P/n 240499 catalog no.: 6200.50 m effective: 04-15-05 replaces: 06-01-00 installation and operating instructions commercial swimming pool heaters raytherm models 514-824 this manual should be maintained in legible condition and kept adjacent to the heater or kept in a safe place for future reference...

Water chemistry (corrosive water voids all warranties) for your health and the protection of your pool equipment it is essential that your water chemically balanced. The following levels must be used as a guide for balance water. Free chlorine must not exceed 5 ppm! • occasional chemical shock dosin...

4 part one - owner’s operating instructions 4 section 1/start-up procedures 4 before start-up 5 operating instructions 6 after start-up 6 section 2/caution 6 section 3/maintenance and care procedures pool & spa water chemistry 7 part two - installation/service instructions 7 section 1/receiving equi...

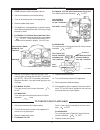

Part one - owner’s operating instructions for your safety - read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result, causing property damage, personal injury or death. Section 1/start-up procedures before start-up burners clean main burners and ...

5 1. Stop! Read the safety information above. 2. Set the thermostat on the lowest setting. 3. Turn off all electric power to the appliance. 4. Remove heater door panel. 5. This appliance is equipped with an ignition device which automatically light the pilot. Do not try to light the pilot by hand. 6...

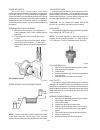

After start-up feel the inlet and outlet pipes. Outlet pipe should be only slightly warmer than the inlet. It should not be hot. Warning: should overheating occur or the gas supply fail to shut off, turn off the manual gas control to the appliance. Visual inspection with the heater on, remove the do...

5. On indoor heater, clean room intake openings to assure adequate flow of combustion and ventilation air. Caution: combustion air must not be contaminated by corrosive chemical fumes which can damage the heater and void the warranty. 6. Keep air around heater clear and free from com- bustible mater...

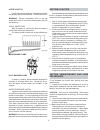

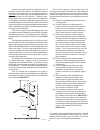

4 foot minimum 4 foot minimum 1 foot minimum 4 foot minimum 3 foot minimum 10 foot minimum forced air inlet 12" minimum 12" minimum 4" minimum hea ter sheet metal 24 gauge 8 high wind conditions (outdoor units only) in areas where high winds are fre- quent, it may be necessary to locate the heater a...

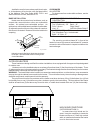

Indoor heater the design is also certified for indoor installation when equipped with the approved draft hood. Locate heater as close as practical to a chimney or gas vent. Heater must always be vented to the outside. See vent piping section for venting details. Minimum allowable space is shown on t...

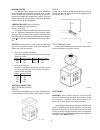

As much as possible avoid long horizontal runs of vent pipe and too many elbows. If installation requires horizontal non-vertical runs, the vent pipe must have a minimum of 1/4 inch per foot rise and should be supported at not less than five foot intervals. Plumbers tape, crisscrossed, will serve to...

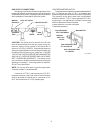

Gas supply connections gas piping must have a sediment trap ahead of the heater gas controls, and a manual shut off valve located outside the heater jacket. All gas piping should be tested after installation in accordance with local codes. Manual shut off valve gas inlet heater jacket sediment gas t...

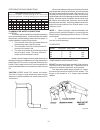

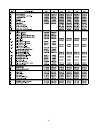

Pipe sizing for gas connections maximum equivalent pipe length natural gas 1000 btu/ft .60 specific gravity @ 0.5” w.C. Pressure drop propane gas 2500 btu/ft 1.53 specific gravity @ 0.6” w.C. Pressure drop 1/2” 1” 1-1/4” 1-1/2” 2” 2-1/2” n p n p n p n p n p n p 514 - 10 15 35 65 150 130 360 500 - - ...

Automatic chlorinators and chemical feed- ers all chemicals must be introduced and completely diluted into the pool or spa water before being circulated through the heater. Do not place chlorine tablets or bromine sticks in the skimmer. High chemical concen- trations will result when the pump is not...

To avoid water damage or scalding due to valve operation, drain pipe must be connected to valve outlet and run to a safe place of discharge. Drain pipe must be the same size as the valve discharge connection through- out its entire length and must pitch downward from the valve. No shutoff valve shal...

15.

16 151965 824 825,000 btuh.

17 152141 514-724 512,000 thru 726,000 btuh 5.

18 152142 824 825,000 btuh 6.

Controls/adjustments/replacements thermostat the heater is built with a single mechanical thermo- stat, located in the front panel above the door. The thermostat maybe set for any desired pool or spa temperature temperature sensor mechanical thermostat fig. # 8060.1 typical comfortable spa temperatu...

Pressure switch the pressure switch, or heater actuator, insures that the heater operates only when the filter pump is in operation. It is factory set at 1.75 psi for deck level installations. When the heater is located below the level of the spa or pool it may be necessary to reset the pressure swi...

Gas valve removal 1. Shut off gas supply to the heater. Remove gas piping to gas valve inlet. 2. Disconnect wires, pilot tubing and bleed line, if required. 3. Turn vertical gas pipe from manifold slightly and unscrew gas valve. 4. Reverse above procedure to re-install. Main burner and orifice remov...

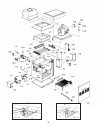

22 shut gas and power off to the unit, close the system off and drain the heater. Remove the draft diverter. Remove the access panel and jacket top. Lift flue collector off. Remove “v” baffles over tube(s) to be replaced. If no pipe unions have been provided, use the header as a union, remove the fl...

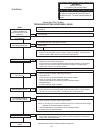

23 section 5/troubleshooting guide important notice these instructions are primarily intended for the use of qualified personnel specifically trained and experienced in the installation of this type of heating equipment and related system components. Installation and service personnel may be require...

Inspect bypass for movement, if no movement, replace. Replace if no movement when heated. Replace well and maintain water chemistry properly. Replace heat exchanger and maintain chemistry properly. See pressure switch adjustment. Replace refractory. Determine cause of sooting and correct. Bypassing ...

12345678901234567890123456789012123456789012345678901234567890121 12345678901234567890123456789012123456789012345678901234567890121 12345678901234567890123456789012123456789012345678901234567890121 12345678901234567890123456789012123456789012345678901234567890121 123456789012345678901234567890121234...

26 section 6/replacement parts list note: to supply the correct part it is important that you state the model number, serial number and type of gas when applicable. Any part returned for replacement under standard company warranties must be properly tagged with raypak return parts tag, completely fi...

This page is empty.

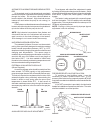

28 pilot assembly- electronic ignition pilot assembly- standing pilot fig # 9293 fig # 9294.

29.

30

Raypak, inc., 2151 eastman avenue, oxnard, ca 93030 (805) 278-5300 fax (800) 872-9725 litho in u.S.A. Www.Raypak.Com.