- DL manuals

- Riso

- Disc Duplicator

- CV1860 Series

- Technical Manual

Riso CV1860 Series Technical Manual - Specifications

2 - 7

CZ80 / CV860 Rev. .0

CHAPTER 2: MACHINE SUMMARY

Specifications

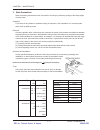

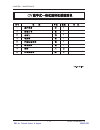

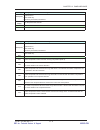

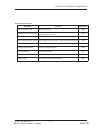

RISO CZ180

Notes

• As we are constantly improving our products, the machine may differ in some respects from the illustrations used

in this manual.

• The specifications are subject to change without prior notice.

Master-making/printing

methods

High-speed digital master-making/fully automatic stencil printing

Original Type

Sheet

Original Size

Max. 310 mm

⋅ 435 mm

Min. 90 mm

⋅ 140 mm

Original Paper Weight

50 g/m

2

-107 g/m

2

Original paper capacity

10 sheets (64 g/m

2

, up to 1 mm high)

Print Paper Size

Max. 297 mm

⋅ 420 mm

Min. 100 mm

⋅ 148 mm

Paper Supply Capacity

1000 sheets (64 g/m

2

)

Paper Receive Capacity

800 sheets (64 g/m

2

)

Print Paper Weight

50 g/m

2

-157 g/m

2

Image Processing Mode

Line, Photo, Duo, Pencil

Master-making Time

Approx. 37 sec. (for A4/portrait/100% reproduction ratio)

Printing Area

Max. 251 mm

⋅ 357 mm

Print Reproduction Ratio

100% reproduction ratio

Standard reproduction ratio(enlargement): 141%, 122%, 116%

Standard reproduction ratio(reduction): 94%, 87%, 82%, 71%

Print Speed

Approx. 60-130 pages per minute (three steps variable)

Print Position Adjustment Vertical:

±10 mm Horizontal: ±10 mm (for B4 portrait in centre position)

Ink Supply

Fully automatic (800 ml per cartridge)

Master Supply/Disposal

Fully automatic (approx. 200 sheets per roll)

Master Disposal Capacity

30 sheets

User Interface

LED panel

Optional Accessories

Colour Drum

Job Separator

Network Interface Card RISORINC-NET

Printer Control Board RISORINC3N

Power Source

CZ180 : 220-240V AC, 50-60 Hz, 1.0 A

CZ180(120) : 100-120V AC, 50-60 Hz, 2.0 A

Dimensions

When in use: 1270 mm (W)

⋅ 645 mm (D) ⋅ 510 mm (H)

When in storage: 655 mm (W)

⋅ 645 mm (D) ⋅ 500 mm (H)

Weight

Approx. 62 kg

RISO Inc. Technical Services & Support

US.RISO.COM

Summary of CV1860 Series

Page 1

Cz180 cv1860 technical manual revision 1.0 august 2007 copyright: 2007 riso kagaku corporation all rights reserved. This technical manual was prepared and written for the exclusive use of riso international group certified dealers. Reproduction and/or transmittal of this material in any form or by a...

Page 2: Contents

Riso inc. Technical services & support us.Riso.Com contents chapter 1 maintenance chapter 2 machine summary chapter 3 main drive chapter 4 first paper feed chapter 5 second paper feed chapter 6 printing pressure chapter 7 paper ejection chapter 8 print drum chapter 9 master clamping chapter 10 maste...

Page 3

Preface this manual provides technical service information for the digital duplicator model cz180 and cv1860 series. This manual provides procedures for removing and installing major components. Following these procedures will minimize machine malfunctions. This information and format will also incr...

Page 4: Chapter

1 - 1 cz180 / cv1860 rev. 1.0 chapter 1: maintenance chapter 1 : maintenance contents 1. Preface ...................................................................................................2 2. Warning ..............................................................................................

Page 5

1 - 2 cz180 / cv1860 rev. 1.0 chapter 1: maintenance 1. Preface this manual provides technical service information for the digital duplicator model cz180 and cv1860 series. This manual provides procedures for removing and installing major components. Following these procedures will minimize machine ...

Page 6: !! Warning !!

1 - 3 cz180 / cv1860 rev. 1.0 chapter 1: maintenance 2. Warning !! Warning !! Important safety precautions 1. Always disconnect electrical supply before placing hands in the machine. I. To avoid injuries: be sure to disconnect the electrical power before disassembling, assembling, or when making adj...

Page 7

1 - 4 cz180 / cv1860 rev. 1.0 chapter 1: maintenance 3. Work precautions when conducting maintenance work, be careful to avoid injury caused by springs or the sharp edges of sheet metal. Inspection if you discover any defects or problems during an inspection, fix the problems or if necessary take st...

Page 8

1 - 5 cz180 / cv1860 rev. 1.0 chapter 1: maintenance electrical system work > after removing wire bundles, fasten them with wire bundle bands (bar lock ties) so that they will not sag. > when installing parts, be careful to avoid pinching or damaging the wire bundles. > if a fuse blows, always repla...

Page 9

1 - 6 cz180 / cv1860 rev. 1.0 chapter 1: maintenance 4. Installation location do not install the machine in any of the following locations. (1) those subject to direct sunlight or any bright location such as by a window (if you must install in such a location, put a curtain or the like over the wind...

Page 10

1 - 7 cz180 / cv1860 rev. 1.0 chapter 1: maintenance 015-26128-008 drum shaft jig 021-16007-005 spring; screen (2 pieces required) cut the ring end to make into hook, as shown on the photograph, and attach wire tie bar on the other end. 5. Jigs riso inc. Technical services & support us.Riso.Com.

Page 11

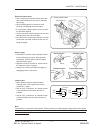

1 - 8 cz180 / cv1860 rev. 1.0 chapter 1: maintenance 6. Instal lation procedures cz180 & cz180(120) 1 1. Noise absorber ......................................... 1 pc. 2. Stabilizer ................................................... 2 pcs. 3. Double-washered screw ............................ 2 pcs...

Page 12

1 - 9 cz180 / cv1860 rev. 1.0 chapter 1: maintenance 2 4. Remove the shock absorbing sheet from the ccd unit. 5. Remove the shock absorbing sheet from the tph unit. 6. Remove the tapes on the paper ejection wing. 7. Remove the shock absorbing sheet from the disposal unit. Shock absorbing sheet tapes...

Page 13

1 - 10 cz180 / cv1860 rev. 1.0 chapter 1: maintenance cv1860 riso inc. Technical services & support us.Riso.Com.

Page 14

1 - 11 cz180 / cv1860 rev. 1.0 chapter 1: maintenance riso inc. Technical services & support us.Riso.Com.

Page 15

1 - 12 cz180 / cv1860 rev. 1.0 chapter 1: maintenance riso inc. Technical services & support us.Riso.Com.

Page 16

1 - 13 cz180 / cv1860 rev. 1.0 chapter 1: maintenance inkless drum (cz180) 1. Print cylinder (drum) preparation important: when installing a black ink cartridge, this procedure is not necessary. Please skip to the procedure 2. 1) remove the print cylinder (drum) cover, the bottle sw cover, and the b...

Page 17

1 - 14 cz180 / cv1860 rev. 1.0 chapter 1: maintenance inkless drum (cv1860) riso inc. Technical services & support us.Riso.Com.

Page 18

1 - 15 cz180 / cv1860 rev. 1.0 chapter 1: maintenance risorinc printer control board riso inc. Technical services & support us.Riso.Com.

Page 19

1 - 16 cz180 / cv1860 rev. 1.0 chapter 1: maintenance riso inc. Technical services & support us.Riso.Com.

Page 20

1 - 17 cz180 / cv1860 rev. 1.0 chapter 1: maintenance riso inc. Technical services & support us.Riso.Com.

Page 21

1 - 18 cz180 / cv1860 rev. 1.0 chapter 1: maintenance 7. External cover removal front cover 1. Remove the drum. 2. Turn off the machine power and detach the front cover. (m3x8 screws; 6 pcs) rear cover 1. Turn off the machine power and detach the rear cover. (m3x8 screws; 5 pcs) master removal upper...

Page 22

1 - 19 cz180 / cv1860 rev. 1.0 chapter 1: maintenance 8. Pcb bracket open procedure 1. Turn off the machine power and detach the rear cover. (m3x8 screws; 5 pcs) 2. Remove the mounting screws (m3x8 screws; 4 pcs) and swing open the pcb bracket. 2) to prevent the power switch wire harness from being ...

Page 23

1 - 20 cz180 / cv1860 rev. 1.0 chapter 1: maintenance 9. Screws which are not to be loosened or removed the master-making unit side frame and the rear stay are both mounted on the machine using jigs at the factory, using screws which cannot be loosened or removed using regular screw drivers. These s...

Page 24: Chapter

2 - cz80 / cv860 rev. .0 chapter 2: machine summary chapter 2 : machine summary contents . Cross-sectional diagram ........................................................................2 2. Operation outline ....................................................................................3 3. O...

Page 25

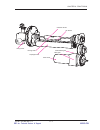

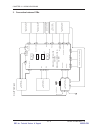

2 - 2 cz80 / cv860 rev. .0 chapter 2: machine summary (7) master-removal section (6) clamp unit (8) scanning section (9) master-making section (4) paper-ejection section (3) press section (5) print drum (2) second paper-feed area () first paper-feed area 1. Cross-sectional diagram (1) first paper-fe...

Page 26

2 - 3 cz80 / cv860 rev. .0 chapter 2: machine summary 2. Operation outline ) set an original, and press the start key. 2) master removal operation removes the used master from the print drum, and sends it to the master disposal box. 3) master-making operation the original is scanned by the image sen...

Page 27

2 - 4 cz80 / cv860 rev. .0 chapter 2: machine summary 4. Master-removal operation ) the clamp plate holding the leading edge of the master opens, and the master-release bar rises to lift the master out from under the clamp plate 2) the vertical transport rollers and print drum rotate, thereby separa...

Page 28

2 - 5 cz80 / cv860 rev. .0 chapter 2: machine summary memo riso inc. Technical services & support us.Riso.Com.

Page 29

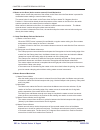

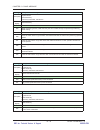

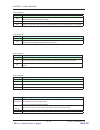

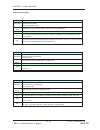

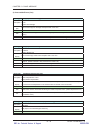

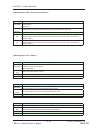

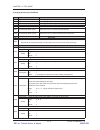

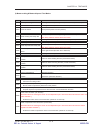

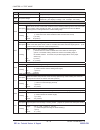

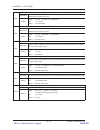

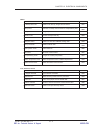

2 - 6 cz80 / cv860 rev. .0 chapter 2: machine summary 7. Machine specification 1) cz180 riso inc. Technical services & support us.Riso.Com.

Page 30: Specifications

2 - 7 cz80 / cv860 rev. .0 chapter 2: machine summary specifications riso cz180 notes • as we are constantly improving our products, the machine may differ in some respects from the illustrations used in this manual. • the specifications are subject to change without prior notice. Master-making/prin...

Page 31

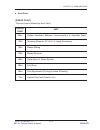

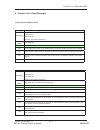

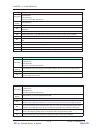

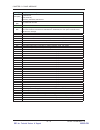

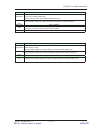

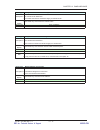

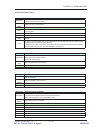

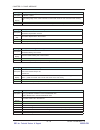

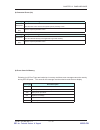

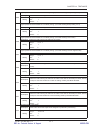

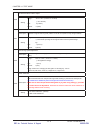

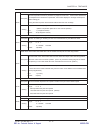

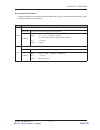

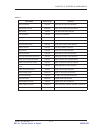

2 - 8 cz80 / cv860 rev. .0 chapter 2: machine summary 2) cv1860 riso inc. Technical services & support us.Riso.Com.

Page 32

2 - 9 cz80 / cv860 rev. .0 chapter 2: machine summary riso inc. Technical services & support us.Riso.Com.

Page 33

2 - 0 cz80 / cv860 rev. .0 chapter 2: machine summary memo riso inc. Technical services & support us.Riso.Com.

Page 34: Chapter

3 - cz80 / cv860 rev. .0 chapter 3: main drive chapter 3 : main drive contents mechanism ...............................................................................................2 . Main drive .....................................................................................2 2. Main motor ...

Page 35

3 - 2 cz80 / cv860 rev. .0 chapter 3: main drive rear cover safety switch rear cover safety switch master making unit safety switch master removal unit safety switch drum safety switch mechanism 1. Main drive 1) drum rotation with the rotation of the main motor, the drive from the main motor is tran...

Page 36

3 - 3 cz80 / cv860 rev. .0 chapter 3: main drive 3. Print drum positions ) the print drum angle positions are checked by position-a sensor and main motor fg sensor. 2) the 0 degrees of the print drum is called the position-a. One drum rotation from the position-a to the next position-a equals to 360...

Page 37

3 - 4 cz80 / cv860 rev. .0 chapter 3: main drive intermediate gear main gear main motor print drum drum main gear disassembly 1. Intermediate gear removal ) remove the drum from the machine, turn off the machine power and unplug the power cord from the machine. 2) remove the rear cover. (m3x8 screws...

Page 38

3 - 5 cz80 / cv860 rev. .0 chapter 3: main drive intermediate gear shaft assembly intermediate gear positioning marks drum main gear hole for allen wrench print drum positioning marks main gear hole for allen wrench intermediate gear positioning marks drum main gear riso inc. Technical services & su...

Page 39

3 - 6 cz80 / cv860 rev. .0 chapter 3: main drive suction unit pressure spring vertical print positioning base unit pressure lever assembly solenoid lever 2. Main motor unit removal ) remove the drum from the machine, turn off the machine power and unplug the power cord from the machine. 2) remove th...

Page 40

3 - 7 cz80 / cv860 rev. .0 chapter 3: main drive drum safety switch mounting screw mounting screw mounting screw mounting screw main motor 3. Drum safety switch removal ) remove the drum from the machine, turn off the machine power and unplug the power cord from the machine. 2) remove the rear cover...

Page 41

3 - 8 cz80 / cv860 rev. .0 chapter 3: main drive adjustment 1. Position-b adjustment (print drum removal position) check and adjustment ) using test mode no. 0892, stop the print drum at position-b. 2) confirm that the print drum can be pulled out from the machine and inserted back in the machine sm...

Page 42: Chapter

4 - cz80 / cv860 rev. .0 chapter 4: first paper feed chapter 4 : first paper feed contents mechanism ...............................................................................................2 . Paper feed tray elevation mechanism ...........................................2 2. First paper feed...

Page 43

4 - 2 cz80 / cv860 rev. .0 chapter 4: first paper feed elevator motor upper limit sensor lower limit sensor paper detection sensor paper feed table mechanism 1. Paper feed tray elevation mechanism paper detection sensor confirms whether paper is set on the paper feed tray. By pressing the print star...

Page 44

4 - 3 cz80 / cv860 rev. .0 chapter 4: first paper feed paper feed clutch main motor pickup roller paper sensor scraper roller 2. First paper feed movement with the start of the printing action, the main motor activates to rotate the print drum in the clockwise direction, as viewed from the operator ...

Page 45

4 - 4 cz80 / cv860 rev. .0 chapter 4: first paper feed stripper unit scraper roller pickup roller paper feed pressure lever stripper pressure adjustment knob 3. Scraper mechanism the scraper roller pulls the paper in between the pickup roller and the stripper pad. The paper is then pinched between t...

Page 46

4 - 5 cz80 / cv860 rev. .0 chapter 4: first paper feed roller elevator junction plate e-ring elevator frame (f) assembly roller elevator junction plate disassembly 1. Removal of elevator link plates removal ) lower the paper feed tray, switch off the machine power, remove master disposal box, and de...

Page 47

4 - 6 cz80 / cv860 rev. .0 chapter 4: first paper feed paper detection sensor wire harness e-ring 2. Removal of paper feed tray unit removal ) lower the paper feed tray all the way down, pull the print drum out and switch off the machine power. 2) remove the front cover. (m3x8 screws: 3 pcs) 3) unpl...

Page 48

4 - 7 cz80 / cv860 rev. .0 chapter 4: first paper feed paper detection sensor paper feed table cover 3. Removal of paper detection sensor removal ) lower the paper feed tray all the way down, pull print drum out and switch off machine power. 2) detach the following parts. Front cover (m3x8 screws; 6...

Page 49

4 - 8 cz80 / cv860 rev. .0 chapter 4: first paper feed pickup roller 4. Removal of pickup roller and scraper roller removal ) lower the paper feed tray all the way down and turn off the machine power. Removing the scraper roller ) remove the plastic clip, which holds the scraper roller in place. 2) ...

Page 50

4 - 9 cz80 / cv860 rev. .0 chapter 4: first paper feed stripper pad base stripper spring stripper pad 5. Removal of stripper pad removal ) lower the paper feed tray all the way down and turn off the machine power. 2) remove both the scraper and pickup roller. 3) remove the stripper pad mount, carefu...

Page 51

4 - 0 cz80 / cv860 rev. .0 chapter 4: first paper feed upper limit sensor upper limit sensor position paper feed stay wire harness band upper limit sensor wire harness the wire should not go under the red dotted line on the photograph. 6. Removal of upper limit sensor removal ) lower the paper feed ...

Page 52

4 - cz80 / cv860 rev. .0 chapter 4: first paper feed lower limit sensor bracket lower limit sensor 7. Removal of lower limit sensor removal ) bring up the paper feed table all the way up using test mode no.708 (elevator motor activation in the up-direction). 2) pull the print drum out of the machine...

Page 53

4 - 2 cz80 / cv860 rev. .0 chapter 4: first paper feed elevator motor unit mounting screw mounting screw mounting screw 8. Removal of elevator motor unit removal ) lower the paper feed tray all the way down, pull the print drum out and turn off the machine power. 2) remove the following parts. Front...

Page 54

4 - 3 cz80 / cv860 rev. .0 chapter 4: first paper feed pickup shaft paper feed clutch 9. Removal of paper feed clutch removal ) turn off the machine power and remove the rear cover. (m3x8 screws; 5 pcs) 2) swing open the pcb bracket on the rear of the machine. (m3x8 screws: 4 pcs) 3) disconnect the ...

Page 55

4 - 4 cz80 / cv860 rev. .0 chapter 4: first paper feed pickup shaft metal bushing pickup shaft bracket pickup shaft assembly 10. Removal of pickup roller shaft assembly removal ) lower the paper feed tray all the way down and turn off the power. 2) remove the following parts. Master removal lower co...

Page 56

4 - 5 cz80 / cv860 rev. .0 chapter 4: first paper feed 11. Removal of guide plate removal ) pull the print drum out of the machine, turn off the machine power and remove the following parts. Front cover (m3x8 screws; 6 pcs) rear cover (m3x8 screws; 5 pcs) master removal lower cover (m3x8 screws; 4 p...

Page 57

4 - 6 cz80 / cv860 rev. .0 chapter 4: first paper feed elevator roller guide roller assembly elevator frame (f) assembly guide plate connector pickup shaft bracket elevator spring bracket (rear) upper limit sensor guide plate riso inc. Technical services & support us.Riso.Com.

Page 58

4 - 7 cz80 / cv860 rev. .0 chapter 4: first paper feed paper sensor (send) guide plate paper sensor (receive) 12. Removal of paper sensor removal ) pull out the print drum, turn off the machine power and remove following parts. Front cover (m3x8 screws; 6 pcs) rear cover (m3x8 screws; 5 pcs) master ...

Page 59

4 - 8 cz80 / cv860 rev. .0 chapter 4: first paper feed adjustment 1. Elevator upper-limit sensor position adjustment ) remove all the papers from the paper feed tray and slide the paper feed pressure adjustment lever to the normal position. 2) raise the paper feed tray all the way up, using test mod...

Page 60

4 - 9 cz80 / cv860 rev. .0 chapter 4: first paper feed 4. Paper sensor sensitivity adjustment adjust the paper sensor sensitivity adjustment when the paper sensor is replaced. ) make the adjustment using a test mode. 2) the test mode makes an automatic sensitivity adjustment on the paper sensor. 3) ...

Page 61

4 - 20 cz80 / cv860 rev. .0 chapter 4: first paper feed memo riso inc. Technical services & support us.Riso.Com.

Page 62: Chapter

5 - cz80 / cv860 rev. .0 chapter 5: second paper feed chapter 5 : second paper feed contents mechanism ...............................................................................................2 . Second paper feed mechanism ...................................................2 2. Vertical print...

Page 63

5 - 2 cz80 / cv860 rev. .0 chapter 5: second paper feed mechanism 1. Second paper feed mechanism ) with the activation of the main motor during a printing job, the main cam makes clockwise rotation (looking from the rear of the machine). 2) the main cam rotation moves the sector gear back and forth ...

Page 64

5 - 3 cz80 / cv860 rev. .0 chapter 5: second paper feed guide roller timing cam timing gear vertical print positioning lever assembly timing gear spring intermediate gear timing lever assembly main cam guide roller spring riso inc. Technical services & support us.Riso.Com.

Page 65

5 - 4 cz80 / cv860 rev. .0 chapter 5: second paper feed timing roller shaft timing cam guide roller spring load spring disassembly 1. Load spring removal ) pull out the print drum, turn the machine power off and remove the front cover. (m3x8 screws; 6 pcs) 2) remove e-ring and collar from the timing...

Page 66

5 - 5 cz80 / cv860 rev. .0 chapter 5: second paper feed mounting screw 3. Guide roller assembly removal ) pull out the print drum, turn the machine power off and remove following part. Rear cover. (m3x8 screws; 5 pcs) 2) open the pcb bracket on the rear of the machine. (m3x8 screws; 4 pcs) 3) remove...

Page 67

5 - 6 cz80 / cv860 rev. .0 chapter 5: second paper feed vertical print positioning lever assembly vertical print positioning plate assembly vertical print positioning hp sensor vertical print positioning pulse motor timing connection late vertical print positioning base unit vertical print positioni...

Page 68

5 - 7 cz80 / cv860 rev. .0 chapter 5: second paper feed vertical print positioning pulse motor 5. Vertical print positioning pulse motor removal ) turn off the machine power and remove rear cover. (m3x8 screws; 5 pcs) 2) open the pcb bracket on the rear of the machine. (m3x8 screws; 4 pcs) 3) remove...

Page 69

5 - 8 cz80 / cv860 rev. .0 chapter 5: second paper feed sector gear timing cam 6. Sector gear removal ) turn off the machine power and remove rear cover. (m3x8 screws; 5 pcs) 2) open the pcb bracket on the rear of the machine. (m3x8 screws; 4 pcs) 3) remove following parts timing cam (6mm dia. E-rin...

Page 70

5 - 9 cz80 / cv860 rev. .0 chapter 5: second paper feed timing roller 7. Timing roller removal ) turn the machine power off, pull out the print drum and remove following parts. Front cover (m3x8 screws; 6 pcs) rear cover (m3x8 screws; 5 pcs) guide plate load spring, guide roller spring and sector ge...

Page 71

5 - 0 cz80 / cv860 rev. .0 chapter 5: second paper feed adjustment 1. Mounting position adjustment of timing cam ) bring the vertical print position to the center, bring the print drum to position-b, turn off the machine power and remove the rear cover. (m3x8 screw; 5 pcs) 2) open the pcb bracket on...

Page 72: Chapter

6 - cz80 / cv860 rev. .0 chapter 6: press section chapter 6 : press section contents mechanism ...............................................................................................2 . Press mechanism ..........................................................................2 disassembly......

Page 73

6 - 2 cz80 / cv860 rev. .0 chapter 6: press section mechanism 1. Press mechanism at the start of the printing job, when the start button is pressed, the main motor activates to rotate the drum and also to feed the paper. When the paper sensor detects the paper coming in and as the clamp plate base a...

Page 74

6 - 3 cz80 / cv860 rev. .0 chapter 6: press section intermediate gear pressure spring pressure cam pressure roller pressure lever assembly solenoid lever pressure solenoid disassembly 1. Pressure roller removal ) remove the drum out of the machine and turn off the machine power. 2) remove the mounti...

Page 75

6 - 4 cz80 / cv860 rev. .0 chapter 6: press section mounting screw mounting screw mounting screw mounting screw pressure lever assembly pressure spring solenoid base assembly solenoid lever 2. Pressure solenoid removal ) turn off the machine power and remove the rear cover of the machine. (m3x8 scre...

Page 76

6 - 5 cz80 / cv860 rev. .0 chapter 6: press section set screw set screw 3. Pressure lever assembly removal ) remove the drum out of the machine and turn off the machine power. 2) remove the rear cover. (m3x8 screws; 5 pcs) 3) open the pcb bracket on the rear of the machine. (m3x8; 4 pcs) 4) being ca...

Page 77

6 - 6 cz80 / cv860 rev. .0 chapter 6: press section c-ring 4. Pressure roller assembly removal ) remove the drum out of the machine and turn off the machine power. Then remove following parts. Front cover (m3x8 screws; 6 pcs) rear cover (m3x8 screws; 5 pcs) pressure lever assembly 2) remove c-ring f...

Page 78

6 - 7 cz80 / cv860 rev. .0 chapter 6: press section pressure shaft allen wrench 3mm alen wrench pressure cam bearing allen wrench adjustment 1. Pressure lever assembly position 1) make confidential master on the drum. 2) bring the drum to position-b. 3) turn the machine power off, and remove the rea...

Page 79

6 - 8 cz80 / cv860 rev. .0 chapter 6: press section memo riso inc. Technical services & support us.Riso.Com.

Page 80: Chapter

7 - cz80 / cv860 rev. .0 chapter 7: paper ejection section chapter 7 : paper ejection section contents mechanism ...............................................................................................2 . Paper ejection mechanism ............................................................2 2...

Page 81

7 - 2 cz80 / cv860 rev. .0 chapter 7: paper ejection section separation fan suction belt suction fan paper ejection motor mechanism 1. Paper ejection mechanism (1) paper separation from the drum the paper is separated from the drum by the paper separation fan and separator. (2) paper ejection suctio...

Page 82

7 - 3 cz80 / cv860 rev. .0 chapter 7: paper ejection section separator main motor separator cam paper separator arm assembly separator lever separator shaft release arm intermediate gear 2. Paper separation mechanism (1) separator the tip of the separator is close to the drum when it separates a pap...

Page 83

7 - 4 cz80 / cv860 rev. .0 chapter 7: paper ejection section paper ejection cover suction unit disassembly 1. Suction unit removal ) turn off the machine power. 2) remove the paper ejection cover. (m3x6 screws; 2 pcs) 3) unplug the wire harness connector of suction unit. 4) remove the mounting screw...

Page 84

7 - 5 cz80 / cv860 rev. .0 chapter 7: paper ejection section 3. Paper ejection motor removal ) turn off the machine power, and remove following parts. Paper ejection cover (m3x6 screws; 2 pcs) suction unit (m3x6 screws; 2 pcs) 2) detach the left and right paper ejection wings. (thumb screws; each) 3...

Page 85

7 - 6 cz80 / cv860 rev. .0 chapter 7: paper ejection section paper ejection motor fg sensor 4. Paper ejection motor fg sensor removal ) turn off the machine power, and remove following parts. Paper ejection cover (m3x6 screws; 2 pcs) suction unit (m3x6 screws; 2 pcs) 2) detach the left and right pap...

Page 86

7 - 7 cz80 / cv860 rev. .0 chapter 7: paper ejection section suction unit top plate suction belt suction unit suction unit top plate riso inc. Technical services & support us.Riso.Com.

Page 87

7 - 8 cz80 / cv860 rev. .0 chapter 7: paper ejection section 6. Paper receiving sensor removal ) turn off the machine power, and remove following parts. Paper ejection cover (m3x6 screws; 2 pcs) suction unit (m3x6 screws; 2 pcs) 2) detach the left and right paper ejection wings. (thumb screws; each)...

Page 88

7 - 9 cz80 / cv860 rev. .0 chapter 7: paper ejection section separation fan unit separation fan unit 7. Separation fan unit removal ) turn off the machine power. 2) remove the mounting screws of the separation fan unit and slide the unit out from the machine. (m3x8 screws; 2 pcs) 3) unplug the wire ...

Page 89

7 - 0 cz80 / cv860 rev. .0 chapter 7: paper ejection section pressure lever assembly hook pressure spring 9. Separator removal ) pull the print drum out of the machine, turn off the machine power and remove following parts. Front cover (m3x8 screws; 6 pcs) rear cover (m3x8 screws; 5 pcs) 2) open the...

Page 90

7 - cz80 / cv860 rev. .0 chapter 7: paper ejection section separator lever separator shaft separator springs separator shaft release arm separator release lever release arm release lever riso inc. Technical services & support us.Riso.Com.

Page 91

7 - 2 cz80 / cv860 rev. .0 chapter 7: paper ejection section paper receiving tray lock plate; front paper receiving tray lock plate; front mounting screw mounting screw 10. Paper receiving tray unit removal ) turn off the machine power, and remove following parts. Front cover (m3x8 screws; 6 pcs) re...

Page 92

7 - 3 cz80 / cv860 rev. .0 chapter 7: paper ejection section adjustment 1. Separator position 1) before making any print job operation, check and confirm that the tip of the separator is not touching the drum. If the separator is touching the drum, do not make any prints, but go directly to the adju...

Page 93

7 - 4 cz80 / cv860 rev. .0 chapter 7: paper ejection section memo riso inc. Technical services & support us.Riso.Com.

Page 94: Chapter

8 - cz80 / cv860 rev. .0 chapter 8: print drum chapter 8 : print drum contents mechanism ...............................................................................................2 . Master on drum (in printing) check mechanism ...........................2 2. Ink bottle set check mechanism .......

Page 95

8 - 2 cz80 / cv860 rev. .0 chapter 8: print drum mechanism 1. Master on drum (in printing) check mechanism master sensor checks the presence of master on the drum before the start of printing. At 74.6 degrees drum rotation after the first position-a, the master sensor looks for the master on the dru...

Page 96

8 - 3 cz80 / cv860 rev. .0 chapter 8: print drum intermediate gear main gear main motor inking motor overflow sensor squeegee roller driving shaft ink sensor riso inc. Technical services & support us.Riso.Com.

Page 97

8 - 4 cz80 / cv860 rev. .0 chapter 8: print drum ink bottle guide ink bottle set switch ink bottle switch cover ink bottle guide disassembly 1. Ink bottle guide removal ) remove the drum out from the machine and pull out the ink bottle. 2) remove the drum cover. (m3x8 screws; 4 pcs) 3) remove the bo...

Page 98

8 - 5 cz80 / cv860 rev. .0 chapter 8: print drum 3. Rf-pcb removal ) remove the drum out from the machine and pull out the ink bottle. 2) remove the drum cover. (m3x8 screws; 4 pcs) 3) remove the bottle switch cover. (m3x8 screws; 2 pcs) 4) unplug the rf-pcb wire harness. 5) remove the antenna holde...

Page 99

8 - 6 cz80 / cv860 rev. .0 chapter 8: print drum holder bracket plate 4. Inking motor removal ) remove the drum out from the machine and pull out the ink bottle. 2) remove the drum cover. (m3x8 screws; 4 pcs) 3) remove the bottle switch cover. (m3x8 screws; 2 pcs) 4) unplug the rf-pcb wire harness. ...

Page 100

8 - 7 cz80 / cv860 rev. .0 chapter 8: print drum 5. Drum set sensor removal ) remove the inking motor. (ref: previous page) 2) remove the drum lock spring from the drum hook right. 3) remove the drum hook right. (6mm dia. E-ring; 1 pcs) 4) carefully, release the hooks on the drum set sensor and remo...

Page 101

8 - 8 cz80 / cv860 rev. .0 chapter 8: print drum screen jig screen hanger hook hook 6. Drum screen removal 1) make a confidential master on the drum and remove the drum from the machine. 2) remove the screen hanger and screen assembly from the drum. (m4x8 screws: 4 pcs) precaution in assembly ) do n...

Page 102

8 - 9 cz80 / cv860 rev. .0 chapter 8: print drum drum body imprinted marking imprinted marking 7. Drum body removal 1) remove the drum out from the machine, and remove following parts. Clamp plate base unit (m4x8 screws; 4 pcs) drum screen (m4x8 screws; 4 pcs) 2) remove the drum body from the drum. ...

Page 103

8 - 0 cz80 / cv860 rev. .0 chapter 8: print drum ink sensor pcb overflow sensor ink sensor 8. Ink sensor pcb removal ) remove the drum out from the machine and pull out the ink bottle. 2) remove the drum cover. (m3x8 screws; 4 pcs) 3) remove following parts. Clamp plate base unit (m4x8 screws; 4 pcs...

Page 104

8 - cz80 / cv860 rev. .0 chapter 8: print drum 9. Drum flanges f (front) & r (rear) removal ) remove the drum out from the machine and pull out the ink bottle. 2) remove the drum cover. (m3x8 screws; 4 pcs) 3) remove following parts. Clamp plate base unit (m4x8 screws; 4 pcs) drum screen (m4x8 screw...

Page 105

8 - 2 cz80 / cv860 rev. .0 chapter 8: print drum rear frame side channel rear frame drum support r set screw ib lock cap screw front frame drum support f riso inc. Technical services & support us.Riso.Com.

Page 106

8 - 3 cz80 / cv860 rev. .0 chapter 8: print drum precaution in assembly ) use the drum shaft jig when mounting the screws back onto the drum shaft clamper. ( dram shaft jig = 05-2628-008 drum shaft jig ) 2) with the drum at position-b, insert the drum shaft jig through the front support plate, drum ...

Page 107

8 - 4 cz80 / cv860 rev. .0 chapter 8: print drum front frame lift the center shaft up. Slide the shaft joint inward. Mounting screw 10. Squeegee roller removal ) remove the drum out from the machine and pull out the ink bottle. 2) remove the drum cover. (m3x8 screws; 4 pcs) 3) remove following parts...

Page 108

8 - 5 cz80 / cv860 rev. .0 chapter 8: print drum shaft joint center shaft front frame squeegee roller driving shaft squeegee roller rear frame riso inc. Technical services & support us.Riso.Com.

Page 109

8 - 6 cz80 / cv860 rev. .0 chapter 8: print drum mounting screw of the intake nozzle mounting screw of the intake nozzle filter inking motor intake nozzle adjustment 1. Cleaning the filter cleaning ) remove the drum out from the machine and pull out the ink bottle. 2) remove the drum cover. (m3x8 sc...

Page 110

8 - 7 cz80 / cv860 rev. .0 chapter 8: print drum 2. Squeegee gap adjustment 1) remove the drum out of the machine, and remove the screen and drum body from the drum. 2) clean out all the ink off the squeegee unit. 3) using a feeler gauge, check and confirm that the gap between the squeegee roller an...

Page 111

8 - 8 cz80 / cv860 rev. .0 chapter 8: print drum memo riso inc. Technical services & support us.Riso.Com.

Page 112: Chapter

9 - cz80 / cv860 rev. .0 chapter 9: clamp unit chapter 9 : clamp unit contents mechanism ...............................................................................................2 . Clamp unit home position movement ..........................................2 2. Clamp plate master release move...

Page 113

9 - 2 cz80 / cv860 rev. .0 chapter 9: clamp unit print drum master release plate clamp motor clamp plate opener arm clamp cam position-a mechanism 1. Clamp unit home position movement clamp open arm and master release arm positions of the clamp unit are checked by the clamp sensor to see if they are...

Page 114

9 - 3 cz80 / cv860 rev. .0 chapter 9: clamp unit position-b 3. Clamp plate master clamp mechanism the master clamp movement is made after the master is removed from the drum. With the activation of the clamp motor in the forward movement, the clamp open arm is pushed down to open the clamp plate. Th...

Page 115

9 - 4 cz80 / cv860 rev. .0 chapter 9: clamp unit clamp motor clamp sensor mounting screw mounting screw mounting screw disassembly 1. Clamp unit removal ) turn off the machine power and remove the rear cover. (m3x8 screws: 5 pcs.) 2) open the pcb bracket on the rear of the machine. (m3x8 screws; 4 p...

Page 116

9 - 5 cz80 / cv860 rev. .0 chapter 9: clamp unit mounting screw clamp motor 2. Clamp motor removal 1) turn off the machine power and remove following parts. Rear cover (m3x8 screws: 5 pcs.) clamp unit (m3x6 screws; 3 pcs) 2) remove e-ring from the clamp gear and detach the gear. (4mm dia. E-ring; 1 ...

Page 117

9 - 6 cz80 / cv860 rev. .0 chapter 9: clamp unit clamp cam clamp sensor actuator plate clamp sensor 3. Clamp sensor removal 1) turn off the machine power and remove following parts. Rear cover (m3x8 screws: 5 pcs.) clamp unit (m3x6 screws; 3 pcs) 2) remove e-ring from the clamp gear and detach the g...

Page 118: Chapter

10 - 1 cz180 / cv1860 rev. 1.0 chapter 10: master removal chapter 10 : master removal contents mechanism ...............................................................................................2 1. Master removal unit home positioning mechanism ....................2 2. Master on the drum (bef...

Page 119

10 - 2 cz180 / cv1860 rev. 1.0 chapter 10: master removal section master compression plate master compression hp sensor (receive) mechanism 1. Master removal unit home positioning mechanism the master removal unit returns to its home position each time the power is turned on, all reset button is pre...

Page 120

10 - 3 cz180 / cv1860 rev. 1.0 chapter 10: master removal master compression hp sensor (receive) 2) when the master compression plate is all the way down. The motor rotates the master compression plate down, but since the actuator disk is already past the master compression hp sensor from the start,...

Page 121

10 - 4 cz180 / cv1860 rev. 1.0 chapter 10: master removal section 2. Master on the drum (before master removal) check mechanism master sensor checks the presence of the master on the drum when the start button is pressed for confidential master making or normal master making. The sensor looks for th...

Page 122

10 - 5 cz180 / cv1860 rev. 1.0 chapter 10: master removal compression motor master removal full detection sensor 5. Disposed master compressing mechanism 1) compression motor as the master is removed from the drum and transferred into the master disposal box, the compressing motor activates and rota...

Page 123

10 - 6 cz180 / cv1860 rev. 1.0 chapter 10: master removal section view with the cover removed disassembly 1. Master removal unit precaution in removal be careful not to catch the wire harness when removing the unit. Removal [ removing the master removal assembly (upper)] 1) lower the paper feed tray...

Page 124

10 - 7 cz180 / cv1860 rev. 1.0 chapter 10: master removal master removal upper assembly housing stay a master removal upper assembly master removal bottom assembly print drum paper feed tray unit view from the top riso inc. Technical services & support us.Riso.Com.

Page 125

10 - 8 cz180 / cv1860 rev. 1.0 chapter 10: master removal section master compression hp sensor master removal motor fg sensor master removal sensor master removal full detection sensor edge saddle position the blue wire tie at this area view from the top precaution in assembly 1) when wiring the mas...

Page 126

10 - 9 cz180 / cv1860 rev. 1.0 chapter 10: master removal 2. Master removal sensor removal 1) turn off the machine power and remove the master removal upper cover. (m3x8 screws; 2 pcs) 2) unplug the wire harness connector of master removal sensor. 3) then detach the sensor by removing the mounting s...

Page 127

10 - 10 cz180 / cv1860 rev. 1.0 chapter 10: master removal section master compression hp sensor removed view of master removal motor fg sensor 4. Master compression hp sensor removal 1) turn off the machine power and remove the master removal upper cover. (m3x8 screws; 2 pcs) 2) remove the gear cove...

Page 128

10 - 11 cz180 / cv1860 rev. 1.0 chapter 10: master removal compression motor mounting screw mounting screw compression motor view of the master compression plate hanging down. 6. Compression motor precaution in removal 1) watch out for the compression plate, which hangs free when the gear to the com...

Page 129

10 - 12 cz180 / cv1860 rev. 1.0 chapter 10: master removal section view of the master compression plate hanging down. Master removal motor master removal motor cover master removal motor 7. Master removal motor precaution in removal 1) watch out for the master compression plate, which hangs free whe...

Page 130

10 - 13 cz180 / cv1860 rev. 1.0 chapter 10: master removal 8. Master compression plate removal 1) turn off the machine power and remove the master removal upper cover. (m3x8 screws; 2 pcs) 2) remove the gear cover (rear). (m3x6 screws; 2 pcs) 3) remove the gear and gear-35. (6mm dia. E-ring; 1 pc) (...

Page 131

10 - 14 cz180 / cv1860 rev. 1.0 chapter 10: master removal section compression spring compression spring master compression plate pulley shaft clip pulley bracket (upper) 9. Pulley shaft, mater removal roller (upper) and o-ring belt. Pulley shaft 1) turn off the machine power and remove following pa...

Page 132

10 - 15 cz180 / cv1860 rev. 1.0 chapter 10: master removal clip master removal roller (upper) pulley shaft master removal roller (upper) - continued from previous page - 3) remove the o-ring belts (4 pcs) from the pulleys on the pulley mounting bracket. 4) remove the stopper ring from the master rem...

Page 133

10 - 16 cz180 / cv1860 rev. 1.0 chapter 10: master removal section wire harness of master loading sensor master removal hook master loading sensor master loading sensor cover master removal hook master removal bottom assembly 10. Master removal hook and master loading sensor master removal hook 1) t...

Page 134

10 - 17 cz180 / cv1860 rev. 1.0 chapter 10: master removal master removal bottom assembly master removal hook master removal roller (lower) 11. Master removal roller (lower) and o-ring belts o-ring belts 1) turn off the machine power and remove following parts. Master removal lower cover (m3x8 screw...

Page 135

10 - 18 cz180 / cv1860 rev. 1.0 chapter 10: master removal section master removal unit safety switch switch master removal unit safety switch master removal lower cover mounting screw mounting screw mounting screw mounting screw 12. Master removal unit safety switch removal 1) lower the paper feed t...

Page 136: Chapter

11 - 1 cz180 / cv1860 rev. 1.0 chapter 11: scanning section chapter 11 : scanning section contents mechanism ...............................................................................................2 1. Original loading mechanism .........................................................2 3. Im...

Page 137

11 - 2 cz180 / cv1860 rev. 1.0 chapter 11: scanning section mechanism 1. Original loading mechanism 1) when the original is placed on the original tray, the original detection sensor is activated and the original is automatically loaded on the af unit. 2) the af stripper solenoid activates to lower ...

Page 138

11 - 3 cz180 / cv1860 rev. 1.0 chapter 11: scanning section stripper solenoid read pulse motor original detection sensor image senser shutter original feed arm original pickup roller stripper roller original in sensor original detection sensor image sensor shutter original feed arm read pulse motor ...

Page 139

11 - 4 cz180 / cv1860 rev. 1.0 chapter 11: scanning section cis (contact image sensor) sliced view dust prevention sponge spacer frame photo conductor led scanner glass cover glass original lens 3. Image scanning mechanism 1) the image scanning is done by a contact image scanner (cis) which emits gr...

Page 140

11 - 5 cz180 / cv1860 rev. 1.0 chapter 11: scanning section memo riso inc. Technical services & support us.Riso.Com.

Page 141

11 - 6 cz180 / cv1860 rev. 1.0 chapter 11: scanning section disassembly 1. Image scanner removal 1) turn off the machine power and remove following parts. Master removal upper cover (m3x8 screws; 2 pcs) scanner upper frame cover (m3x8 screws; 4 pcs) scanner unit cover (m3x8 screws; 4 pcs) 2) open th...

Page 142

11 - 7 cz180 / cv1860 rev. 1.0 chapter 11: scanning section image sensor scanner glass cis spacer scanner guide plate assembly image sensor af cover set sensor original in sensor scanner guide plate assembly scanner glass riso inc. Technical services & support us.Riso.Com.

Page 143

11 - 8 cz180 / cv1860 rev. 1.0 chapter 11: scanning section stripper solenoid link assembly solenoid plunger stripper solenoid 2. Af stripper solenoid removal 1) turn off the machine power and remove following parts. Master removal upper cover (m3x8 screws; 2 pcs) scanner upper frame cover (m3x8 scr...

Page 144

11 - 9 cz180 / cv1860 rev. 1.0 chapter 11: scanning section scanner guide plate assembly original detection sensor shutter spring original in sensor shutter sutter shaft assembly 3. Original detection sensor removal 1) turn off the machine power and remove following parts. Master removal upper cover...

Page 145

11 - 10 cz180 / cv1860 rev. 1.0 chapter 11: scanning section stripper roller joint disc gear 5. Stripper roller removal 1) turn off the machine power and remove following parts. Master removal upper cover (m3x8 screws; 2 pcs) scanner upper frame cover (m3x8 screws; 4 pcs) scanner unit cover (m3x8 sc...

Page 146

11 - 11 cz180 / cv1860 rev. 1.0 chapter 11: scanning section 6. Original pickup roller removal 1) turn off the machine power and remove following parts. Master removal upper cover (m3x8 screws; 2 pcs) scanner upper frame cover (m3x8 screws; 4 pcs) scanner unit cover (m3x8 screws; 4 pcs) 2) open the ...

Page 147

11 - 12 cz180 / cv1860 rev. 1.0 chapter 11: scanning section original feed plate assembly original feed shaft plate af frame assembly lock spring plate lock lever (upper) 7. Original stripper pad removal 1) turn off the machine power and remove following part. Scanner upper frame cover (m3x8 screws;...

Page 148

11 - 13 cz180 / cv1860 rev. 1.0 chapter 11: scanning section original feed plate assembly stripper roller pressure wheel original stripper pad spring a original feed arm spring b original feed shaft pin spring a original feed arm spring b the original feed shaft pin holds spring-a and spring-b while...

Page 149

11 - 14 cz180 / cv1860 rev. 1.0 chapter 11: scanning section read pulse motor timing belt original ejection roller pulley gear read pulse motor gear 8. Read pulse motor removal 1) turn off the machine power and remove following parts. Master removal upper cover (m3x8 screws; 2 pcs) scanner upper fra...

Page 150

11 - 15 cz180 / cv1860 rev. 1.0 chapter 11: scanning section adjustment 1. Af scan start-position adjustment checks and procedure 1) scan and print an original with no white margin on the top. 2) looking at the printed image, confirm that top 4mm plus or minus 2mm of the original is erased. 3) if th...

Page 151

11 - 16 cz180 / cv1860 rev. 1.0 chapter 11: scanning section memo riso inc. Technical services & support us.Riso.Com.

Page 152: Chapter

12 - 1 cz180 / cv1860 rev. 1.0 chapter 12: master making section chapter 12 : master making section contents mechanism ...............................................................................................2 1. Master making unit mechanism .......................................................

Page 153

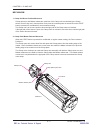

12 - 2 cz180 / cv1860 rev. 1.0 chapter 12: master making section master end sensor master positioning sensor cutter motor write pulse motor load pulse motor tph write roller master loading roller master stocker roller (bottom) load roller (lower) master stocker roller (top) load roller (upper) mecha...

Page 154

12 - 3 cz180 / cv1860 rev. 1.0 chapter 12: master making section master end sensor master positioning sensor cutter tph write roller master loading roller load roller (lower) load roller (lower) master stocker roller (top) load roller (upper) 2. Detection mechanism 1) the set detection of the master...

Page 155

12 - 4 cz180 / cv1860 rev. 1.0 chapter 12: master making section 4. Master set mechanism 1) when the master-making upper unit is closed, the master-making unit safety switch becomes on, and following movements are made. 2) the write pulse motor rotates in the forward direction and sends the master f...

Page 156

12 - 5 cz180 / cv1860 rev. 1.0 chapter 12: master making section disassembly 1. Master making unit safety switch 1) remove the drum from the machine, turn off the machine power and remove the front cover from the machine. (m3x8 screws; 6 pcs) 2) unplug the wire harness connector of the master making...

Page 157

12 - 6 cz180 / cv1860 rev. 1.0 chapter 12: master making section tph ground wire view of the tph removed tph holding plate 2. Thermal print head (tph) 1) open the master making upper unit and detach the tph ground wire. (m3x6 screw; 1 pc) 2) remove the tph support plate. (m3x6 screw; 1 pc) 3) slide ...

Page 158

12 - 7 cz180 / cv1860 rev. 1.0 chapter 12: master making section master holder assembly (front) unit main frame master holder (front) master holder assembly (front) rf-pcb antenna assembly 3. Rf-tag antenna pcb 1) remove the drum from the machine, turn off the machine power and remove the front cove...

Page 159

12 - 8 cz180 / cv1860 rev. 1.0 chapter 12: master making section write pulse motor assembly mounting screw mounting screw 4. Write pulse motor assembly 1) remove the drum from the machine, turn off the machine power and remove the front cover from the machine. (m3x8 screws; 6 pcs) 2) unplug the wire...

Page 160

12 - 9 cz180 / cv1860 rev. 1.0 chapter 12: master making section 5. Load pulse motor assembly 1) turn off the machine power and remove the rear cover. (m3x8 screws; 5 pcs) 2) open the pcb bracket on the back of the machine. (m3x8 screws; 4 pcs) 3) unplug the wire harness connector of the load pulse ...

Page 161

12 - 10 cz180 / cv1860 rev. 1.0 chapter 12: master making section master positioning sensor master positioning sensor bracket assembly master removal upper assembly housing stay a 6. Master positioning sensor assembly 1) remove the master removal upper cover. (m3x8 screws; 2 pcs) 2) remove the maste...

Page 162

12 - 11 cz180 / cv1860 rev. 1.0 chapter 12: master making section cutter guide assembly mounting screw 7. Cutter guide assembly 1) turn off the machine power and remove the rear cover. (m3x8 screws; 5 pcs) 2) remove the master removal upper cover. (m3x8; 2 pcs) 3) remove the master scanning upper fr...

Page 163

12 - 12 cz180 / cv1860 rev. 1.0 chapter 12: master making section pulley guide plate machine frame write roller assembly 9. Write roller 1) remove the drum from the machine, turn off the machine power and remove following parts. Front cover (m3x6 screws; 6 pcs) write pulse motor assembly (m3x6 screw...

Page 164

12 - 13 cz180 / cv1860 rev. 1.0 chapter 12: master making section 10. Master stocker roller (bottom) 1) remove the drum from the machine, turn off the machine power and remove the front cover from the machine. (m3x8 screws; 6 pcs) 2) remove the master removal upper cover. (m3x8; 2 pcs) 3) remove the...

Page 165

12 - 14 cz180 / cv1860 rev. 1.0 chapter 12: master making section load roller gear load roller (lower) e-ring 11. Load roller (bottom) 1) turn off the machine power and remove the rear cover. (m3x8 screws; 5 pcs) 2) remove the master removal upper cover. (m3x8; 2 pcs) 3) remove the master scanning u...

Page 166

12 - 15 cz180 / cv1860 rev. 1.0 chapter 12: master making section master loading roller gear master loading guide master removal unit 12. Master loading roller 1) turn off the machine power and remove the rear cover. (m3x8 screws; 5 pcs) 2) remove the master removal upper cover. (m3x8; 2 pcs) 3) rem...

Page 167

12 - 16 cz180 / cv1860 rev. 1.0 chapter 12: master making section cutter unit mounting screw 13. Cutter unit 1) remove the drum from the machine, turn off the machine power and remove following parts. Front cover (m3x6 screws; 6 pcs) write pulse motor assembly (m3x6 screws; 2 pcs) 2) unplug the two ...

Page 168

12 - 17 cz180 / cv1860 rev. 1.0 chapter 12: master making section adjustment 1. Thermal power of thermal print head (tph) this adjustment must be made each time the tph is replaced. 1) start up test mode and input 9874 to enter into protected test mode. 2) then enter test mode no. 1234 [tph thermal ...

Page 169

12 - 18 cz180 / cv1860 rev. 1.0 chapter 12: master making section 4. Master cut length adjustment 1) the normal length of the master is 461mm plus or minus 7mm. Depending on the drum and the amount of master under the clamp, the length of white margin at the tail of the master on the drum differs. 2...

Page 170: Chapter

13 - 1 cz180 / cv1860 rev. 1.0 chapter 13: panel message chapter 13 : panel message contents 1. Error type & error point .........................................................................2 example ............................................................................................2 2....

Page 171

13 - 2 cz180 / cv1860 rev. 1.0 chapter 13: panel message p 0 1 - 5 2 0 error type error point example : p01-520 (main motor lock) error type : indicates what type of error has occurred. Error point : indicates where the error has occurred. 1. Error type & error point example riso inc. Technical serv...

Page 172

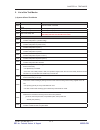

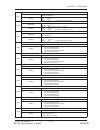

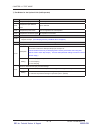

13 - 3 cz180 / cv1860 rev. 1.0 chapter 13: panel message 2. Error display method 7 4 5 1 9 8 2 6 3 the led is lit to indicate where the error occurred. Set / trouble indication led (blinking) error display method led area 1 paper feed tray 2 print drum 3 master removal cover 4 scanning area 5 master...

Page 173

13 - 4 cz180 / cv1860 rev. 1.0 chapter 13: panel message type symbol p-xx serviceman call error repair by the serviceman is required to correct the problem. A-xx jam error jam errors which occurs during the machine usage, and these can be corrected by the operator by following the troubleshooting st...

Page 174

13 - 5 cz180 / cv1860 rev. 1.0 chapter 13: panel message error point unit 0 xx system (hardware, software, communication) & operation panel. 1xx scanning (scanner, af unit) & image processing. 2xx master making 3xx master removal 4xx paper feed & paper ejection 5xx print drum 6xx print adjustments (...

Page 175

13 - 6 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type error description a 07 paper feed jam a08 paper jammed on drum a09 paper ejection jam a10 original jam 7 4 1 3 9 5 8 2 6 9 7 4 1 3 5 6 9 8 2 8 2 while pressing the (*) asterisk key, the error point is displayed. : solid light : blin...

Page 176

13 - 7 cz180 / cv1860 rev. 1.0 chapter 13: panel message 6. Detailed list of panel messages error type p01 [main motor lock] description p01-xxx !!System error!! Press reset key if recovery has failed, call service to reset display press reset key error point error conditions 520 main encoder sensor...

Page 177

13 - 8 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type p03 [clamp motor lock] description p03-xxx !!System error!! Press reset key if recovery has failed, call service to reset display press reset key error point error conditions 500 clamp sensor is off after the completion of the clamp...

Page 178

13 - 9 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type p08 [communication error with ci] description p08-xxx !!System error!! Press reset key if recovery has failed, call service to reset display turn the power off and on. Error point error conditions 951 the file is not a correct rinc ...

Page 179

13 - 10 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type p13 [cutter motor lock] description p13-xxx !!System error!! Press reset key if recovery has failed, call service to reset display press reset key. Error point error conditions 205 master-positioning sensor is on when the print dru...

Page 180

13 - 11 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type p24 [inking motor lock] description p24-xxx !!System error!! Press reset key if recovery has failed, call service to reset dis- play press reset key or turn the power off and on. Error point error conditions 539 inking-motor fg sen...

Page 181

13 - 12 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type p98 [hardware error] description p98-xxx !!System error!! Press reset key if recovery has failed, call service to reset dis- play turn power off and on. Error point error conditions 002 no reply from optional sh3m pcb. If sh pcb si...

Page 182

13 - 13 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type a01 [master feed error] description a01-xxx master mis-feed pull out master making unit and rewind master roll, then reset master in place. To reset display open the master-making unit and rewind the master material on the master r...

Page 183

13 - 14 cz180 / cv1860 rev. 1.0 chapter 13: panel message jxx error display error type a07 [paper feed error] error point error conditions 409 paper-ejection sensor was off when the paper should have arrived, and the paper sensor was on when the machine stopped (paper misfeed). 412 paper sensor was ...

Page 184

13 - 15 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type a17 [cutter error] description a17-xxx system error in master making unit take out master and then close master making unit cover to reset dis- play open the master making unit, remove the master and close the master making unit. E...

Page 185

13 - 16 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type b22 [job separator: power off] description b22-xxx !! Job separator is off !! Turn on power switch of it to reset dis- play press reset key and check and switch on the power of job separator. Error point error conditions 721 with t...

Page 186

13 - 17 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type b31 [network cable not connected] description b31-xxx !! No linked printer detected !! Check cable connection and power supply for linked printer to reset display press reset key and connect the network cable. Error point error con...

Page 187

13 - 18 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type c01 [replace ink cartridge] description c01-xxx no ink replace ink cartridge to reset dis- play remove the empty ink cartridge and replace with a new one. Error point error conditions 512 the ink sensor did not go on even when inki...

Page 188

13 - 19 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type d01 [print drum not set] description d01-xxx set print cylinder (drum) in place to reset display set the print drum in the machine. Error point error conditions 526 print drum is not set in the machine (drum connection signal, drum...

Page 189

13 - 20 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type d05 [master not set] description d05-xxx set master in place to reset display insert leading edge of the master material into the master entrance and close the master making unit. Error point error conditions 210 master material is...

Page 190

13 - 21 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type d23 [af cover not closed] description d23-xxx close the af cover to reset display close the af cover. Error point error conditions 177 the af cover is opened. Riso inc. Technical services & support us.Riso.Com.

Page 191

13 - 22 cz180 / cv1860 rev. 1.0 chapter 13: panel message error type f21 [next original not set on af for multi-up] description f21-xxx to reset dis- play set original on the af. Or press stop key (time-out exists for pressing the stop key). Error point error conditions 032 next original is not set ...

Page 192

13 - 23 cz180 / cv1860 rev. 1.0 chapter 13: panel message message h1 [ink color setting] description h1-566 select the same color as the print cylinder (drum) currently in use. To reset dis- play enter the required parameter value. Message h4 [master density] description h4-242 select the standard d...

Page 193

13 - 24 cz180 / cv1860 rev. 1.0 chapter 13: panel message memo riso inc. Technical services & support us.Riso.Com.

Page 194: Chapter

14 - 1 cz180 / cv1860 rev. 1.0 chapter 14: test mode chapter 14 : test mode contents 1. Operating method ...................................................................................2 1) launching the normal test mode .................................................2 2) launching the protecte...

Page 195

14 - 2 cz180 / cv1860 rev. 1.0 chapter 14: test mode 1. Operating method 1) launching the normal test mode to start test mode, switch on the machine power while simultaneously pressing the left and right keys of the vertical print positioning. The firmware version number is displayed when the test m...

Page 196

14 - 3 cz180 / cv1860 rev. 1.0 chapter 14: test mode no. Sensors, switches detection status 0002 solenoid counter connection signal solenoid counter connected 0003 24v a output signal 24v-a on (24v output) 0004 24v b output signal 24v-b on (24v output) 0005 rear cover safety sw switch on (main unit ...

Page 197

14 - 4 cz180 / cv1860 rev. 1.0 chapter 14: test mode no. Data clear details 0110 clearing jam status data forcibly clears the jam. This test mode can be used to temporary clear error display. For acutal correction of the problem, the cause for the display should be corrected. Consumables error displ...

Page 198

14 - 5 cz180 / cv1860 rev. 1.0 chapter 14: test mode no. Data setting 0143 maintenance - master count entry description selects the maintenance call count for master-making. Setting range: 0 to 9999 (0 to 999,900 master-making) unit: 1 (100 master-making) default: 0 (no entry) 0144 maintenance - cop...

Page 199

14 - 6 cz180 / cv1860 rev. 1.0 chapter 14: test mode no. Sensor switch check detection status 0201 original det. Sensor detecting (original present) 0210 original in sensor detecting (original present) 0211 af cover set sensor detecting (af cover closed) no. Motor, solenoid remarks 0260 af scanner l...

Page 200

14 - 7 cz180 / cv1860 rev. 1.0 chapter 14: test mode 0364 edge emphasis threshold offset for line-mode printing (for master-making density setting 1 to 2) description selects the matrix forming the halftone-curve base setting range : 0 to 7 unit : 1 default : 1 0365 edge emphasis threshold offset fo...

Page 201

14 - 8 cz180 / cv1860 rev. 1.0 chapter 14: test mode 0380 af horizontal scan position adjust description adjusts the original horizontal scan position on the af unit. Setting range : -30 to +30 (-3.0mm to +3.0mm) (+ is to the left ) unit : 5 (0.5mm) default : 0 (0mm) 0381 af scan start position adju...

Page 202

14 - 9 cz180 / cv1860 rev. 1.0 chapter 14: test mode no. Sensor switch check detection status 0400 master-positioning sensor sensor light reflected (master present) / no reflection ( no master) 0402 master end sensor sensor light blocked (master end seal detected) 0403 cutter hp switch switch presse...

Page 203

14 - 10 cz180 / cv1860 rev. 1.0 chapter 14: test mode no. Data check details 0521 tph thermistor temperature data displays the temperature of the tph thermistor in [degrees celsius] 0524 tph power voltage displays the voltage applied to the tph when the power to the tph is switched on. (the display ...

Page 204

14 - 11 cz180 / cv1860 rev. 1.0 chapter 14: test mode 0552 thermal print head (tph) over-heat temperature description sets the temperature reference parameter to judge tph over-heat. If the machine detects the tph temperature to be above this parameter, the machine displays a message and stops the m...

Page 205

14 - 12 cz180 / cv1860 rev. 1.0 chapter 14: test mode no. Sensors, switches detection status 0600 paper detection sensor sensor light reflected (paper detected) 0602 elevator upper-limit sensor a sensor light blocked (sensor detecting paper feed tray at maximum up position) 0604 elevator lower-limit...

Page 206

14 - 13 cz180 / cv1860 rev. 1.0 chapter 14: test mode 0751 paper feed jam detection angle. (paper feed jam at paper sensor) description adjusts the drum angle timing for detecting the paper feed jam by paper sensor. (paper in) setting range : -200 to +200 (-20.0° to +20.0°) unit : 5 (0.5°) default :...

Page 207

14 - 14 cz180 / cv1860 rev. 1.0 chapter 14: test mode no. Sensors, switches detection status 0800 position-a sensor blocked (detection plate detected) drum is at position-b. 0801 main motor fg sensor blocked (detection plate detected) 0802 main-motor limit sensor blocked (encoder disc detected) 0803...

Page 208

14 - 15 cz180 / cv1860 rev. 1.0 chapter 14: test mode 0892 machine position-b stop. (the position in which the print drum can be removed from the machine.) stops the print drum at machine position-b. (the test mode can be activated with or without print drum in the machine.) 0900 vertical-centering ...

Page 209

14 - 16 cz180 / cv1860 rev. 1.0 chapter 14: test mode 0943 inking time adjustment (in normal printing) description sets the timer for the replace ink bottle message to come out after the ink sensor stops detecting the ink bead in the drum. Setting range : 1 to 60 (1 second to 60 seconds) unit : 1 (1...

Page 210

14 - 17 cz180 / cv1860 rev. 1.0 chapter 14: test mode no. Data setting 1233 tph master-making horizontal position adjustment description sets the tph master-making position to the center setting range : -23 to +23 (-2.3mm to +2.3mm) (+ values bring the master-making image to the left) unit : 1 (0.1m...

Page 211

14 - 18 cz180 / cv1860 rev. 1.0 chapter 14: test mode no. Sensors, switches detection status 3100 job separator tape jam sensor jammed tape is detected 3101 job separator tape detection sensor tape is detected 3102 job separator power switch power is supplied to the job separator 3103 job separator ...

Page 212

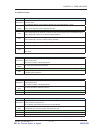

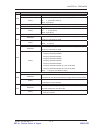

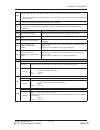

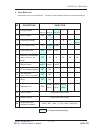

14 - 19 cz180 / cv1860 rev. 1.0 chapter 14: test mode no. Description selection 1 printing speed 1 (60 rpm) 2 (90 rpm) 3 (130 rpm) _ _ _ 2 auto process off on _ _ _ _ 3 scanning contrast 1 2 3 4 5 9 (auto) 4 2-up waiting time off 15 sec. 30 sec. _ _ _ 5 auto reset time off 3 min. 5 min. _ _ _ 6 mini...

Page 213

14 - 20 cz180 / cv1860 rev. 1.0 chapter 14: test mode memo riso inc. Technical services & support us.Riso.Com.

Page 214: Chapter

15 - 1 cz180 / cv1860 rev. 1.0 chapter 15: electrical components chapter 15 : electrical components contents 1. Motors, fan, solenoid & clutches ..........................................................2 2. Sensors .......................................................................................

Page 215

15 - 2 cz180 / cv1860 rev. 1.0 chapter 15: electrical components 1. Motors, fan, solenoid & clutches inking motor suction fan paper ejection motor cutter motor sparation fan pressure solenoid main motor write pulse motor clamp motor load pulse motor master compression motor af read pulse motor af st...

Page 216

15 - 3 cz180 / cv1860 rev. 1.0 chapter 15: electrical components motor part name function test mode af read pulse motor rotation of af pickup, stripper & feed rollers. 0261 clamp motor movement of clamp cam & position-a compensation plate. 0863 & 0864 inking motor inking pump drive 0882 elevator mot...

Page 217

15 - 4 cz180 / cv1860 rev. 1.0 chapter 15: electrical components paper sensor (receive) paper sensor (send) rfid (master) rfid (ink) inking motor fg sensor drum set sensor paper ejection sensor paper ejection motor fg sensor image scanner master positioning sensor original in sensor original detecti...

Page 218

15 - 5 cz180 / cv1860 rev. 1.0 chapter 15: electrical components sensors parts name sensor type function upper limit sensor interrupt paper feed tray upper limit detection paper detection sensor reflective paper on the paper feed tray detection paper sensor transmit first paper feed status detection...

Page 219

15 - 6 cz180 / cv1860 rev. 1.0 chapter 15: electrical components drum safety switch cutter stop position switch ink bottle set switch rear cover safety switch master removal unit safety switch cutter hp switch ink sensor & overflow sensor master making unit safety switch 3. Switches & sensor riso in...

Page 220

15 - 7 cz180 / cv1860 rev. 1.0 chapter 15: electrical components other switches & sensors part name function test mode no. Rear cover safety switch rear cover detection. 0005 master removal unit safety switch master disposal box and master disposal unit set detection. Also acts as interlock switch. ...

Page 221

15 - 8 cz180 / cv1860 rev. 1.0 chapter 15: electrical components memo riso inc. Technical services & support us.Riso.Com.

Page 222: Chapter

16 - 1 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams chapter 16 : wiring diagrams contents 1. Power supply pcb (photograph) ....................................................2 2. Mechanical control pcb (photograph) ............................................3 3. Connection between pcbs .......

Page 223

16 - 2 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams 1. Power supply pcb (photograph) riso inc. Technical services & support us.Riso.Com.

Page 224

16 - 3 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams 2. Mechanical control pcb (photograph) [ photograph of cz180 mechanical control pcb ] note: cv1860 mechanical control pcb differs from that used on cz180. The photograph given below is that used on cz180. Riso inc. Technical services & suppo...

Page 225

16 - 4 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams 3. Connection between pcbs power supply area wiring diagram 042-50000-02 cn3 options wiring diagram: 042-50000-10 job separator power contro l power input rfi d cn4 cn13 cn12 cn2 cn1 paper ejection area sh i/f paper ejection area wirin g dia...

Page 226

16 - 5 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams 4. Power supply cn2 xr10p-y 01 02 03 04 05 06 07 08 da lat /power fai l gnd /24v-on /tph_ctl da cl k slee p da dat 02 07 08 05 06 03 04 01 cn4 cz10p-y mechanical control pcb cn1 3 24v-b 24v-a 5v 5v vh9p gnd 02 07 08 05 06 03 04 cn1 01 power ...

Page 227

16 - 6 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams 5. Main components area master disposal box safety switch drum safety switch master making unit safety switch master disposal box safety switc h cz17p-y mechanical control pcb drum safety switch master disposal box safety switch drum safety ...

Page 228

16 - 7 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams 6. Cn8 and cn12 of mechanical control pcb cn8 paper detection sensor 03 02 01 photo interrupt sensor gnd out vcc xr 3p-h paper sensor 01 02 anode emitte r zh3 p 03 02 01 collecto r cathode emitter sen d receive a0 1 a0 2 a0 3 a0 4 a0 5 a0 6 ...

Page 229

16 - 8 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams 7. Print drum area cn2 1 b1 4 b1 5 b1 3 b1 2 cz30p (15p double) cn3-a cz15p-y cn3-b cz15p-h mechanical control pcb ink sensor inking motor xr4p- y xr2p-y relay connecto r 02 01 04 03 2 yellow 1 re d b1 1 b1 0 b0 9 b0 8 b0 7 b0 6 b0 3 b0 4 b0...

Page 230

16 - 9 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams 8. Master making area power connector gnd vh vh +s vh vh vh vh gnd gnd gnd gnd gnd -s tp h kyt-256-12gae1-rs2 444-80003-109 14 09 12 13 11 10 08 07 05 06 03 04 02 01 13 15 16 14 cn1 8 08 12 11 09 10 06 07 04 05 mini ct16p 01 02 03 12 13 11 1...

Page 231

16 - 10 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams 9. Master removal area out vcc gnd photo interrupt type master removal full sensor 02 01 03 02 actuator type out gnd 01 vcc 03 master removal jam sensor out gnd vcc master compression hp sensor 03 01 02 master removal motor master compressi...

Page 232

16 - 11 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams 10. Paper ejection area mechanical control pcb reflecting type paper ejection sensor cz14p-y cn5 separation fan separation uni t suction uni t suction fan paper ejection motor dc photo interrupt type paper ejection motor fg sensor xr3p-y 03...

Page 233

16 - 12 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams 11. Operation panel area 01 mechanical control pcb 02 04 03 07 06 05 cz7p- y cn1 cz7p- y 03 05 07 06 04 01 02 panel-pcb 042-37031 cn1 front wire harness 042-53002 gnd power gnd power reset panel_rxd panel_txd 5v power 5v power operation pan...

Page 234

16 - 13 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams 12. Options mechanical-ctl-pcb 042-50500 cz17p 47 47 +5.1v pf gnd sh3m-pcb 023-50038 50 49 48 /in t /connec t /ub 48 49 50 10 10 15 16 12 11 14 13 29 vh3p 02 03 01 cn7 38 43 45 46 44 41 42 39 40 36 37 35 34 31 33 32 30 02 01 06 05 03 04 cn1...

Page 235

16 - 14 cz180 / cv1860 rev. 1.0 chapter 16: wiring diagrams 13. Fuses power suppy pcb fuse list fuse no. System status after power reset connecting part f001 primary power system power does not go on. Main power supply. 250 volts 6.3 a f101 24v - a t98 - 947 suction fan 250 volts 24v-a does not turn...

Page 236: Chapter

17 - 1 cz180 / cv1860 rev. 1.0 chapter 17: other cautions chapter 17 : other cautions contents 1. Machine firmware downloading (mechanical control pcb) ..................2 downloading procedure ....................................................................2 precaution in firmware downloading ....

Page 237

17 - 2 cz180 / cv1860 rev. 1.0 chapter 17: other cautions : blink : off : on name of the leds on pcb green 1 green 2 error firmware ready to download firmware being downloaded firmware downloading completed cf card set incorrectly machine data not found incorrect data download failure incorrect data...

Page 238

17 - 3 cz180 / cv1860 rev. 1.0 chapter 17: other cautions 2. Replacing the mechanical control pcb 1) turn off the machine power. 2) remove the rear cover. (m3x8 screws; 5 pcs) 3) remove eeprom from the existing mechanical control pcb and detach the pcb from the machine. 4) put the eeprom, removed fr...

Page 239

17 - cz180 / cv1860 rev. 1.0 chapter 17: other cautions memo riso inc. Technical services & support us.Riso.Com.

Page 240: Chapter

18 - 1 cz180 / cv1860 rev. 1.0 chapter 18: appendix chapter 18 : appendix contents riso i quality system .................................................................................2 1) printing density control ................................................................2 2) drum idling con...

Page 241

18 - 2 cz180 / cv1860 rev. 1.0 chapter 18: appendix riso i quality system with the rf-tag on the master roll and ink bottle, the machine is designed to give best performance for each operating condition in real time. Listed below are the major performance feature of the riso i quality system. 1) pri...

Page 242

Riso inc. Technical services & support us.Riso.Com.

Page 243

Cz180 / cv1860 technical manual (rev. 1.0) published august 2007 reproduction and duplication prohibited. Edited and published by: riso education center, riso kagaku corporation. The contents of this manual are subject to change without notice to permit product improvements. Riso inc. Technical serv...