Electronic boiler sequencer & outdoor reset controller installation and operating instructions catalog no: 5000.54h effective: 06-19-07 replaces: 02-01-04 pn 240692 rev. 9.

Y–series electronic boiler control installation and operating instructions is a registered trademark of underwriters laboratories inc.® is a registered trademark of underwriters laboratories-canada inc. ® before operating this product, please read these instructions completely. 2.

Table of contents contents page basics 4 important safety instructions 4 introduction 5 concept of operation 5 optional configurations 5 control features 6 installation and mounting 7 mechanical installation 7 electrical installation 7 wiring: power to controller 8 air temperature sensor 9 water tem...

Basics contents item quantity y–series boiler control, installed on boiler(s) as ordered outdoor temperature sensor assembly 1 water temperature sensor assembly 1 optional equipment as ordered check packaging for damaged or missing components. Important safety instructions important notice: these in...

Thank you for selecting the raypak y–series electronic boiler control. It is our sincere hope that you will enjoy its outstanding design, ease of use and energy saving features. Introduction the y-series electronic boiler control (controller) is a microprocessor-based energy management system design...

Control features the y-series sequence panel includes: • standard indicator lights: stages 1 to 8: red, indicates which stages are turned on. Pump: green, indicates that the pump circuit is energized. Call for heat: green, indicates that a call for heat signal is present. Control on: green, indicate...

7 installation and mounting if the y–series electronic boiler control was not mounted on the boiler by the factory, care should be taken to select a suitable mounting location. The control should be mounted on a solid and permanent base. The control enclosure is nema 3r rated, rainproof and sleet re...

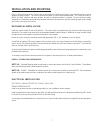

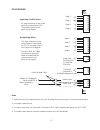

Circuit breaker white ground black green a b c volt-ohm meter check your power source using a volt-ohm meter, check the following voltages at the circuit breaker panel: ac = 108 volts ac minimum, 132 volts max ab = 108 volts ac minimum, 132 volts max bc = must be less than 1.0 volts ac wiring: power...

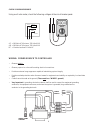

Air temperature sensor fig. #9040 outdoor air temperature sensor outdoor air temperature sensor installation notes: • locate the sensor on the coldest side of building, usually the north or west side. • install the sensor in a shaded area, out of direct sunlight. • locate no higher than 2/3 up the s...

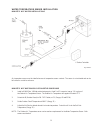

Water temperature sensor installation hydronic installations fig. #9496 typical water sensor • the water sensor should be installed in the system supply. • locate the water temperature sensor in the system piping just prior to the first boiler connections, on the upstream side of the system supply l...

Air temperature sensor must be installed across air temperature sensor contacts. The sensor is not activated and can be left stored in controller enclosure. 11 domestic hot water application setup procedure 1. Install a 10,000 ohm, 1/8 watt resistor between pins 1 and 2 on p2 connector (see pg. 13),...

12 1. Install the air temperature sensor across the air temperature sensor contacts (p2, pins 1 and 2; see the field wiring diagram on pg. 13). 2. On the mode selector switch (s3), set switch #2 (outdoor reset) to on to disable the outdoor reset function. (see pg.S 15 and 23). 3. Set the outdoor cut...

Field wiring single-stage (on/off) boilers - all stage connections on the control board are connected at the {th} (thermostat) location on the boiler wiring diagram. Multiple-stage boilers - first stage connections on the control board are connected at the {th} (thermostat) location on the boiler wi...

Installation verification procedure register before proceeding any further, please verify that the user registration form has been completed and mailed. Mechanical installation verify that the mechanical installation has been completed in accordance with the instructions. Outdoor air temperature sen...

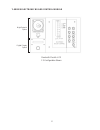

Control familiarization the system is configured using the circuit board jumpers and switches, and the front panel control potentiometers. Open the front cover of the boiler control box for access to the front panel. Remove the front panel to gain access to the jumpers and switches on the y-series e...

16 sequence of operation 1. When the reset is enabled, the y-series control continously monitors outdoor temperature using the outdoor temperature sensor. When the outdoor temperature falls below the outdoor cutoff tempersture, the control becomes active and closes the primary pump relay, energizing...

17 panel with clock & lcd y-5 configuration shown y–series electronic boiler control module night setpoint option digital display option.

Pump call for heat control on setting error sensor error indicator lights stage indicators the pump driver and each of the output stages' drivers has its own led indicator. Each of these leds is lit whenever the corresponding output relay is energized. Pump indicator the pump indicator is illuminate...

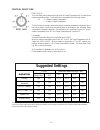

Reset ratio the reset ratio setting determines how much the target temperature will increase as the outdoor temperature drops. The reset ratio is expressed in the following manner: x:y x - change in outdoor temperature y - change in target temperature the first number in the ratio refers to the chan...

Reset ratio chart 20 pump turn-off delay the pump turnoff delay works in conjunction with the outdoor cutoff temperature. The pump turnoff delay sets the delay between the time when the outdoor cutoff temperature is reached and the time when the pump is turned off. The pump turnoff delay is adjustab...

Boiler turn-on delay in a multiple boiler system: the boiler turn-on delay sets the time delay before each additional boiler is turned on in response to a call for heat. This delay starts when the preceding boiler is turned on. The boiler turn-on delay range is from 0 to 5 min. Recommended initial s...

22 maximum water temperature the maximum output temperature is the system output high limit. This potentiometer sets the maximum value the target temperature is allowed to reach regardless of other operational settings or conditions. The maximum water temperature range is from 70°f to 235°f. Recomme...

Circuit board 23 s5 manual bypass switch s4 manual lead/ lag selector switch s2 first stage selector i.D. Maintenance plug test j2 last stage selector jumper s1 system test s3 mode selector.

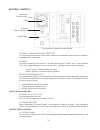

Interior jumper & switches 24 fig # 9242 fig # 9245 fig # 9246 s-3 j-2 the last stage selector jumper (j2) is comprised of an eight (8) position jumper block. A shunt bar jumper is placed in the position corresponding to the last active stage or boiler number. See table below for examples of jumper ...

25 fig # 9244 fig # 9243 fig # 9247 manual lead-lag the lead-lag selector switch (s4) is a ten (10) position rotary switch. Switch positions 0 and 9 are not used. In manual lead-lag selection, the lead-lag selector is used to select the lead boiler (stage). This is normally shipped from the factory ...

26 operational override switch clock alternate setpoint adjustment digital display optional alternate setpoint operation the optional alternate setpoint can be used to establish an independent second set point for setback or temperature boost requirements. Trippers the electro-mechanical timer consi...

3-c 1-c 2-c 1-s 5-s 4-s 6-s 3-s 5-s 2-s 2-n 1-n 27 call out 1-c 2-c 3-c 1-s 2-s 3-s 4-s 5-s 6-s 1-n 2-n description pc board standard pc board w/ night set back programmed eprom programmed eprom w/ night set back transformer door w/window side mount bracket air temperature sensor complete water temp...

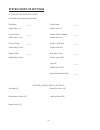

System start-up settings system setting entered on date: front panel control potentiometers (knobs) reset ratio: ______ control band: ______ default value: 1:1 default value: 3°f pump off delay: ______ outdoor cutoff deadband: ______ default value: 3 min. Default value: 3°f boiler on delay: ______ o...

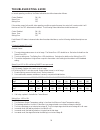

Tem p deg f 40 50 60 70 80 90 100 110 120 res is tance (k) 26.11 19.90 15.31 11.88 9.30 7.33 5.83 4.66 3.76 tem p deg f 130 140 150 160 170 180 190 200 210 res is tance (k) 3.06 2.48 2.04 1.69 1.40 1.17 0.98 0.83 0.70 if all okay, replace y-series boiler contro l bo ard sensor resista nce a t va rio...

Limited warranty b6000, y-series, e-4 & accessories scope of warranty raypak, inc. ("raypak") warrants to the original owner the control system to be free from defects in materials and workmanship under normal use and service for the applicable warranty period. In accordance with the terms of this l...

Raypak, inc., 2151 eastman avenue, oxnard, ca 93030 (805) 278-5300 fax (800) 872-9725 raypak canada limited, 2805 slough st., mississauga, ontario, canada l4t 1g2 (905) 677-7999 fax (905) 677-8036 litho in u.S.A. Www.Raypak.Com.