- DL manuals

- Raypak

- Gas Heater

- VERSA 055B

- Operating And Installation Manual

Raypak VERSA 055B Operating And Installation Manual

Part No. 240428

CATALOG NO. 6100.52-K

Effective:

3-01-00

Replaces:

3-15-99

®

OPERATING AND

INSTALLATION

INSTRUCTIONS

Models

055B

VERSA

SPA

and

HOT TUB HEATER

This manual should be maintained in legible condition and kept adjacent to the

heater or kept in a safe place for future reference.

WARNING: If the information in these instructions are not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

— WHAT TO DO IF YOU SMELL GAS

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

•

If you cannot reach your gas supplier, call the fire department.

— Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

— Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

Summary of VERSA 055B

Page 1

Part no. 240428 catalog no. 6100.52-k effective: 3-01-00 replaces: 3-15-99 ® operating and installation instructions models 055b versa spa and hot tub heater this manual should be maintained in legible condition and kept adjacent to the heater or kept in a safe place for future reference. Warning: i...

Page 2

Contents 2 part one - owner's operating instructions 2 section 1 / start-up procedures 2 before start-up 3 lighting instructions & shut-off procedures (manually lighted pilot mv) 4 operating instructions & shut-off procedures (automatically lighted pilot iid) 5 after start-up 5 section 2 / caution 5...

Page 3

Part one - owner's operating instructions section 1 / start-up procedures before start-up burners clean main burners and air louvers of dust, lint and debris. Keep heater area clear and free from com- bustibles, flammable liquids and chemicals. Do not obstruct the flow of combustion and ventilating ...

Page 4

1. Stop! Read the safety information above. 2. Set the thermostat on the lowest setting. 3. Turn on/off switch to the "off" position. 4. Remove heater door panel. 5. Push in gas control knob slightly and turn clock- wise to "off". Note: knob cannot be turned from "pilot" to "off" unless knob is push...

Page 5

To turn off gas to appliance 4 1. Stop! Read the safety information above. 2. Set the thermostat to the lowest setting. 3. Turn off all electric power to the appliance. 4. This appliance is equipped with an ignition device which automatically lights the pilot. Do not try to light the pilot by hand. ...

Page 6

After start-up feel the inlet and outlet pipes. Outlet pipe should be only slightly warmer than the inlet. It should not be hot. Warning: should overheating occur or the gas sup- ply fail to shut off, turn off the manual gas control valve to the appliance. Visual inspection with the heater on, remov...

Page 7

4. Make visual check of the burner and pilot flame. Flame pattern on the main burner and pilot is indicated in the previous illustration. Yellow flame means restriction of the air openings. Lifting or blowing flame indicates high gas pressure. Low flame means low gas pressure. Should this occur, shu...

Page 8

Part 2 - installation / service instructions section 1 / receiving equipment on receipt of your equipment it is suggested that you visually check for external damage to the carton. If the carton is damaged, a note should be made on the bill of lading when signing for equipment. Remove the heater fro...

Page 9

8 all heaters for clearances from combustible surfaces, see chart below. Clearances from combustible construction. Indoor installation: top* (drafthood) - 35"; vent - 6"; back - 2"; right side - 6"; left side - 6"; floor - 0. Outdoor installation: top* (stackless top) - unobstructed; back - 2"; side...

Page 10

9 high wind conditions (outdoor units only) in areas where high winds are frequent, it may be necessary to locate the heater a minimum of 3' from high vertical walls, or install a wind break so the heater is not in direct wind current. Indoor heaters the design is also certified for indoor installat...

Page 11

Vent piping warning: indoor boilers require a draft hood that must be connected to a vent pipe and properly vented to the outside. Failure to follow this procedure can cause fire or fatal carbon monoxide poisoning. Vent piping the same size or larger than the draft hood outlet is recommended, howeve...

Page 12

Gas supply connections gas piping must have a sediment trap ahead of the heater gas controls, and a manual shut-off valve located outside the heater jacket. All gas piping should be tested after installation in accordance with local codes. Caution: the heater and its manual shut off valve must be di...

Page 13

12 plumbing for water connections location the versa heater requires water flow and posi- tive pressure to fire and operate properly. It must therefore be installed downstream of the discharge side of the filter pump. A typical installation is plumbed as follows: 1. The inlet side of the filter is p...

Page 14

Throughout its entire length and must pitch downward from the valve. No shut-off valve shall be installed between the relief valve and the drain line. Valve lever should be tripped at least once a year to ensure that waterways are clear. Electrical wiring note: if it is necessary to replace any of t...

Page 15

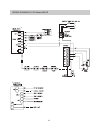

Spk 14 wiring diagram key fig. # 8096 fig. # s86/s8600 s86 s8600 pink connector blue connector for 120 v input power to the unit, connect the black wire to the “l1” or hot leg of the power supply. Connect the white wire to the “l2” or neutral leg of the power supply. Attach the wire nut to the red w...

Page 16

Wiring diagram millivolt units with mechanical thermostat wiring diagram millivolt units with solid state thermostat fig. # 2246e fig. # 1934e 15.

Page 17

16 wiring diagram 152178 model 055 iid bl bl bl.

Page 18

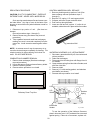

Section 4 / servicing instructions general location of controls drain valve solid state thermostat & ignition control pressure switch burner & pilot thermal fuse controls/adjustments/replacements caution: label all wires prior to disconnection when servicing controls. Wiring errors can cause imprope...

Page 19

Pressure switch adjustment: 1. With pump and heater on, turn adjustment knob (clockwise) until a click is heard from the gas valve. 2. Turn adjustment knob (counter clockwise) 1/4 turn. 3. Turn pump off and on several times. Heater should shut off immediately. If it does not, repeat steps above unti...

Page 20

Burner drawer removal 1. Shut off main electrical power switch to heater. 2. Shut off gas upstream of heater. 3. Remove front door. 4. Disconnect gas line from gas valve. 5. Remove (2) screws that mount burner tray to unit. 6. Disconnect wires that terminate at gas valve, and thermal fuse. 7. Slide ...

Page 21

Desooting procedure caution: soot is combustible. Exercise extreme care. Never use a wire brush. Soot can clog areas between fins and cause even- tual tube failure. Any sign of soot at the base of the burners or around the outer jacket indicates a need for cleaning. 1. Disconnect top portion of unit...

Page 22

Section 5 / trouble shooting guide important notice these instructions are primarily intended for the use of qualified personnel specifically trained and experienced in the installation of this type of heating equipment and related system components. Installation and service personnel may be require...

Page 23

If pilot burner remains lit. Jump across pressure switch terminals if main burner does not fire, remove jumper check for adequate water flow from filter replace pressure switch jump across thermostat if main burner fires, remove jumper if main burner does not fire... Jump across each high limit and ...

Page 24

Electrical (solid state thermostat millivolt) if the pool/spa/hot tub water is too cold, troubleshoot the system as follows: check voltage at + and - terminals. Voltage between + 0.2 v and 0.75 v. (polarity is critical) set control to max. Temperature. After 2-3 cycles, check water temperature. Temp...

Page 25

Electrical (electronic ignition iid) 12345678901234567890123456789012123456789012345678901234567890 12345678901234567890123456789012123456789012345678901234567890 12345678901234567890123456789012123456789012345678901234567890 12345678901234567890123456789012123456789012345678901234567890 12345678901...

Page 26

Electrical (solid state thermostat iid) if the pool/spa/hot tub water is too cold, troubleshoot the system as follows: check voltage at 24 v terminals. Voltage between 21.5-28.5 v. Set control to max. Temperature. After 2-3 cycles, check water temperature. Temperature below 105°f disconnect sensor l...

Page 27

Section 6/replacement parts list note: to supply the correct part it is important that you state the model number, serial number and type of gas when applicable. Any part returned for replacement under standard company warranties must be properly tagged with raypak return parts tag, completely fille...

Page 28

27 13-p 15-p iid mv 1-p 14-p 9-p 12-p 3-p 7-p 14-p 5-p fig. #8132.0 fig. #8133.0 1-v 7-c 1-c 2-c 13-h 12-h 11-h 6-h 5-h 4-h 10-h 1-s 2-s 3-h 7-h 2-h 2-v 4-s 1-r 5-m 3-s 7-m 6-c 5-c 3-c 1-m 2-m 2-b 3-b 1-g 9-m 11-p 4-c 5-s 6-m 1-b 6-s 3-m 4-m 8-h.

Page 29

28.

Page 30

29.

Page 31

Limited warranty raypak residential swimming pool & spa heaters general raypak, inc. Warrants that all parts of this product will be free from defects in materials and workmanship under normal use and service for a period of two years from the date of original purchase for a single family residence ...

Page 32

Raypak, inc., 31111 agoura road, westlake village, ca 91361-4699 (818) 889-1500 fax (818) 889-4522 raypak canada ltd, 2805 slough street, mississauga, ontario, canada l4t 1g2 (905) 677-7999 fax (905) 677-8036 raypak australia pty. Ltd, 7 geddes st., mulgrave, victoria, australia 3170 (6139) 560 4944...