- DL manuals

- Raypak

- Swimming Pool Heater

- C-R185A

- Installation And Operating Instructions Manual

Raypak C-R185A Installation And Operating Instructions Manual

Part No. 240612

CATALOG NO. 6000.52-Z

Effective:

11-01-01

Replaces: 08-01-01

®

INSTALLATION

AND OPERATING

INSTRUCTIONS

Models

P-R185A to P-R405A

C-R185A to P-R405A

Low NOx

P-R185AL to P-R405AL

C-R185AL to C-R405AL

RP2100

SWIMMING POOL

and

SPA HEATER

This manual should be maintained in legible condition and kept adjacent to the

heater or kept in a safe place for future reference.

WARNING: If the information in these instructions are not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

— WHAT TO DO IF YOU SMELL GAS

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

•

If you cannot reach your gas supplier, call the fire department.

— Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

— Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

Summary of C-R185A

Page 1

Part no. 240612 catalog no. 6000.52-z effective: 11-01-01 replaces: 08-01-01 ® installation and operating instructions models p-r185a to p-r405a c-r185a to p-r405a low nox p-r185al to p-r405al c-r185al to c-r405al rp2100 swimming pool and spa heater this manual should be maintained in legible condit...

Page 2

To whom it may concern: the new raypak series rp2100 pool heaters have been designed to eliminate the need for conventional heat sinks (high temperature piping). The initial connection to the heater is made with a 2" pvc union adapter to which pvc may then be connected with appropriate cement. This ...

Page 3

Contents 3 4 part one owner's operating instructions 4 section 1 start-up procedures 4 before start-up 5 lighting instructions & shut-off procedure (manually lighted pilot mv) 6 operating instruction & shut-off procedures (automatically lighted pilot iid) 7 after start-up 7 section 2 caution 7 secti...

Page 4

Part one - owner's operating instructions for your safety - read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result, causing property damage, personal injury or loss of life. Section 1 / start-up procedures your raypak pool/spa heater has been d...

Page 5

4. Push the gas control knob slightly and turn clockwise to "off". Do not force. 5. Replace heater door panel. 1. Set the thermostat to the lowest setting. 2. Turn on/off switch to the "off" position. 3. Remove heater door panel. To turn off gas to appliance a. This appliance has a pilot that must b...

Page 6

A. This appliance is equipped with an ignition device which automatically lights the pilot. Do not try to light the pilot by hand. B. Before operating, smell all around the appliance area for gas. Be sure to smell next to the floor because some gas is heavier than air and will settle on the floor. W...

Page 7

After start-up feel the inlet and outlet pipes. Outlet pipe should be only slightly warmer than the inlet. It should not be hot. Warning: should overheating occur or the gas supply fail to shut off, turn off the manual gas control to the appliance. Visual inspection with the heater on, remove the do...

Page 8

4. Make visual check of the burner and pilot flame. Flame pattern on the main burner and pilot is indi- cated in the previous illustration. Yellow flame means restriction of the air openings. Lifting or blowing flame indicates high gas pressure. Low flame means low gas pressure. Should this occur, s...

Page 9

Winterizing the pool & spa heater when heaters installed outdoors in freezing climate areas are to be shut down for the winter, observe the following step-by-step procedure: 1. Turn off gas valve, manual gas valve, and electrical supply to the heater. 2. Open drain plug located on the inlet/outlet h...

Page 10

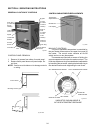

12" minimum 12" minimum 4" minimum hea ter sheet metal 24 gauge section 3 / installation instructions 10 important notice these instructions are intended for the use of quali- fied personnel only, specifically trained and experienced in the installation of this type of heating equipment and related ...

Page 11

Heaters must not be installed under an overhang of less than three (3) feet from the top of the heater. Three (3) sides must be open in the area under the overhang. Roof water drainage must be diverted away from the heaters installed under overhangs with the use of gutters. For u.S. Installations,th...

Page 12

Indoor heater the design is also certified for indoor installation when equipped with the approved draft hood. For canada, indoor installation is restricted to an enclosure that is not occupied and does not directly communicate with occupied area. Refer to the latest edition of can/cga-b149.1 and b1...

Page 13

13 specifications and dimensions *electrical connection on left side is 19-1/8". A. All air from inside the building: each opening shall have a minimum net free square inches as noted: model square inches model square inches 185 181 335 333 265 264 405 399 b. All air from outdoors: when air is suppl...

Page 14

Vent piping warning: indoor boilers require a drafthood that must be connected to a vent pipe and properly vented to the outside. Failure to follow this procedure can cause fire or fatal carbon monoxide poisoning. Vent piping the same size as the draft hood outlet is recommended, however, when the t...

Page 15

Fig. # 8149 note: do not use teflon tape on gas line pipe thread. A flexible sealant is recommended. A minimum of 7" w.C. And a maximum of 14" w.C. Upstream pressure under load, and no load conditions must be provided for natural gas or a minimum of 12" w.C. And a maximum of 14" for propane gas. Gas...

Page 16

Heater must be located so that any water leaks will not damage the structure of adjacent area. Pvc pipe may be glued directly into header unions. Flow rates model pipe size min.Gpm *max.Gpm 185 1-1/4"-1-1/2" - 2 20 125 265 1-1/4"-1-1/2" - 2 25 125 335 1-1/4"-1-1/2" - 2 35 125 405 1-1/4"-1-1/2" - 2 4...

Page 17

17 pressure relief valve installation to conform to local building codes, it may be necessary to install a pressure relief valve. A 3/4" pressure relief valve having a capacity equal to btu/hr output of the model to be installed is recommended for this appliance. The maximum acceptable pressure re- ...

Page 18

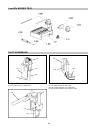

Rp2100+ heat exchanger reversal procedure (capron resin header models) 1. Remove right and left side access panels (figure 1). 2. Disconnect wires at high limit, ags (automatic gas shutoff), and pressure switch on the inlet/outlet header (figure 2). 3. Electronic ignition heaters: remove the thermos...

Page 19

Fig. #4 fig. #5 fig. #3 jaco fitting bulb & clip re-installed in/out header on opposite side. 19.

Page 20

Electrical wiring note: if it is necessary to replace any of the original wiring, it must be replaced with 105° c wire or its equivalent, and /or 150° c wire or its equivalent as originally built. Millivolt system the millivolt system residential heater is equipped with a self-generating electrical ...

Page 21

21 wiring diagram key pink connector blue connector fig. # rp8096 *if required by local code, install at this location. Fig. #2353 for 120 v input power to the unit, connect the black wire to the “l1” or hot leg of the power supply. Connect the white wire to the “l2” or neutral leg of the power supp...

Page 22

Wiring diagram - iid units (atmospheric) 22.

Page 23

Wiring diagram - iid units (low nox) 23.

Page 24

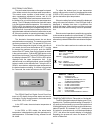

Control panel mounting screws (4) fig. #rp 8267 controls/adjustments/replacements temperature adjust buttons mode button lcd display fig. #2000 millivolt controls the pool or spa water temperature is controlled by the pool heater thermostat on the upper front panel of the heater. The control center ...

Page 25

To adjust the desired pool or spa temperature setting, make sure the control is in the appropriate mode (pool or spa) and push the up or down buttons to get the desired set point temperature. If there is a safety fault, a fault code will be displayed along with a service indication. If the prs fault...

Page 26

Rp2100 remote control installation caution: before installing remote controls to the rp2100 digital heater, read the following: the raypak rp 2100 digital heater is remote ready in most cases. The digital liquid crystal (lcd) display shows the actual pool temperature, operating status, and service c...

Page 27

Pressure switch the pressure switch, or heater actuator, insures that the heater operates only when the filter pump is in operation. It is located on the inlet/outlet header. It is factory set at 1.75 psi for deck level installations. When the heater is located below the level of the spa or pool, it...

Page 28

Burner drawer removal 1. Shut off main electrical power switch to heater. 2. Shut off gas upstream of heater. 3. Remove front door. 4. Disconnect gas line from gas valve. 5. Remove (2) screws that mount burner tray to unit, and (2) screws that secure gas valve to jacket. 6. Disconnect wires that ter...

Page 29

Tube cleaning procedure establish a regular inspection schedule, frequency depending on local water condition and severity of service. Do not let the tubes clog up solidly. Clean out deposits over 1/16" in thickness. The heater may be cleaned from the return header side, without breaking pipe connec...

Page 30

The raypak low nox pool heaters are certified and tested under the ansi z21.56.Csa 4.7 standards for gas fired pool heaters. The heater should be installed to meet all local codes, the latest editions of the national fuel gas code z223.1 and the national electrical code, ansi/nfpa 70. Operation on c...

Page 31

31 burner drawer removal 1. Shut off main electrical power switch to heater. 2. Shut off gas upstream of heater. 3. Remove front door. 4. Disconnect gas line from gas valve. 5. Remove (2) screws that mount burner tray to the base of the unit, and (2) screws that secure gas valve to jacket. 6. Discon...

Page 32

Mechanical (for qualified service personnel only) important notice these instructions are primarily intended for the use of qualified personnel specifically trained and experienced in the installation of this type of heating equipment and related system components. Installation and service personnel...

Page 33

If pilot burner remains lit. Jump across pressure switch terminals if main burner does not fire, remove jumper check for adequate water flow from filter replace pressure switch jump across thermostat if main burner fires, remove jumper if main burner does not fire... Jump across each high limit and ...

Page 34

Warning high voltage for qualified technicians only note: some heaters may be equipped with an ignition module that shuts off pilot gas if pilot fails to light. To reset, interrupt power to heater. Intermittent pilot system troubleshooting honeywell s8600 note:before troubleshooting, familiarize you...

Page 35

35.

Page 36

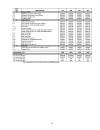

Section 6/replacement parts list note: to supply the correct part it is important that you state the model number, serial number and type of gas when applicable. Any part returned for replacement under standard company warranties must be properly tagged with raypak return parts tag, completely fille...

Page 37

37.

Page 38

38 fig. #8124 honeywell mv fig. #8107 fig. #9369 13-p 5-p 16-p 15-p 1-p 9-p 3-p low nox burner tray pilot assemblies 14-p 16-p 3-p 7-p 16-p 3-p 17-p honeywell iid atmospheric units for units produced prior to 06/01/2000 honeywell iid low nox and atmospheric units for units produced after to 06/01/20...

Page 39

39.

Page 40

40

Page 41

41.

Page 42

Limited warranty raypak residential swimming pool and spa heaters gas models 185, 265, 335 & 405 millivolt 185, 265, 335 & 405 electronic general raypak, inc. Warrants that the cabinet, burner tray (minus controls) and refractory will be free from defects in materials and workmanship under normal us...

Page 43

Raypak, inc., 2151 eastman avenue, oxnard, ca 93030 (805) 278-5300 fax (800) 872-9725 raypak canada ltd, 2805 slough street, mississauga, ontario, canada l4t 1g2 (905) 677-7999 fax (905) 677-8036 raypak australia pty. Ltd, 7 geddes st., mulgrave, victoria, australia 3170 (6139) 560 4944 fax (6139) 5...