- DL manuals

- Raypak

- Swimming Pool Pump

- PS165VSP

- Installation, Operating And Service Manual

Raypak PS165VSP Installation, Operating And Service Manual - Save These Instructions!

Technical Support

Address:

7920 Interstate Court

North Ft. Myers, FL. 33917

Toll Free:

1-877-213-3726

Website:

www.raypak.com

2999999292 - Rev 01/2013 v1

SAVE THESE INSTRUCTIONS!

Date of Installation:

Installed by:

Serial Number:

For Service Call:

Safety

Safety is emphasized throughout the user manual. These are safety alert symbols. They alert the user to

potential personal injury hazards. Obey all safety messages to avoid possible injury or death or damage

to equipment.

CAUTION

WARNING

DANGER

Manufactured for Raypak by Speck Pumps, Jacksonville Florida USA,

© 2012-2013 All Rights Reserved.

This document is subject to change without notice.

Summary of PS165VSP

Page 1

Installation, operating, and service manual ps165vsp variable speed pool pump catalog no. 6000.555 effective. 01/16/2013 replaces: new p/n 241508 rev 1 listed 31b4.

Page 2: Save These Instructions!

Technical support address: 7920 interstate court north ft. Myers, fl. 33917 toll free: 1-877-213-3726 website: www.Raypak.Com 2999999292 - rev 01/2013 v1 save these instructions! Date of installation: installed by: serial number: for service call: safety safety is emphasized throughout the user manu...

Page 3: Table of Contents

Table of contents 1 important safety instructions 4 2 general description 6 3 installation information 7 preparation guide . . . . . . . . . . . . . . . 7 pump location . . . . . . . . . . . . . . . . 8 pipe sizing . . . . . . . . . . . . . . . . . . 8 plumbing installation . . . . . . . . . . . . ....

Page 4

4 important notice: this manual contains important information about the installation, operation and safe use of this product. This information should be given to the owner and/or operator of this equipment. Warning: this product must be installed and serviced by a qualified pool professional, and m...

Page 5

5 the system must be built to include at least two (2) suction outlets (drains) connected to the pump whenever the pump is running. However, if two (2) main drains run into a single suction line, the single suction line may be equipped with a valve that will shut off both main drains from the pump. ...

Page 6: Save These Instructions.

6 important safety instructions when installing and using this electrical equipment, basic safety precautions should always be followed, including the following: read and follow all instructions warning: to reduce the risk of injury, do not permit children to use this product unless they are closely...

Page 7

Controls and leds description led lights (active step leds) when lit, indicates it is in operation or active. Speed led when lit, bar graph displays speed. Duration led when lit, bar graph displays duration in hours speed will run. Bar graph shows current speed and duration (hours) of active program...

Page 8

8 warning: this product must be installed and serviced by a qualified pool professional, and must conform to all national, state, and local codes. Before installing this product, read and follow all warning notices and instructions of this product. Failure to follow warning notices and instructions ...

Page 9

9 pipe sizing - continued for better efficiency and less restriction, use as few fittings (elbows, tees, valves, etc.) as possible. Suction line diameter must be equal or be greater than the discharge line diameter. Suction and discharge lines should be independently supported at a point near the pu...

Page 10

Pin# wire color description l1 black hot 1 l2 red or white hot 2 grd green ground 10 warning:all electrical wiring must conform to the local nec guidelines. A licensed, qualified electrician should complete the wiring for this product. Electrical specifications 1. Voltage: 208-230 vac, 60 hz, single...

Page 11

1 2 3 4 5 on of f 11 caution:voltage at the pump must not vary by more than +/- 10% of nameplate voltage. Components may overheat, causing overload tripping and reduced component life. Consult your power company if this condition exists. Note: use only liquid tight fittings to protect the electronic...

Page 12

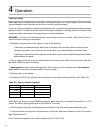

Button speed (rpm) duration (hours) step 1 1100 12 step 2 0 0 step 3 0 0 override 3450 2 12 caution:never run the pump without water. Running the pump “dry“ for any length of time can cause severe damage to both the pump and the motor and will void the warranty. If this is a new pool installation, m...

Page 13

13 start up guide - continued the ps165vsp pumps come with factory defaults of step 1 set for 1100 rpm for 12 hours duration and the override set for 3450 rpm for 2 hours duration. The remainder of the 24 hour day, the pump will be off. These speeds and durations can be programmed on site for each s...

Page 14

14 programming operates on a 24 hour cycle that begins from the time the start button is pushed. To start the cycle at a specific time, see the schedule advance section on page 17. Programmable speed settings: 3450, 3100, 2850, 2600, 2350, 2100, 1850, 1600, 1350, 1100, 850, 600, 0 note: 0 is a progr...

Page 15

15 programming - continued menu structure 1. Step 1 (set schedule) a. Speed and duration 2. Step 2 (set schedule) a. Speed and duration 3. Step 3 (set schedule) a. Speed and duration 4. Override (settings) a. Speed and duration 5. Start press start to run the pump based on the programmed 24 hour sch...

Page 16

16 menu structure - continued the keypad has a “key lockout” feature to prevent unwanted changes to the settings. To lock the keys, hold down the step 1, 2, and 3 buttons all at the same time for more than 3 seconds. The “active step leds” for step 1, 2 and 3 will blink for 30 seconds indicating tha...

Page 17

17 schedule advance the schedule advance feature allows you to program the pump yet start the 24 hour cycle at a different time of day. The following steps should be followed to set the schedule advance: 1. With the motor stopped, press the start key and hold for more than three seconds. The start l...

Page 18

18 the pump is equipped with an override feature, which can be engaged to temporarily run at higher or lower speeds between 600 to 3450 rpm. Once override duration has elapsed, the motor will automatically return to programmed schedule. 1. Pressing the override key; while the motor is running; will ...

Page 19

Pin# wire color description j201-1 red + 12v j201-2 green rs485 - a j201-3 black rs485 - b j201-4 yellow isolated ground 19 communication - continued note: there is no schedule for digital inputs. The timing for each speed is controlled directly by the digital inputs. Note: the digital inputs have t...

Page 20

L2 n l1 12v - pin1 di-1 di-2 di-3 di-4 l1 (black) l2 (red or white) earth earth l1 (black) l2 (red or white) earth earth 208-230v power source 20 3rd party controllers (wiring) figure 8 note: 12v from the rs485 can be wired to the line in of each aux. Load out will be the input for each digital sign...

Page 21

W at er t em p. Se ns or filter pump relay optional relay rs6 or rs8 optional relay rs8 optional relay rs6 or rs8 optional relay rs8 aux. 3 relay aux. 1 relay li ne o ne lo w vo lta ge r ac ew ay (d o no t r un h ig h vo lta ge w ire in th is co m pa rtm en t) li ne t wo lo ad o ne lo ad t wo aux. 2...

Page 22

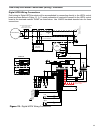

Receiver power supply 120v 240v single pole breaker l1 (black) l2 (red or white) earth earth 208-230v power source 12v - pin1 di-1 di-2 di-3 22 3rd party controllers (wiring) - continued figure 10 wiring diagram for multiwave with ps165vsp make sure that voltage selector switch is in 120v position b...

Page 23

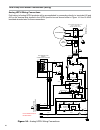

12v - pin1 di-2 di-1 di-3 di-4 l1 (black) l2 (red or white) earth earth l1 (black) l2 (red or white) earth earth 208-230v power source 23 3rd party controllers (wiring) - continued figure 11 wiring diagram for intellitouch with ps165vsp.

Page 24

24 heat pump pool heater connections (wiring) the ps165vsp can be connected directly to single phase or 3-phase raypak, rheem, ruud, weatherking and perfectemp heat pump pool heaters (hpph) without the need for any external sequencer or control. The hpphs will provide an override signal to the pump ...

Page 25

Voltage monitor power defrost heat/cool nc no com l1 l2 l2 bk (to transformer) bl r fan motor bk l1 l1 l2 insert a use copper conductors only use 75 o c 600 v wire torque screws: 40 in-lb m compressor c s r l1 l2 o bk br bl nc no com fr power suppl y 208/230v -1 phase-60h z r 1 bk insert b insert b ...

Page 26

Spa / remote / pool switch shown in pool position use copper conductors only use 75 o c 600 v wire torque screws: 40 in-lb field connections to raypak pumps compressor fan motor power suppl y 208/230v -1 phase-60hz bk o br bk r r y a b c d spa 1 2 3 1 2 3 pool bk bk bk/w bk bk bk bk bk bk bk bk gy/b...

Page 27

27 heat pump pool heater connections (wiring) - continued connect the 18awg wires from the hpph to the ps165vsp pump as show and described below. Wiring connections to the ps165vsp pump figure 15 - ps165vsp wiring connections it does not matter which wire is connected to the io-4 terminal or the ign...

Page 28

28 8. Verify that all valves have been returned to the proper position for normal operation. Turn on the power to the pump. Routine maintenance - continued caution:the pump must be protected when freezing temperatures are expected. Allowing the pump to freeze will cause severe damage and void the wa...

Page 29

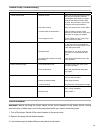

29 general pump troubleshooting problem possible cause solution 1. Pump will not prime. A. Suction air leak b. No water in pump. C. Closed valves or blocked lines. D. Low voltage to motor. Make sure see-through lid and o-rings are clean and properly positioned. Hand tighten see-through lid. Tighten ...

Page 30

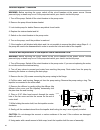

P um p s ea l h ou si ng sealing surfaces rubber collar spring assembly ceramic ring impeller shaft 30 blocked impeller - continued warning: before servicing the pump, switch off the circuit breakers at the power source. Severe personal injury or death may occur if the pump starts while your hand is...

Page 31

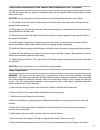

31 10. With the carbon side up, push the mechanical seal onto the impeller shaft and wipe carbon surface with a clean cloth. Caution:do not use grease or lube to install seal. It will damage the seal and cause failure. 11. The ceramic side of the seal can be pushed out from the rear of the seal hous...

Page 32

27.1" 16.6" 17.0" 12.1" 12.7" 13.6" 8.9" 4.3" 6.8" 0.4" 5.1" 6.9" 9.7" b 20 40 60 80 100 120 140 160 a c gallons per minute tot al head in feet 80 70 50 60 40 30 10 20 0 3450 rpm 3100 rpm 2850 rpm 2600 rpm 2350 rpm 2100 rpm 1850 rpm 1600 rpm 1350 rpm 1100 rpm 600 rpm 850 rpm b, a, and c represent av...

Page 33

Auf zu ouvrir fermer open close 5 6 7 10 11 12 19 17 13 16 1 20 2 3 8 15 14 5 6 7 4 9 18 33 replacement parts and exploded view kit number call-out qty description spanner - lid 1 union end - 2” abs 014344f 5 nut - union abs 014328f 2 1 lid - clear 014329f 1 1 lid lock ring - dark gray 014330f 3 1 o...

Page 34

Notes 34.

Page 36

2999999292 - rev 01/2013 v1.