- DL manuals

- Rayne

- Water Filtration Systems

- RayneClear

- Installation, Operation & Service Manual

Rayne RayneClear Installation, Operation & Service Manual

IMPORTANT NOTICES:

This reverse osmosis system contains replaceable treatment components critical for effective performance. It is the user’s

responsibility to, and the manufacturer strongly recommends that the user, periodically test the product water to verify the

system is performing satisfactorily.

DO NOT USE WITH WATER THAT IS MICROBIOLOGICALLY UNSAFE OR OF UNKNOWN QUALITY, WITHOUT

ADEQUATE DISINFECTION BEFORE OR AFTER THE SYSTEM.

R.O. DRINKING WATER SYSTEM

MODEL

INSTALLATION, OPERATION & SERVICE MANUAL

Summary of RayneClear

Page 1

Important notices: this reverse osmosis system contains replaceable treatment components critical for effective performance. It is the user’s responsibility to, and the manufacturer strongly recommends that the user, periodically test the product water to verify the system is performing satisfactori...

Page 2

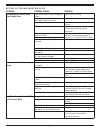

Table of contents page section i. Introduction ........................................................................................... 1 section ii. Specifications .......................................................................................... 3 section iii. Preparation .................

Page 3

Section i. Introduction your new reverse osmosis (ro) drinking water system uses a combination of filtration technologies to reduce unwanted contaminants in a water supply. The following steps combine to give you the best in clear sparkling drinking water: mechanical filtration–the sediment prefilte...

Page 4

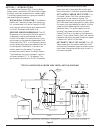

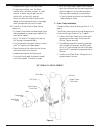

2 optional rayneclear basement installation diagram holding tank shutoff valve (open position) drinking water holding tank dispensing faucet reverse osmosis membrane housing activated carbon post filter housing sediment prefilter housing product (3/8" blue) drain (1/4" black) ro manifold cover inlet...

Page 5

3 section ii. Specifications table a – qualified system performance because the performance of an ro membrane is highly dependent upon pressure, temperature, and tds, the following should be used for comparison purposes only. U.S. Metric membrane production 1 14 ± 2 gpd 45-60 lpd membrane tds reduct...

Page 6

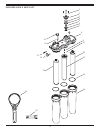

Section iii.Preparation a. Major system components the following components comprise the ro drinking water system. (refer to fig. 1, page 1 for general system layout.) 1. An ro manifold assembly. 2. Housings and housing o–rings. 3. A drinking water holding tank. 4. A dispensing faucet. 5. A feed wat...

Page 7

Prevent a high pressure drop. Remember, these tanks can weigh up to 30 pounds when full of water; a firm, level area is required. 3. Ro manifold assembly–the manifold can be installed on either the right or left side of the under–sink area or a cabinet. The right side is recommended because the tubi...

Page 8

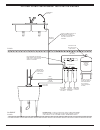

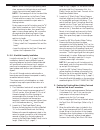

Long reach air gap faucet with 3/8" connector spout plastic shipping plug (remove) 7/16" stud face plate (escutcheon) mounting surface plastic spacer 7/16" washer 7/16" hex nut 3/8" polytube quick connect fitting 3/8" blue polytube cl slotted washer air gap window critical level line reject outlet f...

Page 9

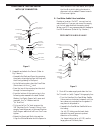

•assemble and tighten the brass screw. •to pierce the tubing, turn the valve handle fully clockwise (inward). A small amount of water may escape from the outlet until you are fully pierced. When you feel the valve handle firmly seated in the clockwise direction, the copper tube is pierced and the va...

Page 10

Note: when cutting the polytubing make clean, square cuts, failing to do so could result in poor connections and possible leaks. Note: the lowest point of the line should be the point of connection to the drain clamp. There should be no sag in the line as this may cause excessive noise as the reject...

Page 11

4. Locate the 3/8" yellow tubing which is attached to the elbow on top of the manifold and run the tubing along its course to the tank and trim to length. Insert the tubing into the holding tank shut–off valve fitting. Make sure the tubing is pressed all the way in past the o–ring. The fitting will ...

Page 12

Section v. Operation & maintenance a. Normal operation 1. It is normal for the total dissolved solids (tds) of the water to be higher than normal during the first 5 gallons of operation, this is due to the sanitizing solution and the new post filter. After this water is rinsed to drain, the removal ...

Page 13

11 •disconnect the yellow product water tubing that runs from the holding tank to the manifold (see fig. 1, page 1). Put 50 drops of bleach (this is ½ tsp. Or 3 ml) into the tubing and reconnect it. •slowly open the feed water saddle valve. When water begins dripping out of the dispensing faucet, in...

Page 14

C. Net pressure differential most r.O. Membranes are rated at a standardized condition of 77°f (25°c) and 65 psig (450kpa) discharging to atmospheric pressure. Product water quality and quantity greatly depend upon the net pressure differential ( ∆ p) across the r.O. Membrane. This pressure differen...

Page 15

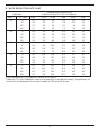

13 d. Water production rate chart estimated water production rate feed water in gallons per day (gpd) for line pressure of: temp.(°f) tds * (ppm) 40 psi 50 psi 60 psi 70 psi 80 psi 90 psi 50 50 5.0 6.5 8.0 9.5 11.0 12.6 500 4.3 5.8 7.3 8.8 10.4 11.9 1000 3.5 5.0 6.6 8.1 9.6 11.1 1500 2.7 4.3 5.8 7.3...

Page 16

Section vii. Trouble shooting guide problem possible cause solution open valve or unclog. Replace filters. Feed water pressure must be above 40 psig. See feed water operating limits. Correct cause of fouling, replace membrane. Empty water from holding tank, and with the faucet open, adjust air press...

Page 17

Correct plumbing. Clear or replace drain restrictor. Clear or replace air gap faucet.. Repair or replace the aso valve components. Flush with several full tanks of product water. An increase in feed water tds will give a corresponding increase in product water tds. Replace filter. Clean, flush and s...

Page 18

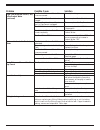

Made in usa 16 1 2 3 4 5 6 7 8 9 10 11 12 13 14 18 19 20 exploded view & parts list 16 17 15 15.

Page 19

17 drawing no. Part no. Description 1 ..................... S2009 .................................... Self tapping screw 2 ..................... S2005 .................................... Aso cap 3 ..................... S2013 .................................... Aso cap o–ring 4 ......................

Page 20

Form no. S1248-rc1 updated 11/01 rayne corporation 3775 market street, suite 201 ventura, ca 93003 phone (805) 676-3090 r.O. Drinking water system five/one year limited warranty what does this warranty cover? This warranty covers any defects in materials and workmanship of the rayne ® r.O. Drinking ...