- DL manuals

- Raypak

- Gas Heater

- 84 professional 259

- Installation & operating instructions manual

Raypak 84 professional 259 Installation & operating instructions manual

INSTALLATION & OPERATING

INSTRUCTIONS

84 Professional

Gas-Fired

Pool & Spa

Heater

Catalog No. 6000.65

Effective: 05-17-12

Replaces: NEW

P/N 241464 Rev. 1

WARNING: If these instructions are not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas sup-

plier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

This manual should be maintained in legible condition and kept adjacent to the heater or in a safe place for future

reference.

Lo NOx Models

259 & 409

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

Summary of 84 professional 259

Page 1

Installation & operating instructions 84 professional gas-fired pool & spa heater catalog no. 6000.65 effective: 05-17-12 replaces: new p/n 241464 rev. 1 warning: if these instructions are not followed exactly, a fire or explosion may result causing property damage, personal injury or death. What to...

Page 2

Water chemistry (corrosive water voids all warranties) for your health and the protection of your pool equipment, it is essential that your water be chemically balanced. The following levels must be used as a guide for bal- anced water. Recommended level(s) fiberglass pools fiberglass spas other poo...

Page 3

3 contents 2 water chemistry 4 warnings 4 pay attention to these terms 8 pool & spa water chemistry 8 automatic chlorinators & chemical feeders 8 cold weather operation 8 winterizing the pool & spa heater 10 code requirements 11 clearances 11 outdoor heater installation 13 florida and texas building...

Page 4

4 danger: indicates the presence of immediate hazards which will cause severe personal injury, death or substantial property damage if ignored. Warning: indicates the presence of hazards or unsafe practices which could cause severe personal injury, death or substantial property damage if ignored. Ca...

Page 5: Part One

5 part one owner's operating instructions for your safety - read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result, causing property damage, personal injury or loss of life. Introduction your pool/spa heater has been designed for years of safe ...

Page 6

6 section 3 - maintenance and care procedures to be followed one month after start-up and then semi- annually. 1. Inspect and operate all controls, gas valve and pressure relief valve. 2. On indoor heaters, clean room intake openings to ensure adequate flow of combustion and ventila- tion air. 3. Ke...

Page 7

7 caution: propane gas is heavier than air and will settle on the ground. Since propane can accumulate in confined areas, extra care should be exercised when lighting propane heaters. Warning: should overheating occur or the gas supply fail to shut off, turn off the manual gas control to the heater..

Page 8

8 chemical imbalance can cause severe damage to your heater and associated equipment. Maintain your water chemistry according to the chart on page 2. If the mineral content and dissolved solids in the water become too high, scale forms inside the heat exchang- er tube, reducing heater efficiency and...

Page 9: Part Two

9 part two installation and service instructions section 1 - receiving equipment the manufacturer recommends that this manual be reviewed thoroughly before installing your pool/spa heater. If there are any questions that this manual does not answer, please contact the factory or your local represen-...

Page 10

10 section 3 - installation instructions california proposition 65 warning: this product contains chemicals known to the state of california to cause cancer, birth defects or other reproductive harm. Important notice these instructions are intended only for the use by qualified personnel, specifical...

Page 11

11 outdoor heater installation these heaters are design-certified for outdoor installation, when equipped with the approved tops designated for outdoor use. Warning: the heater shall not be located in an area where water sprinklers, or other devices, may cause water to spray through the cabinet louv...

Page 12

12 heaters must not be installed under an overhang of less than three 3 ft from the top of the heater. Three sides must be open in the area under the overhang. Roof water drainage must be diverted away from the heaters installed under overhangs with the use of gutters. For u.S. Installations, the po...

Page 13

13 florida and texas hurricane tie-down method wind speed = 186 mph, 3 second gust exposure = c 19-5/8” 27-1/4” 32-1/2” 3” min. Conc. Pad by others 3” min. Conc. Pad by others min. Edge distance min. Edge distance (1)–1/4” x 1-3/4” s.S. Tapcon bolt & washer (field supplied) ea. Pallet anchor bracket...

Page 14

14 indoor heater installation for canada, indoor installation is restricted to an enclosure that is not occupied and does not directly commu- nicate with an occupied area. Refer to the latest edition of can/csa-b149 for specific requirements. Locate heater as close as is practical to a chimney or ga...

Page 15

15 u.S. Installations 1 canadian installations 2 a clearance above grade, veranda, porch, deck, or balcony 1 ft (30 cm) 1 ft (30 cm) b clearance to window or door that may be opened 4 ft (1.2m) below or to side of opening; 1 foot (30 cm) above opening 3 ft (91 cm) c clearance to permanently closed w...

Page 16

16 b. All air from outdoors: when air is supplied directly from outside the building, each opening shall have a minimum net free area as noted: combustion and ventilation air (indoor units only) the heater must have both combustion and ventilation air. Minimum requirements for net free air supply op...

Page 17

17 general appliance categories heaters are divided into four categories based on the pressure produced in the exhaust and the likelihood of condensate production in the vent. Category i – a heater which operates with a non-pos- itive vent static pressure and with a vent gas tempera- ture that avoid...

Page 18

18 support of vent stack the weight of the vent stack or chimney must not rest on the heater vent connection. Support must be pro- vided in compliance with applicable codes. The vent should also be installed to maintain proper clearances from combustible materials. Use insulated vent pipe spacers wh...

Page 19

19 canadian installations refer to latest edition of the b149 installation code. A vent shall not terminate: 1. Directly above a paved sidewalk or driveway which is located between two single-family dwell- ings and serves both dwellings. 2. Less than 7 ft (2.13 m) above a paved sidewalk or paved dri...

Page 20

20 double-wall type b vent should be used to promote draft and to minimize condensation in the vent. The connection from the appliance vent to the stack must be as direct as possible. The horizontal breach- ing of a vent must have an upward slope of not less than 1/4 inch per linear foot from the he...

Page 21

21 horizontal through-the-wall direct venting (category iii) horizontal through-the-wall venting air intake horizontal through-the-wall direct venting caution: this venting system requires the installation of a condensate drain in the vent piping per the vent manufacturer’s instructions. Failure to ...

Page 22

22 termination the direct vent cap must be mounted on the ex-teri- or of the building. The direct vent cap cannot be installed in a well or below grade. The direct vent cap must be installed at least 1 ft above ground level and above normal snow levels. The raypak-approved stainless steel direct ven...

Page 23

23 outdoor installation the stackless top provided with the heater is the stan- dard venting method for outdoor installations. The stackless top may be used in its standard top-mount- ed configuration or moved to the rear of the heater for a rear-exhaust configuration. See the diagram below. Care mu...

Page 24

24 ** subtract 10 ft per elbow. Max. 4 elbows. T adapters supplied by others. Category iii horizontal vent & horizontal direct vent model no. Certified vent material vent size (in.) maximum horizontal vent length (ft)** combustion air intake pipe material air intake max. Length** (ft) 4” Ø 259 categ...

Page 25

25 maximum equivalent pipe length (ft) natural gas 1000 btu/ft 3 0.60 specific gravity @ 0.5 in. Wc pressure drop propane gas 2500 btu/ft 3 1.53 specific gravity @ 0.5 in. Wc pressure drop input 3/4” 1” 1-1/4” 1-1/2” model (kbtu) n p n p n p n p 259 250.0 15 35 50 125 210 480 445 409 399.0 * 15 20 5...

Page 26

26 prv field- supplied note: to avoid water damage or scalding due to valve operation, drain pipe must be connected to valve outlet and run to a safe place of discharge. Drain pipe must be the same size as the valve discharge connec- tion throughout its entire length and must pitch down- ward from t...

Page 27

27 transformer wiring 120 vac wiring for 120 vac input power to the unit, connect the pair of black wires to the “l1” or hot leg of the power sup- ply. Connect the red/white wire and the white wire to the “ret” or neutral leg of the power supply. Attach the wire nut to the red wire. There should be ...

Page 28

28 plumbing—water connections optional left-hand wiring if the standard right-hand electrical wiring is not acces- sible or convenient, wiring can be done from the left- hand side instead. Conversion is done using the fol- lowing method: 1. Locate the plug on the left-hand side of the unit. 2. Remov...

Page 29

29 the conversion is performed using the following pro- cedures: left hand plumbing 1. Rotate and remove the prv and reducer bushing from in/out header. 2. Rotate and remove the t&p gauge. 3. Remove cover from flow switch and disconnect wiring. 4. Rotate and remove flow switch from in/out head- er. ...

Page 30

30 straight plumbing setup (front view) 90° plumbing setup (top view) recommended plumbing setups loose plumbing parts.

Page 31

31 the heater requires water flow and positive pressure to fire and operate properly. It must therefore be installed downstream of the discharge side of the filter pump. A typical installation is plumbed as follows: 1. The inlet side of the filter is plumbed directly to the discharge side of the fil...

Page 32

32 wiring diagram.

Page 33

33 section 4 - servicing instructions general location of controls direct vent access panel right access panel bonding lug location temperature sensor air pressure switch vent pressure switch prv left access panel bonding lug location (optional) drain valve hl1 & hl2 high limits t&p gauge flow switc...

Page 34

34 lcd display temp adjust buttons mode button on off control adjustments control panel removal to remove the pc board from the heater, use the following procedure: 1. Turn off main power to the heater. 2. Remove front door to access wire harnesses. 3. Reaching underneath the pc board, carefully rem...

Page 35

35 the pool heater touchpad, located on the upper front panel of the heater, allows the user to select either pool or spa operation, and to adjust the setpoint temperature. The lcd display window indicates the mode (off, spa, pool) and the actual water temper- ature. A manual power switch provided t...

Page 36

36 resets board to factory default settings. Resets faults in the history file. Change from fahrenheit to celsius. Spa setpoint maximum adjustment. Pool setpoint maximum adjustment. Set factory defaults refer to step one above to access the program screen. Set factory defaults should appear on the s...

Page 37

37 status and diagnostics the digital thermostat models are programmed to display a variety of status and diagnostic messages, depend- ing on the operating conditions. Note: the lcd temperature display may not agree with the temperature reading of your pool or spa ther- mometer. The heater reads the...

Page 38

38 remote control installation and operation caution: before installing remote controls to the heaters, read the following: the digital thermostat model is remote-ready in most cases. The digital liquid crystal display (lcd) shows the actual pool temperature, operating status, and service codes (see...

Page 39

39 remote control wiring important installation notes for remote or external wiring configuration • remote wiring must be run in a separate conduit. • remote wiring must not be run parallel to high voltage lines. • for runs of under 30 feet, remote wiring should have stranded conductors with a minim...

Page 40

High limit removal 1. Shut off main electrical power switch to heater. 2. Remove front door. 3. Remove defective high limit and replace with a new high limit. 4. Replace inspection panel. Note: an erratic high limit is often characteristic of an internal heat exchanger problem, e.G. Scale build-up, ...

Page 41

41 igniter .18” ± .03” orifice removal 1. Locate and close the external manual shut-off valve. 2. Loosen the external gas union. 3. Locate and remove front door panel. 4. Locate and remove the (4) bolts & nuts holding the gas orifice in place. See the figure above. 5. Carefully remove the gas orific...

Page 42

42 mechanical important notice these instructions are intended for the use of qualified personnel who are specifically trained and experienced in the installation of this type of heating equipment and related system components. Installation and service personnel may be required by some states to be ...

Page 43

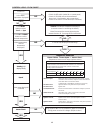

43 power on is the water temperature displayed? No yes push mode button to select "pool" or "spa" push up or down button to scroll to desired temperature no water temperature and set temperature displayed? Yes “heating” will display briefly no no yes yes water temp displayed? (rectified) heater fire...

Page 44

44 section 6 - replacement parts.

Page 45

45 note: to supply you with the correct part, it is impor- tant that you supply the heater model number, serial number and type of gas when applicable. Any part returned for replacement under standard company warranties must be properly tagged with a return parts tag, completely filled in with the h...

Page 46

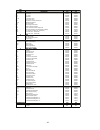

46 call out description 259 409 m miscellaneous components 1-m prv 125 psi 011912f 011912f 2-m t & p gauge 007399f 007399f 3-m wire/harness 014117f 014117f 4-m blower harness 120v 014118f 014118f blower harness 240v 014119f 014119f 5-m control bezel (includes switch decal) 014120f 014120f 6-m switch...

Page 47

47 (b) exemptions: the following equipment is exempt from 248 cmr 5.08(2)(a)1 through 4: 1. The equipment listed in chapter 10 entitled "equipment not required to be vented" in the most current edition of nfpa 54 as adopted by the board; and 2. Product approved side wall horizontally vented gas fuel...

Page 48: Www.Raypak.Com

Www.Raypak.Com raypak, inc., 2151 eastman avenue, oxnard, ca 93030 (805) 278-5300 fax (805) 278-5468 litho in u.S.A. 48.