Installation & operating instructions x94 professional gas-fired pool & spa heater catalog no. 6000.66 effective: 10-15-14 replaces: new p/n 241494 rev. 1 this manual should be maintained in legible condition and kept adjacent to the heater or in a safe place for future reference. Low nox model sr-4...

Water chemistry (corrosive water voids all warranties) for your health and the protection of your pool equipment, it is essential that your water be chemically balanced. The following levels must be used as a guide for bal- anced water. Recommended level(s) fiberglass pools fiberglass spas other poo...

3 contents 2 water chemistry 4 warnings 4 pay attention to these terms 7 lighting & shutdown instructions 8 pool & spa water chemistry 8 automatic chlorinators & chemical feeders 8 cold weather operation 8 winterizing the pool & spa heater 10 code requirements 11 clearances 11 outdoor heater install...

4 danger: indicates the presence of immediate hazards which will cause severe personal injury, death or substantial property damage if ignored. Warning: indicates the presence of hazards or unsafe practices which could cause severe personal injury, death or substantial property damage if ignored. Ca...

5 part one owner's operating instructions for your safety - read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result, causing property damage, personal injury or loss of life. Introduction your pool/spa heater has been designed for years of safe ...

6 section 3 - maintenance and care procedures to be followed one month after start-up and then semi- annually. 1. Inspect and operate all controls, gas valve and pressure relief valve. 2. On indoor heaters, clean room intake openings to ensure adequate flow of combustion and ventila- tion air. 3. Ke...

7 warning: should overheating occur or the gas supply fail to shut off, turn off the manual gas control to the heater. Caution: propane gas is heavier than air and will settle on the ground. Since propane can accumulate in confined areas, extra care should be exercised when lighting propane heaters....

8 chemical imbalance can cause severe damage to your heater and associated equipment. Maintain your water chemistry according to the chart on page 2. If the mineral content and dissolved solids in the water become too high, scale forms inside the heat exchang- er tube, reducing heater efficiency and...

9 part two installation and service instructions section 1 - receiving equipment the manufacturer recommends that this manual be reviewed thoroughly before installing your pool/spa heater. If there are any questions that this manual does not answer, please contact the factory or your local represen-...

10 section 3 - installation instructions california proposition 65 warning: this product contains chemicals known to the state of california to cause cancer, birth defects or other reproductive harm. Important notice these instructions are intended only for the use by qualified personnel, specifical...

11 outdoor heater installation x94 professional heaters are design-certified for outdoor installation, when equipped with the approved vent ter- minals designated for outdoor use. The heaters are designed for outdoor operation in non-freezing conditions only. Freezing conditions may cause condensate...

12 heaters must not be installed under an overhang of less than five 5’ (1.52 m) from the top of the heater, and the vent terminal must be a minimum of 5’ (1.52 m) from any overhang. See page 18 for vent terminal location requirements. Three sides must be open in the area under the overhang. Roof wa...

13 florida building code 2010 ultimate wind speed = 170 mph, 3 second gust nominal wind speed = 132 mph exposure = c gas heater model no. 410 fig. 3: hurricane tie down instructions.

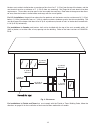

14 indoor heater installation the heater must always be vented to the outside. See the venting section (beginning on page 17) for details. Minimum allowable space is shown on the nameplate. Notes: 1. The model number prefix indicates: (s=stainless steel heat exchanger), (r=raypak) model number suf- ...

15 u.S. Installations 1 canadian installations 2 a clearance above grade, veranda, porch, deck, or balcony 1 ft (30 cm) 1 ft (30 cm) b clearance to window or door that may be opened 4 ft (1.2m) below or to side of opening; 1 foot (30 cm) above opening 3 ft (91 cm) c clearance to permanently closed w...

16 table 3: combustion air requirements b. All air from outdoors: when air is supplied directly from outside the building, each opening shall have a minimum net free area as noted: combustion and ventilation air (indoor units only) the heater must have both combustion and ventilation air. Minimum re...

17 general appliance categories heaters are divided into four categories based on the pressure produced in the exhaust and the likelihood of condensate production in the vent. Category i – a heater which operates with a non-pos- itive vent static pressure and with a vent gas tempera- ture that avoid...

18 support of vent stack the weight of the vent stack or chimney must not rest on the heater vent connection. Support must be pro- vided in compliance with applicable codes. The vent should also be installed to maintain proper clearances from combustible materials. Use insulated vent pipe spacers wh...

19 a vent shall not terminate: 1. Directly above a paved sidewalk or driveway which is located between two single-family dwell- ings and serves both dwellings. 2. Less than 7’ (2.13 m) above a paved sidewalk or paved driveway located on public property. 3. Within 6’ (1.8 m) of a mechanical air suppl...

20 caution: this venting system requires the installation of a condensate drain in the vent piping per the vent manufacturer’s instructions. Failure to install a condensate drain in the venting system will void all warranties on this heater. Condensate is acidic and highly corrosive. Note: ensure ad...

21 the connection from the appliance vent to the stack must be as direct as possible and shall be the same diameter as the vent outlet. The horizontal breaching of a vent must have an upward slope of not less than 1/4” (6.35 mm) per linear foot from the heater to the vent terminal. The horizontal po...

22 horizontal through-the-wall venting (category iv) fig. 8: horizontal through-the-wall venting table 7: max. Horizontal vent lengths caution: this venting system requires the installation of a condensate drain in the vent piping per the vent manufacturer’s instructions. Failure to install a conden...

23 fig. 9: horizontal through-the-wall direct venting the total length of the through-the-wall flue and air intake cannot exceed 65' (19.81 m) equivalent ft each (130' (39.62 m) combined) in length. Each elbow used is equal to 10’ (3.05 m) of straight pipe. This will allow installation in one of the...

24 fig. 10: outdoor venting fig. 11: 3 in 1 multi-vent adapter.

25 with the nfgc (u.S.) or b149 (canada). Vent pipes supported only by flashing and extended above the roof more than 5’ (1.52 m) should be securely guyed or braced to withstand snow and wind loads. The air inlet opening must be installed 1’ (0.3 m) above the roof line or above normal snow levels th...

26 maximum equivalent pipe length (ft) natural gas 1000 btu/ft 3 0.60 specific gravity @ 0.5 in. Wc pressure drop propane gas 2500 btu/ft 3 1.53 specific gravity @ 0.5 in. Wc pressure drop input 3/4” 1” 1-1/4” 1-1/2” model (kbtu) n p n p n p n p 410 399.0 * 15 20 55 95 225 215 480 4.6 ** 6.1 ** 16.8...

27 model pipe size min. Gpm max. Gpm* 410 1-1/4”–1-1/2” - 2” 40 (151.4 lpm) 125 (473.2 lpm) *when flow rates exceed maximum gpm an external auxiliary bypass valve is required. See external auxiliary bypass valve sec- tion for details. Flow rates external automatic bypass valve an external automatic ...

28 transformer wiring 120 vac wiring the heater requires 5 amps of 120v/1ph/60hz power. To wire the 120v power supply to the heater, connect the pair of black wires to the “l1” or hot leg of the power supply. Connect the pair of white wires to the “ret” or neutral leg of the power supply. Attach the...

29 plumbing—water connections the heater has standard right-hand plumbing connections, but can be converted to alternate configurations as shown below. The loose parts bag contains the pieces needed to connect your plumbing to the heater, see page 9 for list. Two options are recommended for the inst...

30 fig. 22: single pool or spa heater installation fig. 21: plumbing setup the heater requires water flow and positive pressure to fire and operate properly. It must therefore be installed downstream of the discharge side of the filter pump. A typical installation is plumbed as follows: 1. The inlet...

31 fig. 23: multiple pool or spa heaters installation fig. 24: single pool/spa heater installation fig. 25: multiple pool/spa heaters installation.

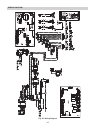

32 wiring diagram fig. 26: wiring diagram.

33 section 4 - servicing instructions general location of controls fig. 27: location of controls.

34 control adjustments control panel removal to remove the pc board from the heater, use the following procedure: 1. Turn off main power to the heater. 2. Remove front door to access wire harnesses. 3. Reaching underneath the pc board, carefully remove all connectors and wires from the pc board and ...

Period. Run schedule a/b run schedule a/b modes will operate the heater and all controlled features according to a user defined 7 day schedule. The schedules are programmed by pressing and holding the mode button for 5 seconds while in run schedule mode. Schedules a and b may each be set with up to ...

36 service. Fan rpm (view only) - indicates fan rpm target (lower left) and actual (lower right) speeds. The installer setup mode is accessed by pressing and holding the program button (sw1) on the back of the temperature/ignition control board (see page 35) for 5 seconds. Sw1 can be accessed by eit...

37 enable and disable a pump with full time power). The control will also power one of the variable pump outputs to select the pump speed. Pin 5 will enable speed 1, pin 4 speed 2 , pin 3 speed 3 and pin 2 speed 4. • variable - the control will close and open the pump relay to turn the pump on and o...

38 low temp lockout use the up and down buttons to enable or disable the low water temperature lockout function. Low temp lockout will inhibit the pool heater from firing if water temperature is sensed below 36ºf (2.2ºc). The x94 is designed to operate with low inlet water temperatures under start u...

39 display condition h2o sensor fail water temperature sensors open, shorted, or disagree aux ctrl fault 2 rom crc failure on companion board aux ctrl fault 3 ram failure on companion board aux ctrl fault 5 a/d reference failure on companion board aux ctrl fault 6 a/d multiplexor failure on companio...

40 remote control installation and operation caution: before installing remote controls to the heaters, read the following: the digital thermostat model is remote-ready in most cases. The digital liquid crystal display (lcd) shows the actual pool temperature, operating status, and service codes (see...

41 remote control wiring important installation notes for remote or external wiring configuration • remote wiring must be run in a separate conduit. • remote wiring must not be run parallel to high voltage lines. • for runs of under 30 feet (9.1 m), remote wiring should have stranded conductors with...

High limit removal 1. Shut off main electrical power switch to heater. 2. Remove front door. 3. Remove defective high limit and replace with a new high limit. 4. Replace inspection panel. The heater is equipped with two automatic high limits. Both are located in the inlet/outlet header. Both are set...

43 orifice removal the gas orifice is located on the gas train, between the gas valve and the combustion blower. 1. Locate and close the external manual shut-off valve. 2. Loosen the external gas union. 3. Locate and remove front door panel. 4. Locate and remove the (4) bolts & nuts holding the gas ...

44 important notice these instructions are intended for the use of qualified personnel who are specifically trained and experienced in the installation of this type of heating equipment and related system components. Installation and service personnel may be required by some states to be licensed. P...

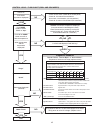

45 power on is the water temperature displayed? No yes push mode button to select "pool" or "spa" push up or down button to scroll to desired temperature no water temperature and set temperature displayed? Yes “purge” no no yes yes water temp displayed? (rectified) heater fired? End • check on/off s...

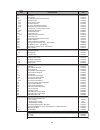

46 section 6 - replacement parts.

47.

48 note: to supply you with the correct part, it is impor- tant that you supply the heater model number, serial number and type of gas when applicable. Any part returned for replacement under standard company warranties must be properly tagged with a return parts tag, completely filled in with the h...

49 call out description 410 m miscellaneous components 1-m prv 75 psi 007223f 2-m t & p gauge 014647f 3-m wire harnesses (all unit harnesses) 015467f 4-m cabinet harness 015468f 5-m blower harness 120v 015469f 6-m gas valve harness 015470f 7-m high limit / flow switch harness 015471f 8-m condensate ...

50 (b) exemptions: the following equipment is exempt from 248 cmr 5.08(2)(a)1 through 4: 1. The equipment listed in chapter 10 entitled "equipment not required to be vented" in the most current edition of nfpa 54 as adopted by the board; and 2. Product approved side wall horizontally vented gas fuel...

51 installer setup record use this sheet to record installer setup mode settings. This record will simplify setup in the event it is necessary to reset factory defaults or install a new control. It is also a help- ful troubleshooting tool, allowing all setup parameters to be viewed on a single page....

Www.Raypak.Com raypak, inc., 2151 eastman avenue, oxnard, ca 93030 (805) 278-5300 fax (805) 278-5468 litho in u.S.A..