- DL manuals

- Raypak

- Water Heater

- HI DELTA HD101 THRU 2342B

- Installation & Operating Instructions Manual

Raypak HI DELTA HD101 THRU 2342B Installation & Operating Instructions Manual

INSTALLATION & OPERATING

INSTRUCTIONS

CATALOG NO. 1000.52

Effective: 06-11-09

Replaces: NEW

P/N 241356 Rev. 1

WARNING: If these instructions are not followed exactly, a fire or explosion may

result causing property damage, personal injury or death

.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors and

liquids or other combustible materials in the vicinity of this or any other appliance. To

do so may result in an explosion or fire.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

This manual should be maintained in legible condition and kept adjacent to the heater or in another safe place for

future reference.

Models

HD101–HD401

Types H & WH

®

L

W

Summary of HI DELTA HD101 THRU 2342B

Page 1

Installation & operating instructions catalog no. 1000.52 effective: 06-11-09 replaces: new p/n 241356 rev. 1 warning: if these instructions are not followed exactly, a fire or explosion may result causing property damage, personal injury or death . For your safety: do not store or use gasoline or o...

Page 2

2.

Page 3

Warnings 4 pay attention to these terms 4 before installation 5 product receipt 5 model identification 5 ratings and certifications 5 installations at elevation 5 component locations 6 general information 7 general safety 8 time/temperature relationships in scalds 8 installation 9 installation codes...

Page 4

Danger: indicates the presence of immediate hazards which will cause severe personal injury, death or substantial property damage if ignored. Warning: indicates the presence of hazards or unsafe practices which could cause severe personal injury, death or substantial property damage if ignored. Caut...

Page 5

Before installation raypak strongly recommends that this manual be re- viewed thoroughly before installing your hi delta heater. Please review the general safety information before installing the heater. Factory warranty does not apply to heaters that have been improperly installed or operated (refe...

Page 6

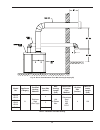

Fig. 1: component locations — angle view fig. 2: component locations — left side fig. 3: component locations — front (panels removed for clarity) 6 component locations.

Page 7

General information table a: basic data model no. Quantity of burners vent size (in.) flue intake hd101 2 4 4 hd151 3 4 hd201 4 5 hd251 5 5 hd301 6 5 hd401 8 6 7 fig. 5: gas valves fig. 4: air shutter adjustment.

Page 8

General safety to meet commercial hot water use needs, the high limit safety control on this water heater will shut off the main gas valve before the outlet temperature reaches 210°f. However, water temperatures over 125°f can cause instant severe burns or death from scalds. When supplying general p...

Page 9

Installation installation installation codes installations must follow these codes: · local, state, provincial, and national codes, laws, regulations and ordinances. · national fuel gas code, ansi z223.1- latest edi- tion (nfgc). · national electrical code, ansi/nfpa 70 - latest edition (nec). · sta...

Page 10

Top view front view 2 fig. 7: minimum installed service clearances — indoor/closet installations the heater must be installed in a manner that will enable the heater to be serviced without removing any structure around the heater. Outdoor installations these heaters are design-certified for outdoor ...

Page 11

Area per 20,000 btuh (111 mm 2 per kw) of total input rating of all equipment in the room when the opening is communicating directly with the out- doors or through vertical duct(s). The total cross-sectional area shall be at least 1 in. 2 of free area per 10,000 btuh (222 mm 2 per kw) of total input...

Page 12

Warning: do not use one permanent opening method if the equipment room is under negative pressure conditions or the equipment is common vented with other gas-fired appliances. 1. Ventilation of the space occupied by the heater shall be provided by an opening(s) for ventilation air at the highest pra...

Page 13

13 warning: pressure relief valve discharge piping must be piped near the floor and close to a drain to eliminate the potential of severe burns. Do not pipe to any area where freezing could occur. Refer to local codes. Reversing water connections follow these instructions to change the water connec-...

Page 14

14 low temperature system heater requires minimum inlet temperature of 105°f. Consult the following sections for piping details. Temperature & pressure gauge the temperature and pressure gauge is shipped loose for field installation. Hydronic heating pump selection in order to ensure proper performa...

Page 15

15 fig. 10: single boiler — low temperature application (heat pump) primary/secondary piping fig. 11: dual boiler—primary/secondary piping *maximum 4 times the pipe diameter or 12”, whichever is less. *maximum 4 times the pipe diameter or 12”, whichever is less..

Page 16

16 table f: domestic water heater flow rate requirements Δt = temperature rise, °f. Δp = pressure drop through heat exchanger, ft. Shl = system head loss, ft. (system head loss is based on the heater and tank placed no more than 5 feet apart and 50 feet equivalent length of tubing and fittings.) gpm...

Page 17

17 gas supply connection caution: the heater and its manual shutoff valve must be disconnected from the gas supply during any pressure testing of the gas supply system at test pressures in excess of 1/2 psi (3.45 kpa). The heater must be isolated from the gas supply piping system by closing the manu...

Page 18

18 fig. 13: sediment trap orientation gas supply pressure a minimum of 4 in. Wc and a maximum of 10.5 in. Wc upstream gas pressure is required under load and no load conditions for natural gas. A minimum of 11 in. Wc and a maximum of 13 in. Wc is required for propane gas. The gas pressure regulator ...

Page 19

19 electrical power connections installations must follow these codes: · national electrical code and any other national, state, provincial or local codes or regulations hav- ing jurisdiction · safety wiring must be n.E.C. Class 1 · heater must be electrically grounded as required by n.E.C. · in can...

Page 20

20 single stage tankstat stage 1 connection attach stage 1 connections on heater to the single stage tankstat as shown in the diagram above. 2-stage tankstat stage 1 connection stage 2 connection or stage 1 connection of heater 2 attach stage 1 connections on heater to stage 1 connection on tankstat...

Page 21

See table h for appliance category requirements for the hi delta. Determination of appliance category for venting purposes and venting arrangements 21 heater must be electrically grounded in accordance with nec and c22.1(in canada). Notes: 1. Field installed ground to inside of junction box. 2. If a...

Page 22

22 table h: venting category requirements combustion air supply exhaust configuration venting category certified appliance material combustion air inlet material from inside building (non-direct venting) vertical natural draft venting i type b or any category i venting system* horizontal thru-wall v...

Page 23

23 u.S. Installations 1 canadian installations 2 a clearance above grade, veranda, porch, deck, or balcony 1 ft (30 cm) 1 ft (30 cm) b clearance to window or door that may be opened 4 ft (1.2m) below or to side of opening; 1 foot (30 cm) above opening 3 ft (91 cm) c clearance to permanently closed w...

Page 24

24 ances shall not terminate over public walkways or over an area where condensate or vapor could create a nuisance or hazard or could be detrimen- tal to the operation of regulators, relief valves, or other equipment. Where local experience indi- cates that condensate is a problem with category i a...

Page 25

25 venting installation tips support piping: · horizontal runs- at least every five (5) feet. · vertical runs - use braces: · under or near elbows follow items listed below to avoid personal injury or property damage. · cut nonmetallic intake pipe with fine-toothed hack- saw. · do not use nonmetalli...

Page 26

26 natural draft vertical venting system installation natural draft venting uses the natural buoyancy of the heated flue products to create a thermal driving head that expels the exhaust gases from the flue. The neg- ative draft must be within the range of –0.01 in. To –0.08 in. Wc as measured 12 in...

Page 27

27 each appliance. Adjust thermostat so appliance will operate continuously. E) check the pressure at a pressure tap located 12 in. Above the bottom joint of the first vertical vent pipe. Pressure should be anywhere between -.01 to -.08 in. Wc. F) after it has been determined that each appliance rem...

Page 28

28 horizontal thru-wall venting system (category iii) installation these installations utilize the heater-mounted blower to vent the combustion products to the outdoors. Combustion air is taken from the space and the vent is installed horizontally through the wall to the outdoors. Adequate combustio...

Page 29

29 fig. 20: direct vent horizontal thru-wall venting (category iii) model no. Appliance category certified venting material vent size (inches) max. Venting length (feet) combustion air intake pipe material air inlet size (inches) max. Air intake length (feet) hd101 hd151 iii stainless steel (gas tig...

Page 30

30 model no. Appliance category certified venting material vent size (inches) min./max. Vertical venting height (feet) combustion air intake pipe material air inlet size (inches) max. Air intake length (feet) min. Max. Hd101 hd151 i type b equivalent 4 6 25* galvanized steel pvc abs cpvc 4 100 hd201...

Page 31

31 vertical direct vent system installation these installations utilize the heater mounted blower to draw combustion air from outdoors and uses the natural buoyancy of the heated flue products to create a thermal driving head that expels the exhaust gases from the flue. The negative draft must be wi...

Page 32

Modulating temperature control (optional) this heater can be equipped with a raypak modulat- ing temperature control. For operation with this control, refer to the temp-tracker installation and operating instructions, raypak catalog number 5000.66 (p/n 241177). High limit (manual reset) the heater i...

Page 33

33 low water cut off (optional) the low water cut off automatically shuts down the burner whenever water level drops below the level of the sensing probe. A 5-second time delay prevents premature lockout due to temporary conditions such as power fluctuations or air pockets. Fig. 26: flow switch fig....

Page 34

34 wiring diagram—models hd101–hd401.

Page 35: Hd Troubleshooting

35 step 8 hd troubleshooting step 8 step 9 step 1 step 2 step 3 step 4 step 5 step 6 step 7 is there a call for heat? Is disable connection intact? Does the pump come on? Is 24vac at the nc side of the air pressure switch? Is blower pressure setting correct? Does igniter prove? Is air switch bouncin...

Page 36

36 pre-start-up filling system-heating heaters fill system with water. Purge all air from the system using purge valve sequence. After system is purged of air, lower system pressure. Open valves for normal system operation, fill system through feed pressure. Manually open air vent on the compression...

Page 37

37.

Page 38

38 check the gas supply pressure 1. Slowly turn on main gas shut-off valve. 2. Read the gas supply pressure from the manome- ter; minimum supply pressure is 4 in. Wc, recommended supply is 7 in. Wc for natural gas (minimum 11.0 in. Wc for lp gas). 3. If pressure is > 14 in. Wc, turn off the valve. 4...

Page 39

39 3. Carefully remove 2-stage solenoid. 4. Skip to step 9 for lo-fire adjustment only. 5. Locate and remove lo-fire adjustment cap. 6. Carefully remove the spring & weight. 7. Using an allen wrench, turn clockwise to increase and counterclockwise to decrease the hi-fire man- ifold pressure. Heater ...

Page 40

40 • insert ignition control lockout tests as safety check. Follow-up • safety checks must be recorded as performed. • turn unit on. After main burner ignition: • check manometer(s) for proper reading(s). • cycle unit several times and recheck readings. • re-analyze with unit running record or print...

Page 41

41 3. Remove the (4) screws holding the panel in place. 4. Pull the air filter out for inspection. Replace if nec- essary. 5. When replacing, note the direction of the air flow defined on the side of the filter. The arrow should be pointing downward. 6. Replace the panel and screws before operating....

Page 42

Heater operating efficiency. Maintenance as outlined below may be performed by the owner. Yearly (beginning of each heating season): 1. Annual service call by qualified service agency. 42 maintenance suggested minimum maintenance schedule: regular service by a qualified service agency and maintenanc...

Page 43

43 2. Visually check top of vent for soot. Call service person to clean. Some sediment at bottom of vent is normal. 3. Visually inspect venting system for proper func- tion, deterioration or leakage. 4. Check that heater area is free from combustible materials, gasoline, and other flammable vapors a...

Page 44

44 • hydrochloric acid/muriatic acid • cements and glues • antistatic fabric softeners used in clothes dryers • chloride-type bleaches, detergents, and cleaning solvents found in household laundry rooms • adhesives used to fasten building products • ... And other similar products. Areas causing cont...

Page 45

45.

Page 46

46.

Page 47

47.

Page 48: Www.Raypak.Com

Www.Raypak.Com raypak, inc., 2151 eastman avenue, oxnard, ca 93030 (805) 278-5300 fax (805) 278-5468 litho in u.S.A..