- DL manuals

- Raynor

- Garage Door Opener

- Safety signal 3220RGD

- Owner's Manual

Raynor Safety signal 3220RGD Owner's Manual

Raynor Garage Doors

1101 E. River Road

Dixon, Illinois 61021

www.raynor.com

GARAGE DOOR OPENER

Models 3220RGD 1/2 HP

For Residential Use Only

Owner’s Manual

■

Please read this manual and the enclosed safety materials carefully!

■

Fasten the manual near the garage door after installation.

■

The door WILL NOT CLOSE unless the Protector System

®

is connected and

properly aligned.

■

Periodic checks of the opener are required to ensure safe operation.

■

The model number label is located on the front panel of your opener.

TM

Summary of Safety signal 3220RGD

Page 1

Raynor garage doors 1101 e. River road dixon, illinois 61021 www.Raynor.Com garage door opener models 3220rgd 1/2 hp for residential use only owner’s manual ■ please read this manual and the enclosed safety materials carefully! ■ fasten the manual near the garage door after installation. ■ the door ...

Page 2: Warning

2 introduction 2-5 safety symbol and signal word review........................2 preparing your garage door ........................................3 tools needed ...............................................................3 planning ..................................................................

Page 3: Warning

3 to prevent damage to garage door and opener: • always disable locks before installing and operating the opener. • only operate garage door opener at 120v, 60 hz to avoid malfunction and damage. To prevent possible serious injury or death: • always call a trained door systems technician if garage d...

Page 4

Safety reversing sensor horizontal and vertical reinforcement is needed for lightweight garage doors (fiberglass, steel, aluminum, door with glass panels, etc.). See page 19 for details. Finished ceiling support bracket & fastening hardware is required. See page 15. — — — — — — — — header wall safet...

Page 5

5 straight door arm section curved door arm section safety labels and literature header bracket up ce ilin g m ou nt o nl y 2 conductor bell wire white & white/red remote control transmitter visor clip door bracket multi-function door control panel lock light (2) safety reversing sensors (1 sending ...

Page 6

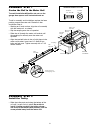

6 assembly step 1 fasten the rail to the motor unit to avoid installation difficulties, do not run the garage door opener until instructed to do so. To aid in assembly and installation, replace the foam packing around the motor unit. Remove it after installation step 4. • working on a level surface,...

Page 7: Warning

7 assembly step 3 attach the rail brackets • align rail brackets to end of rail assembly, as shown. • insert two 1/4"-20 x 5/8" hex bolts and lock nuts. Tighten securely with a 7/16" socket. You have now finished assembling your garage door opener. Please read the following warnings before proceedin...

Page 8: Warning

8 installation step 1 determine the header bracket location installation procedures vary according to garage door types. Follow the instructions which apply to your door. 1. Close the door and mark the inside vertical centerline of the garage door. 2. Extend the line onto the header wall above the d...

Page 9

9 installation step 2 install the header bracket you can attach the header bracket either to the wall above the garage door, or to the ceiling. Follow the instructions which will work best for your particular requirements. Do not install the header bracket over drywall. If installing into masonry, u...

Page 10

10 clevis pin 5/16"x2-3/4" ring fastener installation step 3 attach the rail to the header bracket • position the opener on the garage floor below the header bracket. Use packing material as a protective base. Note: if the door spring is in the way you’ll need help. Have someone hold the opener secu...

Page 11: Warning

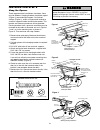

11 invisible light beam protection area sensor beam 6" (15 cm) max. Above floor sensor beam 6" (15 cm) max. Above floor facing the door from inside the garage installation step 4 install the protector system ® the safety reversing sensor must be connected and aligned correctly before the garage door...

Page 12

12 door track mount (right side) indicator light lens lip sensor bracket door track floor mount (right side) wall mount (right side) indicator light sensor bracket lens extension bracket (see accessories) inside garage wall (provided with extension bracket) (provided with extension bracket) figure 1...

Page 13

13 carriage bolt 1/4"-20x1/2" lens wing nut 1/4"-20 figure 5 mounting and wiring the safety sensors • slide a 1/4"-20x1/2" carriage bolt head into the slot on each sensor. Use wing nuts to fasten sensors to brackets, with lenses pointing toward each other across the door. Be sure the lens is not obs...

Page 14: Warning

14 one-piece door without track a 2x4 on its side is convenient for setting an ideal door-to-rail distance. • remove foam packaging. • raise the opener onto a stepladder. You will need help at this point if the ladder is not tall enough. • open the door all the way and place a 2x4 on its side on the...

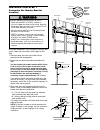

Page 15: Warning

15 installation step 6 hang the opener three representative installations are shown. Yours may be different. Hanging brackets should be angled (figure 1) to provide rigid support. On finished ceilings (figure 2), attach a sturdy metal bracket to structural supports before installing the opener. This...

Page 16: Warning

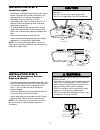

To release wire, push in tab with screwdriver tip door control connections red grey white strip wire 7/16" (11 mm) 7/16" (11 mm) 16 installation step 7 install the door control locate door control within sight of the door at a minimum height of 5 feet (1.5 m) where small children cannot reach, and a...

Page 17: Warning

17 installation step 8 install the lights • install up to a 100 watt maximum light bulb in each socket. The lights will turn on and remain lit for approximately 4-1/2 minutes when power is connected. Then the lights will turn off. • insert bottom lens tabs into slots on chassis. Tilt towards chassis...

Page 18: Warning

18 installation step 10 electrical requirements to avoid installation difficulties, do not run the opener at this time. To reduce the risk of electric shock, your garage door opener has a grounding type plug with a third grounding pin. This plug will only fit into a grounding type outlet. If the plu...

Page 19: Warning

19 installation step 12 fasten the door bracket follow instructions which apply to your door type as illustrated below or on the following page. A horizontal reinforcement brace should be long enough to be secured to two or three vertical supports. A vertical reinforcement brace should cover the hei...

Page 20

20 header wall vertical centerline of garage door finished ceiling optional placement of door bracket header bracket door bracket 2x4 support for a door with no exposed framing, or for the optional installation, use lag screws 5/16"x1-1/2" (not provided) to fasten door bracket. Metal door top of doo...

Page 21

21 installation step 13 connect door arm to trolley follow instructions which apply to your door type as illustrated below and on the following page. Sectional doors only • make sure garage door is fully closed. Pull the emergency release handle to disconnect the outer trolley from the inner trolley...

Page 22

22 all one-piece doors 1. Assemble the door arm, figure 4: • fasten the straight and curved door arm sections together to the longest possible length (with a 2 or 3 hole overlap). • with the door closed, connect the straight door arm section to the door bracket with the 5/16"x1-1/4" clevis pin. • se...

Page 23: Warning

23 adjustment step 1 adjust the up and down travel limits limit adjustment settings regulate the points at which the door will stop when moving up or down. To operate the opener, press the door control push bar. Run the opener through a complete travel cycle. • does the door open and close completel...

Page 24: Warning

Adjustment step 2 adjust the force force adjustment controls are located on the back panel of the motor unit. Force adjustment settings regulate the amount of power required to open and close the door. If the forces are set too light, door travel may be interrupted by nuisance reversals in the down ...

Page 25: Warning

Without a properly installed safety reversal system, persons (particularly small children) could be seriously injured or killed by a closing garage door. • safety reversal system must be tested every month. • if one control (force or travel limits) is adjusted, the other control may also need adjust...

Page 26: Warning

Operation 26 important safety instructions to reduce the risk of severe injury or death: using your garage door opener your s afety s ignal™ opener and hand-held remote control have been factory-set to a matching code which changes with each use, randomly accessing over 100 billion new codes. Your o...

Page 27: Warning

B) to operate one door using all three buttons on the hand-held remote: you may program the remote to open the door with the large button, close it with the middle button, and stop the door’s movement with the third button. Note: if remote is already programmed, you must first erase all codes. See p...

Page 28: Warning

The remote control battery the lithium battery should produce power for up to 5 years. To replace battery, use the visor clip or screwdriver blade to pry open the case as shown. Insert battery positive side up (+). Dispose of old battery properly. Care of your opener limit and force adjustments: wea...

Page 29

29 having a problem? 1. My door will not close and the light bulbs blink on my motor unit: the safety reversing sensor must be connected and aligned correctly before the garage door opener will move in the down direction. • verify the safety sensors are properly installed, aligned and free of any ob...

Page 30

30 installed safety sensor — — — — — — — — led or diagnostic led "learn" button diagnostics located on motor unit your garage door opener is programmed with self-diagnostic capabilities. The “learn” button/diagnostic led will flash a number of times then pause signifying it has found a potential iss...

Page 31

*3-button remotes if provided with your garage door opener, the large button is factory programmed to operate it. Additional buttons on any s afety s ignal™ 3-button remote or mini-remote can be programmed to operate other s afety s ignal™ garage door openers. To erase all codes from motor unit memo...

Page 32

1. Enter a four digit personal identification number (pin) of your choice on the keypad. Then press and hold enter. 2. While holding the enter button, press and hold the light button on the multi-function door control. 3. Continue holding the enter and light buttons while you press the push bar on t...

Page 33

7 6 notic e 11 4 up ce ili ng m ou nt o nl y 8 12 5 1 9 10 lock light 2 3 key part no. No. Description 1 41a5273-6 multi-function door control 2 373rgd 3-button remote control 3 10a20 3v 2032 lithium battery (1 required) 4 29b137 visor clip 5 41a5047 door bracket w/clevis pin & fastener 6 41a2828 em...

Page 34

Motor unit assembly parts dn up brown wire (down) contact limit switch assy. Grey wire yellow wire (up) contact center limit contact drive gear 2 1 3 4 5 6 7 8 8a 8b 8c 9 10 11 11a 11 12 13 14 15 16 17 8d 8d 8e 8f 8g 18 34 key part no. No. Description 1 31d477 drive shaft cover 2 41b4245 line cord 3...

Page 35

35 accessories lock light 374rgd 88sd 1702lm outside quick release: required for a garage with no access door. Enables homeowner to open garage door manually from outside by disengaging trolley. 8 foot (2.4 m) complete rail: to allow an 8 foot (2.4 m) door to open fully. Extension brackets: (optiona...

Page 36: Raynor Garage Doors

© 2006, the chamberlain group, inc. 114a3078c all rights reserved raynor garage doors service is on call our large service organization spans america installation and service information is as near as your telephone five days a week. Simply dial our toll free number: 1-800-472-9667 hours: (central s...