- DL manuals

- Raynor

- Garage Door Opener

- MH5011ULCHB

- Installation Manual

Raynor MH5011ULCHB Installation Manual

MEDIUM DUTY DOOR OPERATOR

MODELS

MJ5011UCHB, MH5011URCHB, & MH5011ULCHB

INSTALLATION MANUAL

NOT FOR RESIDENTIAL USE

Now with

Built in

Radio Receiver

315 MHz

Now with

Built in

Radio Receiver

315 MHz

Your model may look different than the model illustrated in this manual.

INTENDED FOR PROFESSIONAL

INSTALLATION ONLY.

Visit www.Raynor.com to locate a

professional installing dealer in your area.

Serial #

(located on electrical box cover)

Installation Date

2 YEAR WARRANTY

OPERATOR RATING: 12 cycles per hour,

50 cycles per day; maximum.

Summary of MH5011ULCHB

Page 1

Medium duty door operator models mj5011uchb, mh5011urchb, & mh5011ulchb installation manual not for residential use now with built in radio receiver 315 mhz now with built in radio receiver 315 mhz your model may look different than the model illustrated in this manual. Intended for professional ins...

Page 2: Table of Contents

2 safety information 3 application 4 operator specifications 5-6 weights and dimensions . . . . . . . . . . . . . . . . . . . . . . . . 5 motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 3: Safety Information

3 safety information mechanical electrical warning warning caution important notes: • before attempting to install, operate or maintain the operator, you must read and fully understand this manual and follow all safety instructions. • do not attempt repair or service of your commercial door and gate...

Page 4: Application

4 sectional door rolling door sq. Ft 24 ga. Steel 22 ga. Steel --- 20 ga. Steel 18 ga. Steel 16 ga. Steel aluminum grilles aluminum doors --- 20 ga. Steel insulated --- fiberglass aluminum doors wood doors note: on steel insulated doors, a 24 ga. Back panel is assumed. This operator includes a numbe...

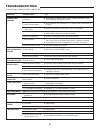

Page 5: Operator Specifications

5 models mh and mj hanging weight: 60-70 lbs. (27.22-31.75 kg) a a a a b b b b 6.34" (16.1 cm) hand chain wheel present with model mh only. 7.19" (18.26 cm) 12.69" (32.23 cm) mounting dimensions a - wall mounting b - bracket mounting (rolling door) 6.34" (16.1 cm) 12.15" (30.86 cm) 15.78" (40.03 cm)...

Page 6: Operator Specifications

6 motor type: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Limited duty horsepower: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2 hp voltage: . . . . . . . . . . . . . . . . . . . . . 115 vac, single phase, 60 hz operator current (amperage): vol...

Page 7: Preparation

7 handing identification for mh model operators with manual hoist hand chain systems, the handing of the operator must be determined at the time of the order. The handing is indicated by last letter of the model name (r or l). The illustration shown is a right-handed operator for models mh and mj se...

Page 8: Typical Installation

8 determine mounting location for operator optimum distance 12"-15" optimum distance 12"-15" the operator may be mounted on the wall, shelf or bracket (not provided, see accessories or door manufacturer). The optimum distance between the door shaft and operator drive shaft is 12-15 inches. Wall moun...

Page 9: Typical Installation

9 wrap drive chain around operator sprocket. Door sprocket electrical box operator drive sprocket drive chain wrap drive chain around door sprocket. Door sprocket drive chain master link typical installation 3 4 door door sprocket key key operator drive sprocket position the operator until chain is ...

Page 10: Typical Installation

10 typical installation install emergency disconnect system floor 2' 4' above floor wrap hand chain around hand chain wheel and through chain guide. Secure chain retaining bracket to wall 4 feet above the floor. Connect the ends of the hand chain. Hand chain hand chain wheel keyhole bracket chain re...

Page 11: Typical Installation

11 power wiring chart typical installation to reduce the risk of severe injury or death: • any maintenance to the operator or in the area near the operator must not be performed until disconnecting the electrical power and locking-out the power. Upon completion of maintenance the area must be cleare...

Page 12: Typical Installation

12 ^ o open st op ^ close typical installation 3-button control station install 3-button control station 5' (1.5 m) ground screws wall ^ o open stop ^ cl ose ^ o open stop ^ close knockout conduit power control hot neutral ground line power 115 vac single phase attach power and ground wires to termi...

Page 13: Typical Installation

13 power d14 com intrlk stop led open close ttc learn 1 lmep1 lmep2 2 3 4 5 6 7 stop close open r27 ^ open ^ close o stop aux ant ^^^^ aux ant aux ant d14 com intrlk stop led open close ttc learn 1 lmep1 lmep2 2 3 4 5 6 7 stop close open logic board remove factory jumper if external interlock is use...

Page 14: Typical Installation

14 option b locate the wire antenna on the outside of the electrical box. Cut wire ties and discard standoff. Attach the antenna to the electrical box using the wire tie holes. Bend antenna across the front of the electrical box, ensuring that the antenna is 4 inches away from the front of the elect...

Page 15: Adjustment

15 a b clutch nut to loosen to tighten apply power to operator. Adjust the limits depress retaining plate. Adjust open limit. Adjust close limit. Retaining plate decrease door travel increase door travel open limit switch open limit nut close limit switch close limit nut safety limit switch decrease...

Page 16: Warning

16 to prevent possible serious injury or death from a closing door: • be sure power is not connected to the door operator before installing the photoelectric sensor. • the door must be in the fully opened or closed position before installing the liftmaster monitored entrapment protection device. To ...

Page 17: Entrapment Protection

17 mounting bracket with square holes #10-32x3/8" screws “c” wrap 10-32 ock nuts mounting bracket with square holes “c” wrap #10-32x3/8" screws #10-32 lock nuts “c” wrap inside wall mounting bracket with square holes mounting bracket with slot sensor with wire indicator light floor floor indicator l...

Page 18: Entrapment Protection

18 ^^^^ x ant ant d14 com intrlk stop led open close ttc learn 1 lmep1 lmep2 2 3 45 67 st op close open primary installation: cps-u photoelectric sensors (provided) (white) (white/black) note: when installing model cps-un4, connect the brown wire to terminal 1 and the blue wire to terminal 2. Entrap...

Page 19: Logic Board Layout

19 aux ant ^^^^ aux ant d14 com intrlk stop led open close ttc learn 1 lmep1 lmep2 2 3 4 5 6 7 stop close open logic board layout 5 10 9 8 7 6 4 3 2 1 item description function 1 open button open door 2 close button close door 3 stop button stop door 4 learn button programs the remote controls and p...

Page 20: Basic Programming

20 determine the wiring type the functionality of this operator is based on the wiring type. The operator is shipped from the factory in standard c2 wiring type (factory default). Liftmaster monitored entrapment protection (lmep) device is required. A liftmaster entrapment protection (lmep) device i...

Page 21: Basic Programming

21 photoelectric sensor alternate installation: c2 wiring type with monitored entrapment protection device • momentary contact to open and stop with constant pressure to close. • open override that reverses when closing by any opening device. • wiring for entrapment protection device to reverse. Not...

Page 22: Basic Programming

22 d14 com intrlk stop led open close ttc learn 1 lmep1 lmep2 2 3 45 67 st op close open r27 press and release the ttc button. D14 com intrlk stop led open close ttc learn 1 lmep1 lmep2 2 3 45 67 st op close open r27 aux ant ^^^^ aux ant aux ant d14 com intrlk stop led open close ttc learn 1 lmep1 l...

Page 23: Basic Programming

23 d14 com intrlk stop led open close ttc learn 1 lmep1 lmep2 2 3 45 67 st op close open r27 aux ant ^^^^ aux ant aux ant d14 com intrlk stop led open close ttc learn 1 lmep1 lmep2 2 3 45 6 7 st op close o pen press and release the learn button (led will light). Requires b2 wiring type and compatibl...

Page 24: Warning

24 to prevent possible serious injury from a moving chain: • disconnect electric power to the operator before manually operating your door. • if possible, use emergency disconnect only when door is closed. Weak or broken springs or unbalanced door could result in an open door falling rapidly and/or ...

Page 25: Troubleshooting

25 condition possible cause fix operator will not respond to any commands a) no power ➤ verify primary line voltage (120 vac, 60 hz) is present at terminals l1 & l2. The led will fl ash when power is present. B) stop circuit not complete ➤ verify stop button input (terminals 3 & 5) is properly wired ...

Page 26: Troubleshooting

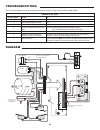

26 ant j2 a ux ant com intrlk stop led open close ttc learn 1 lmep1 lmep2 2 3 45 67 st op close open open close stop brake (optional) capacitor motor interlock open limit switch close limit switch safety limit switch yellow red red brown** grey purple orange grey yellow brown** green yellow the stat...

Page 27: Accessories

27 ^^ open close o stop cps-ei monitored sensing edge interface: requires 4-wire monitored sensing edge. Antenna: external kit for medium duty. Ext-ant medium duty angle mounting bracket: heavy-gauge steel bracket. May be welded. For use with mj, mgj, and mh operators. 10-9095 commercial protector s...

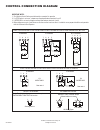

Page 28: Control Connection Diagram

© 2010, the chamberlain group, inc. 01-34221c all rights reserved important notes: 1. The 3-button control station provided must be connected for operation. 2. If a stop button is not used, a jumper must be placed between terminals 3 and 5. 3. If interlock is not used a jumper must be placed between...