- DL manuals

- Raypak

- Boiler

- 503-2003

- Installation And Operating Instructions Manual

Raypak 503-2003 Installation And Operating Instructions Manual

CATALOG NO. 3400.53A

Effective: 8-1-06

Replaces: 6-15-06

P/N 241288 Rev 2

INSTALLATION

AND OPERATING

INSTRUCTIONS

Models 503-2003

Types H & WH

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids or other combustible materials in the vicinity of

this or any other appliance. To do so may result in an explosion or fire.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal injury,

exposure to hazardous materials* or loss of life. Review the information in this manual carefully. Installation and

service must be performed by a qualified installer, service agency or the gas supplier.

* This unit contains materials that have been identified as carcinogenic, or possibly carcinogenic, to humans.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

This manual should be maintained in legible condition and kept adjacent to the heater or in a safe place for future

reference.

Summary of 503-2003

Page 1

Catalog no. 3400.53a effective: 8-1-06 replaces: 6-15-06 p/n 241288 rev 2 installation and operating instructions models 503-2003 types h & wh for your safety do not store or use gasoline or other flammable vapors and liquids or other combustible materials in the vicinity of this or any other applia...

Page 3: Table of Contents

1 warnings................................................................2 section a before installation ..............................3 product receipt .......................................................3 model identification ................................................3 ratings and certif...

Page 4: Warnings

2 pay attention to these terms: danger: indicates the presence of immediate hazards which will cause severe personal injury, death or substantial property damage if ignored. Warning: indicates the presence of hazards or unsafe practices which could cause severe personal injury, death or substantial ...

Page 5: Section A

Section c: installation 3 raypak strongly recommends that this manual be re- viewed thoroughly before installing your mvb heater. Please review the general safety information in sec- tion b before installing the heater. Factory warranty does not apply to heaters that have been improperly installed o...

Page 6

Section a: before installation 4 all raypak heaters are national board approved, and design-certified and tested by the canadian standards association (csa) for the u.S. And canada. Each heater is constructed in accordance with section iv of the american society of mechanical engineers (asme) heater...

Page 7: Section B

Section c: installation 5 to meet commercial hot water use needs, the high limit safety control on this water heater is adjustable up to 210°f. However, water temperatures over 125°f can cause instant severe burns or death from scalds. When supplying general purpose hot water, the recommended initia...

Page 8

Section b: general safety 6 time/temperature relationships in scalds the following chart details the relationship of water temperature and time with regard to scald injury and may be used as a guide in determining the safest water temperature for your applications. Water temp. Time to produce seriou...

Page 9: Section C

Section c: installation 7 installation codes installations must follow these codes: • local, state, provincial, and national codes, laws, regulations and ordinances • national fuel gas code, ansi z223.1/nfpa 54 – latest edition (nfgc) • national electrical code, ansi/nfpa 70 - latest edition (nec) •...

Page 10

Section c: installation 8 fig. 5: minimum clearances from vent/air inlet terminations – indoor and outdoor installations u.S. Installations 1 canadian installations 2 a clearance above grade, veranda, porch, deck, or balcony 1 ft (30 cm) 1 ft (30 cm) b clearance to window or door that may be opened ...

Page 11

Section c: installation 9 venting not shown for clarity. Heater must be vented per instructions in this manual fig. 6: minimum clearances from combustible surfaces – indoor and outdoor installations when installed according to the listed minimum clear- ances from combustible construction, these heat...

Page 12

Section c: installation 10 caution: combustion air must not be contaminated by corrosive chemical fumes which can damage the heater and void the warranty. (see section h.) notice: it is recommended that the intake vent be insulated to minimize sweating. Optional construction air filter an optional c...

Page 13

Section c: installation 11 b. Where communicating with the outdoors through horizontal ducts, each opening shall have a minimum free area of 1 in. 2 per 2,000 btuh (1,100 mm 2 per kw) of total input rat- ing of all equipment in the enclosure. 2. One permanent opening, commencing within 12 in. (305 m...

Page 14

Section c: installation 12 relief valve piping warning: pressure relief valve discharge piping must be piped near the floor and close to a drain to eliminate the potential of severe burns. Do not pipe to any area where freezing could occur. Refer to local codes. Hydrostatic test unlike many types of...

Page 15

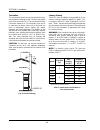

Section c: installation 13 matic valve system, such as a three-way proportional valve or a modulating two-way valve to control the bypass, should be utilized. Fig. 7: cold water start cold water run cold water run differs from cold water start in that the system water entering the heater remains bel...

Page 16

Section c: installation 14 hydronic heating pump selection in order to ensure proper performance of your heater system, you must install a correctly-sized pump. Ray- pak recommends designing for a ∆t within the range of 10°f to 40°f. See table f for acceptable flow rates for each model ( ∆t is the t...

Page 17

Section c: installation 15 fig. 12: single domestic hot water heater and storage tank potable water and space heating caution: when this heater is used for both potable water and space heating, observe the following to en- sure proper operation. 1. All piping materials and components connected to th...

Page 18

Section c: installation 16 to complete the installation of the pool heater, the pool thermostat needs to be installed in the main return wa- ter line, upstream of the heater. This will ensure that the heater will be energized at the right time. Fig. 13: single pool heater application adjustment of t...

Page 19

Section c: installation 17 note: there are 2 separate drains on the mvb that must both be drained to protect the heat exchanger. These are both accessible by removing the lower front door from the heater. Drain any piping of all water that may experience below-freezing temperatures. Pool/spa water c...

Page 20

Section c: installation 18 gas supply connection caution: the heater must be disconnected from the gas supply during any pressure testing of the gas supply system at test pressures in excess of 1/2 psi (3.45 kpa). The heater must be isolated from the gas supply piping system by closing the upstream ...

Page 21

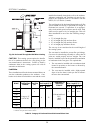

Section c: installation 19 manifold gas pressure (high fire values) model no. Natural gas propane gas 503 -0.1 -0.1 753 -0.1 -0.1 1003 -0.2 -0.2 1253 -0.1 -0.1 1503 -0.4 -0.3 1753 0.4 0.4 2003 0.6 0.6 note: manifold pressures should be + 0.2” wc. Table i: manifold gas pressure settings during normal...

Page 22

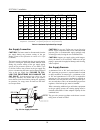

Section c: installation 20 circuit breaker white ground black green a b c fig. 17: wiring connections check the power source: ac = 108 vac minimum, 132 vac max ab = 108 vac minimum, 132 vac max bc = fig. 18: multi-meter making the electrical connections refer to fig. 16-19. 1. Verify that circuit br...

Page 23

Section c: installation 21 venting caution: proper installation of flue venting is criti- cal for the safe and efficient operation of the heater. General appliance categories heaters are divided into four categories based on the pressure produced in the exhaust and the likelihood of condensate produ...

Page 24

Section c: installation 22 vent terminal location notice: during winter months check the vent cap and make sure no blockage occurs from build-up of snow or ice. 1. Condensate can freeze on the vent cap. Frozen condensate on the vent cap can result in a blocked flue condition. 2. Give special attenti...

Page 25

Section c: installation 23 5. Within 6 ft (1.8 m) of any gas service regulator vent outlet. 6. Less than 1 ft (305 mm) above grade level. 7. Within 3 ft (0.9 m) of a window or door which can be opened in any building, any non-mechanical air supply inlet to any building or the combustion air inlet of...

Page 26

Section c: installation 24 termination the vent terminal should be vertical and should termi- nate outside the building at least 2 ft above the highest point of the roof within 10 ft. The vent cap should have a minimum clearance of 4 ft horizontally from and in no case above or below (unless a 4 ft ...

Page 27

Section c: installation 25 fig. 21: typical common venting horizontal through-the-wall direct venting (category iv) fig. 22: horizontal through-the-wall venting fig. 23: alt. Horizontal through-the-wall venting note: while a drain connection is required in the vent of all mvb installations, the drai...

Page 28

Section c: installation 26 fig. 24: horizontal through-the-wall direct venting caution: this venting system requires the installa- tion of a condensate drain in the vent piping per the vent manufacturer’s instructions. Failure to install a condensate drain in the venting system will void all warrant...

Page 29

Section c: installation 27 3. The vent must be insulated through the length of the horizontal run. Termination the flue direct vent cap must be mounted on the ex- terior of the building. The direct vent cap cannot be installed in a well or below grade. The direct vent cap must be installed at least ...

Page 30

Section c: installation 28 outdoor installation outdoor models are self-venting when installed with the optional factory-supplied outdoor vent kit. Addi- tional vent materials are required as outlined in the outdoor vent kit instructions. A special vent cap and air intake elbow are offered in accord...

Page 31

Section c: installation 29 the raypak modulating temperature control is pro- vided to maintain the desired system water temperature. The control has various modes of operation which are listed below. Operating modes mode 1 – setpoint operation using parallel piping. The heater outlet water temperatu...

Page 32

Section c: installation 30 system operation by means of three push buttons (item, ▲,▼). Item advances the display, while ▲,▼are used in the adjust menu. Fig. 27: modulating temperature control user interface all items displayed by the control are organized into two menus, the view menu and the adjus...

Page 33

Section c: installation 31 to make an adjustment to a setting in the control, begin by selecting the “adjust” menu. To change from the view menu to the adjust menu, simultaneously press and hold all three buttons for 1 second. The menu name, “adjust” will be displayed in the menu field. The menu wil...

Page 34

Section c: installation 32 (cfh) of the udb board. In addition, the amber “call-for-heat” led on the front of the heater will illuminate. 14. The pump contact on the modulating temperature control closes sending 24 vac to the pump switch located on the front exterior panel of the heater. 15. When th...

Page 35

Section c: installation 33 pump relay and the blower receives power but does not energize at this time and terminal l1 the ignition module is powered. 3. The 120/24 vac transformer sends a 24 vac hot power signal to the 24v terminal block. 4. 24 vac is sent from the 24v terminal block to pin l1 of t...

Page 36

Section c: installation 34 when the 24 vac signal is sent from the flow switch to p4-9, the same signal then de-energizes the coil of the time delay relay to remove a heat demand from the modulating temperature control and restart the ignition sequence after the five- second time delay. Upon ignitio...

Page 37

Section c: installation 35 fig. 29: ignition module the standard single-try ignition module will lock out after failing to light one time. To reset it, press and release the small, recessed black push button located inside of the cut-out on the lower right-hand corner of the ignition module case. Tu...

Page 38

Section c: installation 36 fig. 32: flow switch modulating temperature control the heater is equipped with a raypak modulating tem- perature control. Refer to information starting on page 28 for information on the setting and use of this control. Fig. 33: modulating temperature control low water cut...

Page 39

Section c: installation 37 fig. 36: air pressure switch blocked vent switch this heater is equipped with a blocked vent pressure switch to prevent the operation of the heater when too much of the vent is blocked. This switch is located on the right side of the heater near the right rear corner. Fig....

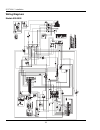

Page 40

Section c: installation 38 wiring diagrams models 503-1503.

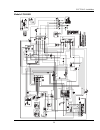

Page 41

Section c: installation 39 models 1753-2003.

Page 42

Section c: installation 40

Page 43: Section D

41 pre start-up filling system (heating boilers) fill system with water. Purge all air from the system. Lower the system pressure. Open valves for normal system operation, and fill system through feed pressure. Manually open air vent on the compression tank until water appears, then close vent. Air ...

Page 44

Section d: start up 42 of the control system and any gas control which has been under water. • check around unit for debris and remove combusti- ble products, i.E. Gasoline, etc. Pre start-up check 1. Verify heater is filled with water. 2. Check system piping for leaks. If found, repair immediately....

Page 45

Section d: start up 43 5. Check blower motor amp draw and the manometer attached to fan pressure switch with the blower running at 100% speed. The reading should be as noted in tables p and q for both natural gas and propane gas. If not, adjust the air shutter on the blower to attain the correct val...

Page 46

Section d: start up 44 safety inspection 1. Check all thermostats and high limit settings. 2. During the following safety checks leave manome- ters hooked up, check and record. 3. If other gas-fired appliances in the room are on the same gas main, check all pressures on the mvb with all other equipm...

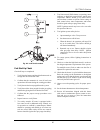

Page 47

Section d: start up 45 fig. 40: leak test procedure post start-up check check off steps as completed: 1. Verify that the heater and heat distribution units or storage tank are filled with water. 2. Confirm that the automatic air vent (if used) was opened two full turns during the venting procedure. ...

Page 48

Section d: start up 46.

Page 49: Section E

Section d: start up 47 lighting instructions 1. Before lighting, make sure you have read all of the safety information in this manual. 2. Remove upper front panel. 3. Set the thermostat to the lowest setting. 4. Turn off all electrical power to the appliance. 5. This appliance is equipped with an ig...

Page 50

Section e: operation 48.

Page 51: Section F

Section d: start up 49 section f troubleshooting step 8 step 7 step 6 step 9 step 1 step 2 step 3 step 4 step 5 is there a call for heat? Is disable connection intact? Does the combustion air blower come on? Is 4-20ma present at the quick disconnects on the black and blue wires of the temperature co...

Page 52

Section f: troubleshooting 50 udb fault history to view the fault codes in the udb history file: 1. Press and hold the switch labeled “sw1” for 5 seconds to access the fault history. Led 17 will begin to flash when the history has been accessed. See fig. 38 on page 37. 2. Press the switch labeled “s...

Page 53: Section G

51 suggested minimum maintenance schedule regular service by a qualified service agency and mainte- nance must be performed to ensure maximum operating efficiency. Maintenance as outlined below may be performed by the owner. Daily 1. Check that the area where the heater is installed is free from com...

Page 54

Section g: maintenance 52 11. Check for piping leaks around pumps, relief valves and other fittings. Repair, if found. Do not use pe- troleum-based stop-leak. Periodically 1. Check relief valve. Refer to manufacturer’s instruc- tions on valve. 2. Test low water cut-off (if equipped). Refer to manu- ...

Page 55: Section H

53 inside air contamination all heaters experience some condensation during start- up. The condensate from flue gas is acidic. Combustion air can be contaminated by certain vapors in the air which raise the acidity of the condensate. Higher acid- ity levels attack many materials including stainless ...

Page 56

Limited parts warranty mvb – types h and wh models 503-2003 scope raypak, inc. (“raypak”) warrants to the original owner that all parts of this heater which are actually manufactured by raypak will be free from failure under normal use and service for the specified warranty periods and subject to th...

Page 57

Notes: _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ ___________...

Page 58: Www.Raypak.Com

Www.Raypak.Com raypak, inc., 2151 eastman avenue, oxnard, ca 93030 (805) 278-5300 fax (805) 278-5468 raypak canada limited, 2805 slough st., mississauga, ontario, canada l4t 1g2 (905) 677-7999 fax (905) 677-8036.