- DL manuals

- Riso

- Printer

- ComColor IS900C

- Instruction Manual

Riso ComColor IS900C Instruction Manual

Summary of ComColor IS900C

Page 1

Comcolor queries and support ver6.1 5 may 2011 rkc london office 1.

Page 2

Index1 6 scanner scan to share folder (smb) 7 scanner scan to share folder (smb unc) 8 scanner create the share folder on the mac os10.5/10.6 9 scanner set up scan to folder function for macintosh share folder 10 scanner scan to pc 11 scanner scan to e-mail 12 scanner scanning image direction 13 sca...

Page 3

62 control panel screws for touch panel 63 control panel touch panel failure 64 un-box/re-box i03-1814 65 un-box/re-box move to packing condition for the bp unit 66 un-box/re-box user guide box for finisher machine 67 un-box/re-box recommend setting for demo van 68 un-box/re-box releasing the head c...

Page 4

114 remote agent confirmation and troubleshooting for remote agent connection 1 115 remote agent confirmation and troubleshooting for remote agent connection 2 116 remote agent remote agent transfer specification 117 remote agent dns for remote agent setting 118 remote agent proxy for remote agent s...

Page 5

5 index4 168 electrical problem s98-0110-1 169 electrical problem usb function unable 170 scanner u03-43xx (scanner fb error) u04-4430 (scanner af error) 171 ink pan rubber tube protection in the area with high ozone level.

Page 6

1, create the share folder on the desktop of your computer or share server 2, set up the data directory in the admin mode settings=>scanner data directory=>add share folder name ip address of the computer “domain name” ¥ “login name” scan to share folder (smb) when you set up the share folder on the...

Page 7

1, create the share folder on the desktop of your computer or share server 2, set up the data directory in the admin mode settings=>scanner data directory=>add “domain name” ¥ “login name” scan to share folder (smb unc) when you set up the share folder on the computer which is used dhcp , you should...

Page 8

Create the share folder on the mac os10.5/10.6 8 1. Create a folder 2. Click the “sharing” in the system preferences 3. Tick the file sharing and then press “+” 4. Add the folder 5. Check the share users if everyone is included. Then press the options 6. Tick the smb function and the login account f...

Page 9

Set up scan to folder function for macintosh share folder 9 share folder name computer name login name and password ip address for the mac select [smb] function scanner.

Page 10

Scan to pc 2,press the ok button 3,select the networked computer 4,directory will be changed to computer name 5,after scanning, the scan data will be saved into the share folder soon 1,press the scanner button if the scan direction setting is not correct, w60 error will be displayed. You can registe...

Page 11

Scan to e-mail regarding the scan to mail setting, you need to ask customer’s network environment. Especially when the customer uses smtp authentication on the mail server, it is better to ask them to set up. For this setting, you can normally confirm it from the mailer (mail application) on the cli...

Page 12

Scanning image direction function scanner when you scan the custom size original etc, you need to specify the size by the “scanning size” function in the function tab. If you change the “image size”, scanning image might be incorrect. Original scanning result (ng) scanning direction when “a4” is sel...

Page 13

Sort printing with fb scanning function scanner when you make some copies from the flatbed with some pages original, you need to change the collate function from “auto” to “sort”. If you don’t change this, machine will print soon after one page scanning without confirmation screen. Scan from the fb:...

Page 14

Ic card activation specification iso14443 typea typec (mifare/felica) up to 300 users set up procedure 1) perform the key code by test mode 716/717/718 2) press the admin button, then the machine will request the admin ic card 3) set the admin ic card on the reader and press the setting button 4) in...

Page 15

Cancel the ic card function when you need to cancel the ic card function, if amount of the following test-modes turn to “0”, ic card function will disable. After re-enter the test-mode, the registered ic card information will return again without re-enter 716 to “0” 717 to “0” 718 to “0” function ic...

Page 16

Individual touch panel setting when the ic card reader is installed, the machine can set up individual default screen for each ic card (each user) before individual setting, you must switch the login setting to “required” in admin mode if the login setting is “not required”, “save as default” button...

Page 17

Save as default setting for all users log in as admin set up the functions as default setting select the function tab select the check setting button press the save as default button then the default screen will save for all users when you want to save individually, ic card reader and login setting ...

Page 18

User setting data upload/download 1) download the csv file from riso console as admin mode ( write csv file button) 2) change the extension code from .Csv to .Txt. Or you should open the file as “note pad” by right click. 3) add or change the data, after that save as text data. 4) change the extensi...

Page 19

Retrieve the common touch panel setting for each ic card user function user setting when ic card users are registered as login required, all ic card user can set up own screen setting individually. If the admin has set up the recommend setting as default screen, all user can download this setting in...

Page 20

Confirm the current counter for each user when print limitation function is used, each user can find the own current counter. 1) login as user 2) press the meter reading button 3) you can see it in the limit tab b/w print: 2000 colour print: 500 b/w copy: 1000 colour copy: prohibited 20 function use...

Page 21

Forgot admin password (typing password) 1. Downgrade the firmware to ver7.16. 2. Create the admin backup using tm460 3. Delete the all users using tm504 and tm510 4. Retrieve the admin backup data using tm461 5. Connect an ic card reader 6. Activate the ic card reader using tm716, tm717, tm718 7. Wh...

Page 22

Lost the admin ic card when the firmware version is ver10.16 or before 1. Retrieve the user setting csv file via riso console 2. Change one of the user authority from “user” to “admin” on the csv file 3. Overwrite this revised csv file via riso console 4. Login admin mode using this revised new admi...

Page 23

Copy from booklet original to booklet output 1) place the original on the af 3) select the function tab 4) select the booklet button 5) remove the imposition 6) press the ok button 2) set up duplex to duplex comcolor can make the booklet print from booklet paper original paper original you should se...

Page 24

A3 mix size copy original size and direction paper direction is also same as original direction b4 a3 a4 b5 a4 b4 b5 function copy 24.

Page 25

Mac address confirmation 1) open the riso console and select the login button 2) enter the user name as “admin” and press “ok” 3) press the admin mode button then it turn to black button, and the admin tab will appear at left side 4) there is a “network setting” in the admin tab 5) you can see the m...

Page 26

Folder function in the printer driver three kind of output function printer driver 26 if you use the folder function, you need to set it up in the admin setting and “environment tab” of the printer driver. After that you can select three kind of output “print”, “print and save to folder” or “save to...

Page 27

Booklet to booklet from the printer driver when you print from the “booklet original” to the “booklet output”, you can set the driver with following steps. 1) select “short edge” in the duplex menu function printer driver 2) select “fold + staple” in the booklet binding menu 3) return the imposition...

Page 28

Printer driver installation for macintosh os10.5/10.6 printer driver 28 open the system preferences add the printer after install the printer software from the cd to the mac, you should set up the printer next. Ip address lpd normal is900c etc change from “generic” to “select printer software” selec...

Page 29

Property settings for macintosh printer driver printer driver 29 depends on the customer’s macintosh, detail setting screen for printer might be hidden hidden condition open condition click pull down menu when you select is900c in the pull down menu, property settings button will appear. Function.

Page 30

Printer driver (ppd) installation for ubuntu10 printer driver 30 is900c is not compatible with ubuntu os, but riso ppd might work on ubuntu with following installation to add the printer driver, open “system tab”-”administration”-”printing”-add(+) enter the ip address and press “find” few minutes la...

Page 31

Signal light connection (patlite) compatible signal light (patlite) with comcolor product code: [les-402a-rygb] http://gb.Patlite.Eu/ required option pcb and spare parts s-2050 option pcb 050-75057-000 if connector ; pato-light 050-75064-103 bushing plate ; su 665-04064-108 cord bushing ; sr 6l-1 le...

Page 32

Signal light installation (patlite) 1. Cut the harnesses 50cm from the pole end if you change the pole to longer one, you must change it before cutting the harness 2. Strip the cable 10mm from the harness end (excluding blue line) 3. Wrap the harnesses with tape 10cm from the pole end 4. Through the...

Page 33

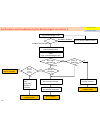

- login setting - user management - group management etc… comcolor authentication server (third party) “kerberos protocol” the new comcolor firmware has been modified to use “ldap” and “kerberos” protocol for user authentication. These features bring administrators to manage users with an external a...

Page 34

Ldap setting up example 1 step 1: upgrade firmware to ver11.16 or later step 2: change the test mode 784 to “1” step 3: change the authentication servers setting in admin mode to “on” step 4: setting up the ad server details. Following settings is one of the example when active directory is used as ...

Page 35

Ldap setting up example 2 a. Realm name b. Ic card no homephone pager mobile facsimiletelephone number ipphone info c. Samaccountname d. Ou=admin staff, dc=risodirect ,dc=co, dc=uk e. Scope of search f. Dns ldap function 35.

Page 36

Count pattern 21 and finisher no category paper size charge to (type b) charge to (type f) 1 colour a3 c1 (large; 2 click)=ftl c1 (large; 2 click)=ftl 2 colour a4 c3 =fts c3 =fts 3 colour b4 c1 (large; 2 click) c1 (large; 2 click) 4 colour b5 c3 c3 5 colour foolscap c3 c3 6 colour long irregular siz...

Page 37: Note

Count up specification with copy mode color mode original copy count as… note auto color normally color depends on the color level and size of the image on the original depends on the “color/black slice level in the admin mode b/w monochrome full color color color default setting at the installation...

Page 38

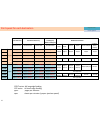

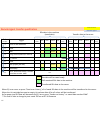

Print speed for each destination face down tray face down offset tray auto-control stacking tray /wide stacking tray multifunction finisher standard stack standard stack offset stack standard stack standard stack offset stack punch staple punch & staple booklet (fold + staple) cc9050 simplex 150ppm ...

Page 39

Ejection speed for facedown offset tray when the offset stacking tray is connected with cc9050, maximum ejection speed will be 120ppm. (a4r standard stacking) when you change the test mode 3729 to “1”, ejection speed will be faster. But paper alignment is not good. Explanation print speed 39.

Page 40

Resolution paper type original image maximum ink drops comcolor hc5500 300x300dpi plain photo-based 5 5 line-based 5 4 ij paper photo-based 5 5 line-based 5 5 matt coated photo-based 6 6 lone-based 6 6 card-ij high-quality photo-based 7 7 line-based 7 7 card stock (only for hc) photo-based - 5 line-...

Page 41

Remaining ink in the cartridge if the firmware version is old, when ink cartridge become to empty, the machine might indicate ink volume as still remain (30% etc) firmware ver5.34 or older ink consumption for head cleaning is not calculated for ink volume indication firmware ver5.57 or later ink con...

Page 42

Difference of “basic” and “school” at the set up wizard multi-up booklet head cleaning book shadow erase multi-up program booklet head cleaning basic school end of the set up wizard, you have to select user category “basic” or “school”. After the set up wizard, frequent functions of the copy mode wi...

Page 43

Recommend screen setting of copy mode for school when you set up the top screen of copy mode as following, teacher basically can manage almost their jobs by only this screen. You need to log in as admin to register them as default setting. Auto auto direct access: “ select layout ”, “ program ”, “ a...

Page 44

Security level usability explanation security level 1(low) 2(normal) 3(high) a dm in se tti ng s folder function on on off additional copies permitted prohibited prohibited finished job re-printing permitted prohibit prohibit waiting job setting not auto deleted not auto deleted auto deleted all job...

Page 45

Pause the print job usability explanation when you stop or pause the print job from the pc, you need to open the printer screen to do. You cannot stop it on the “mode selection screen”. As for the copy job, you can pause it on the copy screen cannot stop can stop 45.

Page 46

W70-0247-01 when you active the test mode, if there are some exclusion combination on the machine, for example a4 landscape paper and booklet. As for test mode 2428, when front cover is closed, the machine will display w70-0247-01. W70-0247-02 when the combination between the control card and the ma...

Page 47

W70-0247-3 47 if you open and close the front cover during the test mode, and then if you perform the test mode 2405 (bp unit move up) or tm2437 and tm2439 (maintenance unit action), w70-0247-3 will be displayed. Enter the test mode open the front cover and close w70 occurs when perform tm2405 if yo...

Page 48

Error history display on the panel you can see the error history on the touch panel by test mode 630 normally each errors are showed error no which is started from 1, 2 or 3. 1: service error (s-) 2: unit error (u-) 3: jam error (x-) explanation error code 48.

Page 49

Auto color level regarding the auto colour, the slice level of colour and black is calculated from colour tone , saturation and number of pixels of scanned data. Depends on the above condition, the machine will decide if this document is b/w or colour. Therefore when there are two paper originals wh...

Page 50

Combination between rgb and cmyk 50 green r: 0 g: 255 b: 0 red r: 255 g: 0 b: 0 blue r: 0 g: 0 b: 255 cyan r: 0 g: 255 b: 255 yellow r: 255 g: 255 b: 0 magenta r: 255 g: 0 b: 255 black r: 0 g: 0 b: 0 white r: 255 g: 255 b: 255 you can change the gamma settings in the printer driver. For example, gre...

Page 51

Paper size and type setting there is not ”any” on the “paper type menu” there is a selection “any” in the menu. (“any” is default) for hc5500, you usually set up the tray selection by test mode 5-8-17, “size” or “size and paper type”. For comcolor, there are not any setting for tray selection such a...

Page 52

Auto tray selection basic concept (when same “size”, “direction” and “type” paper are loaded for all trays) 1) tray priority: standard>tray3>tray2>tray1 2) when the all trays become to empty, the feed tray priority return to the standard tray 3) the feed tray is selected the same tray which is used ...

Page 53

Line smoothing 300dpi 300dpi 300dpi 600dpi 600dpi normal line smoothing line smoothing normal printer driver: create 300x300dpi or 300x600dpi bitmap data 300 - 900dpi 300 - 900dpi gdi: create 300x300 - 900x900 dpi data application machine when the line smoothing is used, gdi creates basically 900x90...

Page 54

W39-1154 (no destination for continuous output) maintenance right side ejection if this error is displayed when you set up the paper eject destination to finisher side, you should check the connection condition for the wire harness of the paper ejection unit which is circled with red colour paper ej...

Page 55

Side wing width tm1856 (big amount is wider) when use this position, you need to press the “jump wing control button” for each mode (copy or printer) side fence width tm3703 (+100 means 1cm wider) in order to use this position, you need to change the paper type to “card” tm3702 (+100 means 1cm wider...

Page 56

Ejection unit m4x 6mm screw touch x17-3140 / 3164 when print over 4 pages to finisher you must use m4x6mm (short) screws for fixing the ejection motor when 8mm screws are used, the top of the screw might contact on the ejection gear. As a result, rotation of the ejection roller slows down, then rema...

Page 57

Re-use the auto stacking tray from hc5500 to comcolor 57 when you re-use the auto stacking tray from hc5500 to comcolor, you need to prepare following parts 050-21057-004 wide stacking tray adaptor f 050-21058-000 wide stacking tray adaptor r 050-21061-001 magnet catcher bracket ; auto staking tray ...

Page 58

When you install the printer driver, riso management tool also will be installed. After open the software, all riso printers in the network will be displayed. When you click the “change button”, you can set up the ip address. After set up the ip address at once, you cannot change the ip address on t...

Page 59

Led condition during the is900c is updated time (minute) beep sound error ready data comment 00:00 light light light 00:01 blink blink blink 00:02 1 light light light re-booting blink blink blink 00:05 1 light light light re-booting 00:06 2 light light light re-booting blink blink blink 00:08 3 ligh...

Page 60

Riso management tool cannot search is900c to set up ip address when you set up ip address for is900c at installation, you might be unable to do it with the riso management tool application. If your laptop wi-fi function is on during the searching is900c, the application cannot recognize is900c. You ...

Page 61

Is900c firmware upgrade (another procedure) 61 if the is900c does not start firmware upgrade using usb key due to some reason, you can also upgrade it with following procedure. Open the riso console and then click the upload arrow button in the normal queue search the firmware on your pc and then pr...

Page 62

Screws for touch panel you must use rounded top screws for base plate of the touch panel. If you don’t use it, customer might scratch on back of their hand when they remove a jammed paper. Round top screw maintenance control panel 62.

Page 63

Touch panel failure maintenance control panel if some dust or some crisps etc come into the gap between the control panel cover and the touch panel, the touch panel might not work because these objects are pushing the touch panel. When you clean the touch panel, you need to be careful. Control panel...

Page 64

I03-1814 when the machine works under the temporary mode , i03-1814 will display until this mode has finished you can switch from this mode to normal mode by test mode 8400 maintenance un-box/re-box 64.

Page 65

Move to packing condition for the bp unit when packing the machine, you need to fix the bp unit with special bracket. When the machine is turned off, the bp unit will go down to lower position. Before turning off the machine, if you change the test mode 2701 to “1” , the bp unit will stop at fixatio...

Page 66

User guide box for finisher machine when the multi finisher is installed, you can set up the “user guide box” at rear side of the finisher i/f unit which has two screw holes. Finisher i/f unit scanner main printer user guide box maintenance un-box/re-box 66.

Page 67

Recommend setting for demo van test mode 2701 to “1” when the tm2701 is 1, the bp unit will stop at the packing position after turning off the machine. You can fix the bracket without lifting by the box driver test mode 1878 basically comcolor can start printing when the head temperature over 25 deg...

Page 68

Releasing the head carriage at the installation 68 if release of the head carriage is not correct at the installation, image problem or paper jam might occur. Certain method remove two screws and push both to rear screw driver push push turn ccw check point ng ok loose belt tension enough belt tensi...

Page 69

S03-2011 (right side of bp lift wire is loose) paper guide touch you should check whether the paper guide is not opened. If the paper guide has big gap from the bp belt, the paper guide might touch to the maintenance unit, as a result, the lift wire is loose. Solutions and check point basically the ...

Page 70

S03-2012/2015-1 to 8 error code bp gap failure position correct condition (sw) s03-2012-1 standard paper rear left touch s03-2012-2 standard paper rear right touch s03-2012-3 standard paper front left touch s03-2012-4 standard paper front right touch s03-2012-5 card rear left touch s03-2012-6 card r...

Page 71

Check points for s03-2012/2015 1) when paper guide of the bp unit might open, it might touch on the ejection unit when lift up. 2) you should check whether gap adjuster works smooth. 3) clean the metal plate on the bp. Gap adjuster metal plate 4) you should check whether four metal actuators don’t b...

Page 72

S03-2012/2015 (occasionally) 1 2 3 test mode 2442 (envelope gap) test mode 1870 to “1” turn off the machine you can keep the bp position 0.8mm envelope gap card gap adjust the sw gap as 0.8mm after adjustment of envelope sw gap, you can perform tm 2441 (card gap) to confirm the sw detection of card ...

Page 73

S03-2012/2015 (often) 0.8mm 0.5mm after adjustment of envelope sw gap, you can perform tm 2441 (card gap) to confirm the sw detection of card gap. Adjust the sw gap as 0.8mm 1 2 3 4 5 turn off the machine lift up the bp by box driver to upper position (standard gap) move down the bp more 12mm lift u...

Page 74

Ground harness at the bp unit (direction) maintenance bp unit 74 bp unit 200mm bp unit 150mm bp unit 200mm 1 st generation 2 nd generation 3rd generation current ground harness arrangement is opposite “c” direction with the 200mm harness. If your arrangement is not correct or you use the short harne...

Page 75

Front cover open error in case click feeling at catch holding is not enough when cover is closed in case catch holding is proper but door open error occur easily insert cutting stripper pad between the cover and the catch insert some washers between the cover and the actuator maintenance front cover...

Page 76

Setting of test prints regarding the test print 1481 , you can set up some detail condition as follows. For another test print, depends on the tray setting and paper size, but basically the machine will feed paper from the standard tray even if paper size mis-match. Test mode no process name default...

Page 77

Maintenance test prints there are many kind of test print function in comcolor name how to print information note print system info status button on the touch panel firmware version/option from the console also available print sample image status button on the touch panel bird photo image from the c...

Page 78

Set up wizard in japanese normally japanese set up wizard will appear after replace the hdd or machine installation. If you perform the test mode 510 and re-booting, english set up wizard will be displayed. You can change the language in the second screen of the wizard, attention! After perform the ...

Page 79

Test mode 510 (japanese characters) from the firmware 5.12, the test mode 510 is available. You should use this test mode after replace the hdd. According to this test mode, the machine will set up basic default setting depends on the model. Because brand-new hdd is compatible with all comcolor mode...

Page 80

Initialization for main printer 502 503 504/510 505 1502 admin setting (network etc) - default default - - user data (ic card, email address etc) - default default - - folder data (saved data) - default default - - scand data - default default - - ic card serial code (12 digits) remote agent setting...

Page 81

Test mode 504 (hdd initialization) when you perform the test mode 504, all admin settings, all saved data and test mode 7xx settings will be cleared. After that you need to perform the test mode 510. Following no is the test modes that you should set up again. 707 if necessity 708 710 if necessity 7...

Page 82

Backup procedure for user setting and admin setting maintenance initialization comcolor firmware ver7.16 and later can backup the all admin settings and the user settings include individual settings etc into the usb memory. Applicable backup data admin settings (network settings, email settings, sca...

Page 83

Overview of image adjustment after head replacement order scanner manual 1 423 (3mm gap) + head jig angle adjustment (by viewing) tm436 proof is useful to check target is parallel with each colour 2 424 (3mm gap) + head jig x adjustment (by viewing) tm436 proof is useful to check target is less than...

Page 84

Adjustment setting data factory default data back up data engine pcb hdd tm440 (copy) tm441 (retrieve) after scanning, update immediately print tm1497 (save as factory default) tm503 (return to factory default) system figure of image adjustment data attention if you perform the test mode 503, user d...

Page 85

Physical adjustment during the automatic image adjustment test mode adjustment scanning position target note 423 head angle 3-4 mm gap and open less than ±1.0 “+” = cw 0.1 = 1/8 turns 424 head x position 3-4 mm gap and open less than ±1.0 “+” = cw 0.1 = 1/8 turns 421 bp angle 3-4 mm gap and open les...

Page 86

Automatic image adjustment test mode adjustment scanning position recommend qty of print 420 print timing (rough) no gap and close 1-2 prints 425 print timing (fine) 3-4 mm gap and open 4-5 prints 426 overlap 3-4 mm gap and open 4-5 prints 442 head parameter - - 427 print density no gap and close - ...

Page 87

Manual image adjustment test mode adjustment step information target 428 top and end margin 1mm bigger margin = +10 top: 5mm, end: 0.5mm 432 side margin 1mm bigger margin = +10 right/left 0.5mm 435 x direction 1 dot to left ≒ +85points(each) amount will link with a dot 436 y direction 1 dot to down ...

Page 88

Adjustment procedure of print head angle head jig print head lock plate angle adjuster x adjuster a1 a2 b1 b2 1) place the head jig 2) set two screws at a1 and a2 loosely (about 70%) 3) lock the lock plate 4) tighten the a1 and a2 screws 5) release the lock plate 6) loosen b1 and b2 screws (70%) 7) ...

Page 89

Adjustment procedure of print head position (x) head jig print head lock plate angle adjuster x adjuster a1 a2 b1 b2 1) place the head jig 2) set two screws at a1 and a2 loosely (70%) 3) lock the plate 4) tighten the a1 and a2 screws 5) release the lock plate 6) loosen b1 and b2 screws (70%) 7) turn...

Page 90

Quick confirmation after head replacement basically when you replace the print head perfectly, you don’t need image adjustment, only you should input the voltage and a/l type by test mode 442 . You can judge with the following order whether image adjustment is needed or not. Test mode 404 5) overlap...

Page 91

Direction of adjustment for paper feed angle test mode 421 when the plus amount shows after scanning, you need to adjust bp angle to left direction test mode 422 when the plus amount shows after scanning, you need to spread the gap (move to left direction) bp angle timing roller angle plate maintena...

Page 92

Target of margin adjustment by auto image adjustment 0.5mm 0.5mm 0.5mm 5.0mm test mode 428 test mode 428 test mode 432 test mode 432 + - + - + - + - print direction maintenance image adjustment 92.

Page 93

Recover physical head position to middle when replace the print head, if you forget to use the head jig, you will lost the head position completely. You can fix the print head on middle position roughly with following procedure. 1) prepare two countersunk screws 2) prepare the head jig with followin...

Page 94

X03 or x05 error during the print head adjustment during the head adjustment, if ribbon cables arrangement are not good, horizontal transfer sensor might make mis-detection due to reflection from ribbon cable. If you can see the ribbon cable from the square hole on the horizontal transfer unit, you ...

Page 95

Envelope image margin maintenance image adjustment test mode 2926 test mode 2925 test mode 2928 test mode 2927 window image print direction default settings are 90 for all sides (9mm margin), “+10” means 1mm more margin if you reduce the margin too much, the bp belt will have ink stain easily and th...

Page 96

S35-2069-2, 2070-2, 2071-2, 2072-2 caption error means, [pressure ink tank ink sensor remained on for more than a particular number of cycles, despite circulation] basically ink level sensor of the pressure tank will repeat “on” and “off” during the printing. If the tank has more ink due to some rea...

Page 97

S35-2069-2, 2070-2, 2071-2 2072-2, 2055 ink tube failure 2069-2: pressurized tank ink sensor k remained on for more than a particular number of cycles despite circulation 2070-2: pressurized tank ink sensor c remained on for more than a particular number of cycles, despite circulation 2071-2: pressu...

Page 98

Negative ink tank variation 1 st generation 2 nd generation 3 rd generation 4 th generation serial no cc9050 33350187,189,190,194~ cc7050 33360315~ cc3050 33370208~ cc7010 33460129~ cc3010 33470160~ cc9050 33350409~ cc7050 33360936~978,1185~ cc3050 33370573~ cc7010 33460161~163,176~ cc3010 33470424~...

Page 99

S35-2069-1, 2070-1, 2071-1, 2072-1, 2055 cartridge joint mechanism 2069-1: pressurized tank ink sensor k was not activated even once as the printer detected no black ink three times 2070-1: pressurized tank ink sensor c was not activated even once as the printer detected no cyan ink three times 2071...

Page 100

Ink drain down procedure for old ink tower (for single tank replacement) page1 100 1. Clamp pressure air tubes excluding cyan tube 2. Open the bellows unit and disconnect the connecter 3. Disconnect the drain tube and then insert it into the overflow pan 4. Ink will flow down slowly 5. Few minutes l...

Page 101

101 13. Open the front cover and remove ink cartridge 14. Turn on the machine with cover open condition 15. Perform the test mode 2483 (ink valve) with 20 times if you should drain ink for another colour, you should use another test mode black: 2482 cyan: 2483 magenta: 2484 yellow: 2485 after this t...

Page 102

102 20. Turn on the machine with cover close condition 21. When pressure ink tank level goes up, you can remove three scissors 22. After about 10 minutes later, ink circulation will finish automatically after the tank replacement ink drain down procedure for old ink tower (for single tank replacemen...

Page 103

Ink drain down procedure for new ink tower (for single tank replacement) page1 103 1. Clamp pressure air tubes excluding cyan tube 2. Open the bellows unit and disconnect the connecter 3. Disconnect the drain tube and then insert it into the overflow pan 4. Ink will flow down slowly 5. Few minutes l...

Page 104

104 13. Clamp the right side of ink drain tube and then disconnect it from left pipe 14. Insert the drain tube into the overflow pan 15. Remove the scissor 16. Open the front cover and remove ink cartridge 17. Turn on the machine with cover open condition 18. Perform the test mode 2483 (ink valve) w...

Page 105

105 23. If some ink overflow, you should drain down to waste ink tank 24. Turn on the machine with cover close condition 25. When pressure ink tank level goes up, you can remove three scissors 26. After about 10 minutes later, ink circulation will finish automatically after the tank replacement over...

Page 106

Ink drain down procedure for new ink tower (for four tanks modification) page1 1. Open the bellows unit and disconnect the connecter 2. Disconnect the 4 drain tubes and then insert them into the overflow pan (step by step) 3. Ink will flow down slowly 4. Few minutes later, check whether pressure tan...

Page 107

107 13. Insert the tube into the overflow pan and then remove the scissor 15. Open the front cover and remove all ink cartridges 16. Turn on the machine with cover open condition 17. Perform the following test modes (ink valve) with 20 times each black: 2482 cyan: 2483 magenta: 2484 yellow: 2485 aft...

Page 108

108 22. Put back the bellows unit to original position 23. If some ink overflow, you should drain down to waste ink tank 24. Turn on the machine with cover close condition 25. After about 10 minutes later, ink circulation will finish automatically after four tanks modification overflow tank ink drai...

Page 109

Adjustment test mode of multi finisher for comcolor for hc 04733 763-213 04734 763-214 04735 763-215 04743 763-223 04749 763-229 04749 763-229 04752 763-232 04753 763-233 04766 763-246 04767 763-247 04768 763-248 04769 763-249 04773 763-253 04774 763-254 04875 763-355 04876 763-356 04879 763-359 048...

Page 110

U17-3094, u17-3327 110 according to the technical manual, u17-3094: when the front cover is closed, the booklet drawer set sensor is deactivated. U17-3327: booklet tray is operational at the machine is power on, but becomes non-operational while in operation due to mechanical error. Basically you sh...

Page 111

Useful test modes (setting up) test mode no name description 716/717/718 ic card activate you can enter each four digits key code 726 usb port enable 0: off 1: on 727 is900c enable 0: off 1: on 728/5715 scanner enable 0: off 1: on (728) 0: on 1: off (5715) 756 count charge setting 2: type b 1832 pap...

Page 112

Useful test modes (maintenance) test mode no name description 404/411 maintenance print and nzl check paper feed from standard tray 407 rev information save you can save rev data into the usb memory 409 touch panel calibration 440/1497 image adjustment parameter save 440: copy to hdd 1497: save as f...

Page 113

Remote agent setting 721 to 1 722 to 1 740 to 1 748 744 to 1 745 to 1 412 747 741 to 1 742 10 or 11 are recommended 743 network setting ip address subnet mask gateway address detail setting (press “change”) dns address proxy server (if used) rev setting connection ra setting reboot in action => in p...

Page 114

Confirmation and troubleshooting for remote agent connection 1 remote agent settings w67 error no error re-confirm all of settings tm412 open the file wait 5minutes insert usb key perform tm413 [yyyy/mm/dd hh:mm:ss, remoteagent.C, info, 637, successful completion] ra activation done [yyyy/mm/dd hh:m...

Page 115

Confirmation and troubleshooting for remote agent connection 2 ping risoremoteagent.Com feedback 202.248.103.148 no address feedback ask it person if dns is correct proxy login requirement set up proxy address and port into the web browser enter https://risoremoteagent.Com no yes no [test] is displa...

Page 116

Remote agent transfer specification order (sample) trigger s / i error jam firm count ink job setting s / i error jam firm count ink job setting 1 turn on the machine 2 print 3 jam renewed 4 designated time(tm742) or wake up 5 s / i error clear 6 print 7 jam (paper jam etc) renewed 8 ink empty 9 pre...

Page 117

Dns for remote agent setting maintenance remote agent you can basically find the dns address for the customer by using “command prompt”. We recommend to ask it it person for double check. 1. Input “ipconfig/all” 2. Press enter key 3. You can find basically two or more addresses at “dns servers” 117.

Page 118

Proxy for remote agent setting maintenance remote agent normally you need to ask to it person if proxy function is used in the network. Sometimes we can find the proxy setting on the web browser. However this setting might not be same as actual proxy setting. Tools - internet options - connections –...

Page 119

Send error history (rev data) when the machine is installed the remote agent function, the customer can send the rev data such as error history or counter data etc to lyon server in the admin mode. Maintenance remote agent 119.

Page 120

Data list of riso remote agent (rev exchange tool) you can see the contents of riso remote agent by using rev file with following procedure 1) activate the test modes 726, 721 and 722 to “1” 2) insert the usb memory into the machine and perform tm407 3) save the rev file on the laptop and then drag ...

Page 121

X02-1101 (paper catch on the paper gate) maintenance paper jam insert the minus driver height adjuster paper gate (right side of the ccd) up down you can adjust height of the paper gate from the panel side and the rear side. When both of the height adjuster move to the standard tray direction, the p...

Page 122

X02-1101/w56-1300/s98-0114/z-folding apply some liquid underneath of bp belt 790-14076-005 head cleaner c (1000 ml) x02-1101: the paper gate detects paper lifting or wavy condition during the paper feeding w56-1300: the paper size detected by the system does not match with transferred paper size whe...

Page 123

X04-1060 x05-1080 (paper jam around upper transfer) maintenance paper jam when the rollers on the upper transfer are not gripping well, paper can remain on the unit or paper can become crumpled. Check points 1) clean the drive rollers 2) clean the shaft of the pressure rollers and inside of the brac...

Page 124

X06-1062, x06-1081, x07-1082 (paper jam around switch back) maintenance paper jam when the rollers on the upper transfer unit or switch back rollers are not gripping well, paper can become crumpled at switch back unit. This symptom mainly occurs while duplex printing. Check points 1) clean the drive...

Page 125

W24-1150 (face down tray full) at installation when slightly thin paper is used (80g/m2 etc), ejection speed might not be enough depends on paper condition. You can change (speed up) the ejection speed by test mode 1855 tail of paper is remained on the end wall test mode 1855 0; fastest 1; faster 2;...

Page 126

W24-1150 (face down tray full) few months later after the installation cause of the problem 1, drive roller slips due to ink stain 2, pressure roller does not rotate smoothly 3, roller pressure is not enough drive roller clean the ink stain pressure roller clean the roller shaft and inside of the br...

Page 127

W24-1150/x28-1084 (individual face down ejection speed adjustment) paper size simplex/duplex test mode default comment all size simplex 1840 850 large value is faster tm1850 must be 1 duplex 1841 paper size simplex/duplex test mode default comment a4 short edge any 6724 860 large value is faster tm1...

Page 128

Dog ear good not good if the printed paper is fold at somewhere, you should check the metal paper guide for vertical transfer unit at first. If it does not hang on correctly, paper pass gap is wider and then corner of the paper bends easily. * this metal paper guide is used when the right ejection u...

Page 129

Check points for dog ear problem single/face down duplex/face down single/face up duplex/face up check points case1 dog ear dog ear ok ok 6 case2 ok dog ear ok dog ear 7,8,9 case3 dog ear dog ear ok dog ear 4,5 case4 ok ok dog ear dog ear 3 single/face down duplex/face down single/face up duplex/fac...

Page 130

X14-1102 (double feed) maintenance paper jam x14-1102-1: double feed from the standard tray x14-1102-2 : double feed from the tray 1 x14-1102-3 : double feed from the tray 2 x14-1102-4 : double feed from the tray 3 step1 change the pad and holder to wide type step2 adjust the pad angle from 4 to 3 s...

Page 131

X17-3140 (paper jam in interface module) maintenance paper jam when the finisher is connected, the side wings are in maximum position. If down curled paper feeds to the finisher, edge of the curled paper might catch on the static blush or the fence guide hole. You might need to remove the static blu...

Page 132

X02-1058 (paper bent at 6cm from the top edge) maintenance paper jam when x02-1058 occurs or paper have some bent, you need to confirm and adjust the paper slack condition. (much bigger paper slack is one of the reason of paper bent) in addition, comcolor uses the paper assist technology, so if regi...

Page 133

X01-1058, paper tear, dog ear if top edge of paper does not reach to contact position of registration roller correctly, x01-1058 paper jam, paper tear or dog ear might occur. Basically paper touch on the guide roller first, then registration roller adjust paper skew at the contact position paper tea...

Page 134

Compatibility of transfer pressure rollers maintenance 134 1 st generation 2 nd generation 3 rd generation face down a pressure roller 050-62068-088 050-62068-207 b support plate 050-64328-087 050-64328-281 c socket - 050-64369-000 x2 050-62381-002 f 050-62382-009 r switch back a pressure roller 050...

Page 135

Compatibility of transfer motor (the vertical motor and the right ejection motor) maintenance paper jam 135 gear motor belt motor belt motor old harness old harness + yellow harness (service part) new harness vertical transfer motor and right ejection motor are the same motor (compatible with each o...

Page 136

X03-1065 (paper jam in the fu paper ejection unit) 136 spring paper gate when x03-1065 error occurs, you should check the spring condition for right side paper ejection unit. (come off or catch on something etc) if this spring is not proper, paper gate does not work correctly. Then finally paper wil...

Page 137

Upper limit position for standard feed tray (x14-1102-1 double feed) 137 if paper double feed occur often, you should check the upper limit position whether it has 2mm gap. Standard feed tray 2mm basically when upper limit gap is 2mm, the sensor bracket is over about 1mm from the adjuster bracket. C...

Page 138

Replacement procedure for the upper limit actuators of multi tray 138 when you replace the actuator of the multi tray, you don’t need to remove the paper feed unit. When you remove the three trays, you can remove the actuators from the underneath. Actuators (upper limit and paper detection) loosen t...

Page 139

S10-1031/1032/1033 tray elevation motor lock when you find some s10-10xx errors in the error history, you should check following three points. S10-1031/1045 are for tray1 s10-1032/1046 are for tray2 s10-1033/1047 are for tray3 1. Check whether customer does not load a lot of paper into the tray 2. C...

Page 140

Noise from the upper transfer unit if the upper transfer unit comes off slightly, machine might make gear noise. In order to reduce the gap, you can insert old stripper pad etc between the upper transfer unit and the stopper upper transfer unit insert stopper maintenance paper jam 140

Page 141

X12-1055 gear slip x12-1055: paper being transferred did not reach vertical paper feed sensor 3 in time, based on the transfer speed x12-1055-1: paper comes from tray2, x12-1055-2: paper comes from tray3 613-00003-000 pulley ; m1x22+30s2m totally 4 one-way clutch gears are used in the internal paper...

Page 142

Ccd off mode ccd unit (cis) might not detect paper width when dark coloured paper is fed. If this detection is not correct, horizontal printing image will be shifted. When the following test modes are switched to “ 0 ”, ccd will be deactivated, print position will be decided from paper width of the ...

Page 143

W68-0245/w73-1303/i08-0229 bp belt stain detection w68-0245: bp belt stain detected i08-0229: bp belt maintenance alert above error message might display even though bp belt is clean. After the cleaning for ccd and bp belt, you can switch off this function using tm1934 to 0 (default is 5) this test ...

Page 144

Misty image at top of paper maintenance image problem when you print a document with a small margin on the lead edge on a comcolor machine, you may find a misty image at the top of the paper. The new type bp belt will help to improve this condition, also you can reduce the power of the bp fans using...

Page 145

White line for cyan head maintenance image problem 145 step1 load 330mm width paper on the standard tray (if you don’t have some, test mode 2477 without paper mode is useful) extend the paper guides to maximum width position perform the test mode 2472 (cyan md recovery mode) print the nzl check patt...

Page 146

Head cleaning point using cleaning liquid 146 when you clean the print head using duck cleaner, you need apply enough liquid on the head nozzle position. Cc print head has a ink supply pipe between two nozzle lines, ink collection pipes are out side of nozzle lines. (you should aim well at the nozzl...

Page 147

Image problem for y direction 147 the y image position might be lost such as in following pictures very rarely. Ip-pcb has a highest possibility of the cause of this problem. Nzl check pattern in addition, following image problem also ip-pcb is a highest possibility part. Maintenance image problem.

Page 148

Envelope print quality 148 when tm1925 is set to "1", image quality for envelope mode is slightly better, however print speed will slow down about 20% to 30% depending on the envelope size. For the normal paper, print speed does not change. Tm1925 is “0” (default setting) slightly misty image tm1925...

Page 149

Ink drip down on the bp belt after head cleaning if ink drip down on the bp belt after head cleaning, head wipers on the maintenance unit might not touch on surface of the print head correctly check points 1. Check whether maintenance unit moves to bp unit correctly 2. Check whether two screws on th...

Page 150

Pcbs compatibility part no part name compatibility with another model/machine brand-new spare part second hand part 050-79664-008 hdr-pcb (a3) ○ all a3 colour/models are compatible. ○ all a3 colour/models are compatible. 050-79895-060 hdr-pcb (a4) ○ all a4 colour/models are compatible. ○ all a4 colo...

Page 151

Swap second hand hdd or engine pcb maintenance pcb hdd #33360002 ver7.16 engine pcb #33350001 ver7.16 control card #33350001 copy 151 hdd #33350001 ver7.16 engine pcb #33350001 ver7.16 control card #33350001 turn on second hand hdd hdd #33350001 ver7.16 engine pcb #33360002 ver7.16 control card #333...

Page 152

Swap hdd or engine pcb (compatibility) maintenance pcb 152 failure part machine status firmware replace part availability note engine pcb at the installation (temporarily registered) 7.16 or later brand-new ok tm451 is required second hand ok tm451 is required less than 7.16 brand-new x ask to rkcl ...

Page 153

Matching between hdd, engine pcb and control card maintenance pcb serial no blank model id blank counter blank image position test mode settings accounting data admin settings serial no 12345678 model id cc9050 counter 0 image position test mode settings serial no blank model id cc9050 at the instal...

Page 154

Firmware compatibility maintenance pcb 154 hdd replacement snall:0.0.0, following version is snps version standard update following version is snall version before 0.91.7 0.91.8 1.Xx 2.18~5.34 5.57~7.16 step1 ↓ ↓ 2.18 ↓ ↓ step2 97.18 97.18 hdd replacement standard update before 0.91.7 0.91.8 1.Xx 2....

Page 155

S98-0022 (pms and engine pcb communication error) maintenance pcb 155 option pcb engine pcb ip pcb mother board flat cable flat cable when s98-0022 error occurs, you need to check all of connection from the mother board(control pcb) to option pcb. To discover cause of this symptom, you should take o...

Page 156

S98-0022-3 s98-0018-2 156 engine pcb has “watch dog timer” device which checks the processing condition. If this device detects cpu hung-up etc, the engine pcb will reset the processing automatically. S98-0018-1 hung-up due to system high load etc s98-0018-2 hung-up due to unstable power supply to e...

Page 157

S99-0246 s94-19xx (engine pcb replacement) when you replace the engine pcb, you need to install the firmware. You might face s99-0246 or s94-19xx error after upgrade the firmware. Check point 1 check the flat cable connection when the connection is not correct, firmware data cannot transfer from pms...

Page 158

Efficient installation main printer scanner finisher/face up tray/ejection unit offset tray option pcb ic card is900c 1 build up front side of the machine picking two harnesses and arranging picking one harness and arranging put pcb and flat cable 2 put the ejection unit and the bracket put the brac...

Page 159

Configuration at the installation source target default new setting decision description tray setting standard tray manual auto (load a4l) customer tray1 auto auto (load a4) customer put the size sticker tray2 auto auto (load a4l) customer put the size sticker tray3 auto auto (load a3) customer put ...

Page 160

Come off white arm of the maintenance unit at the installation maintenance installation 160 slider arm inner wall inner wall slider arm ok ng before turning on the machine at the installation, please check the position of the slider arm (white colour) if it is positioned with the inner wall between ...

Page 161

S99-0006/0166, s98-0036 when lift up (open) the engine pcb, if you forget to remove the earth plate beforehand, the engine pcb could be damaged. If the caption error occur, you should check whether there are some damage or not on the pcb. Damage maintenance electrical problem 161.

Page 162

Check points for wire harness for electrical problems if you have any unusual electrical problems example power cut off, s9x error etc, bellow positions it is a high possibility for this kind of trouble is due to cutting down or trapping of wire harness etc. Maintenance electrical problem 162 right ...

Page 163

Check points for offset stacking tray installation when you install the offset stacking tray, you should take care of harness arrangement harness might hung on the bracket harness might touch on the encoder encoder if you have some tie wraps, we recommend to band with tie wraps 163 maintenance elect...

Page 164

Jobs stop as idle status in the active tab 164 if the machine does not print any jobs for a long time as “idle status”, system program in the hdd might be crashed. (enable to print from pc but unable to copy, unable to print everything etc) 1. You should make a backup user settings using *tm460 , an...

Page 165

S35-2060, s96-1207, s98-0100-3, s98-0101-3 165 following error messages might be saved in the error history even though the touch panel did not display. Because if customer shut down the main power, system program will confuse the machine latest condition. S35-2060 overflow sensor is activated s96-1...

Page 166

S35-2057/2079/2081/2082/2083/2084 s36-2080 166 error codes description from technical manual test mode to clear error codes s35-2057 the bellows arm is out of the fix position when the machine turns on tm1533 s35-2079 -1/2/3/4 on/off cycle of the ink level sensor on the negative tank is too long whe...

Page 167

S99-0152-06 167 s99-0152-6: when comcolor starts printing, the engine detects time out error due to pms does not send data commands continuously. Pms engine pcb slow time out s99-152-6 when you face this error, we recommend to use an another computer to have a test. This problem comes from the speci...

Page 168

S98-0110-1 check point 1 check whether the flat cable from the controller does not touch on the vertical transfer motor check point 2 check whether the metal plate on the upper transfer unit touches on the sensor bracket correctly check point 3 if the upper transfer unit come out slightly, machine c...

Page 169

Usb function unable if usb port on the control panel does not work even though tm726 is on, you should check the connector connection on the pms pcb (mother board) when the connection is not correct, -usb key led does not flash -firmware update screen does not come up usb connector (brown colour) pm...

Page 170

U03-43xx (scanner fb error) u04-4430 (scanner af error) 170 regarding the hs4000 scanner errors, following part has the highest possibility of cause for each error messages u03-4310, 4311, 4316 050-30048-000 asy-ccd ; ccd unit especially less than #33441376 scanner has high possiblity u03-4320, 4321...

Page 171

Rubber tube protection in the area with high ozone level 450mm 55mm 2. Marking and pull out the rubber tube 1. Cut plastic thin tube 450mm 3. Insert tube cover and then push back rubber tube to original position 4. Keep 3mm gap for clumping by a tie wrap 5. Fasten plastic tube in place with a tie wr...