Catalog no. 6200.51o effective: 04-09-07 replaces: 05-15-05 models 2100-4001 p/n 240251 rev. 16 installation and operating instructions raytherm tm commmercial swimming pool heater models p-926 to p-1826 and p-2100 to p-4001 this manual should be maintained in legible condition and kept adjacent to ...

Contents section 1: receiving equipment section 2: general specifications section 3: installation instructions code requirements base installation clearances combustion air venting connections gas supply connections water connections controls wiring diagrams section 4: servicing instructions general...

12" minimum 12" minimum 4" minimum hea ter sheet metal 24 gauge important notice these instructions are intended for the use of qualified personnel only, specifically trained and experienced in the installation of this type of heating equipment and related system components. Installation and service...

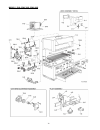

4 fig. #8245 clearances all heaters for clearances from combustible surfaces, see chart below. We require a minimal vertical clearance of three feet between the upper surface of the flue outlet to a non- combustible material. Minimum clearances from combustible construction indoor heaters top - 24" ...

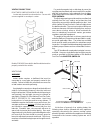

5' min 2' min 10' or less 2' min vent cap vent pipe draft hood heater for protection against rain or blockage by snow, the vent pipe must terminate with a vent cap which complies with the local codes or, in the absence of such codes, to the latest edition of the national fuel gas code, ansi z223.1/n...

(a) seal any unused openings in the common venting system. (b) visually inspect the venting system for proper size and horizontal pitch and determine there is no blockage or restriction, leakage, corrosion and other deficiencies which could cause an unsafe condition. (c) insofar as is practical, clo...

Gas pressure regulator the gas pressure regulator is preset and sealed at 4 in. Wc for natural gas, and 11 in. Wc for propane gas. Between the gas valve and the burners is a 1/8" pipe plug. The pressure at this point, taken with a manometer, should be about 3.7 in. Wc natural gas and 10.5 in. Wc pro...

When local codes permit the use of less than four feet high temperature piping or two elbows, provisions should be made to always shut the heater off a minimum of 15 minutes prior to pump shut down in order to carry away residual heat and prevent damage to the low temperature piping. A fireman switc...

9 models 1287/1336 - 1758/1826 i n l e t / o u t l e t header 2-1/2" inlet 2-1/2" outlet 1-1/2" slip ball valve 2" slip ball valve 3" outlet fig. #9270 fig. #9200 pump 3" inlet 2 h.P. Pump inlet/outlet header models 2100-4001 flow rates/water connections model connection size min gpm max gpm 926-122...

10 raypak recommends the installation of an air bleed vent at a suitable location (usually the highest point) to remove air from the piping system. These units should be available at your local wholesale supplier. Raypak does not provide this item. Caution: power to the heater should be interlocked ...

Note: the drawings and instructions above show only one of several acceptable ways of installing the dry well into main system loop. The use of saddle clamps and “weld o lets” (shown in fig. 10) are acceptable. Follow clamp manufacturer’s instructions. Mounting well into system return loop pipe - fr...

4. If the heater inlet temperature remains less than 100°f and valve "a" is fully open, leave valve "a" fully open and throttle valve "b" until the heater inlet temperature rises to within the range of 100°f-105°f. 5. The resultant heater outlet temperature should be in the range of 120-130°f. 6. As...

Models 2100 thru 4001 13 piping configurations for raytherm commercial pool heaters fig # 9268 fig # 9269 blended water temperature (thermometer at heater inlet) heater outlet temperature thermometer heater thermostat recommended field installed isolation valves for service t i t o t c.

14 external auxiliary bypass valve (where required) 926-1223 models only an auxiliary bypass valve should be used when flow rates exceed 120 gpm (usually a high performance pump size larger than two hp will exceed this flow rate). This valve is required to complement the function of the automatic by...

15 high & low gas pressure switches pressure switches sense either high or low gas pressure and automatically shut down burners if abnor- mal pressures exsist. Standard on models 3001-4001. Pressure switch gas manifold fig. #8236 electrical wiring caution: label all wires prior to disconnection when...

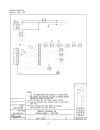

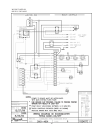

16 wiring diagram models 926 - 1223.

17 wiring diagram models 1287-1826.

Wiring diagram models 2100-2500 18.

Wiring diagram models 3001-4001 19.

Temperature control the pool water temperature is controlled by the pool thermostat. The heater water temperature high limit is controlled by the manual reset high limit. Pressure switch the pressure switch, or heater actuator, ensures that the heater operates only when the filter pump is in operati...

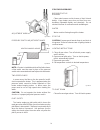

Adjustment knob fig. # 8069.1 pressure switch adjustment range heat exchanger height 5' max 5' max fig. # 8152.0 note: if heater is installed outside of the limits shown, a flow switch must be used in place of the pressure switch when mounted and wired adjacent to the heater. Two-speed pumps in some...

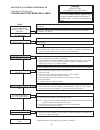

After start-up pilot system checkout procedure 1.Turn on power to the ignition systems and turn gas supply off. 2.Check ignition module as follows: a.Set the thermostat above pool water temperature to turn heater on. B.Watch for continuous spark at the pilot burner. C. Time the spark operation. Time...

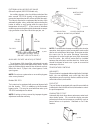

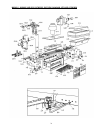

Servicing procedures tube cleaning procedure (typical) establish a regular inspection schedule, the fre- quency depending on the local water condition and severity of service. Do not let the tubes clog up solidly. Clean out deposits over 1/16" in thickness. Although the illustration shows the mechan...

5. Remove heat exchanger corner brackets. 6. Remove combustion chamber clips at the four corners of the heat exchanger. 7. Lift heat exchanger straight up using caution not to damage refractory. Heat exchanger reassembly 1. Heat exchanger header o-rings should be replaced with new ones. 2. Install i...

Control well replacement remove top, sensing bulb and clip. Collapse well tube at the open end and with a chisel, push through into the header, and remove the well through header. Insert a new well and roll into place. If a roller is not available, solder the well in place with silver solder. Immers...

Models 926-1223 unitherm governor inlet/outlet header outlet inlet fig. #8224.0 gasket unitherm governor with power element models 1287-1826 (models prior to jan. '95) double external u.G. Models 2100-4001 (models prior to jan. '95) external u.G. To test operation of unitherm governor, place in hot ...

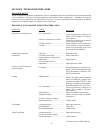

Section 5 / troubleshooting guide important notice these instructions are primarily intended for the use of qualified personnel specifically trained and experienced in the installation of this type of heating equipment and related system components. Installation and service personnel may be required...

Outer jacket very hot (paint blistered) *broken refractory caused by shipping damage or improper combustion………………………….. Excessive sooting of heat exchanger…………………………... Calculate temperature in °f/hr……... Filter not running long enough…….... Dirty filter…………………………….. Gas line or meter under- sized……...

12345678901234567890123456789012123456789012345678901234567890121 12345678901234567890123456789012123456789012345678901234567890121 12345678901234567890123456789012123456789012345678901234567890121 12345678901234567890123456789012123456789012345678901234567890121 123456789012345678901234567890121234...

Section 6 / replacement parts list note: to supply the correct part it is important that you state the model number, serial number and type of gas when applicable. Any part returned for replacement under standard company warranties must be properly tagged with raypak return parts tag, completely fil...

Models: 926/962, 1083/1125, 1178/1223, 1287/1336, 1414/1468, 1571/1631, 1758/1826 31 2-c.

32.

33.

Models: 2100, 2500, 3001, 3500, 4001 34.

35.

36.

37 limited warranty raytherm type p sizes 0926-4001 scope: raypak, inc. (“raypak”) warrants to the original owner that all parts of this heater which are actually manufactured by raypak will be free from failure under normal use and service for the specified warranty periods and subject to the condi...

Raypak, inc., 2151 eastman avenue, oxnard, ca 913030 (805) 278-5300 fax (800) 872-9725 raypak canada ltd, 2805 slough street, mississauga, ontario, canada l4t 1g2 (905) 677-7999 fax (905) 677-8036 litho in u.S.A. Www.Raypak.Com.