belt: 1. ...

Page 34: Replacing The Belt

3 2 this procedure is usually sufficient to correct a slipping or dragging drive belt. In some cases, however, you may need to repeat the steps to adjust the clutch further. Replacing the belt the drive belt is designed to be user serviceable. If there is insufficient adjustment to cure a slipping c...

Page 35: Control Unit

3 3 control unit routine checks the control unit is a sealed unit. As a result, user maintenance is limited to the following routine checks: • make sure all cable connectors are firmly attached • examine the cables for signs of wear or damage – replace any damaged cables cleaning the display caution...

Page 36: 4.3 Product Support

3 4 minimum interaction between different items of equipment, i.E. Ensure optimum electromagnetic compatibility (emc). • always report any emc-related problems to your nearest raymarine dealer. We use such information to improve our quality standards. • in some installations, it may not be possible ...

Page 37

81131_8.Book page 76 thursday, october 7, 2004 11:03 am 3 5.

Page 38

User notes 81176_4.Fm page 22 tuesday, april 18, 2006 9:26 am.

Page 39

User notes 81176_4.Fm page 22 tuesday, april 18, 2006 9:26 am.

Page 40: Www.Raymarine.Com

Www.Raymarine.Com.