- DL manuals

- Raynor

- Garage Door Opener

- 3270RGD

- Owner's Manual

Raynor 3270RGD Owner's Manual

Raynor Garage Doors

1101 E. River Road

Dixon, Illinois 61021

www.raynor.com

GARAGE DOOR OPENER

Model 3280RGDM 1/2 HP

For Residential Use Only

Owner’s Manual

■ Please read this manual and the enclosed safety materials carefully!

■ Fasten the manual near the garage door after installation.

■ The door WILL NOT CLOSE unless the Protector System

®

is connected and properly aligned.

■ Periodic checks of the opener are required to ensure safe operation.

■ The model number label is located under the light lens on the front panel of your opener.

™

Summary of 3270RGD

Page 1

Raynor garage doors 1101 e. River road dixon, illinois 61021 www.Raynor.Com garage door opener model 3280rgdm 1/2 hp for residential use only owner’s manual ■ please read this manual and the enclosed safety materials carefully! ■ fasten the manual near the garage door after installation. ■ the door ...

Page 2: Table of Contents

2 introduction 2-5 safety symbol and signal word review . . . . . . . . . . . . . . . 2 preparing your garage door . . . . . . . . . . . . . . . . . . . . . . . 3 tools needed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 planning . . . . . . . . . . . . . . . . . . . . . . ...

Page 3

3 to prevent damage to garage door and opener: • always disable locks before installing and operating the opener. • only operate garage door opener at 120v, 60 hz to avoid malfunction and damage. To prevent possible serious injury or death: • always call a trained door systems technician if garage d...

Page 4

4 one-piece door without track planning identify the type and height of your garage door. Survey your garage area to see if any of the conditions below apply to your installation. Additional materials may be required. You may fi nd it helpful to refer back to this page and the accompanying illustrati...

Page 5

5 carton inventory installation hardware hex bolt 5/16"-18x7/8" (4) lag screw 5/16"-9x1-5/8" (2) lag screw 5/16"-18x1-7/8" (2) clevis pin 5/16"x2-3/4" (1) clevis pin 5/16"x1-1/4" (1) clevis pin 5/16"x1" (1) nut 5/16"-18 (4) lock washer 5/16" (4) screw 6abx1-1/4" (2) screw 6-32x1" (2) self-threading ...

Page 6: Assembly Step 1

6 assembly step 1 attach the rail to the motor unit to avoid installation diffi culties, do not run the garage door opener until instructed to do so. • remove the bolt and lock nut from the top of the motor unit. • place rail onto the bolt mounted on the motor unit and align the back hole with the ho...

Page 7: Warning

7 important installation instructions warning warning warning warning to reduce the risk of severe injury or death: installation 1. Read and follow all installation warnings and instructions. 2. Install garage door opener only on properly balanced and lubricated garage door. An improperly balanced d...

Page 8: Installation Step 1

8 installation procedures vary according to garage door types. Follow the instructions which apply to your door. 1. Close the door and mark the inside vertical centerline of the garage door. 2. Extend the line onto the header wall above the door. You can fasten the header bracket within 4 feet (1.21...

Page 9: Installation Step 2

9 installation step 2 install the header bracket you can attach the header bracket either to the wall above the garage door, or to the ceiling. Follow the instructions which will work best for your particular requirements. Do not install the header bracket over drywall. If installing into masonry, u...

Page 10: Installation Step 3

10 installation step 3 attach the rail to the header bracket • position the opener on the garage fl oor below the header bracket. Use packing material as a protective base. Note: if the door spring is in the way you’ll need help. Have someone hold the opener securely on a temporary support to allow t...

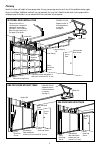

Page 11: Installation Step 5

11 installation step 5 hang the opener three representative installations are shown. Yours may be different. Hanging brackets should be angled (figure 1) to provide rigid support. On fi nished ceilings (figure 2 and figure 3), attach a sturdy metal bracket to structural supports before installing the...

Page 12: Installation Step 6

12 to prevent possible serious injury or death from electrocution: • be sure power is not connected before installing door control. • connect only to 24 volt low voltage wires. To prevent possible serious injury or death from a closing garage door: • install door control within sight of garage door,...

Page 13: Installation Step 7

13 installation step 7 install the light • press the release tabs on both sides of lens. Gently rotate lens back and downward until the lens hinge is in the fully open position. Do not remove the lens. • install a 100 watt maximum light bulb in each socket. Light bulb size should be a19, standard ne...

Page 14: Installation Step 9

14 installation step 9 electrical requirements to avoid installation diffi culties, do not run the opener at this time. To reduce the risk of electric shock, your garage door opener has a grounding type plug with a third grounding pin. This plug will only fi t into a grounding type outlet. If the plug...

Page 15: Installation Step 10

15 facing the door from inside the garage installation step 10 install the protector system ® the safety reversing sensor must be connected and aligned correctly before the garage door opener will move in the down direction. Important information about the safety reversing sensor when properly conne...

Page 16

16 installing the brackets be sure power to the opener is disconnected. Install and align the brackets so the sensors will face each other across the garage door, with the beam no higher than 6" (15 cm) above the fl oor. They may be installed in one of three ways, as follows. Garage door track instal...

Page 17

17 figure 5 figure 6 figure 7 figure 9 figure 8 safety reversing sensor wires not provided pre-installed wires pre-installed wires 7/16" (11 mm) 7/16" (11 mm) safety reversing sensor wires wing nut 1/4"-20 carriage bolt 1/4"-20x1/2" lens mounting and wiring the safety reversing sensors mounting: • s...

Page 18

18 connect to garage door opener: • strip 7/16" (11 mm) of insulation from each set of wires. Separate white and white/black wires suffi ciently to connect to the opener quick-connect terminals. Twist like colored wires together. Insert wires into quick-connect holes: white to white and white/black t...

Page 19: Installation Step 11

19 fiberglass, aluminum or lightweight steel garage doors will require reinforcement before installation of door bracket. Contact your door manufacturer for reinforcement kit. Installation step 11 fasten the door bracket follow instructions which apply to your door type as illustrated below or on th...

Page 20

20 one-piece doors please read and comply with the warnings and reinforcement instructions on the previous page. They apply to one-piece doors also. • center the door bracket on the top of the door, in line with the header bracket as shown. Mark either the left and right, or the top and bottom holes...

Page 21: Installation Step 12

21 straight door arm curved door arm (groove facing out) straight door arm curved door arm incorrect correct installation step 12 connect door arm to trolley follow instructions which apply to your door type as illustrated below and on the following page. Sectional doors only • make sure garage door...

Page 22

22 all one-piece doors 1. Assemble the door arm, figure 5: important: the groove on the straight door arm must face away from the curved door arm. • fasten the straight and curved door arm sections together to the longest possible length (with a 2 or 3 hole overlap). • with the door closed, connect ...

Page 23: Adjustment Step 1

23 adjustment step 1 adjust the up and down travel limits limit adjustment settings regulate the points at which the door will stop when moving up or down. To operate the opener, press the door control push bar. Run the opener through a complete travel cycle. • does the door open and close completel...

Page 24: Adjustment Step 2

24 adjustment step 2 adjust the force force adjustment controls are located on the back panel of the motor unit. Force adjustment settings regulate the amount of power required to open and close the door. If the forces are set too light, door travel may be interrupted by nuisance reversals in the do...

Page 25: Adjustment Step 3

25 adjustment step 3 test the safety reversal system test • with the door fully open, place a 1-1/2" (3.8 cm) board (or a 2x4 laid fl at) on the fl oor, centered under the garage door. • operate the door in the down direction. The door must reverse on striking the obstruction. Adjust • if the door sto...

Page 26: Operation

26 important safety instructions using your garage door opener your s afety s ignal ™ opener and hand-held remote control have been factory-set to a matching code which changes with each use, randomly accessing over 100 billion new codes. Your opener will operate with up to eight s afety s ignal ™ r...

Page 27

27 the door should be fully closed if possible. Pull down on the emergency release handle and lift the door manually. To reconnect the door to the opener, press the door control push bar. The lockout feature prevents the trolley from reconnecting automatically. Pull the emergency release handle down...

Page 28

28 care of your opener limit and force adjustments: weather conditions may cause some minor changes in door operation requiring some re-adjustments, particularly during the fi rst year of operation. Pages 23 and 24 refer to the limit and force adjustments. Only a screwdriver is required. Follow the i...

Page 29

29 having a problem? 1. My door will not close and the light bulbs blink on my motor unit: the safety reversing sensor must be connected and aligned correctly before the garage door opener will move in the down direction. • verify the safety sensors are properly installed, aligned and free of any ob...

Page 30

30 your garage door opener is programmed with self-diagnostic capabilities. The “learn” button/diagnostic led will fl ash a number of times then pause signifying it has found a potential issue. Consult diagnostic chart below. Diagnostic chart 1 flash 5 flashes 3 flashes 2 flashes 6 flashes 4 flashes ...

Page 31: Programming

31 to add or reprogram a hand-held remote control using the “learn” button using the multi-function door control programming your garage door opener has already been programmed at the factory to operate with your hand-held remote control. The door will open and close when you press the large push bu...

Page 32

32 to add, reprogram or change a keyless entry pin note: your new keyless entry must be programmed to operate your garage door opener. Using the multi-function door control using the “learn” button 1. Press and release the “learn” button on motor unit. The learn indicator light will glow steadily fo...

Page 33: Repair Parts

33 repair parts installation parts rail assembly parts key no. Part no. Description 1 4a1008 master link kit 2 41b5424 belt pulley bracket 3 41b3869-3a complete trolley assembly 4 2777bd 2778bd 2770bd one-piece rail 7' (2.1 m) one-piece rail 8' (2.4 m) one-piece rail 10' (3 m) 5 41a5434-11 full belt...

Page 34

34 motor unit assembly parts key no. Part no. Description 1 41a4371 belt cap retainer 2 41a4885-5 gear and sprocket assy, complete with: spring washer; thrust washer; retaining ring; bearing plate; roll pins (2); drive gear and worm gear; helical gear w/retainer and grease 3 41a2817 drive/worm gear ...

Page 35: Accessories

35 accessories 59lm outside keylock: opens the garage door automatically from outside when remote control is not handy. 97lm extension brackets: (optional) for safety sensor installation onto the wall or fl oor. 1702lm outside quick release: required for a garage with no access door. Enables homeowne...

Page 36: How to Order

How to order repair parts selling prices will be furnished on request or parts will be shipped at prevailing prices and you will be billed accordingly. When ordering repair parts, always give the following information: • part number • part name • model number address orders to: raynor garage doors t...