Installation & operating instructions catalog no. 3000.50g effective: 04-08-09 replaces: 05-06-08 p/n 240687 rev. 8 this manual should be maintained in legible condition and kept adjacent to the heater or in a safe place for future reference. Models 0090a, 0135a & 0195a – type wh what to do if you s...

2 rev. 8 reflects the following: changes to: paragraph 3 of the general specifications section on page 6; fig. 7 on page 12; the wiring diagrams on pages 14 and 15; fig. 8 on page 16; fig. 12 on page 19; fig. 15 on page 20; the trou- bleshooting chart on page 23. The addition of: a note to fig. 2 on...

Warnings 4 pay attention to these terms 4 general safety 5 time/temperature relationships in scalds 5 receiving equipment 6 general specifications 6 installation 8 code requirements 8 mounting base 8 clearances 8 combustion & ventilation air 8 venting connections 9 gas supply connections 11 water co...

4 danger: indicates the presence of immediate hazards which will cause severe personal injury, death or substantial property damage if ignored. Warning: indicates the presence of hazards or unsafe practices which could cause severe personal injury, death or substantial property damage if ignored. Ca...

5 general safety to meet commercial hot water requirements, the tank- stat is adjustable up to 190°f. However, water temperatures over 125°f can cause severe burns instantly or death from scalds. This is the preferred starting point for setting the control for supplying gen- eral purpose hot water. ...

6 receiving equipment on receipt of your equipment it is suggested that you visually check for external damage to the carton. If the carton is damaged, it is suggested that a note be made on the bill of lading when signing for equipment. Remove the heater from the carton and if it is dam- aged repor...

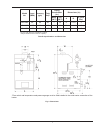

7 model no. Input (mbh) recovery (gph) tank (gal)** piping connections (in.) dimensions (in.) water (npt) gas (npt) a b k (vent dia.) wh-0090 90 90 80 1 1/2 11 5-3/4 5 wh-0135 135 132 80 1-1/4 1/2 18 6-1/4 6 wh-0195 195 192 80 1-1/4 1/2 18 6-1/4 7 recovery gph based on manufacturer's rating. **may b...

8 installation code requirements installation must be in accordance with local codes, or, in the absence of local codes, with the latest editions of the national fuel gas code, ansi z223.1,/nfpa 54, and the national electrical code, ansi/nfpa 70. In canada installations must conform with the current...

9 1. The heater must be provided with adequate sup- ply of air for proper combustion and ventilation in accordance with sec. 5.3 of the latest edition of the national fuel gas code, ansi z223.1, or applicable provisions of the local building codes. 2. If the heater room is located against an outside...

10 common vents manifolds that connect more than one heater to a com- mon chimney must be sized to handle the combined load. Consult available guides for proper sizing of the manifold and the chimney. At no time should the area be less than the area of the largest outlet. At the time of removal of a...

11 (g) any improper operation of the common venting system should be corrected so the installation conforms with the latest edition of the national fuel gas code, ansi z223.1. When re-sizing any portion of the common venting system, the com- mon venting system should be re-sized to approach the mini...

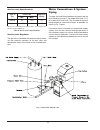

12 gas pressure specifications gas pressure regulator the gas valve is provided with pressure taps to meas- ure gas pressure upstream of the gas valve and downstream which is the same as the manifold pres- sure. Type of gas inches wc regulator setting min. Max.* natural 4.5 10.5 3.5 propane 12.0 13....

13 when this water heater system is supplying general purpose hot water requirements for use by individuals, a thermostatically controlled mixing valve is recom- mended to reduce the risk of scald injury. Contact a licensed plumber or the local plumbing authority for further information. Thermometer...

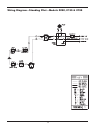

14 wiring diagram—standing pilot—models 0090, 0135 & 0195.

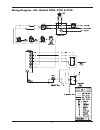

15 wiring diagram—iid—models 0090, 0135 & 0195.

16 servicing procedures general location of controls sequence of operation intermittent ignition device (iid) heaters equipped with the iid system will automatical- ly light the pilot burner first and then the main burner, each time there is a call for heat from the tankstat. Whenever the tankstat c...

17 for standing pilot model with robertshaw gas valve, on/off operation 1. Stop! Read the safety information. 2. Set the tankstat on the lowest setting. 3. Turn off all electric power to the heater. 4. Remove heater door panel. 5. Push in gas control knob slightly and turn clock- wise to "off". 6. W...

Instructions. • if you cannot reach your gas supplier, call the fire department. C. Use only your hand to push in, move or turn the gas control knob or lever. Never use tools. If the knob or lever will not push in, move or turn by hand, don't try to repair it, call a qualified service technician. Fo...

19 of the control system and any gas control which has been under water. For intermittent ignition (iid) with honeywell or robertshaw gas valve 1. Stop! Read the safety information above on this label. 2. Set the tankstat on the lowest setting. 3. Turn off all electric power to the appliance. 4. Thi...

20 testing the ignition safety shut-off the ignition system safety shutoff must be tested by conducting the following tests: for standing pilot systems 1. With the main burners on, remove the pilot adjust- ment cover screw. 2. Insert a small slot screw driver and turn the adjust- ment screw clockwis...

Normal inspection procedures first and third month after initial start up and then on an annual basis. If problems are found, refer to trouble shooting guide for additional directions. 1. Remove top of heater and inspect heat exchanger for soot and examine venting system. 2. Remove rear header and i...

22 repair section tube cleaning procedure (typical) establish a regular inspection schedule, the frequency depending on the local water condition and severity of service. Do not let the tubes clog up solidly. Clean out deposits over 1/16" in thickness. The heater may be cleaned from the side opposit...

23 these instructions are primarily intended for the use of qualified personnel specifically trained and experienced in the installation of this type of heating equipment and related system components. Installation and service personnel may be required by some states to be licensed. Persons not qual...

24 1) adjust inlet gas pressure as shown on rating plate. 2) clean pilot orifice. 3) replace thermocouple. 1 ) adjust manifold pressure as shown on rating plate. 2) clean burners free of debris or insects. 3) clean gas line or increase gas line piping. 1) refer to installation instructions regarding...

25 adjustments & replacement of components gas valve replacement 1. Shut off electrical power and gas supply to the heater. 2. Remove gas piping to gas valve inlet. 3. Disconnect wiring connections, pilot tubing (when equipped). 4. Remove screws (2) holding the burner tray. 5. Slide burner tray out....

Replacement parts any part returned for replacement under standard company warranties must be properly tagged with raypak return parts tag, completely filled in with the heater serial number, model number etc., and shipped to the company freight prepaid. If determined defective by the company and wi...

27 limited parts warranty econopak water heaters models wh - 0090 to 0195 scope: raypak, inc. ("raypak") warrants to the original owner that all parts of this water heater which are actually manufactured by raypak will be free from failure under normal use and service for the specified warranty peri...

Www.Raypak.Com raypak, inc., 2151 eastman avenue, oxnard, ca 93030 (805) 278-5300 fax (805) 278-5468 litho in u.S.A..